Lubricating oil for slag vertical mill

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient grinding plants for its customers Loesche plants are specifically planned for the required process steps UBE Vertical Mill is used for grinding of cement raw materials, coal, cement clinker, blast furnace slag and other material Restoring your equipment to its original performance Maximizing your equipment performance Further UBE Vertical Mill UBE Machinery Corporation, Ltdslag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as 2 µm 5 µm LoescheLubrication of Vertical Mill Central lubrication system is generally adopted for roller bearing lubrication of vertical mill, main reducer lubrication and hydraulic oil During the operation of VERTICAL MILL – Brugarolas Industrial Lubricants

.jpg)

How to lubricate mill components to improve vertical mill

The lubricating oil used by the vertical mill is not the more the better If there is too much lubricating oil, it will not only reduce the original cleaning and antiwear functions of the Before driving, check whether the rotating parts are flexible, whether the motor electrical terminals are firm and reliable, and whether the reducer is filled with lubricating oil 2 During the use of How to maintain the details of the slag vertical millThe authors’ results revealed that MQL grinding using vegetable oil offered a lower specific grinding energy than flood cooling Among the grinding fluids, castor oil provided the best A review on conventional and advanced minimum quantity Vertical Roller Mills (VRM) have a clearly higher energy eficiency than ball mills, even if the ball mill is combined with a roller press This and further arguments led to the increased share of SikaGrind® for vertical roller mills

.jpg)

Lubricants for the Steel Industry CITGO MarketNet

Coke is used in the smelting of iron ore to produce iron that is suitable for the manufacture of steel The product is often referred to as pig iron Sintering is the process of agglomerating 2021年10月1日 More precisely, Metalub is one of the most versatile models of lubricated cold rolling due to its numerous features: (1) an elastothermoviscoplastic material description of An advanced model of lubricated cold rolling with its 2011年9月20日 Bridgeport without one shot lube I have operated a few mills like that I used to have a paint brush that lived in a old coffee can, and used that to brush on the oil for the XYZ ways I have the one shot on my 9X42 mill, and I still brush it on just for good measure A little too much oil wont hurt your machine, not enough, willLubricating A Vertical Knee Mill The HobbyMachinist2021年4月19日 As the mill equipment of solid waste slag industry, vertical roller mill is more professional, higher powder yield, environmental protection and energy saving It is an excellent equipment for grinding water slag, steel slag and other solid wasteWe have been deeply engaged in the grinding market for nearly 50 years, with sufficient experience, many cases, What is the grinding mill for grinding slag? – gkmill

.jpg)

Energysaving and Efficient Vertical Roller Mill Fote

A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, TRM SERIES SLAG VERTICAL ROLLER MILL TRM SERIES SLAG Oil lubrication system for grinding roller Triple fluoro rubber framework oil seal for grinding roller Adjustable gas ring area and dam ring height Auto liftup grinding roller and no load startupTRM SERIES SLAG VERTICAL ROLLER MILL TRM SERIES SLAG 2024年4月1日 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw Summary of intelligent fault diagnosis technology for vertical millsMill Shell:The foundation of the Slag ball mill, the mill shell, is a cylindrical structure made of premiumgrade steelTongli heavy machinery is equipped with a large annealing furnace of 65x65x20m and a 65x65x20m large sandblasting room, which can conduct overall heat treatment and sandblasting on the ball mill to ensure the service life and appearance of the slag grinding ball mill Manufacturer Tongli Machinery

.jpg)

Cement Vertical Mill

This vertical roller mill itself can crush, dry, grind and classify, so the system is simple, and occupation area is about 50% of ball mill system In addition, it can be the outdoor installation that reduces a large number of investment costsTongli slag ball mill is an industrial equipment for processing steel slag, mainly used to grind steel slag into the required fineness for recycling and reuse Steel slag is a byproduct of steel production, and its main components include iron oxide, calcium oxide and other metal oxidesSteel slag Ball Mill CEMENTLSome use waste engine oil to replace lubricating oil, and the impurities in the waste engine oil may cause more serious gear wear In order to effectively reduce the wear phenomenon of the ball mill gears during operation, we should scientifically and reasonably select the lubricating oil and lubrication mode Sealing Performance of GearsHow to Extend Service Life of Ball Mill Girth GearsPFRM30 vertical mill is one of honor products of Jiangsu Pengfei Group Co, Ltd, through many years of production practice tests for this vertical mill, product performance continuously improved, gradually entered the international advanced level of similar products, won the majority of users at home and abroadPFRM30 vertical mill user manualvertical millcoal vertical

Operating experience with a vertical roller mill for grinding

Operating experience with a vertical roller mill for grinding granulated blastfurnace slag and composite cements* ) Betriebserfahrungen mit einer VertikalRollenmühle bei der Mahlung von HüttensandCompany Introduction: Founded in 1958, Xinxiang Great Wall Machinery Co, Ltd is a wellknown national hightech enterprise specializing in the development, production and sales of largescale building materials making equipment including crushing and grinding equipment It covers an area of 700, 000 square meters and has a total asset value of RMB 500 millionHigh Capacity Vertical Mill for Blast Furnace SlagTherefore, when the vertical mill is operated, the control of the inlet and outlet dampers should be balanced by the kiln mill When the vertical mill inlet and outlet dampers are balanced, the system's wind will be balanced and will not affect Important Operation Tips For Cement Vertical MillFor example, the output of the ZJTL 1900 vertical mill is 5060 tons/hour, while the output of the ZJTL 5500 vertical mill can reach 400500 tons/hour Therefore, when selecting the model, it is necessary to select the appropriate equipment according to the specific production capacity requirements of the cement plantCement Vertical Roller Mill CEMENTL

.jpg)

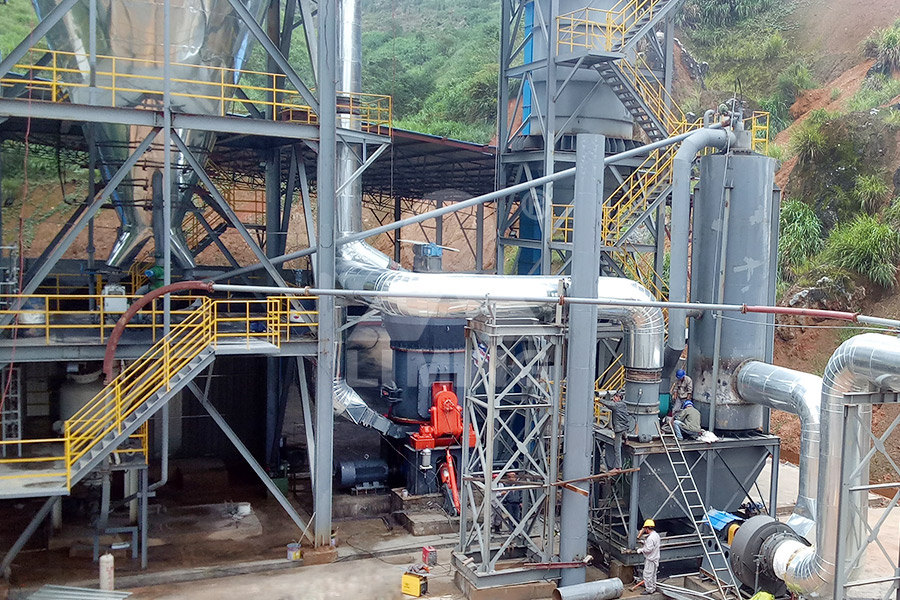

Slag Mill Vertical Slag Mill Provider SINOMALY

Since 2007, SINOMALY has begun to develop and manufacture vertical slag mill, which has been successfully applied in the market, with a output range from 45t/h to 300t/h that can satisfy the slag powder production lineSimple and reliable operation: Limit device for preventing the direct contact between grinding roller and grinding table, to avoid the severe vibration of the mill caused by the collision between roller and tables; With hydraulic roller turningout device, the grinding roller can be turned out of the machine completely to ensure enough maintenance space,which replace and repair easy LM Vertical Roller Mill, slag vertical mill, coal vertical mill Vertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding The vertical cement mill of AGICO CEMENT is inseparable from the following points:Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill2016年1月10日 This is kind of why I asked I've never been inside a Bridgeport mill, or really, any other quilltype vertical mill, and don't know how they apply or control the oil My Bridgeportclone Grizzly has an oil cup for the spindle, but I never see Lubricating a mill spindle? Oil? Grease? Seals?

.jpg)

MPS vertical roller mills for slag and slag cements

2007年11月1日 The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3) The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and 4300cm²/g2023年1月10日 As the core equipment in the production process of slag grinding, the LM slag vertical roller mill of SBM integrates fine crushing, grinding, drying, powder selection and transportation, ensuring the continuity and stability of slag powder production and improving the efficiency of slag grinding 1Slag Vertical Roller Millconventional lubrication used in steel mill applications, oil/air lubrication reduces environmental pollution, increases lubricating and sealing performance, more than 1 000 oil supply positions) The main lubricating method for rolling bearings used in steel production facilities is grease or oil mist lubrication Recently, Oil/Air Lubrication Systems for Steel Production FacilitiesVertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine

.jpg)

2 µm 5 µm Loesche

a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, BrazilHigh quality Automatic Slag Vertical Pressure Leaf Filters For Diesel Oil , Lubricating Oil from China, China's leading Vertical Pressure Leaf Filters product market, With strict quality control Vertical Pressure Leaf Filters factories, Producing high quality Automatic Slag Vertical Pressure Leaf Filters For Diesel Oil , Lubricating Oil productsAutomatic Slag Vertical Pressure Leaf Filters For Diesel Oil HLM series vertical mill is a largescale advanced,highefficiency and energysaving grinding product developed by China Henan Fote Group using the world's advanced material bed grinding and partial external circulation technology,combined with more than 40 years of experience in mill production and manufacturing of China Henan Fote GroupGrinding,grading,drying and HLM Series Vertical Mill Fote Machine2024年5月10日 Baichy Mill is a globally successful vertical roller mill solution for grinding raw materials, cement, and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and costeffective to operate over your cement plant’s lifetimeVertical roller mill for cement and slag grinding

OK™ Raw and Cement Mill

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeSAE 20 oil 9 Oil cup (not shown) lubricates quill feed pinion shaft Requires oil once each day of operation SAE 20 oil 10 Oil cups (not shown) one each side Lubricates vertical ways of knee Oil week ly with Citgo Sliderite 112 or equivalent 11 Oil reservoir for Bijur way lubricating pump Fill as necessary with Citgo SlideMODEL 2UVRC VERTICAL MILLING MACHINEThe document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller Mills PDF MillOverview Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, Slag Mill

Automatic Slag Vertical Pressure Leaf Filters For Diesel Oil

High quality Automatic Slag Vertical Pressure Leaf Filters For Diesel Oil , Lubricating Oil from China, China's leading Vertical Pressure Leaf Filters product market, With strict quality control Vertical Pressure Leaf Filters factories, Producing high quality Automatic Slag Vertical Pressure Leaf Filters For Diesel Oil , Lubricating Oil productsSection 3: Factors to Consider When Choosing Lubrication Oil Machine specifications and requirements Temperature considerations Contamination control Section 4: Lubricating Your CNC Machine: Best Practices Daily lubrication routine Lubrication points and methods Cleaning and maintenance tips Section 5: Common Lubrication The Ultimate Guide to CNC Machine Lubrication Oil: Everything Some of the outstanding milestones along the way were: 1950's Construction of rolling ball type mill (E type mill ) 1960's Production of plate type mill 1970's Manufacture of rolling ball type mill (ZQM series) 1980 Start to manufacture of roller type mill (ZGM series) 1985 MPS mill license agreement with DEUTSCHE BABCOCK 1991 ZGM113 (MPS225), Output of mill 877t/h 1992 Vertical roller mill ZGM BEIJING POWER EQUIPMENT GROUP 2020年8月30日 The ISO 68 oil appears to be the most commonlyaccepted lathe oil for headstocks Slideways on the lathe bed may require something a little bit lighter, to prevent any sticking in the middle of a delicate adjustment Try your ISO 68 oil first, however, in case it does work and you can save the hassle of purchasing an entirely different oil All About Lathe Oils And How To Use Them Summit Machine Tool

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive merits2013年5月6日 Coal Mill Introduction: Coal mill is device and lubricating system Coal processing system CCM Mining Machine Company provide Crusher,Grinding Mill,Ball lubrication system for mining processing mill2021年10月26日 3 Lubricating material: Graphite is often used as a lubricant in the machinery industry Lubricating oil often cannot be used under highspeed, hightemperature, and highpressure conditions, while graphite lubricating materials can work without lubricating oil at a temperature of 2000°C 4Graphite Grinding Machine Powder Mill EquipmentOur vertical wood pellet machine adopts External Circulation Cooling System for main transmission box and transmission gear oil: External circulation cooling (air cooling or water cooling selection, according to the use environment) would reduce the working temperature of the gear oil, so that its normal working temperature is 4050 °C Adopt Gear Transmission ModeVertical Ring Die Pellet Machine for

Way Oiler: Automatic Machinery Lubrication [ + Vactra 2

Way Oil has been formulated with specific properties: It's a hydraulic oil It contains chemicals called "Tackifiers" that make it stick to the surfaces and not run off For example, your Z axis has vertical ways Oil is slippery by design, so it'd be hard