Mechanical principle class design calcite grinding machine

.jpg)

Principles of Modern Grinding Technology

2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent 2015年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation Grinding Machines SpringerLink2021年7月12日 The expert system analyses the experimental results and applies the NSGAII optimization method to suggest a set of grinding parameters to grind a surface with the desired Development of an expert system for optimal design of the new machine classes are generated: – Universal grinding machines: As shown in Fig 6 2nd row, right, they are derived from circular grinders and are a subgroup of them Those machines are Grinding Machines

.jpg)

Modelling of grinding mechanics: A review ScienceDirect

2023年7月1日 To fill this gap, this work reviews and introduces theoretical methods and applications of mechanics in grinding from the aspects of modeling principles, limitations and 2018年1月1日 Starting from the analysis of processmachine interaction according to selfexcited vibrations theories (the most relevant), this paper outlines a path for surface grinding Design criteria for grinding machine dynamic stabilityInitial considerations include types of inaccuracy, principles of machine design to achieve high machine stiffness and low deflections levels due to grinding forces, temperature rise or Principles of Modern Grinding Technology ScienceDirectIt provides a concise treatment of the principles involved and shows how grinding precision and quality of results can be improved and costs reduced Every aspect of the grinding processtechniques, machines and machine design, process Principles of Modern Grinding Technology 2nd

Elements of Mechanical Design MIT OpenCourseWare

These principles are reinforced via (1) handson laboratory experiences wherein students conduct experiments and disassemble machines and (2) a substantial design project wherein students model, design, fabricate and characterize a Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as GRINDING MACHINES Carnegie Mellon University2020年12月14日 With SEW‑EURODRIVE, you get firstclass linear motors for applications that require direct translational movement Gear Up for the Toughest Jobs! Aug 28, 2024IP Ratings Guide Machine Protection Machine This is an advanced course on modeling, design, integration and best practices for use of machine elements such as bearings, springs, gears, cams and mechanisms Modeling and analysis of these elements is based upon Elements of Mechanical Design MIT OpenCourseWare

.jpg)

Grinding Machines SpringerLink

2019年1月1日 As grinding machines belong to the class of machines for the material removal with geometrically nondefined cutting edges, those machines can be classified in correlation to the classification of the different process technologies with geometrically nondefined cutting edges as it is given in DIN 8589, parts 11, 12, and 13 (DIN 858911 2003; DIN 858912 2003; Types of Grinding Machine Grinding machines are broadly classified into two categories which are further classified as follows: – A) Rough Grinder/Grinding Machines Rough grinders are those types of grinders which are used to the machining process and where the accuracy is not the main concern 1 Bench Grinder: ( Types of Grinding Machine )Types of Grinding Machine: Parts, Working Principle Grinding Wheel2020年8月12日 3 Grinding Machine The grinding machine is a kind of tool which is used for grinding work pieces Grinding machine it makes use of an abrasive wheel in the form of a cutting tool The rough surface of the abrasive wheel shreds away small pieces of the work piece as needed Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece Grinding machine PPT Free Download SlideShare2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

The 10 Best Grinding Machine Manufacturers Brands

2024年11月19日 Shenyang Machine Tool, established in 1993 with roots tracing back to 1933, stands as a pillar in China’s machine tool industry Listed on the Shenzhen Stock Exchange (stock code: ), the company emerged from the strategic merger of four industry titans, including the prestigious Shenyang First Machine Tool Factory2024年1月27日 H3: Grinding Machine History and Developments from Ancient Times to Modern Days The evolution of grinding machines is marked by several key developments: Ancient Times: The origins of grinding can be traced back to ancient civilizations where What is a Grinding Machine: Definition, Types, Components2019年4月8日 Cutting tools and machine tools are the two main factors to achieve removal Based on the needs of processing technology in the movement requirement of the tool, the machine tool can achieve the tool’s trajectory and then achieve removal, and the cutting tools in contact with the workpiece can remove the workpiece material directly (Altintas 2012)Design of Tools, Grinding Wheels, and Precision Spindles2018年9月1日 When grinding high demands are usually placed on the geometrical tolerances of the workpiece surface For this reason, the spindles of the grinding machines are normally designed with requirements (PDF) Design of Grinding Machine Spindle ResearchGate

.jpg)

Machine Tool Engineering Introduction to Machine

Machine Tool Engineering BITS Pilani Pilani Campus Girish Kant Garg Department of Mechanical Engineering BITS Pilani Pilani Campus Introduction to Machine Tool Drives and MechanismsGeneral Principles of Machine Tool 2018年12月21日 The principle behind EDM was first observed in 1770 by Joseph Priestley, who was experimenting with electrical discharges He noticed that the sparks had eroded some of the electrode material Almost 200 years EDM Machine types working principles£ÿÿ0 af=,¨ÎÄ 7ôǯ?ÿ~ pÎÿéõW Ò À ?ÀKxëQ »•Oƒ 9«AG8û†;Îe ‰âìcgÝqÖuœ]ÛÈ)ª“Œ3Ž³²âP Mc qVdÔÉ8óU d+• J¡ Qˆ7òÖJ2vÆ?ofý c ÉÊ o Ö[#c?û ™µ³öœ³?ýõˆÕ{òëiáÉ Ö–ôò¢ ¨'hjøýrÄ ‰DÒ²KFJ ˆß†l~ 6SA,D± ‡}ü MxÅãÃ$$ŠÆhn¥‘*¥ "Q´ L†j'Òþ˜^,!“š¬ £P —d`aä@D hlllDD`!fv0¶FDàçg*q1# ‘ƒ {Æ Design Of Mini Abrasive Vertical Belt Grinding MachineA mechanical crusher machine is used for crushing aluminium cans and punched sheet metal wastes for recycling purpose and also for easy storage and transportation The crank and slotted lever mechanism converts the rotating motion into reciprocating motion, this is the principle which is used in the mechanical crusher 4(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE

.jpg)

(PDF) Machining Processes and Machines: Fundamentals

2020年12月15日 PDF Machining is one of the eight basic manufacturing processes This textbook covers the fundamentals and engineering analysis of both conventional Find, read and cite all the research you 2018年9月1日 Abstract When grinding high demands are usually placed on the geometrical tolerances of the workpiece surface For this reason, the spindles of the grinding machines are normally designed with requirements for a minimum position change of the grinding disks due to external forces and bending moments The design theory of these spindles is relatively well [PDF] Design of Grinding Machine Spindle Semantic Scholar2020年5月31日 Design and Development of a Rice Milling and Grinding Machine EPHInternational Journal of Science and Engineering 2(8):614 Rice' in GlutenFree Cereal Products and BeveragesDesign and fabrication of a motorized rice hulling machine2024年10月5日 Highspeed grinding (HSG) is an advanced technology for precision machining of difficulttocut materials in aerospace and other fields, which could solve surface burns, defects and improve surface integrity by increasing the linear speed of the grinding wheel The advantages of HSG have been preliminarily confirmed and the equipment has been built for Highspeed grinding: from mechanism to machine tool

.jpg)

(PDF) A comprehensive review on the grinding process:

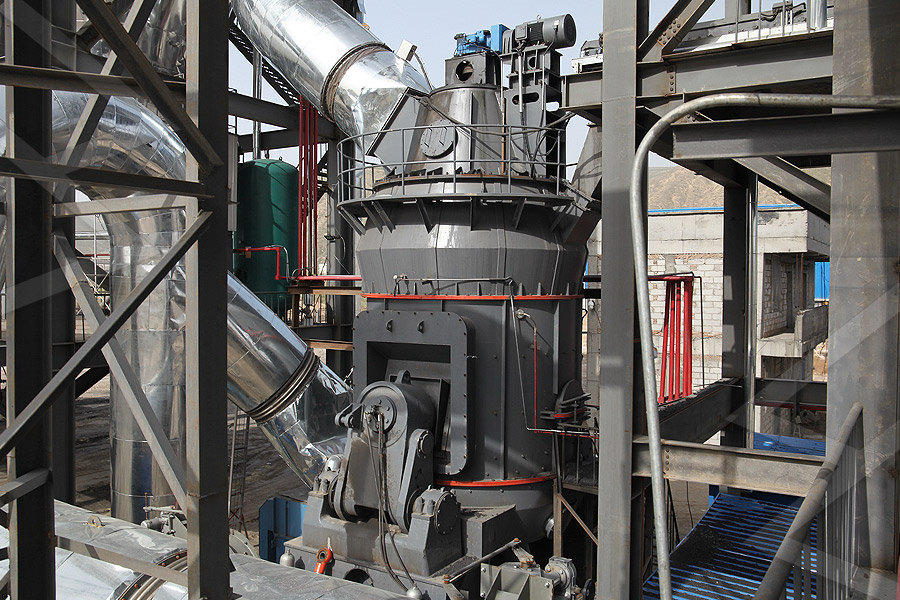

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107III DESIGN THE KINEMATIC DIAGRAM OF BELT GRINDING MACHINE The principle of cutting on belt grinding machine [8] Figure 3: The principle of cutting on belt grinding machine An abrasive belt grinding process consists of a coated abrasive belt that is fixed firmly around, at least, two rotating polymer contact wheelsNguyen Thuan Quest Journals2021年8月27日 The grinding wheel is the most important and unique part of the electrochemical grinding machine It is connected to the negative terminal of the power supply and acts as the cathode The grinding wheel is made of Electrochemical Grinding: Definition, Parts or 2019年7月15日 Processing calcite mechanical equipment factory, calcite powder production equipment Calcite vertical roller mill grinding machine manufacturers Calcite is a calcium carbonate mineral, which is more common in natural calcium carbonate, is a widely distributed mineral, application The wider field is the papermaking processProcessing calcite machinery equipment factory vertical roller mill

.jpg)

DESIGN AND CONSTRUCTION OF GRAIN GRINDING MACHINE

DESIGN AND CONSTRUCTION OF GRAIN GRINDING MACHINE CHAPTER ONE INTRODUCTION 11 Background of the Study The grinding of grain occurs by the a support@iprojectmaster +234 813 292 6373 +233 55 397 年9月27日 design and development of rice milling and grinding machine Brian Kristoffer M Caringal 1 *, Zyrom S Dela Rosa 2 , Kyle Vergel R Maan 3 , Nestor C Camello 4DESIGN AND DEVELOPMENT OF RICE MILLING AND GRINDING MACHINE Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders They are versatile tools that offer efficient and reliable grinding and mixing capabilitiesBall Mill Grinding Machines: Working Principle, Types, Parts Vol4 Issue2 2018 IJARIIE ISSN(O) 2395 4396 7897 ijariie 2058 DESIGN AND FABRICATION OF MULTIPURPOSE GRINDING MACHINE Rohit U1, Naresh B2, Ravindra S3, Arun N4, Akshay Z5, Ravindra G6 1 Student , Mechanical Engineering, AGPCE, Maharashtra, India 2 Student , Mechanical Engineering, AGPCE, Maharashtra, India 3 Student , Mechanical DESIGN AND FABRICATION OF MULTIPURPOSE GRINDING MACHINE

Fabrication of Mini Abrasive Vertical Belt Grinding Machine IJAEM

grinding operation may be used for removing thick layer (05mm) of material in general class of work Abrasive belt grinding is a common finishing process in the metal and wood industryBelt grinding can be used for both coarse and fine grinding The principle parts of this attachment areGrinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mmGrinding Machine Definition,Working,Parts,OperationTypes2023年10月16日 There are many established basic rules in mechanical drafting, and specifically, the ASME Y1452009 sets forth sixteen essential rules These rules must be thoroughly understood and applied in drafting, interpreting, or reviewing technical drawings16 Essential Principles of Mechanical Drafting You Must KnowMachine design asks us to consider even very small deflections hundredths of mm or less This is why the use of castings are so common in heavy machinery: there is no better solution for stiffness than to add steel / iron to a structure: the balance is in reducing weight, so that our machines do not require infinite energy to move aboutPrinciples Mech Design Massachusetts Institute of Technology

.jpg)

Types of Grinding Machine: Parts, Working Principle

Working Principle of Grinding Machine The grinding machine works on the principle of the grinding process This is a machining process in which finishing work is carried out on the workpiece In this process, a solid object composed Working Principle of Grinding Machine Grinding machines employ a rotating abrasive wheel that removes material from the workpiece through abrasion The grinding wheel is composed of abrasive particles bonded together, which vary Grinding Machine: Learn its working, types, and 2018年7月19日 The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screen(PDF) Design, construction and performance lights the value of good design and quality equipment in grinding, and thus for productivity We focus on improved tool efficiency, operator comfort and safety Aspects covered are tool weight and dimensions, grip and working posture, work rotas, vibration, dust, noise and safetyPocket Guide to Grinding Technique Atlas Copco

DESIGN, CONSTRUCTION AND TESTING OF MANUAL AND

end of the punched plate (Olatunji, 2002) It was noted that the design of an efficient single meat grinding machines with both manual and motorized mode of operation can be used anywhere (i e urban or rural) and at any time (Bako et al, 2015) A manually operated double face meat mincer was design and constructed with locally available What is the working principle of a Lathe Machine? Working principle of a lathe machine These days lathe machine is the most popular and essential machinery in metalworking LATHE is an abbreviation of “Longitudinal Access Turning Horizontal Equipment” Lathes are intended to spin a workpiece against a tool bit, unlike milling machinesWhat is Lathe Machine? Working Principle, Main Parts and 2023年5月1日 There are several key principles that form the foundation of mechanical engineering These principles include: Mechanics: Mechanics is the study of the motion and forces that govern the behaviour of objects In mechanical engineering, mechanics is used to design and analyse mechanical systems, from simple machines to complex structuresPrinciples of Mechanical Engineering: Understanding the Basics2018年1月1日 Anyway, an effective design approach should take into account the specificity of the particular process in a holistic 6th CIRP Global Web Conference “Envisaging the future manufacturing, design, technologies and systems in innovation era†Design criteria for grinding machine dynamic stability Marco Leonesioa*, Giacomo Bianchia, Nicola Caub aCNR – Design criteria for grinding machine dynamic stability

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Modification, Fabrication, and Performance Evaluation of Maize

grinding process [7] H Principle of Operation of the machine The threshing and grinding machines have two chambers These are the threshing unit and grinding unit An electric motor of 2 hp provides drive through belt connections to drive the pulley on the threshing unit, and2020年4月24日 6 6 • The grinding machine consists of a bed with a fixture to guide and hold the work piece, and a powerdriven grinding wheel spinning at the required speed The speed is determined by the wheel’s diameter and manufacturer’s rating The user can control the grinding head to travel across a fixed work piece, or the work piece can be moved while the grind head Grinding Machine PPT PPT SlideShare