Coal mill accessories

Various accessories of coal mill hxprecision

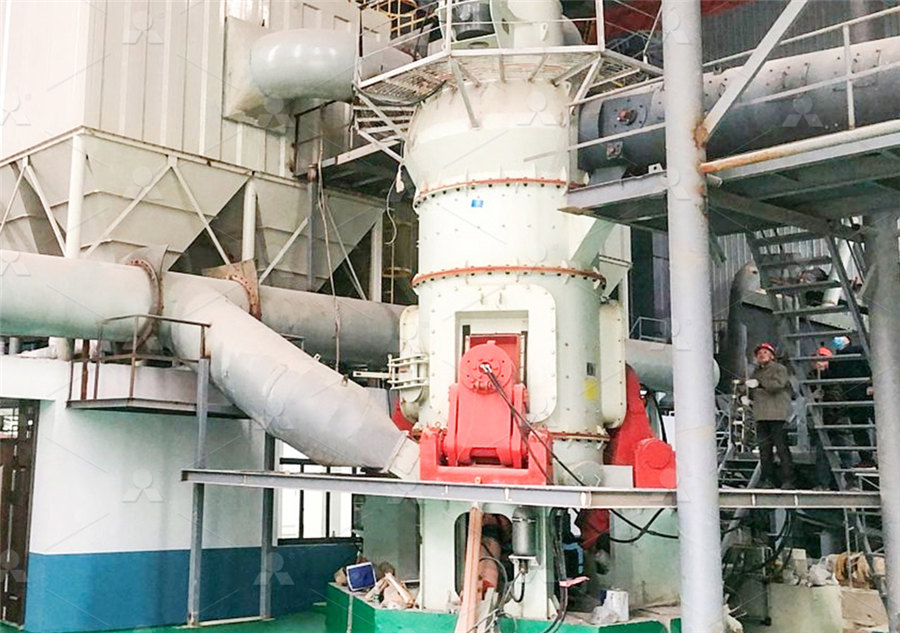

Various accessories of coal mill Haixin Power Equipment Manufacturing (Nantong) Co, Ltd Learning from new and advanced oversea technologies, our company researched and CHASE supplies coal mill parts and spares for grinding rings, motors, gear boxes, bellows and seals to customers around the worldCOAL MILL PARTS AND SPARES CHASE InternationalWe’re a world leader in coal pulverizing and boiler mill operations for horizontal and vertical boiler mills—committed to highefficiency performance, reduced maintenance costs, and longer time between outagesBoiler Mill and Coal Pulverizer Performance GE Steam With a holistic approach to wear part design that improves original equipment’s weight, weight distribution and alloy selection, our coal industry products include wear parts for hammermills, Coal Plants Replacement Wear Parts Mills, Feeders Breakers

.jpg)

Coal Testing Equipment Gilson Co

Gilson laboratory coke and coal testing equipment are widely used for sample preparation, particle sizing, and hardness determinations of samples Hardness and grindability testers, Medium speed coal mill is suitable for grinding bituminous coal, lean coal and other medium hardness material powder grinding operation It can be widely used in the pulverization system of power, metallurgy, cement, building materials, Mediumspeed coal mill wearresistant ceramic linerJohnstown Specialty Castings, LORAIN® Mill Liners produces the world’s only Hot Rolled Steel Grinding Mill Liners, designated for the shell lining of Grinding and Pulverizing Mills at Cement, Coal, and Mineral production plants Our two Mill Liners WHEMCOPart of what marks Magotteaux out as a leader in vertical coal mill technology is our ongoing commitment to making things better for power station managers and other users of milled coal Vertical Coal Mill Magotteaux

Raymond Bowl Mill designed and built for flexibility Qlar

The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and 2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, Coal mill pulverizer in thermal power plants PPTObserverBased and Regression ModelBased Detection of Emerging Faults in Coal Mills Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007 2 THE COAL MILL The work presented in this paper, is based on a Babcock MPS 212 coal mill used at Elsam’s Nordjyllandsværktet Unit 3 However, the Coal Mill an overview ScienceDirect Topics2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and

.jpg)

Mill Liners WHEMCO

Johnstown Specialty Castings, LORAIN® Mill Liners produces the world’s only Hot Rolled Steel Grinding Mill Liners, designated for the shell lining of Grinding and Pulverizing Mills at Cement, Coal, and Mineral production plants Our twopiece Mill Liner system has been increasing the production and longevity of Grinding Mills for over 70 yearscoal conditions for mill performance parameters are as follows3: 21 Preparation of the Bowl Mill and Accessories Before the performance study of the bowl mills is undertaken, an initial survey about the condition of the mill and its assembly is ascertained The mill running hour data pulverized coal fineness report, coal data,A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill Steel Plants – Screen Plates, Scroll casing liners, Sinter Fan Blades, Crusher liners, Transfer chutes, Coke Guide plates, Bunker liners, Cyclones, Chain Guides, Raw Mill bins, Vibratory Feeder liners, Storage hoppers, Scrubber Discharge chute, Shell liner for Dryer, Pipe for Coal Mill of Blast Furnace, Product feed feeding chute, Liner for DP Flap, Liners for Feeder of Sinter plantLiners For Coal Mills – Altra Inc2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required particle size and temperature at the outlet channel throughout with better classifier performance are crucial indicators that characterize the coal mill performanceAn investigation of performance characteristics and energetic

Promotion Coal Mill Liner EB Castworld

Coal Mill Liner Common aliases: Coal mill liner, cylind [] Skip to content Leading supplier of high alloy castings and forgings Leading supplier of high alloy castings and forgings Office Hours 9:0018:00 {Sun:Closed} WeChat ID / Number 0086131 7966 3014 Us sales@ebcastworld Home;2021年6月11日 Relying on excellent products and complete services, our company keeps business contacts with several large domestic thermal power, iron and steel and cement plants for years successively and provides them with manufacturing and repairing of medium speed coal mill accessoriesHaixin Power Equipment Manufacturing (Nantong) Co, LtdThe ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40%Coal Mill in Cement Plant• Coal characteristics profoundly influence risk – Lower rank coals are generally more easily ignited inside the coal mill – High volatile matter and highly reactive coals encourage preignition inside the mill – Higher moisture content requires temperature extremes inside the millMill Inerting and Pulverizer/Mill Explosion Mitigation

.jpg)

Rolling Mill Machinery Accessories

Rolling Mill Machinery and Accessories, Mill Stand, Fly Wheel, Pinion Stand, Reduction Gear Box, Straightening Machine, Coal Pulverisers, Pinch Roll, Plate Cutting Shearing Machine, our organization is engaged in offering a wide Equipment composition: one VRM2800S vertical mill (1400kw), feeder, elevator, raw material bin, screw feeder, vertical mill, dust collector, fan and control cabinet, etc Learn More Desulfurization Vertical Mill Production Line of 40 Tons Per HourHome YingYong MachineryThe MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking systemMPS ZGM Coal MillGrinding Equipment YingYong Machinerycoal grinding applications in the cement industry, where normally a twomillsystem is used 1 Introduction Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90 % and, on the other hand, ball mills whose share de Reprint from ZKG 3 Gebr Pfeiffer

.jpg)

Vertical Coal Mill Magotteaux

As a leading innovator with power station technologies – and other industries that need to process coal, Magotteaux is the ideal firm to turn to when seeking cuttingedge vertical coal mill technologyOur tires and tables mean that vertical coal mills can run more efficiently than ever beforeIn many cases, there is a compromise that needs to be made between the length of According to the running characteristics of vertical coal mill, KINGCERA has designed different wearresistant lining plates for coal mill barrel and coal mill shell The coal mill liner can be installed onsite, or on the curved steel plate in the factory and then welded to the mill barrelMediumspeed coal mill wearresistant ceramic liner Composite Ball mill dan pabrik vertikal adalah jenis utama coal mill yang digunakan untuk menggiling batubara menjadi bubuk halus di pabrik bubuk batubara dan pembangkit listrik berbahan bakar batubara Coal mill seperti hammer crusher dan pabrik Raymond juga digunakan untuk menghancurkan dan menggiling batubara Proses penggilingan batubara melibatkan Jenis Coal Mill PDF ScribdRolling Mill Machinery and Accessories, Mill Stand, Fly Wheel, Pinion Stand, Reduction Gear Box, Straightening Machine, Coal Pulverisers, Pinch Roll, Plate Cutting Shearing Machine, our organization is engaged in offering a wide ambit of Coal Pulverisers Machine Specifications Less maintenance; Excellent functionality; Simply usage;Rolling Mill Machinery Accessories

Rubber Mill Liners Multotec

Rubber mill liners from Multotec extend the lifespan of your mineral processing equipment by protecting the inner shell from impacts and abrasions caused by processing different types of minerals Multotec, a leader in wear solutions, has developed optimised rubber mill liner designs that result in less wear than standard linersWood and coal replacement parts to keep your stove running smoothly with many different manufacturers to choose from all in one convenient placeWood Stove Parts Alternative Heat Coal Stove PartsGrinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsanalisis pengaturan kerja coal mill a unit 2 terhadap potensi self combustion batubara pada pltu keban agung 2 x 135 mw pt chd lahat, sumatera selatan siti fadiyah maharani 062 jurusan teknik pertambangan fakultas teknik universitas sriwijaya 2018 skripsiANALISIS PENGATURAN KERJA COAL MILL A UNIT 2 TERHADAP

.jpg)

Raymond® Bowl Mill Coperion

The Raymond® Bowl Mill is considered the finest vertical rollermill available for pulverizing coal Each bowl mill system is designed to achieve thebest solution forthe processing application The mill, feeder, classifier, fan, cyclone,dust collector and other system components are selected to meet the requirementsand characteristics of the material processedCoal Mills are used to pulverize and dry to coal before it is blown into the power plant furnace Operation The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particlesCoal Mills SolidsWikiCoal Mills are used to pulverize and dry to coal before it is blown into the power plant furnace Operation The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particlesCoal Mills SolidsWikiProper Ventilation: Ensuring adequate ventilation in the coal mill area helps disperse coal dust and reduce the risk of ignition Ventilation systems must be designed to handle the specific needs of the mill Regular Maintenance: Routine maintenance of coal mills and associated equipment is vital for preventing mechanical failuresCoal Mill Safety: A Critical Aspect of Power Plant Operations Coal

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millXKJ Group products center column provides you with the advantages, parameters, quotation and picture information of Mill accessories series Home Coal Mill Rod Mill Raymond Mill Classifying Equipment Tire Ball Mill Diesel Engine Ball Mill Mill accessories Ore Mill accessories XKJ Group,Crusher,Ball mill,Mineral processing In discussion: Coal Mill Safety At best, coal mill safety is not well understood and, at worst, it is ignored When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the standards and rules and is 100% capable of making a system that conforms to these and is therefore safeIn discussion: Coal Mill Safety Coal Mill Safety, Explosion and Since the first application using an MPS mill to process pulverized coal in Germany in the mid 1960s, there have been over 2,000 different MPS mill installations operating in coalfired power plants worldwide As one of the most popular coal pulverizers in the utility industry, the MPS mill was first introduced into the US in the early 1970sCOAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS

.jpg)

HighEfficiency Vertical Coal Mill Enhancing Coal

The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer TUSK Parts and accessories for dirt bikes, UTVs, SxS, ATVs, Dual TUSK Parts and accessories for dirt bikes, UTVs, SxS, Materials are constituent items that are dropped by many enemies in Blox Fruits Each material has its own usage, most of such being able to upgrade weapons, some materials are needed to craft different weapons such as Soul Guitar and learn fighting styles like Godhuman, and many more Most have one or more purposes, excluding Yeti Fur and Gunpowder, which are notable Materials Blox Fruits Wiki FandomKota Colmillo “DOD Entrance Pose” Unisex Long Sleeve Shirt $ 2600 – $ 3450 Select options This product has multiple variants The options may be chosen on the product pageKota Colmillo – Brainbuster Tees

.jpg)

The layout of the coal mill with a rotary classifier

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining 2009年9月1日 The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the educational simulator The coal mass flow and the outlet temperature are modeled by reinvestigating the mass balance and heat balance models physically The archived data from a plant database are utilized to identify the model Modeling and Parameter Identification of Coal Millalso find an application in grinding a wide variety of coal types in cement and power plants Gebr Pfeiffer SE (GPSE) describes its vertical roller mills for coal grinding and provides a case study of an MPS225BK installed at CBR’s Lixhe cement works in Belgium COAL GRINDING Figure 1: MPS coal grinding mill with SLS highefficiency classifierCOAL GRINDING IMPS: more than meets the eye Gebr Pfeiffer2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Modeling and Parameter Identification of Coal Mill

Accessories Haas Automation Inc

Automation Accessories Shop Support Mill Toolholding Mill Cutting Tools Boring Systems Mill Workholding Lathe Toolholding Lathe Cutting Tools Lathe Workholding Package Kits ER Collets Chucks Holemaking Threading Broaching Tombstones Kits Manual Chucks For Turning Holder Accessories; Lathe Tooling Lathe Tooling Shop All CutOff Tool