Is there any iron oxide plant processing and production procedures

.jpg)

(PDF) An Overview of the ReductionSmelting Process

2022年8月23日 This study gave an overview of the reductionsmelting process as a third generational alternative for the modernday iron and steelmaking process whose hallmark is to mitigate the2024年6月21日 Direct reduction of iron oxide with ammonia offers a novel process for sustainable ironmaking at low temperatures and low carbon emissions Previous studies Iron Oxide Direct Reduction and Iron Nitride Formation Using 2021年6月14日 General protocol for the biosynthesis of Iron oxide nanoparticles by using plants, algae, fungi and bacteria which includes drying, grinding and extraction of the biomaterial in the case of plants and algae whereas in case Green Synthesis: An Ecofriendly Route for the 2021年5月18日 Iron and steel industries use iron (III) oxide as one of the primary raw materials for the production of many iron and steel alloys Iron (III) oxide reacts with aluminum to Synthesis, Properties, and Applications of Iron Oxides: Versatility

A case study on largescale production for iron oxide pellets:

2017年12月14日 The innovation and creation of process and equipment of Ezhou pelletization plant of BAOWU plays an exemplary role for the application of largescale gratekilncooler in 2023年4月3日 Further processing of these iron oxide powders could enable the production of iron powder for various applications in powder metallurgy For this purpose, a new process route with an ecofriendly hydrogen reduction Manufacturing and Properties of Spherical Iron 2019年7月19日 Molten oxide electrolysis (MOE) has been identified by the American Iron and Steel Institute (AISI) as one of four possible breakthrough technologies to alleviate the Electrolysis of Iron Ores: Most Efficient Technologies for 2017年10月17日 Direct iron reduction processes produce a form of sponge iron called direct reduced iron (DRI) Smelting reduction and direct iron reduction can reduce energy input, lower greenhouse gas emissions and minimize slag From Ore to Iron with Smelting and Direct Iron

(PDF) Iron Oxide Nanoparticles: Green Synthesis and

2023年11月8日 The production of iron oxide nanoparticles via fungal synthesis is considered an attrac tive option due to its simplicity of scaling, the low cost of the materials necessary for growth,Resource Recovery and Recycling from Metallurgical Wastes S Ramachandra Rao, in Waste Management Series, 2006 98 Production of Ceramic Tiles from Iron Ore Tailings Current practice of washing iron ore before it is processed for extractive metallurgical operation results in three products, coarse ore lumps with sizes in the range 1080 mm, which are directly charged Iron Ore Processing an overview ScienceDirect Topics2023年4月5日 The blast furnace and direct reduction processes have been the major iron production routes for various iron ores (ie goethite, hematite, magnetite, maghemite, siderite, etc) in the past few decades, but the Recent Trends in the Technologies of the Direct 2020年6月1日 Coprecipitation is by far the most common synthesis for magnetic iron oxide nanoparticles (IONPs), as cheap and environmentally friendly precursors and simple experimental procedures facilitate (PDF) CoPrecipitation Synthesis of Stable Iron Oxide

.jpg)

New Sustainable, Scalable and OneStep Synthesis of Iron Oxide

2021年3月20日 This work introduces an innovative, sustainable, and scalable synthesis of iron oxides nanoparticles (NPs) in aqueous suspension The method, based on ion exchange process, consists of a onestep procedure, time and energy saving, operating in water and at room temperature, by cheap and renewable reagents The influence of both oxidation state of the 2013年2月23日 Recrystallization of iron oxides is essentially a physical process in which smaller particles consolidate into larger ones with the loss of surface energy During the recrystallization of iron oxides, continued growth of iron oxide crystals imparts sufficient strength During the process, the grain growth for hematite starts at around 1100 deg CIntroduction to Iron ore Pellets and Pelletizing processes2016年4月19日 Recently, iron oxide nanoparticles (NPs) have attracted much consideration due to their unique properties, such as superparamagnetism, surfacetovolume ratio, greater surface area, and easy Synthesis, characterization, applications, and challenges of iron oxide 2019年11月19日 PDF A tremendous amount of research has been done on refining the flotation process for iron ore and designing the reagents which go into it This Find, read and cite all the research you (PDF) Flotation of Iron Ores: A Review ResearchGate

.jpg)

Iron Ore Pelletizing Process: An Overview ResearchGate

2018年7月11日 Iron Ores and Iron Oxide Materials 50 Bentonite, an inorganic binder, has been the main binder used in the iron ore pelletizing process since the beginning of pellet production in the 1950sMost of this material is recycled, however, since steel scrap is an essential resource in steelmaking Scrap which isn't recycled eventually turns into iron oxide, or rust, and returns to the ground The Future On the surface, the future of iron production—especially in the United States—appears troubledHow iron is made material, manufacture, making, history, used 2021年1月1日 The word “iron” was originated from the word “iren” in AngloSaxon [1]Some linguistics speculated that the word “iron” was derived from Etruscan aisar, meaning the “gods” [2]The symbol “Fe” was taken from the Latin word ferrum meaning “holy metal,” which was used to prepare the crusades in earlier days People have been using iron for more than 5000 years Green synthesis of iron oxide nanoparticles using plant extracts and Iron processing Smelting, Refining, Alloying: The primary objective of iron making is to release iron from chemical combination with oxygen, and, since the blast furnace is much the most efficient process, it receives the most attention Iron processing Smelting, Refining, Alloying

Optimization of Hydrogen Utilization and Process Efficiency in the

At high gas flow rates, there is a risk of insufficient contact time between H 2 and the iron oxides, leading to suboptimal reduction conditions and carbon deposition[22] This deposition usually occurs when the CO present in mixed gas scenarios interacts insufficiently with the iron oxide, leaving unreacted CO thatThe iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the Iron Ore Pelletizing Process: An Overview IntechOpenSubscriber: University of Sheffield; date: 04 August 2017 African Iron Production and IronWorking Technologies: Methods In order for these chemical and physical events to successfully take place, three conditions have to be met: (1) a high enough temperature to melt the gangue minerals and facilitate their separation from the iron oxides, (2) a means by which to physically African Iron Production and IronWorking Technologies: MethodsBauxite is a weathered rock containing two forms of hydrated aluminum oxide, either mostly a monohydrate AlO(OH) in caustic bauxite, or mostly a trihydrate Al(OH) 3 in lateric bauxite Besides these compounds, bauxite contains iron oxide, which usually gives it a reddishbrown colour, as well as silicates (clay, quartz) and titanium oxide The Chapter 2 Production and Processing of Aluminum The

(PDF) A narrative review of the synthesis, characterization, and

2023年10月10日 Mechanochemical nanoparticle processing of iron/iron oxide is a novel technology for iron or e production and characterization The method combines concurrent pr ocedures that combine ballmilling pigments includes iron oxide pigments, which also can be natural and synthetic Iron oxide pigments are the most frequently used among colour pigments The colour of pigments is determined by iron oxides: FeO, Fе2О3, Fе3O4 Iron oxide pigments have wide colour palette due to chemical compounds diversity 2 Subject of investigationEffective Processing of the Iron Ores e3sconferences2022年1月5日 Recent years have witnessed an extensive application of iron oxide nanoparticles within a wide variety of fields, including drug delivery, hyperthermia, biosensing, theranostics, and cell and molecular separation Consequently, synthesis and characterization methods have continuously evolved to provide the possibility for controlling the physicochemical and New Approaches in Synthesis and Characterization Methods of Iron Oxide 2024年8月1日 Recent attention has been generated by the low expense and environmentally awakened technique of generating iron oxide nanoparticles, Fe 3 O 4 NPs utilizing plant extracts The remarkable ability of these Fe 3 O 4 NPs in eliminating heavy metal ions from pollutant water sources resolves a significant environmental concern This review article affords a concise A recent review of the synthesis of plantderived iron oxide

(PDF) NOx Emission in Iron and Steel Production: A

Iron ores are grounded into suitable particle size allowing the concentrated iron oxides content to be agglomerated and charged into the furnace Such particles are formed as green ball called pellet This involved the use of binders holding 2024年10月15日 There is a complex relationship between the different processing conditions and the composition of the iron oxide pellets in influencing H 2 consumption As can be seen from the scatter plots in Figure 2 and 3 , the results obtained give an overview of the complex interaction between these factors and the effects of each oneOptimization of Hydrogen Utilization and Process Efficiency in the 2022年5月1日 Iron oxide nanoparticles are becoming progressively significant for the improvement of innovative biomedical and nanotechnology requests The keywords iron oxide nanoparticles, Fe 3 O 4 nanoparticles and magnetite nanoparticles have been utilized as a research object in the gross database of articles from the Web of Science The results of these Iron oxide nanoparticles: Preparation methods, functions, Production of Red Iron Oxide Related projects: Mining, Quarrying, Mineral and Ore Processing, Coal, Iron Ore, Limestone, Chromite and Granite Mining Projects From procurement and production to costing and provide, there are several departments where the iron and steel industry needs capable professionalsProduction of Red Iron Oxide (Mining of Mineral Ore with Processing

.jpg)

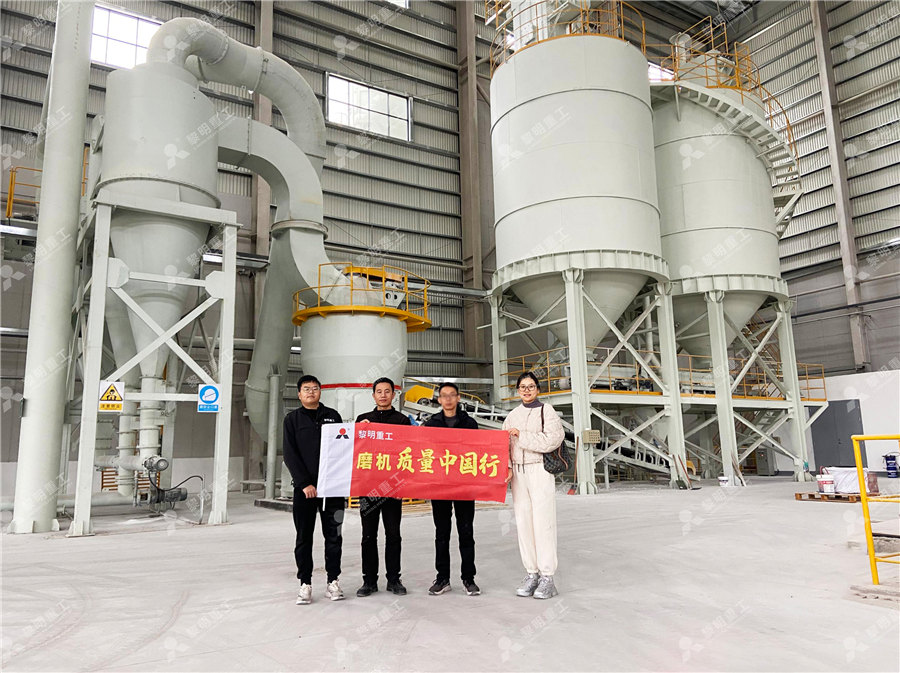

A case study on largescale production for iron oxide pellets:

2017年12月14日 The Ezhou pelletization plant of the BAOWU with production capacity of 5,000,000 ton oxide pellets per year has the biggest single production line of Grate–Kiln–Ring cooler, which was provided by Metso Company The iron concentrate was mainly imported from Brazil and selfprovided by Jinshandian2018年1月1日 Iron oxide and its derivatives have been receiving importance and broad scale applications during the last two decades, due to their specific characteristics and use(PDF) The Importance of Iron oxides in Natural Environment and 2022年4月1日 Objective Green synthesized iron(III) oxide (Fe 3 O 4 ) nanoparticles are gaining appeal in targeted drug delivery systems because of their low cost, fast processing and nontoxicityGreen synthesis and characterization of ironoxide nanoparticles 2023年9月22日 Nature has many resources that are continuously used by human for many purposes Among these, one most important source of nature is the natural products In this article we discuss about the potential of natural products (especially plants extracts) in the synthesis of nanoparticles There is significant variation in the chemical composition of plants Synthesis of Metal and Metal Oxide Nanoparticles using Plant

.jpg)

PlantMediated Synthesis and Applications of Iron Nanoparticles

2018年2月1日 Iron (III) oxides include more than one crystal structure that there is a need for an alternative, economic, and safe method for nanoparticles production [136] Plantmedi2024年4月26日 Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applications This article provides a comprehensive overview of the iron ore processing journey, from extraction to manufacturing, highlighting the key stages and technologies involvedIron Ore Processing: From Extraction to Manufacturing2023年6月1日 Iron oxide nanoparticles (Fe 2 O 3) are the ecofriendly approach towards the plantsThe plant response towards the Iron oxide nanoparticles are involved in the different physiological processes and increased the photosynthetic pigment and gene expression Fe 2 O 3 have efficient role in water remediation and can be use as a catalyst, adsorbent and iron fertilizerIron Oxide Nanoparticles: Plant Response, Interaction, 2013年3月16日 Direct reduction can be defined as reduction in the solid state at O2 potentials which allow reduction of iron oxides, but not of other oxides (MnO, and SiO2 etc), to the corresponding elements Since reduction is in the solid Direct Reduced Iron and its Production Processes –

.jpg)

The six main steps of iron ore processing Multotec

The best advice that we at Multotec can give you is to use products specially adapted to iron processing and also get to know your machines Our team of experts can help you with any questions you may have about cyclones, 2023年11月15日 Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market However, battery manufacturing process steps and their product quality are also important parameters affecting the final products’ operational lifetime and durability In this review paper, we have provided an indepth LithiumIon Battery Manufacturing: Industrial View on Processing PDF On Jul 11, 2018, Guangrong Li published The Chinese Iron Ore Deposits and Ore Production Find, read and cite all the research you need on ResearchGate(PDF) The Chinese Iron Ore Deposits and Ore Production2024年3月20日 Ironmaking processes that do not generate greenhouse gas (GHG) emissions are needed for netzeroemissions energy systems 1 Most emissions associated with iron and steel production result from stochiometric quantities of CO 2 (∼15 kg CO 2 per kg Fe) produced during reduction of iron oxide ores in blast furnaces 2, 3 Demand for steel is unlikely to Electrochemical chloriron process for iron production from iron oxide

(PDF) Effective Processing of the Iron Ores ResearchGate

2017年1月1日 Production of red iron oxide pigment based on haematite ores of the Yakovlevskoe deposit is promising and it makes it possible to satisfy the demand for high quality and inexpensive pigment2024年6月6日 The synthesis of zinc oxide nanoparticles (ZnO NPs) through the use of plant extracts is a remarkably simple, costeffective, efficient, and environmentally friendly approach In recent years, there has been a surge in the exploration of ecofriendly methods for synthesizing ZnO NPs, with researchers addressing the potential of extracts derived from various plant Green Synthesis of Zinc Oxide Nanoparticles Using Plant Extracts 2018年11月5日 Sampling and analysis occur along the milk processing train: from collection at farm level, to intake at the diary plant, the processing steps, and the end products Milk has a short shelf life; however, products such as milk powders have allowed a global industry to be developed Quality control tests are vital to support activities for hygiene and food standards to The Dairy Industry: Process, Monitoring, Standards, and Quality2024年9月21日 This study has explored how synthesis procedures have advanced recently, Plant extract is utilized in the green synthesis process as a reducing and stabilizing chemical to regulate the (2020) Production of iron oxide nanoparticles by coprecipitation method with optimization studies of processing temperature, pH and Exploring the Advanced Synthesis Strategies and Biomedical