Lithium ore processing

.jpg)

Lithium extraction from hard rock lithium ores (spodumene,

2023年1月1日 The process flow is to convert lithium in ore into lithium sulfate by mixing roasting lithium mineral and excessive potassium sulfate (or calcium sulfate or a mixture of both), leach SGS Minerals Services has experience with complete flowsheet development to recover high grade lithium products from hard rock lithium minerals SGS offers a multidisciplinary team Hard Rock Lithium Processing SGS2022年12月21日 Existing methods are summarized by the main resources, such as spodumene, lepidolite, and brine The advantages and disadvantages of each method are compared A review of lithium extraction from natural resources2021年2月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies

Processing of lithium ores: Industrial technologies and case studies

2021年2月22日 Based on studies of the decomposition of petalite ore, the hydrothermal method for the extraction of lithium and aluminum compounds from lithium aluminosilicate Li[AlSi4O10] 2024年6月13日 Here, the authors report an electrochemical leaching method which can directly extract lithium from natural state spodumene ores with low energy consumption, Direct extraction of lithium from ores by electrochemical leaching4 天之前 Lepidolite ore was subjected to roasting with a mixture of sodium sulfate (Na2SO4) and calcium sulfate (CaSO4) as roasting agents A comprehensive investigation was conducted to Study on the Extraction of Lithium from Lepidolite Ore by 2023年10月6日 Discover sustainable lithium extraction methods and how lithium is mined and processed for electric vehicle battery production Explore responsible extraction techniques from brine and ore sources to support clean Sustainable Lithium Extraction: How is Lithium Mined

.jpg)

Lithium Extraction Methods

The increasing need for lithium has prompted the development of extraction methods to ensure a sustainable supply Traditional approaches include evaporative brine processing, where lithiumrich brine is pumped into large Lithium is also recovered from lithiumbearing ores, such as spodumene, through a process that involves crushing, roasting and acid leaching Other methods of lithium extraction, such as direct lithium extraction from geothermal and oil Lithium handling Carmeuse Systemslithium processing operation in mind – now and into the future Marketleading technologies Spodumene ores are typically consolidated from ore comprising 1–15% Li20 to a concentrate of about 6–65% Li20 To achieve this, the ore passes through a typical concentratorLithium processing technology Complete solutions thatA high lithium ore, containing approximately 6% lithium, is the main raw material used in the production of lithium salts (lithium hydroxide or lithium carbonate) from hard rock sources Building on globally diverse lithium conversion sites in the Lithium Resource Processing Albemarle

.jpg)

Critical materials for the energy transition: Lithium

of lithium minerals, clays and geothermal resources widen the resource base further The processing of the mined lithium ore is concentrated in China, which accounts for more than half of all processing, most notably of spodumene ore However, new processing capacity is being developed outside China close to alternative mining sites2024年6月13日 Sustainable harvesting of lithium is critical to the success of the entire battery industry Here, the authors report an electrochemical leaching method which can directly extract lithium from Direct extraction of lithium from ores by electrochemical leaching The extraction process is a complex and important phase in the lithium production and processing cycle Many industry professionals are interested in how litThe Lithium Extraction Process Educational 3D Animated VideoHard rock / spodumene lithium extraction While accounting for a relatively small share of the world’s lithium production, mineral ore deposits yield nearly 20 tons of lithium annually Well over 100 different minerals contain some amount of lithium, however, only five are actively mined for lithium productionWhat Is Lithium Extraction and How Does It Work?

.jpg)

Lithium Production Processes ScienceDirect

2015年1月1日 Table 31 lists major lithiumcontaining ores, their chemical formula, and lithium grade The processing of these ores initially involves comminution of raw materials, followed by beneficiation using techniques such as flotation, magnetic separation, optical sorting, or heavy media separation to produce concentrates containing 4–6% Li 2 O 7, 8, 9, 10Solar evaporative brine processing has been a dominant method for lithium extraction, particularly in South America's Salars Solar evaporation is commonly employed in lithium extraction from brine and relies on solar evaporation to concentrate lithium and other saltsLithium Extraction MethodsLithium Ore Processing – an Overview of the Current and New Processes N J Welham1, A Nosrati2 and N Setoudeh3 1 FAusIMM, Principal, Welham Metallurgical Services, South Lake, WA 6164 : nicholaswelham@gmail 2 MAusIMM, Lecturer, Chemical Engineering, School of Engineering, Edith Cowan University, Joondalup, WA 6027Lithium Ore Processing – an Overview of the Current and New Lithium forms saltlike derivatives with all halides and pseudohalides Some examples include the halides LiF, LiCl, LiBr, LiI, as well as the pseudohalides and related anions Lithium carbonate has been described as the most important Lithium Wikipedia

.jpg)

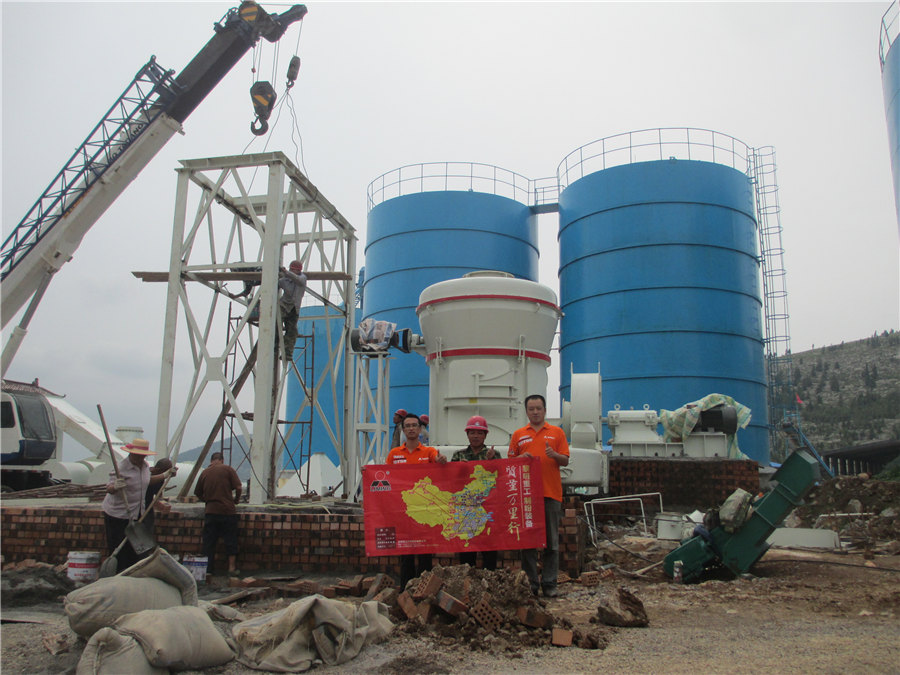

Lithium Processing Plant JXSC Machine

2022年7月5日 Lithium is an element valuable for the production of glass, aluminum products, and batteriesWith the development of technology, electronic equipment, and new energy industries, the demand for lithium ore has 2019年1月15日 Processing of lithium ore, like most minerals, begins with beneficiation prior to extraction of its compounds in downstream processes The aim of this review is to consolidate current literature on beneficiation of lithium from lithium bearing economic oresThe beneficiation of lithium minerals from hard rock ores: A 2020年8月21日 Most lithium is commercially produced from either the extraction of lithiumcontaining salts from underground brine reservoirs or the mining of lithiumcontaining rock, such as spodumene Lithium production from clay sources is expected to become commercially viable, though perhaps not until mercial Lithium Production and Mining of Lithium2023年9月8日 FTM Machinery can provide a series of lithium ore processing equipment, which is wellreceived in the world market Our goal is to create more wealth for our customers How to choose an efficient beneficiation method needs to be The Most Effective Lithium Ore Processing Method You Must Know

.jpg)

Recent advances in lithium extraction from lithiumbearing clay

2023年3月1日 Among these, brines and several ores (eg, spodumene, lepidolite) were considered valuable for Li extraction due to the economic enrichment of lithium It is worth mentioning that, as shown in Fig 2 , over 80% of the world's Li production comes from spodumene operations in Australia and brine operations in Chile and Argentina ( Liu et al, 2023年2月11日 This work addresses a mineral processing study by froth flotation of samples collected in two European lithium ore pegmatites deposits Länttä (Finland) and Gonçalo (Portugal) and aims at (PDF) Characterization and Beneficiation of Nigerian Lithium Ore: This paper will give an overview of the strengths and weaknesses of the current and alternative processesCITATION:Welham, N J, Nosrati, A and Setoudeh, N, 2017 Lithium ore processing an overview of the current and new processes, in Proceedings MetPlant 2017, pp 185194 (The Australasian Institute of Mining and Metallurgy: Melbourne)Lithium ore processing an overview of the current and newAny lithium ore with an industrial value could apply the flotation method Skip to content Call Us Today! +87 info@pineerminingmachinery Home; HARD ROCK LITHIUM ORE PROCESSING PLANT Achieve optimal mineral ore recovery with minimal impact on Lithium Ore Flotation Plant Pineer Mining Machinery

.jpg)

(PDF) Lithium Mining, from Resource Exploration to

2021年10月7日 These generally low grades re quire a concentratio n step prior to metallurgical ore processing and lithium leaching In general, lithium occurs in more tha n 145 different minerals, 2023年6月29日 The objective of this study is to describe primary lithium production and to summarize the methods for combined mechanical and hydrometallurgical recycling of lithiumion batteries (LIBs) This study also Lithium Production and Recovery Methods: Overview 2022年8月2日 It has been demonstrated in the literature that lithium extraction from differing resources is based on the generic mineral processing and extractive metallurgical techniques and resource typeA Review of Characterization Techniques and Regarding reserves, the globally confirmed lithium resources have significantly increased, totaling approximately 98 million tons Bolivia boasts the highest reserves, accounting for 2157 % of the global total, followed closely by Argentina and Chile (Fig 1 d) [6]Among these, salt lake brine resources make up 723 % of the reserves, while ores account for 203 %, with nearly 50 % of Advances and promotion strategies of processes for extracting lithium

Transformations of Critical Lithium Ores to BatteryGrade MDPI

2024年10月28日 The escalating demand for lithium has intensified the need to process critical lithium ores into batterygrade materials efficiently This review paper overviews the transformation processes and cost of converting critical lithium ores, primarily spodumene and brine, into highpurity batterygrade precursors We systematically examine the study findings 2016年5月9日 Lithium Ore (Spodumene) Flotation The conditioned pulp is diluted to approximately 20% solids for flotation in “SubA” Flotation Machines of standard steel construction and the spodumene is then ready for shipment to market or chemical processing for recovery of lithium salts Lithium Sector ReportProcessing Spodumene by Froth Flotation for Lithium Extraction2015年1月1日 In this review, the current state of global lithium resources, global lithium material flow, and forecasts of future lithium supply–demand dynamics are discussed Persistent challenges in mining, processing and industrialscale recycling operations are also examined and recent innovations to address these issues are introducedLithium Production Processes ScienceDirectCrushing screening: In the crushing and screening stage of lithium ore, a threestage and one closedcircuit crushing and screening process, or a twostage and one closedcircuit crushing and screening process can be adoptedSpecifically, it is necessary to refer to the particle size of the raw ore and equip a reasonable lithium ore crushing processLithium Processing Plant, Equipment JXSC Machinery

Accurate mineralogical analysis for lithium ore processing

• Samples from several parts during mining and processing of lithium ores were analyzed • Lithium ore (raw material) • Concentrate (α– Spodumene) • Flotation tailings • Calcination product (β– Spodumene) • Residue (Analcime) • Sample preparation • Automatic mill / press combination to ensure minimum sample preparation errors2019年10月2日 The irregular distribution of lithium mineral resources in countries and the unequal concentration in brine reserves also causes lithium extraction to be of critical importance Today lithium is mainly recovered from minerals (especially spodumene) by acid, alkaline, and chlorination processes, and from brines by crystallization, solvent extraction, and ion Review of Lithium Production and Recovery from Minerals, Our 100% owned Pilgangoora Operation is located 120 km from Port Hedland in Western Australia’s resourcerich Pilbara region The Pilgangoora ore body is one of the largest hardrock lithium deposits in the world and is considered Pilgangoora Operation Pilbara Minerals2024年9月30日 Lithium (Li), a leading cathode material in rechargeable Liion batteries, is vital to modern energy storage technology, establishing it as one of the most impactful and strategical elements Given the surge in the electric car Aspects of Spodumene Lithium Extraction Techniques

Spodumene Wikipedia

Spodumene is a pyroxene mineral consisting of lithium aluminium inosilicate, Li Al(Si O 3) 2, and is a commercially important source of lithiumIt occurs as colorless to yellowish, purplish, or lilac kunzite (see below), yellowishgreen or emeraldgreen hiddenite, prismatic crystals, often of great sizeSingle crystals of 143 m (47 ft) in size are reported from the Black Hills of South Dakota 2020年11月18日 Extracting lithium from ores has higher operating costs than conventional extraction from brine, however, the theory of supply and demand makes the processing economically prudent because of the increasing price of lithium Spodumene is the main ore of interest due to its high lithium content (~8 wt% as Li 2 O in a pure mineral specimen) Roasting Processes for Lithium Extraction Encyclopedia MDPILithium is an element valuable for the production of glass, aluminum products, and batteries It is mined from ores of petalite (LiAl(Si2O 5) 2, lepidolite K(Li,Al) 3 (Al,Si,Rb) 4 O 10 (F,OH) 2, spodumene LiAl(SiO 3) 2 and also subsurface brines Australia and Chile are the world’s largest producers of lithiumLithium Mining Processing Equipment Flow Chart JXSC2023年4月20日 Cabinet has approved a new Lithium Ore Policy, which introduces new regulations for the mining and processing of lithium ores The policy outlines several key principles, including the requirement for any individual or entity owning a lithium concession to either mine lithium ores for processing at their own approved processing plant, or for sale to Cabinet approves a new Lithium Ore Policy Mining Zimbabwe

METHODS FOR LITHIUMBEARING RAW MATERIALS PROCESSING

Methods of lithium extraction from ores and ore concentrates To obtain lithium concentrates from ores, thermal enrichment, flotation, magnetic separation and enrichment in heavy suspensions are used In industrial practice, three methods are mainly used for the decomposition of lithium concentrates based on the sulfuric acid,2023年4月6日 All told, processing accounts for about 70% of CO 2 emissions associated with lithium production 6; mining and transport are responsible for the rest (see ‘Emissions from lithium extraction’)How to make lithium extraction cleaner, faster and cheaper Nature2023年1月15日 Compared with extracting lithium from brine, extracting lithium from ores, calcination, roasting, purity, and other processes consume more resources and energy; and its environmental impact mainly comes from the pollutants discharged by fossil energy, 93‒604 times that of lithium extracted from brine The processing cost of lithium Lithium extraction from hard rock lithium ores (spodumene, The focus of this thesis project has been on recovering lithium from its mineral ores, primarily being from spodumene The general process for recovering lithium has been to begin with a roast to improve the dissolution rate of lithium ions This occurs by expanding the crystal structure from an alpha to betaspodumene form However, this initial roast contributes a significant energy [PDF] Processing hard rock lithium Semantic Scholar