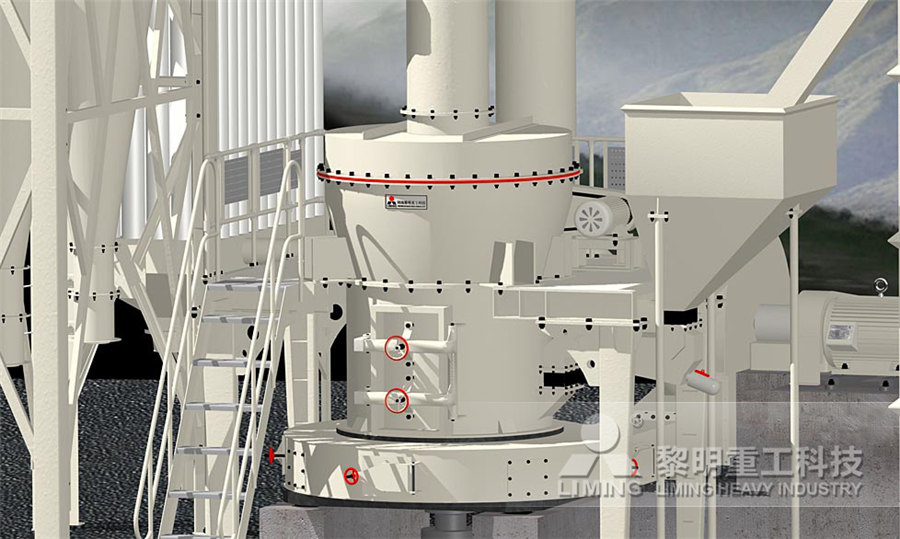

30T limestone calcined quicklime grinding machine per hour

quicklime processing plant, quicklime grinding machine, quicklime

Hebei lime grinding production line with output of 400,000 tons per hour Raw material: limestone Processing capacity: 400,000 tons/year Finished powder fineness: 325 mesh D90Crush large pieces of limestone into small pieces to increase surface area and improve calcination efficiency This step includes preliminary crushing and screening to remove The Right Grinding Machines for Your Quicklime Industry Liming We can provide technological solutions and complete production equipment for 50800TPD quicklime (active lime) production lineActive Lime Production LineHenan Zhengzhou Mining Machinery 2022年4月20日 Production advantages: simple structure, easy installation; deep crushing cavity, not easy to block material; reliable performance, low failure rate Basic information of the Limestone crushing and grinding production line SBM Ultrafine

Limestone Powder Production Line, Limestone Grinding plant,

Limestone powder production line is a complete powder grinding system, including jaw crusher, bucket elevator, raymond mill, dust collector, etc The capacity (tons per hour) in limestone We design and manufacture lime production equipment for active lime (quicklime/hydrated lime) production lines ranging from 50 TPD to 1200 TPD Our innovative, energyefficient, and eco Lime Production Line AGICO Cement PlantWe can provide technology solutions and complete calcined lime plant for quicklime (active lime) production Design capacity: 50700TPD We have professional engineer teamSmall Scale Rotary Kiln Making Quick Active Lime Processing PlantWilliams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are Limestone Mills Williams Crusher

.jpg)

Lime Quicklime Limestone 911Metallurgist

2020年10月29日 Lime is a very general term applied to products of limestone, in popular treatises often incorrectly, including ground or pulverized limestone used in agriculture When used without qualifying adjective, the term usually means burned or calcined limestone, or quicklime, or calciastarting position was 4 degrees and ends at 75 degrees with a two–theta step of 0 at 867 seconds per step 4 and 5 hours After heating the calcined sample, it was allowed to cool for 515minutes The calcined sample was Chemical compositions of the quicklime (calcined limestone) Oxide of the limestone Compositions (%) Al 2 O 3Effects of calcination variables on quicklime yield of Nkalagu limestone2024年6月13日 Quicklime, rich in CaO(s), is generated by calcining limestone at high temperatures Parallelflow regenerative lime kilns are the most energyeffective industrial method available today To prevent major disruptions in Characterization of Limestone Surface Impurities and 2019年3月1日 Limestone calcined clay cement (LC 3 ) is a recently developed ternary cement system based on clinker, calcined clay (CC) and limestone (LS) [1], which can significantly reduce CO 2 emissionsInfluence of fineness of raw clay and calcination temperature on

Assessing the effect of alkanolamine grinding aids in limestone

Assessing the effect of alkanolamine grinding aids in limestone calcined clay cements hydration Franco Zunino⇑, Karen Scrivener Laboratory of Construction Materials, EPFL STI IMX LMC, École Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 machine The Reversible Nuggetizer® Crusher is built with heavyduty construction, and capable of handling 2,400 tons per hour—making it a reliable solution to limestone grindingLimestone Mills Williams CrusherIntroduction of Lime Briquetting Machine This quicklime/calcined briquetting machine can produce a variety of lime briquettes with all kinds of shapes High Efficiency Crusher Realizes Sustainable Use of Limestone Sep 04,2017; Technical Data Model: Roller Diameter (mm) Capacity(t/h) Power(kw) Reducer: FTMQ290: 290: 24 hours for Lime Briquette Machine/ Quicklime/Calcined Lime Briquetting Machine 2014年10月31日 Development on Iron Ore Pelletization Using Calcined Lime and MgO Combined Flux Replacing Limestone and Bentonite October 2014 ISIJ International 54(10):21692178Development on Iron Ore Pelletization Using Calcined Lime and

.jpg)

Limestone calcined clay cements (LC3): raw material

2020年6月5日 Limestone calcined clay cements (LC3) are blended cements that combine clinker, limestone, calcined clay and gypsum The availability of the materials required to produce LC3 and the good 2023年10月27日 Quicklime is an alkaline substance produced from heating limestone in specialized kilns Humans have used quicklime since antiquity for construction, agriculture and metalwork applications It is still used in all of these industries and more; there is a lot to learn about this substance It is Produced from Limestone Quicklime is used as a building material, Quicklime: A Primer2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine How to do a good job of grinding in the lime industry?2021年11月30日 Chemical compositions of the quicklime (calcined limestone) and ends at 75 degrees with a two – theta step of 0 at 867 seconds per step 4 and 5 hours After heating the calcined Effects of calcination variables on quicklime yield of Nkalagu limestone

.jpg)

6 Types Of Limestone Dry Powder Grinder Machines

2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired finenessQuick lime making machine calcined limestone shaft kiln quick lime making machine/calcined quick lime making machinery and 500 ton per day quick lime Production Line quick lime high throughput rate quick lime powder making machine and quick lime grinding mill machine $26,00000$69,00000 Min Order: 1 set Previous slide Next slide Premium quick lime making machine For Industries2023年10月2日 The impact of the calcination temperature and grinding time on the mechanical properties and durability of limestonecalcined clay concrete (LC3) is crucial In this research, calcined clay was produced within the temperature range of 700 °C to 900 °C, and the grinding time varied from 15 to 120 min This study examines compressive strength and chloride Investigating the Calcination Temperature and Grinding Time of Calcined 2015年9月4日 This paper, however, concerns only that lime produced from limestone and shipped in dry bulk The limestone must be crushed and screened to a size suitable for feeding a kiln Kiln feed limestone for a rotary kiln is normally sized approximately 2″ x 1/2″ The ratio of kiln feed limestone to lime produced is approximately 2 to 1Lime Slaking Equipment 911Metallurgist

limestone grinding mill, limestone grinding machine, limestone

Limestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limeLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone Request PDF On Jan 1, 2021, Weifeng Li and others published The Properties and Hydration of a Calcined Coal GangueLimestonePortland Cement System Find, read and cite all the research you The Properties and Hydration of a Calcined Coal GangueLimestone For fine grinding lime hydrate lumps, grinding circuits comprising ball mills and separators are provided Instead of separators, screening machines are used in case of coarse grinding The fineness of the products can be set within wide Quicklime preparation Gebr Pfeiffer

.jpg)

The Effect of Calcination Temperature on The Quality of Quicklime

2022年2月28日 Maximum heating rate of 750°C/s was implemented to investigate calcination of limestone and its effect on carbonation and desulphurization reaction of calcium oxide calcined from limestone The 2013年5月2日 Limestone is generally classified into the two types namely (i) high calcium in which the carbonate content is composed mainly of CaCO3 with a MgCO3 content not more than 5 % (usually less), (ii) magnesium or dolomitic Calcination of Limestone IspatGuruChina Limestone Grinding Mill wholesale High Capacity Silica Sand Grinding Machine Limestone Quartz Ball Mill US$ 400015000 / Piece 1 Piece (MOQ) Zhengzhou Hongji Mining Machinery Co, 1 2 5 10 Ton Per Hour Limestone Grinding 1200X2400 1200X3000 Ball Mill for Chrome Ore Mineral US$ 12801380 / Piece 1 Piece Limestone Grinding Mill MadeinChina2024年11月7日 In above quicklime grinding plant case, the customer using our HGM grinding mill as a stone dust making machine to process quicklime (calcium oxide) and calcium carbonate into a fine, 325 mesh powder Quicklime, due to its chemical properties, is in high demand for various industrial applications, including water treatment, chemical manufacturing, and Stone Dust Making Machine For 325 Mesh Quicklime Grinding

The Right Grinding Machines for Your Quicklime Industry

Mankind discovered the benefits of quicklime thousands of years ago The only way to make it is to burn limestone in a kiln The natural CO2 contained in the stone is released into the atmosphere The customer case of quicklime grinding machines Request a Quotation Thank you for your interest in Our Industrial Grinding Mill If you want Dolime is calcined at temperatures somewhat lower than limestone During the calcination Carbon Dioxide (CO 2) gas is released and first MgO and later CaO are formed Dolime contains MgO minimum 32% and up to 38%, and CaO minimum 55% up to 62% Quicklime Powder Kiln Quicklime Lump Quicklime Pebble Grinding PlantBusiness Operation2023年11月15日 Limestone powder resulting from marble dust and stone waste One of the most used raw materials in cement production Hence it is widely available [14]Slag is solely used to reduce CO 2 emissions produced as a byproduct from iron manufacturing and locally available Slag has produced a rate of 045–050 tons per ton of steel when disposed of as Limestone powder, calcined clay and slag as quaternary blended The limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder Fineness

Solid biofuel combustion or electrification for limestone

2022年10月15日 The limestone used in the experiments was a high purity (defined according to [42], [43], [44]) sedimentary fossiliferous limestone with high porosity and an open pore size of 01–10 µm The limestone was fine grained with rounded grains smaller than 01 mm The composition of the limestone is presented in Table 22024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the bulk concentration of Impact of Limestone Surface Impurities on Quicklime 2017年7月7日 It is also a component of synthetic slag Limestone is normally used in three forms These are (i) raw limestone which is also the natural form of limestone, (ii) calcined limestone or quicklime, or simply lime, and (iii) as hydrated lime When limestone is used as a fluxing material then it is used as either raw limestone or as calcined limestoneLimestone – Its Processing and Application in Iron and2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder

.jpg)

Limestone and the resulting quicklime chemical analysis after

Download Table Limestone and the resulting quicklime chemical analysis after calcination in a kiln from publication: Management of Lime in Steel The EU28 total lime demand in 2017 was 2023年9月13日 To further verify the effect of texture and calcite particle size of limestone on quicklime reaction activity, this study, based on DLT 3232010 (measurement method for activity of quicklime used in dry flue gas desulfurization) for the determination of quicklime reaction activity, analyzes eleven (11) groups of limestone collected from nine (9) limestone mines in Effect of the Textures and Particle Sizes of Limestone on the Quicklime Cement and Concrete Research 31 (2001) 633 ± 639 The effects of limestone characteristics and calcination temperature to the reactivity of the quicklime Antonia Moropoulou*, Asterios Bakolas, Eleni Aggelakopoulou Department of Chemical Engineering, Materials Science and Engineering Sector, National Technical University of Athens, Iroon Polytechniou 9, Athens 15780, Greece (PDF) The effects of limestone characteristics and calcination 2023年9月29日 PDF China’s 2022 crude steel production soared to an impressive 1018 billion tons, and steel slag constituted approximately 10% to 15% of this Find, read and cite all the research you (PDF) Dissolution Behavior of Lime with Different Properties into

.jpg)

Dissolution Behavior of Lime with Different Properties into MDPI

The raw material used in this experiment is laboratorycalcined quicklime, which is derived from limestone provided by a large domestic steel company The composition of the limestone was determined by using Xray fluorescence (XRF) analysis, which showed that the main component of the limestone is CaCO 3 , with a content of 9855%Clirik Calcined petroleum coke powder grinding machine and Calcined petroleum coke micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ hardness under six Such as calcite, chalk, steatite, kaolin, dolomite, kaolin, gypsum, and talc etc, totally more than 100 kinds of materials Product fineness can be controlled between Calcined petroleum coke grinding machine Clirik