Safety production layout demonstration of concrete mixing station

.jpg)

Site Planning Of Concrete Batching Plant Aimix Group

Site planning and layout optimization of concrete batching plants are critical for ensuring efficient, safe, and environmentally friendly operations Through scientific and rational design, concrete batching mixing plants can maximize At present, there are three common control modes of concrete mixing station: relay control, PLC control and single chip microcomputer control The mixing station controlled by PLC has The Control System Design of Concrete Mixing Station based on PLCOn the basis of analyzing technology processes and control demands of concrete mixing station, a design of control system for this construction machinery based on SIEMENS S7300 PLC Design of Control System for Concrete Mixing StationThis paper mainly focuses on the design and research of the control system of the concrete mixing station, mainly designs a control system which can detect and control the workflow of Design of Control System for Concrete Mixing Plant

.jpg)

Concreting Job Safety Analysis (JSA) PDF Personal

This document provides a job safety analysis for concrete work It identifies potential hazards for various concrete work tasks such as material handling, cutting and pouring cement bags, using electrical vibrators, transporting 2020年11月6日 In view of current production technology of asphalt concrete mixing plant and technology, a distributed computer control system based on PLC and field bus is developedThe Control System Design of Concrete Mixing Station based on PLCLearn about our Concrete block production plants The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates, the Concrete block production safety concept Masa GroupAbstract: Ready mixed concrete (RMC) industry, one of the barebones of construction sector, has its distinctive occupational safety and health (OSH) risks Employees experience risks that Safety in ready mixed concrete industry: descriptive analysis of

.jpg)

Concrete batching and mixing plants: A new modeling and control

The research is based on HKCONSIM, a valid simulation modeling platform Another application of HKCONSIM is presented in [7] where the concrete plant operations are optimized by Based on the theories and methods of IOT technology, this article applies IOT technology to concrete mixing plant equipment, creatively proposes an integrated system of concrete mixing Research on Equipment of Concrete Mixing Plant Based on The InHand delivers a remote maintenance system for concrete mixing equipment based on PLC and wireless communication technology Leveraging the advanced industrial router IR915, this solution enables realtime remote diagnostics, Concrete Mixing Station InHand Networks2016年8月13日 Akboga and Baradan [4] noted that in the US, the readymixed concrete industry experiences safety issues regardless of production size and sophistication of plant facilitiesSafety in ready mixed concrete industry: Descriptive

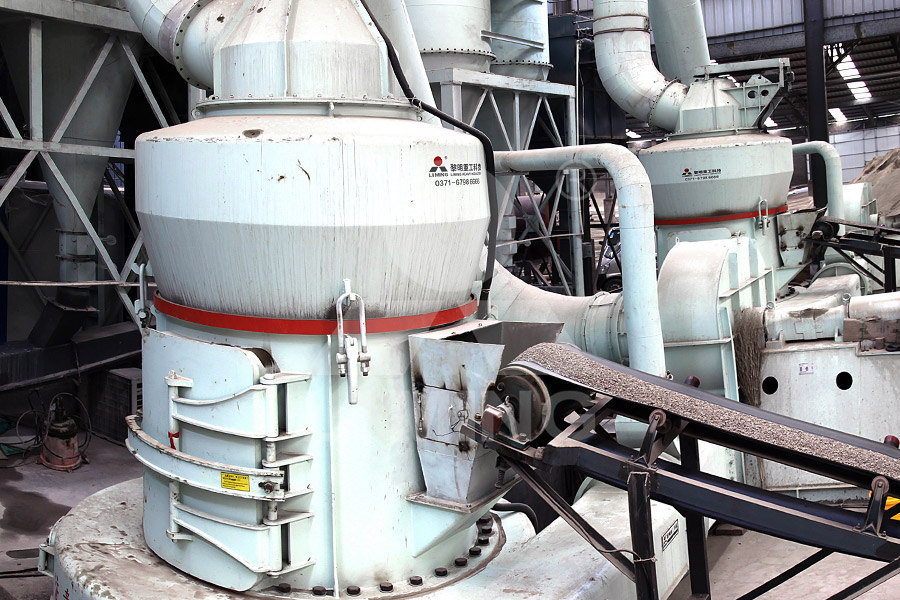

Concrete Mixing Stations MadeinChina

The Concrete Mixing Stations is a premium choice in the Concrete Machinery categoryWhen sourcing Concrete Machinery suppliers in China, consider factors such as product quality, production capacity, reputation, and aftersales service Conduct thorough research, request samples, and visit suppliers' facilities to assess their capabilitiesWith the rapid development of China's infrastructure construction and the start of a series of national key projects, the demand for concrete is increasing day by day China has become the country with the largest production and use of concrete As the main equipment for preparing concrete and the direct supply source of concrete, concrete mixing station has become an Design of Control System for Concrete Mixing Plant2021年6月1日 In the application of MCDM method, there are three methods namely VIKOR, TODIM, and TOPSIS, which have wide applications in various fields As for VIKOR method, the ranking results are sensitive on the values of β (the weight for strategy of maximum group utility) (Bakioglu Atahan, 2021; Das et al, 2020; Joshi, 2020; Rani et al, 2019; Suganthi, 2018)Comprehensive environmental impact evaluation for concrete mixing Mixing Stations available online and instore at Total Tools Safety Equipment Safety; MAKINEX 100L Concrete Mixing Station MS100 $ 1870 Add to Cart Free Delivery Add to Wishlist Add to Compare Show per page Own your own Franchise Mixing Stations Total Tools

(PDF) Research on Equipment of Concrete Mixing Plant Based on

2021年1月1日 Cai et al [91] proposed an innovative IoTbased method to control the production process of concrete mixing plants for improving the quality and production efficiency 2023年6月5日 Concrete Operations: Mixing, Placing, and Curing Concrete operations involve various stages, each with its unique safety considerations From the initial mixing of the concrete ingredients to the final placement and curing, every step requires meticulous attention to safety precautions Concrete Mixing SafetyAn InDepth Guide to Concrete Delivery Safety Procedures and 2024年8月24日 The construction of traditional concrete mixing station is extensive, dust pollution and sewage discharge is a common source of pollution problems, concrete mixing plant industrial zone is the scale of the concrete mixing plant, the construction of refinement, focusing on environmental protection, no dust, no wastewater and waste residue discharge, reuse of water Project Design of Sponge City in Industrial Zone: A Case Study of a Concrete safety is a recruiting safety topic across many different industries and workplaces, so it will need to be continuously addressed This is why you should use this toolbox talk concrete safety template to hold better toolbox talks on safety Safety Precautions During Concrete Work Sitemate

Concrete Production and Construction Safety Hazards

Concrete Production and Construction Safety Hazards When mixing, pouring, or during other concrete work activities that may endanger the eyes, suitable eye protection must be worn When kneeling on fresh concrete, use a dry board or 2020年11月6日 Experiments show that the control process of concrete mixing station controlled by PLC has the characteristics of strong reliability and easy operation, and meets the requirements of the design In recent years, with the largescale development of infrastructure construction, the concrete mixing station was constantly updated and iterated At present, The Control System Design of Concrete Mixing Station based on 2022年5月9日 Concrete mixing is the process of properly mixing the materials needed to form concrete, such as cement, sand, aggregate, water, and admixtures (if any) The primary goal of concrete mixing is to make the Mixing of Concrete Civil Engineering Notes2018年12月13日 The Makinex Mixing Station with stirrer can mix batches up to 220lbs (100kg) in three minutes For large jobs (larger than 80m² or 861ft²) additional stations are recommended It also features a dust/splash reduction cover for safer use and less mess and has a vacuum attachment on the lidMakinex Mixing Station Concrete Construction Magazine

Standard Maintenance For Ready Mix Concrete Production

This document provides a checklist of standard maintenance items for ready mix concrete production facilities It outlines the key items that must be completed prior to producing concrete, such as reviewing project specifications, checking aggregate stockpiles and plant equipment, and ensuring proper site layout It also lists items that must be maintained throughout the project, 2021年1月18日 2 Mixing of concrete: Mixing is necessary to make homogeneous concrete To obtain a good quality of concrete, it is necessary to do proper mixing of concrete ingredients The mixing of concrete depends on the types of mixing Generally mixing is done by three ways Hand mixing; Machine mixing; Readymix concrete; i Hand Mixing:Concrete Production, Placement, Curing Process Summary2020年11月6日 In view of current production technology of asphalt concrete mixing plant and technology, a distributed computer control system based on PLC and field bus is developedThe Control System Design of Concrete Mixing Station based on 2015年12月2日 Question: What are some important steps to remember in setting up a mixing station? Answer: A properly set up mixing station is an important part of a successful topping installationNot only should the mixing station be outfitted with all the equipment and supplies you’ll need to mix materials properly, it should also provide efficient access to the point of Setting up a Mixing Station Concrete Construction

Mixing Station: Useful Custom Layouts for m32/x32 mixers

how to make custom layouts in mixing station app for m32 and x32 mixers My Instagram: https://instagram/danielkharrat/ Mixing Figure 2 IOT integrated system of concrete mixing plant 31 Concrete mixing reservation system According to the actual construction progress, the construction personnel can access the concrete mixing reservation system through various ways such as concrete mixing plant integrated IOT system machine, mobile appResearch on Equipment of Concrete Mixing Plant Based on The 2019年4月3日 Therefore, in this paper, it mainly demonstrates the analysis of prefabricated concrete production layout design based on SLP An HSL120*2 mixing station is set up to ensure the concrete supply 3th International Conference on Transportation Information and Safety, pp 848–851 IEEE, Wuhan, China (2015)Research on Production Layout Design of Concrete Springer2021年6月1日 Thus, environmental impact assessment is a significant aspect for the concrete mixing station (CMS) Some pioneering research has been performed For example, Müller et al (2014) improved the sustainability of a concrete structure through reducing the environmental impact of concrete and increasing the lifetime of concrete prehensive environmental impact evaluation for concrete mixing

Key Points in Concrete Batching Plant Design and

Selection and Configuration of Mixing Equipment Producing highquality concrete requires reliable production equipment When determining the selection and configuration of equipment for a batching plant, it’s essential to consider In recent years, with the largescale development of infrastructure construction, the concrete mixing station was constantly updated and iterated At present, there are three common control modes of concrete mixing station: relay control, PLC control and single chip microcomputer control The mixing station controlled by PLC has reliable performance and high cost The Control System Design of Concrete Mixing Station based on Performance advantages of concrete planetary mixer:1 The models of concrete planetary mixer are complete, and the equipment models can meet the requirementsConcrete planetary mixer Visual demonstration of mixing process2021年11月1日 According to Ref [6] the degree of automation is more advanced in the precast concrete component production than any other part of the industryWith concrete being the most utilised building material worldwide [7, 8] a high ecologic potential, in regard to resourceefficient design and production through automation, is available Automated optimisation processes of State of practice of automation in precast concrete production

.jpg)

mixingstationdocs/docs/customlayoutsmd at master

A layout can be configured to have different behaviors, which are also indicated in the Mixer and Startup column above Override mixer layout: A layout with this flag will replace the default mixer layout of the app; Open on start: The layout will be opened directly after connecting to your mixerYou'll be able to press the back button to return to the mixer viewMixing plant safety production rules 1, mixing station staff not to work in spite of;Shall not be exhaustedAnd severely stop station all homework personnel mount guard after drinkingBanned all kinds of mixing station don't gauge behavior is likely to cause safety issueMixing plant safety production rules HAOMEI2010年10月14日 Monthly production of concrete by the LowLevel and HighLevel Mixing Plants at Hoover Dam (in thousands of cubic yards) versus the various project elements that were constructed (USBR, 1947)(PDF) Hoover Dam: Construction Milestones in Concrete Delivery 2023年8月10日 Machine Mixing of Concrete The process of mixing concrete materials in a concrete mixer is known as machine mixing This sort of concrete mixing technique is commonly used for mediumlarge construction projects where a huge amount of concrete is required and hand mixing is ineffective These machine mixers are classified into two types mainly :Mix Proportion of Concrete Methods Steps of concrete mixing

Design of Control System for Concrete Mixing Station using PLC

production Therefore, solution to the problem is a control system for a concrete mixing station using a programmable logic controller to achieve the best quality of concrete by ensuring accuracy in the content ratio of the mixed material The concrete mixing station shown in Figure 11 is an important component in thedrives, piping, control valving, flow metering, pump station structures, and operational features 13 PLANNING FACTORS Main pumping stations which supply water to the distribution system will be located near the water treatment facility or a potable water storage facility and will pump directly into the piping system These pump stations mayIntroduction to Pumping Stations for Water Supply SystemsProper and sufficient mixing of the materials is essential for the production of uniform concrete The mixing process ensures that concrete becomes homogeneous, uniform in color, and consistent There are two methods used Mixing of Concrete Methods of Mixing ConcreteReady mixed concrete is proportioned and mixed off the project site and is delivered to the construction area in a freshly mixed and unhardened state It can be manufactured by any of the following methods: MIXING CONCRETE All concrete should be mixed thoroughly until it is uniform in appearance, with all ingredients evenly distributedBatching, Mixing, Transporting, and Handling Concrete

.jpg)

Optimizing Ready Mixed Concrete Production Plants via a

2014年11月3日 A concrete batch plant is an important element in any concrete construction process, whether it is working as a central mixing plant onsite or is offsite supplying ready mixed concrete to a projectThis document provides a detailed work program and sitespecific environmental and social management plan for the construction of a concrete batching plant (CVC plant) for the Nam Ngiep 1 Hydropower Project in Laos The document includes details on materials, equipment, construction procedures, safety controls, quality assurance, and an environmental and social Method Statement For Construction of Concrete Batching Plant5 Work Station of Pencil Shoe Production 6 Work Station of Concrete Mixxing Process 7 Work Station of Concrete Placing Process 8 Work Station of Tension Process 9 Work Station of Spinning Process 10 Work Station of Drying using Steam Boiler 11 Work Station of Setting Process (Setting 1) 12 Work Station of Demolding Process 13 Stock AreaRelayout Production Facility of PC Spun Pile Using Systematic Layout The manufacturing of autoclaved aerated concrete products demands high standards for mixing and dosing of the aggregates, the control of the fermentation process and the control of each production step Masa's aerated concrete installations are proven advanced technology processes, designed according to customers specific requirementsConcrete block production safety concept Masa Group

Optimizing Ready Mixed Concrete Production Plants Via a

However, locating concrete production equipment (batching plant) layout was not considered despite the significance of layout factor at minimizing the cost of concrete production Another study planned and allocated the resources in the batching plants to optimize production, and maximize revenue and profit factors in the context of a linear programming model (Zayed 2004)2021年3月1日 With the rapid development of China's infrastructure construction and the start of a series of national key projects, the demand for concrete is increasing day by day China has become the country with the largest production and use of concrete As the main equipment for preparing concrete and the direct supply source of concrete, concrete mixing station has Design of Control System for Concrete Mixing Plant