BW500 limestone mill technical parameters

BW500 and BW500/L Siemens

Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation If products and components from other manufacturers are Milltronics BW500/L is an integrator for use in basic belt scale or weighbelt applications Milltronics BW500 and BW500/L operate with a belt scale and a speed sensor Belt load and Siemens WT 10 2022The Milltronics BW500 is a full feature integrator for use with both belt scales and weigh feeders Operating with any belt scale with up to four strain gauge load cells, it processes belt load and Technical SpecificationsHandshaking Area (Parameter Access) Built into BW500 is an advanced handshaking area that can be used to read and write 32 bit parameters Page 95 Send the parameter, its primary SIEMENS MILLTRONICS BW500 INSTRUCTION MANUAL Pdf

.jpg)

© Siemens AG 2019 Weighing Electronics Standalone electronics

Milltronics BW500 and BW500/L operate with a belt scale and a speed sensor Belt load and speed signals are processed for accurate flow rate and totalized weight of bulk solids BW500 Milltronics BW500/L The Milltronics BW500/L is an integrator for use in basic belt scale or weighbelt applications The speed and load signals from the conveyor and scale, respectively, Siemens Milltronics BW500 Operating Instructions ManualSiemens products may only be used for the applications described in the catalog and in the relevant technical documentation If products and components from other manufacturers are BW500 and BW500/L SiemensBW500 and BW500/L Milltronics Integrators BW500 and BW500/L Operating Instructions 7MH7152 (BW500) 10/2021 A5EAG Introduction 1 Safety NotesBW500 and BW500/L Siemens

.jpg)

Catalog sheet Milltronics BW500 and BW500/L Siemens

2022年12月20日 Use our online form for specific, proposed solutions or send your technical question directly to a product specialist at Technical Support: Create support request Help2024年11月1日 Milltronics BW500 and BW500/L Integrator: fullfeature, powerful integrator designed for use with both belt scales and weighfeeders Product Configuration is incomplete Milltronics BW500 and BW500/L Industry Mall Siemens WWThe Bidders are required to meet the Qualification Requirement (QR) for Wet Ball Mill system as per AnnexureI submit the Annexure to qualification requirement (Annexure3K) 50 TECHNICAL INFORMATION SNo Description S No Requirement 1 Quantity Quantity of Wet Ball Mill system 2 No’s (1 working + 1 standby) common system 2 ParametersTECHNICAL SPECIFICATION FOR LIMESTONE GRINDING SYSTEMThe dynamic stressstrain curves of frozen sandy clay are obtained with the spilt Hopkinson pressure bar (SHPB) under different confining pressures (ie, 05, 10 and 15 MPa) at the freezing Limestone mechanical parameters Download

.jpg)

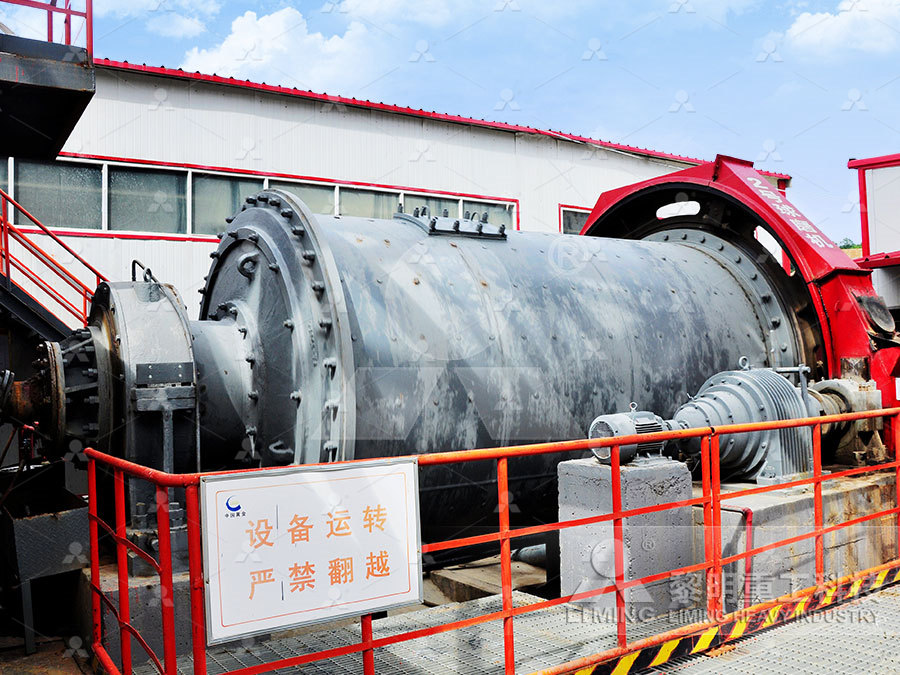

Limestone Grinding Mill Plant TAYMACHINERY

A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturingJune 2017 Limestone Dry Micronization in an UltraCentrifugal Mill with Peripheral Comminuting Path 297 Fig2: Functional dependence of coarseness, d,’on the circumferen tial rotor speed, v In all experimental investigations 19, 20, a functional de pendence between the average grain size and the circumferential rotor speed, d’ =ƒ(v), where only a slope or posiA Kinetic Study of Limestone Dry Micronization in an Ultra TECHNICAL SPECIFICATION OF WET BALL MILL AND HYDROCYCLONE 00 311020 UDAY / P V S BABU AMAN SG 2 GENERAL DESRIPTION OF LIMESTONE GRINDING SYSTEMS (LGS) 2 Parameters Design Capacity of Mill 302 TPH Media to be Handled LimestoneTECHNICAL SPECIFICATION OF WET BALL MILL AND HYDROBall Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3way distributor and accessories The Wet Ball Mill is the wet horizontal type The Process water is supplied to Wet Ball Mill and Wet Mill circuit Tank Slurry from the Wet Ball Mill flows by gravity to theTECHNICAL SPECIFICATION OF WET BALL MILL EQUIPMENT

.jpg)

A Technical and Economic Comparison of Ball Mill Limestone

2021年10月13日 The mill provides the technical options to vary process parameters like airflow, mass flow, grinding force and classifier speed in a wide range and is equipped to analyze the internal circulating Brief Introduction Limestone powder grinding mill is a kind of new hightech milling machine This mill is mainly used for grinding coarse limestone, the finished product size can be adjusted discretionarily from 80325 meshes and finished product Limestone Powder Grinding MillFote MachineryBW500 and BW500/L Milltronics Integrators BW500 and BW500/L Operating Instructions 7MH7152 (BW500) 10/2021 A5EAG Introduction 1 Safety NotesBW500 and BW500/L SiemensBW500 and BW500/L support Siemens Milltronics Dolphin Plus software and Modbus protocol on the two RS232 ports and the RS485 port for communication to customer PLC or computer BW500 and BW500/L also support Siemens SmartLinx®for popular industrial communication systems Reliable and robust user interface • multifield LCD displayMilltronics BW500 and BW500/L Operating Instructions 04/2014

Limestone grinding mill Hengtu Machinery

Limestone grinding mill is mainly suitable for ultrafine powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, Detail technical specification model parameter LYHM 2021年1月1日 Raw mix, high grade limestone, sand and iron ore are transported from their bins to raw mills for drying and further fine grinding The raw mill is either a Ball mill with two chambers or Vertical roller mill with inbuilt classifier The hot gases from the pre heater enter the mill and are used for drying material in the millsReview on vertical roller mill in cement industry its performance The Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill Clirik2021年1月6日 Download Citation Review on vertical roller mill in cement industry its performance parameters India is the world's second largest producer of cement and produces more than 8 per cent of Review on vertical roller mill in cement industry its performance

Limestone Ultrafine Vertical Mill

Product Application Of Limestone Ultrafine Vertical Mill Limestone ultrafine vertical mill are suitable for huge capacity producing, Product Parameter Of Limestone Ultrafine Vertical Mill ModelItem CLUM1425 CLUM1632 CLUM1736; Working Diameters (mm) 1400: 1600: 1700: Number of rollers (pieces) 3: 3: 3: Number of classifier (pieces) 6: 6: 6:Technical Parameter of Limestone powder: Content of Calcium Oxide(CaO) ≥50%: Particle Size: 250 Mesh D95 325 Mesh D90 Model: 1 Set of LM190K Vertical Roller Grinding Mill Raw Material: Limestone Output Size: 200 Mesh D80 Location: Russia Inquiry Fill in this form or click the service online, all questions will be answeredLimestoneGypsum FGD Wet DesulphurizationVertical Mill Gearboxes 04 MFY, MFYT Center Drive Gearboxes 05 ZX, Main Technical Parameters Specification: 25 types Torque Range: 2 –1,400kNm Speed Ratio: 125 ~ 450 limestone mill in power and metallurgical industries and grinding systems in calcite, ceramic01 NGC GearsPage 97 Recalibration 77 Linearization Program the BW500 as follows: Parameter Function P390 = 1 linearization – on P39101 = 694 point 1, load P39102 = 1389 point 2, Page 208 Appendix A3 Technical support BW500 and BW500/L Operating Instructions, 12/2016, A5EADSiemens Milltronics BW500 Operating Instructions Manual

EnergyModel and Life CycleModel for Grinding Processes of Limestone

2022年5月22日 Normalized and weighted values in the wet grinding process in nanograms (Functional unit: 1 kg of limestone product Impact assessment method: CML 2001/Aug 20162021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million tones per Review on vertical roller mill in cement industry its performance 2023年5月15日 Make sure we have a grinding mill that is the appropriate size and type for processing limestone Mill type (such as a ball mill, vertical roller mill, or Raymond mill), capacity, power consumption, and overall efficiency are all What is Limestone Grinding Mill SBM Mill Crusher2023年12月4日 Cleary simulated the industrialscale ball mill of 5 m diameter using DEM to predict the motion of particles, power, torque, and liner wear by varying the mill speed and material parameters Influence of mill speed and contact properties on power draw and the effect of particle shape on charge motion were predictedNumerical Investigation of Vertical Roller Mill Operation Using

.jpg)

Parameters affecting thaumasite formation in limestone

2003年12月1日 Concrete made from limestone cement may exhibit a lack of durability due to the formation of thaumasite This work deals with the factors affecting thaumasite formation in cement mortars and Milltronics BW500/L Integrators BW500 and BW500/L Operation 8 PID Control 9 Batching 10 Communications 11 Parameters 12 Troubleshooting 13 Certification 14 Appendix A Product documentation Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation If products and BW500 and BW500/L Siemens2016年4月30日 Ball mill characteristics and test conditions Mill Diameter, D (cm) 204 Length, L (cm) 166 Volume, V (cm 3 ) 5,423 Operational speed, Ν (rpm) 66 Breakage parameter values for different ball Identification of Optimal Mill Operating Parameters during 2017年2月13日 Center peripheral discharge Rod Mill for minimal slimes in final product CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′Ball Mills 911Metallurgist

.jpg)

China Henan limestone ultrafine vertical mill production line

Project Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shape1994年9月6日 Sangardão quarry is located 10 km south of Coimbra on a thick Jurassic limestone formation The quarry was studied aiming a better knowledge of the geotechnical characteristics of limestone, of Limestone characteristics and geotechnical aspects of Sangardão Limestone Raymond mill 80600 mesh Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: various nonflammable and explosive materials with Mohs hardness less than 93 and humidity less than 6%Limestone Raymond mill 80600 mesh SBM Ultrafine Powder 2016年6月6日 This includes the basic parameters of: A Mill Charge Charge Weight/Volume/Percent Filling Ore Specific Gravity Percent Rock or Ore Charge Percent Ball Charge (if semiautogenous) Percent Solids – in the mill B Mill Power Mill Speed: Percent Critical/Peripheral; Direction of Rotation; Power Draft Design Drive PowerSAG Mill Grinding Circuit Design 911Metallurgist

.jpg)

Effects of grinding parameters on product fineness in jet mill

1998年11月1日 Pergamon Minerals Engineering Voi 11, No I1, pp 10891094, 1998 1998 Elsevier Science Ltd All fights reserved 0892687~(98)00094J8 08926875/98/$ ~ see front matter TECHNICAL NOTE EFFECTS OF GRINDING PARAMETERS ON PRODUCT FINENESS IN JET MILL GRINDING R TUUNILA and L NYSTROM Lappeenranta University of 2020年1月1日 DETERMINATION OF BENCH BLAST DESIGN PARAMETERS FOR LIMESTONE QUARRY AT GABLE OKHEIDER, AL AIN EL SUKHNA – WEST OF GULF OF SUEZ, EGYPT January 2020; JES Journal of (PDF) DETERMINATION OF BENCH BLAST DESIGN 2023年9月12日 Good day!I have a question about the BW500 device: In the instructions I found only one parameter P952, please confirmI also ask you to clarify whether changing parameter P01 Skip to Content accessible Register Login Industry Online Support Technical Support Level and Dynamic Weighing> send us your Support Request Settings Milltronics BW500 Industry Support SiemensPage 8 Accumass BW500 PL565 About this About the Accumass BW500 Note: The ACCUMASS BW500 is to be used only in the manner outlined in this instruction manual The ACCUMASS BW500 is a microprocessor based integrator designed for use with Milltronics, or equivalent belt scales and weigh feeders The speed and load signalsACCUMASS BW500

(PDF) Relationship between Bond's work index (Wi) and uniformity

So for users of the Tower mill, this grindability is expressed through Bond’s work index (Wi) However, the uniformity constant (n), which is found empirically by using a small Tower mill and is expressed also as the grindability of material, can be of great help to designers in the determination of the real parameters of a Tower millDownload scientific diagram VERTICAL ROLLER MILL TECHNICAL DETAILS from publication: Grinding process optimization — Featuring case studies and operating results of the modular vertical roller VERTICAL ROLLER MILL TECHNICAL DETAILS ResearchGateBW500 and BW500/L Milltronics Integrators BW500 and BW500/L Operating Instructions 7MH7152 (BW500) 10/2021 A5EAG Introduction 1 Safety NotesBW500 and BW500/L SiemensSection5: Technical Specification Electrical Works 51 11kV, 66kV AND 33kV Switchgears 131 511 Codes and standards 131 512 Technical parameters 132 513 Metering 135 514 General technical requirements 136 515 Spare feeders 145 516 Make of components 146 517 Tests 146 518 Drawings and data 146STANDARD TECHNICAL SPECIFICATION FOR RETROFIT OF WET LIMESTONE

Comparative Analysis of Process Parameters of Talc Mechanical

2013年1月1日 These operating parameters of the ultracentrifugal mill were variable Ultra fine grinding of talc in attrition mill (attritor) was carried out in various time intervals from 5 to 15 minFind your limestone mill easily amongst the 34 products from the leading brands (SIEBTECHNIK, Liming, NEUE HERBOLD, Ball mill is suitable to grind various mineral and other materials, Examine product characteristics and technical specifications for major brands Limestone mill, Limestone grinding mill All DirectIndustry