Zibo raw lime limestone deep processing equipment

Lime Production Line Zhengzhou Shibo Machinery

Lime Production Line Processing capacity: 300 t/d3000 t/d Output: 500t/d, 700t/d, 100t/d, 1500t/d, 2500t/d Applied materials: limestone, clay, iron ore, coal,etc : The company provides lime kiln equipment design consultation, equipment manufacturing, installation, commissioning, process guidance, personnel training, technical services and other Zibo Kangqi Machinery Equipment Co, LtdBlowerDistributor2023年2月15日 How is lime produced by limestone? Lime is made of limestone which needs to be calcinated with a temperature over 900℃ Limestone is a kind of sedimentary rock that is alkaline, and the main component is calcium Lime Production Process and Required EquipmentFind production technology for making Limestone, Conveyors for causticizing and lime kilns Modern lime processing occurs on an extremely large scale and process interruptio There is currently no equipment listed with your specified properties, Limestone Processing Equipment Making

.jpg)

(PDF) Environmental Hazards of Limestone Mining

2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of timeAdditionally, since the mid1980s, we’ve developed extensive experience in Circulating Fluidized Bed (CFB) technology and our limestone mills have proven themselves as an essential part of CFB systems The limestone crushers and mills are effective for directinjection of dry sorbent lime or limestone during the CFB processLimestone Mills Williams CrusherLime Calcination Plant Finished products: active lime Limekiln: rotary kiln (vertical shaft kiln upon request) Capacity: 2001000t/d Limestone granularity: 2040 mm Fuel: gas, pulverized coal Get the solution now!Lime Calcination Plant Solution 2001000tpd Quicklime CNBM 2020年6月5日 Limestone calcined clay cements (LC3) are blended cements that combine clinker, limestone, calcined clay and gypsum The availability of the materials required to produce LC3 and the good Limestone calcined clay cements (LC3): raw material processing,

10 Types of Equipment Every Industrial Lime Plant Needs

2022年2月3日 Procuring the right equipment is one of the most critical steps in getting a new lime plant up and running Here are the top ten types of equipment every lime plant needs to compete In the last 3 years, many companies have announced new 2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLinkHLMX superfine limestone grinding equipment is a preferred powder making equipment for processing superfine limestone powders, it can process the fineness between 45um7um, if used a secondary classification system, Applicable materials: raw cement, clinker, lime powder, slag powder, manganese ore, gypsum, coal, barite, calcite , etcLimestone Processing Equipment Using Superfine Grinding Millii table of contents 1 introduction 1 2 limestone quarrying and processing operations 2 21 limestone 2 22 limestone quarrying operations 2 23 limestone processing operations 3 3 lci methodology 5 31 lci data collection 5 32 quality of lci data set 5 331 limestone quarry operations 5 332 limestone processing operations 6 4 lci results 7Limestone Quarrying and Processing: A LifeCycle Inventory

.jpg)

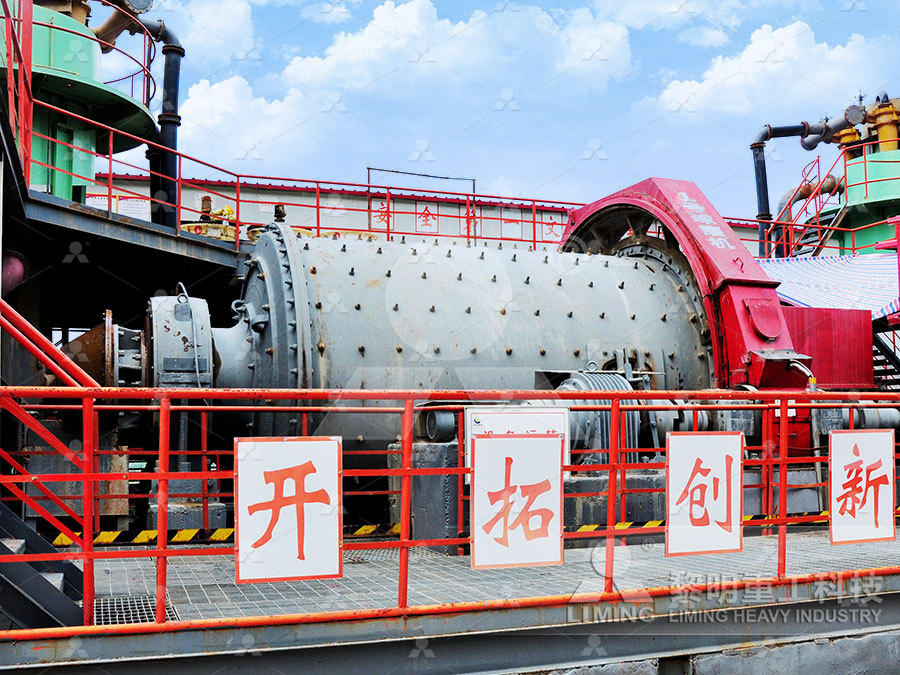

Type Selection of Quicklime Deep Processing Equipment

2022年12月22日 It is the preferred choice for deep processing of quick lime HGM Ring Roller Micro Powder Mill It is a lowconsumption ultrafine powder processing equipment developed by CLIRIK with more than 30 years of mill manufacturing experience, after many innovations, tests, and designs It has successfully replaced the traditional jet mill and ball mill2020年10月29日 Limestone (or lime rock) is the source of raw material for most of the lime manufactured but calcium carbonate or hydrate from any source may be used in a properly selected type of kiln Crushed and washed oyster shells are used to a considerable extent; also calcium carbonate and hydrate wastes from the paper and other industriesLime Quicklime Limestone 911MetallurgistThe major uses are in two areas: as aggregate in construction and as the primary raw material for cement making The quantity of limestone used in the manufacture of cement is estimated at about 1500 million tonnes or onethird Everything you need to know about cement Raw 2007年12月21日 When the choice of the raw material falls on marly limestone composed of 6520 wt% clays, the production process is obviously characterized by different temperatures and times and the finished Lime and Limestone: Chemistry and Technology, Production and

.jpg)

Vertical Shaft Kilns in Optimizing Lime Calcination

Verticle Shaft Kiln Introduction In factory of lime calcination, where precision and efficiency are paramount, vertical shaft kilns (VSKs) stand as stalwart contributors to the chemical transformation of limestone into quicklime As an engineer navigating the intricacies of industrial processes, understanding the design, components, and operational aspects of VSKs becomes 2022年4月20日 Lime is divided into quick lime and slaked lime After being calcined, limestone becomes calcium oxide CaO (commonly known as quicklime), which is generally in the form of lumps and is used in water quality treatment, asphalt improvement, desulfurization, building materials, medicine and other industriesLimestone crushing and grinding production line SBM Ultrafine 2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine The more complicated the limestone structure, the more sampling and testing required to ensure the delivery of quality limestone to the process In these conditions, the number of core holes will have to increase to define the areas of quality limestone and the geologic structures, and to determine the “mineability” of the depositLimestone Sampling and Testing – Cement and Lime Mines

.jpg)

The Availability of Limestone and Other Raw Materials for Ocean

2022年5月25日 assessment of limestone extraction could be derived from cement, lime and limestone production f or some coun tries (Chilamkurthy et al, 2016 ; Peduzzi et al, 2013 ; Svendrup et al, 2017 )2021年6月18日 Primary Information Services offers several databases related to limestone production in India, including information on mining, lime kilns, technology, products, and the mineral industriesLimestone mining amp; processing PPT SlideShare2023年8月14日 Grinding Equipment Lime grinding equipment is an important machine that determines the fineness of lime powder For producing 200 mesh and 325 mesh commonly used lime powder, one of the main machine Equiment List For Lime Processing Plant2024年1月11日 Equipment Configuration Of Limestone SandMaking Plant The equipment for the limestone sand production line mainly includes a vibrating feeder, jaw crusher, sand making machine, circular vibrating screen, sand Limestone Crushing And SandMaking Plant

Choose Hydrated Lime Plant for Advanced Lime Processing

Process Flow of Hydrated Lime Production Line Raw Material Preparation: Quicklime needs to be crushed and screened to obtain the raw material with uniform particle monly used raw materials are limestone, dolomite and so on Hydration of Quicklime: the raw materials quick lime after crushing and screening are mixed with appropriate amount of water, and the hydration 2019年11月4日 The compressive strength of limestone is generally around 150 MPa, which belongs to soft rock The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing plant for different requirements to meet high efficiency, energysaving performanceLimestone Rock Crushing Flow Price JXSC MachinePEC Consulting Group is a trusted advisor to leading lime manufacturers and mining companies worldwide With a deep understanding of the unique challenges and opportunities within these industries, we provide tailored consulting services to drive operational excellence, enhance profitability, and mitigate risksLime Industry Consultants PEC Consulting Group2024年10月3日 The lime is the cheapest and most required clarifying agent The consumption of lime in different processes is as follows In Defecation Process – 008 to 012% on cane; In Sulphitation Process – 014 to 020% on cane; The availability of lime in different forms like quick lime , limestone and hydrated limeMilk of Lime in sugar Industry MOL System Capacity Requirement

.jpg)

Limestone extraction – underground mining techniques,

Limestone is a sedimentary rock comprising about 15% of the earth's sedimentary crust Limestones are generally mined using the methods of openpit mining and underground mining based on economic and environmental conditions WHERE DO THEY FORM LIMESTONE : Limestone forms in a variety of marine, freshwater, and terrestrial environments2018年1月1日 In Malaysia, limestone is essentially important for the economic growth as raw materials in the industry sector Nevertheless, a little attention was paid to the physical, chemical, mineralogical Characterization of Limestone as Raw Material to Hydrated LimeThe principal raw materials for cement manufacturing are: Limestone; Silica and alumina from basalt , shale or sand; Iron from iron ore or steel mill scale Sand stone; Pumice (volcanic ash for Portland Pozzolana cement ) Gypsum General Properties of Raw Material Sources Limestone; The basic raw material of the cement production is limestoneCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2021年4月27日 I The status quo and development of domestic lime deep processing China's annual lime output is over 300 million tons, accounting for more than half of the world's totalLime Calcium hydroxide Raw Material Process Tech LinkedIn

Limestone Lime TerraSource Global

Limestone Lime TerraSource Global’s flagship brands offer advanced solutions for secondary crushing and feeding in limestone and lime processing Gundlach Crusher’s CagePaktor and MultiRoll Crushers provide precise size control and energyefficient processing for wet, sticky materials The NANOSIZR and Centroload Feeders ensure uniform, highcapacity 2019年12月6日 1 Mine machinery and equipment: Supply in different types of kilns, ball mills, dryers, rotary kilns, crushers, concrete mixing stations, hoists and other mechanical equipment 2 Environmental protection equipment: Bag dedusting equipment, wet electrostatic dedusting equipment, flue gas desulfurization equipment, flue gas denitrification Environmental Protection Lime Kiln and Its Supporting Equipment2012年8月20日 In this activity, students view the interactive Calcination – lime from limestone, which shows the industrial processing of limestone into lime, and use the information to complete a matching activity By the end of this activity, students should be able to: describe the effect of heat on limestoneLimestone to lime — Science Learning HubLimestone processing equipment plays a critical role in transforming quarried limestone into a variety of valuable products, but the material’s diverse characteristics often present unique challenges in production From its variable chemical composition to its tendency for buildup and abrasion, limestone can complicate operations if not properly managedChallenges in Limestone Processing FEECO International Inc

Processing of lithium ores: Industrial technologies and case

2021年5月1日 Today, the other schemes, such as sulfuric acid and calcareous (lime or limestone) (Neikov et al, 2019), have been identified as the main technological schemes for spodumene concentrates processing Both schemes ensure the selective extraction of lithium, and the advantages (as well as disadvantages) of each scheme are determining by specific 2017年7月7日 Limestone is normally used in three forms These are (i) raw limestone which is also the natural form of limestone, (ii) calcined limestone or quicklime, or simply lime, and (iii) as hydrated lime When limestone is used as a fluxing material then it is used as either raw limestone or as calcined limestone Hydrated lime is generally produced Limestone – Its Processing and Application in Iron andLimestone Crushing Production Line The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, centralized electronic control, and other equipment To meet the different processing needs of customers, it can be equipped with a cone crusher, dust collector Equipment, etcLimestone Crushing Equipment and Production Line2022年4月1日 HLMX superfine limestone grinding equipment is a preferred powder making equipment for processing superfine limestone powders, it can process the fineness between 45um7um, if used a secondary classification system, Applicable materials: raw cement, clinker, lime powder, slag powder, manganese ore, gypsum, coal, barite, Limestone Processing Equipment Using Superfine Grinding Mill

New Wet FGD Process Using Granular Limestone ResearchGate

2002年6月1日 Commercial wet, dry and/or semidry FGD use calcite (CaCO 3 ) from limestone, slaked lime (Ca(OH) 2 ), or a mixture of Ca(OH) 2 and alkaline fly ash (FA) sorbents, the purpose being to react with Lime Dosing Especially tailored to lime dosing requirements of processing plant engineers from various industries, WAMGROUP has developed highly applicationoriented equipment for silo venting and silo safety, for discharging, feeding, conveying, and intercepting lime powder in special Lime Dosing PlantsLime Dosing WAMGROUP