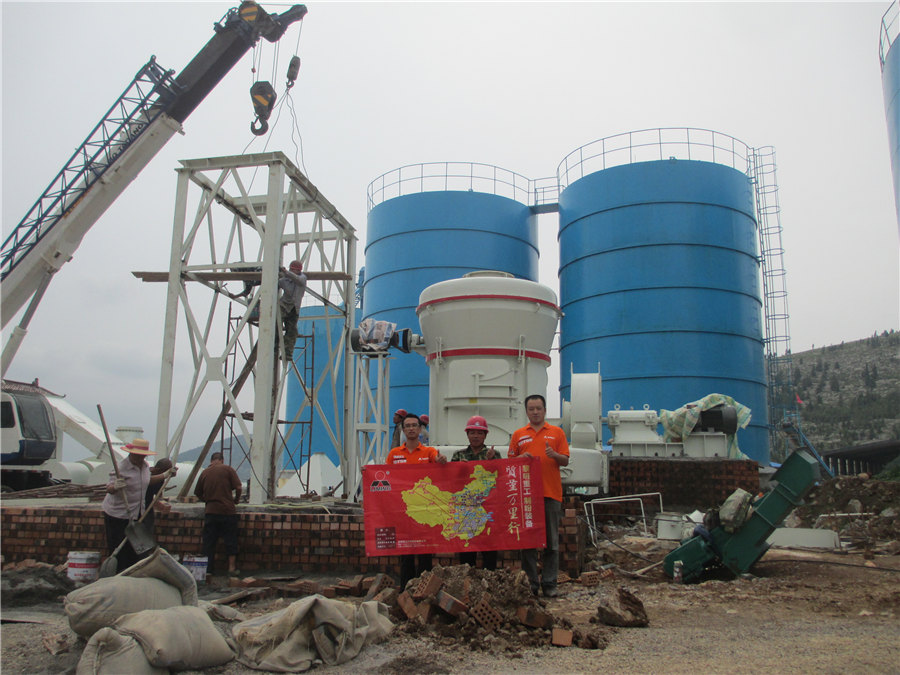

Hydraulic rock mill crushing plan

.jpg)

Crushing Plant Design and Layout Considerations 911 Metallurgist

The principal design parameters that drive crushing plant selection and configuration include: • Production requirements • Capital cost • Ore characteristics • Safety and environment • Project 2016年4月14日 In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons Crushing Screening Plant Design FactorsCrushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the (PDF) Field monitoring and performance evaluation of Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the (PDF) Crushing and Screening Handbook Academia

Crushing Plant an overview ScienceDirect Topics

Crushing is the first mechanical stage in the process of comminution in which a principal objective is the liberation of the valuable minerals from the gangue Crushing is typically a dry operation However, operational characteristics or crusher settings are by far the most critical variable in rock quarrying In this regard, the crusher discharge settings (ie, openside setting (OSS)Layout of a fourstage crushing plant for ballast productionYeco Machinery’s engineers will prepare a layout that suits the design criteria, flowsheet and selected equipment in the most economical possible configuration It’s important to keep structural costs down, to design for ease of maintenance Crushing Plant Design and Layout Yeco MachineryThe objective of the crushing plant operation for the aggregates industry is to supply specific size fractions of rock material for infrastructure development, while the objective in minerals Optimization Capabilities for Crushing Plants Chalmers

.jpg)

Construction, Working and Maintenance of Crushers for Crushing

Information about crushing technology, construction, working and maintenance of crushers for bulk materials is given in this article There are four basic ways to reduce size of a material: by This project is all about Hammer mill failure during flux crushing The Hammer Mill consists of Crusher settings play a leading role in achieving Energy considerations in compressive and impact crushing of rock, Minerals (PDF) Field monitoring and performance evaluation We take immense pride in being a 100% South African company, with our Workshop and Manufacturing facilities proudly located in South Africa To ensure authentic and reliable service, we urge you to contact us directly at our South CE AFRICA – Crusher Equipment Africa2024年1月7日 Mobile crushing plants are generally more efficient than stationary crushing lines, and they can produce large quantities of products in a short period of time Low cost and high efficiency For occasional or Portable crushing plant SBM Mill Crusher

.jpg)

Small Portable Rock Crushing Machinery Senya Crushers

Small Portable Rock and Concrete Crushers Senya Crushers is proud to be the world leader in pioneering the MICRO Crushing category of highly portable crushing machinery for on site processing Jaw crushers are the primary and most prevalent type of heavy machinery used to crush rocks and concrete2017年12月1日 PowerPacker’s hydraulic stabilization legs for rock crushers PowerPacker offers 4”, 5” and 6” bore hydraulic stabilization legs for leveling and holding mobile crushing plants in the field Designed to withstand the harshest environments, our legs arrive completely assembled and tested with a bolton, outer tube mount conveniently integrated into the designPowerPacker’s Hydraulic Legs Rock!2024年6月3日 Crusher Clicker is an addictive game where you smash rocks and crystals, then upgrade to enhance your crushing power and speed It#39;s like operating a hydraulic press but with a satisfying, stressrelieving twist Boost your crusher#39;s power, speed, and gravity for even more dramatic destruction Get lost in the colorful physics and the endlessly engaging Crusher Clicker ️ Play on CrazyGamesIn quarries, they transform rock into a finished construction product (gravel, sand, etc) or a raw material for industrial use They are also used to recycle concrete, road surfacing and other materials Technologies The different crushing systems are adapted to the hardness of the material to be handledCrusher, Crushing plant All industrial manufacturers

Energy considerations in compressive and impact crushing of rock

2008年8月1日 The reduction ratio in the preceding crushing circuit is about 40–100, from typically blast rock of maybe 200–500 mm down to the 5 mm particles fed to the grinding mill But in a mine, the cost and energy consumption associated with fine grinding are considerably larger than those associated with the compressive crushing2008年12月1日 The rock blocks extracted by blasting which are larger than the opening of the primary crusher are usually fragmented by hydraulic hammerThe paper presents the results of the testing of impact of Impact of rock hardness on fragmentation by hydraulic 2016年7月14日 HPGRs produce a product with substantially more lines (for a given P80) than a crushing circuit In this regard, the size distribution of an HPGR circuit is much more similar to the product of an SAG circuit than a HPGR 911MetallurgistFind the best crushing equipment for sale at Ritchie Bros today! Browse by category Auctions How it 9 ft x 16 ft Vibratory Grizzly Feeder w/Hydraulic Fold Hopper Wings • Nordberg NP1213M 48 in Impact Crusher • 15 ft x 5 ft Single Deck Screen • 20 in Wide Fines Discharge Conveyor • 46 in x 28 ft Crusher to Screen Conveyor • 46 Used Crushing Equipment For Sale Ritchie Bros Auctioneers

.jpg)

K Series Mobile Crushing Plant Shanghai Zenith Company

Zenith new generation K series portable crushing plants contain 7 series and 72 models products And one series mainframes share one kind of metalframe in the machine farm, so freshinvestors can get machine quickly and reinvestment won’t take too much cost to update the crushing plantcircuits, on both greenfield and retrofit projects, to increase feed rate to the SAG mill In other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment selection, and layoutCrushing Plant Design and Layout Considerations MINE 2023年7月3日 The Stone Crushing Plant, as showcased in the video titled “Stone Crushing Plant Business Plan,” demonstrates the layout of various equipment used in the process of crushing stones The plant boasts a vast scale, complete set of machinery, impressive production output, and is exclusively supplied, designed, and supported by the renowned SBM CompanyStone Crushing Plant Business Plan SBM Mill Crusher2023年2月28日 They play a crucial role in a wide range of applications, from processing minerals and ores to recycling waste materials Crushers are designed to meet specific requirements, and choosing the right type of crusher for your needs is critical to ensure that your operation runs smoothlyA Comprehensive Guide to Understanding the Different Types of

Lab Crushers Laboratory Small Rock Crusher JXSC Machine

JXSC provides types of Lab Crushers for small processing plants and school laboratory research, includes hammer mill, jaw crusher, cone crusher, ball mill, etc Gold Mining Equipment Chat on WhatsAppAN EXPERT IN CRUSHING NONABRASIVE MATERIALS Primary impact crushers are preferred for their high performance and high reduction ratios in crushing softer substances like gypsum and limestone Due to the different principle of crushing these materials, the reduction ratio is higher than in jaw crushers MPI1313 MPI 1515 MPI 1620CRUSHING SCREENINGStone crushing plant is ideal for processing various kinds of stone and rock, and widely appled in quarry, mining, road construction, etc Skip to content Menu Home; Ball Mill Capacity: 065130 T/H Feed Size(mm): ≤25 Output Size(mm): 0074089AIMIX Stone Crushing Plant For Sale 701200t/hDownload scientific diagram Layout of a fourstage crushing plant for ballast production from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregate Layout of a fourstage crushing plant for ballast production

%3C1PGHL[2}HK_]YT.jpg)

A Guide to Mobile Crushing Plants: Types,

2023年2月24日 Mobile crushing plants are commonly used in mining to crush and screen ore for further processing They can also be used for secondary and tertiary crushing to produce the desired particle size Quarrying: Mobile Hydraulic cone crusher is mainly used for the secondstage crushing and thirdstage crushing in metal mines and construction sand and gravel processing Because the hydraulic cone crusher has a strong crushing capacity and large Hydraulic Cone Crusher Stone Crusher Grinding Mill The type of rock you plan to focus on processing in your operation will dictate the types of rock crushers you’ll need to include in your crushing circuit The more you know about the type of rock you wish to crush and what its enduse will Types of Rock Crushers Quarry Crushing Equipment2014年1月1日 Conference: Proceedings of the 23rd International Mining Congress and Exhibition of Turkey IMCET 2013; At: Kemer, Antalya, Turkey, April 1619, 2013, pp 293301Factors affecting the performance of crushing plant operations

Optimization Framework for Crushing Plants Chalmers

Crushed rock materials such as crushed stone, gravel, sand, clay are base materials used in infrastructure development for roads, railways and housing constructions Mineral ores are rock materials which have specific chemical composition containing one Big Foote Portable Rock Crushing, Weare NH 03281 Big Foote Portable Rock Crushing, 174 S Stark Hwy Lot 2, Weare, NH Tel: 6035294079 Get Maps, Driving Directions portable rock crushing nh Mining Quarry Plant2024年3月5日 Seller: Northeast Rock Crushing 2001 KPIJCI K400 Crusher Aggregate Equipment Featured Listing View Details USD $285,000 Apply for Financing Opens in a new tab When the rock hits the plate or anvil, it breaks Crusher Aggregate Equipment For Sale MachineryTrader2023年2月24日 Learn about the factors that affect the setup cost of a stone crusher plant, get an estimate of the cost, and explore ways to reduce the cost Setting up a stone crusher plant can be a daunting task, but understanding the factors involved can help you make an informed decisionStone Crusher Plant Setup Cost: Factors, Estimate, and Ways to

.jpg)

Stone Crushers, Mill and Grinding

China LIMING Heavy Industry Science and Technology Co LTD which mainly manufacture large and mediumsized crushing and grinding equipments was founded in 1987 Mine Crushing Smart Mine Overall Plan READ MORE 03 Industrial Milling LM Vertical Mill LM Vertical Mill integrates crushing, drying, grinding, Crushing Plant Process Optimisation Design of processes in order to find the most efficient solution to a specific task is a difficult problem Often the number of solutions are large and the optimal solution is therefore difficult to identifyx000D Crushing plant process design is no exception from this statement In order to find the best solution issues like equipment selection Crushing Plant Process Optimisation AusIMMDownload scientific diagram Specific energy of crushing of various rock types from publication: Impact of rock hardness on fragmentation by hydraulic hammerand crushing in jaw crusher The Specific energy of crushing of various rock types2023年6月12日 Sandstone: A sedimentary rock consisting of sandsized grains of mineral, rock, or organic material cemented together Dolomite: A sedimentary rock similar to limestone but containing a high percentage of magnesium How To Crush Rocks? Simple Information Sharing

Portable Crushing Plant PK Mining

1 Portable Crushing Plant Primary Unit ( Jaw Crusher Feeder) This unit is used as a primary crushing unit for working singly to provide“allin”material or the first stage of complete portable plant Rock is fed to the crusher by vibrating grizzly Introduce how to crush rock gold ore, whole gold ore processing plant flow layout The crushed gold ore materials are sent to a multicylinder hydraulic cone crusher for fine crushing; The gold powder of 012mm sieved by the vibrating screen is evenly sent to the ball mill for grinding, and sieved by the spiral classifier Ball MillGold Ore Processing Solution Eastman Rock Crusher2023年6月13日 Then goes to the ball mill for grinding into fine powder :01mm; The output from the ball mill goes to hydrocyclone for classifying More than 0074mm (Underflow) back to the ball mill for grinding again The overflow goes to a slurry tank The output goes to the gold concentrator for the first gold separationHard Rock Gold Processing Plant Solutions For Your Choices2020年12月21日 Industrial background crusher (rock stone crushing machine) at open pit mining and processing plant for crushed stone, sand and gravel the Caterpillar CAT 325C hydraulic crawler excavator rocks into the Keestrack mobile crushing and sorting plant in a quarry Ball mill at a Copper Mine in Chile at dawnCrushing Plant royaltyfree images Shutterstock

Batch Small Ball Mill JXSC Machine

A batch ball mill is a machine to grinds the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, and glass ceramics The batch mill is mainly used for the mixing and grinding materials, with uniform product fineness and saving power2024年5月30日 So, let’s embark on this journey to understand rock crushing equipment better Understanding Rock Crushing Equipment Rock crushing equipment is a broad term It refers to any machine that reduces large rocks into smaller pieces These machines work by applying force to break rocks They are essential in industries like mining and construction The Ultimate Guide to Rock Crushers Mellott2023年2月28日 Discover the best practices for designing a successful stone crusher plant, including factors to consider, equipment selection and configuration, environmental management, and safety and maintenance priorities Learn how to optimize crushing operations and minimize environmental impact for efficient and effective productionStone Crusher Plant Design: Best Practices for Efficient Crushing 2023年3月2日 Such equipment moves with wheels or caterpillar tracks to a convenient position The same principles used in crushing and screening are now also applied to shredding, washing, and recycling machines that shred and sort waste for recycling A mobile crushing plant uses either an electromechanical or a hydraulic drive for the main crushing mechanismProductivity in Crushing Screening: Hydraulic Control and