Raw coal screening

凉水井煤矿选煤厂原煤分级筛改造研究 道客巴巴

2022年1月24日 The application results show that the screening efficiency of raw coal has been significantly improved after the transformation, while ensuring the screening accuracy of lump coal, thus the workload on the slime water system is reduced and the processing capacity of 2018年6月20日 We propose a novel variableamplitude equalthickness elastic screen (VAETES) to solve the problem of material accumulation and screen aperture blockage during Impact of screening coals on screen surface and multiindex 2018年6月20日 With the increase in coal production, vibrating screen with large processing capacity, high reliability, and excellent screening effect is essentially required In this study, Impact of screening coals on screen surface and multiindex 2023年4月1日 The characteristics of coal include nonstick and longflame type with low ash, ultralow phosphorus, and low sulfur content The raw coal was sieved into four different Evaluation of coal screening performance by spatial image

Impact of screening coals on screen surface and multiindex

2018年3月1日 Dry deep screening plays an important role in the cleaner production of steam coal, increasing the sorting proportion of steam coal and realizing the reduction of the 2022年5月27日 In this research, we skilfully transform the tough problem of image detection for particle size distribution into the calculation of the fractal dimension of the coaledge image, and closely associate the fractal dimension An Online Detection Method for Coal Dry Screening 2019年9月29日 This new screening machine provides maximum screening efficiency of 8736%, 8052%, and 6642% for screening coal feed of 6 + 4 mm, −4 + 2 mm, and −2 + 05 mm size Screening performance of coal of different size fractions with The efficiency of the raw coal sizing screen in the raw coal pretreatment working of Tashan mine coal washery is affected due to accumulation of material on screen plate Therefore, work is 基于筛孔形状的原煤分级筛筛板改造与应用【维普

.jpg)

Study on impact mechanical characteristics and screening

2024年1月30日 Screening, as a key link in the efficient and clean utilization of coal resources, undertakes the functions of raw coal classification, inspection screening, preliminary desliming, In the early days of coal mining in South Africa, coal was selectively mined to satisfy the requirements of local industries mainly the gold and diamond mines and the transport industry The requirement was for coarse coal and it was Processing lowgrade coal to produce highgrade 2021年9月7日 Wet processing of raw coal Due to the high demand, AO “Stroyservis” has increased its capacities from 3 million tons of material to 55 million tons in the last few yearsHowever, in order to continue to achieve excellent screening results with a simultaneous increase in plant throughput, the operator decided to replace the previously installed Russian raw coal producer relies on Austrian screening technology2016年10月22日 This article presents a method and a mechanized crushing and screening plant designed to sort loading of raw coal into gondola cars, in which the ROM is separated by size, thus allowing for a mechanical waling of rock and separate loading of coal, first small and then large grades to prevent floating the coal away from gondola cars during movement, and MECHANIZED CRUSHING SCREENING PLANT SpringerLink

Fine coal screening performance enhancement

2003年3月1日 An excellent overall screening efficiency of 98% is obtained from the Pansep screen in comparison to the 44% obtained from the sieve bend and 57% from the raw coal classifying cyclone operating in Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce highquality coal for energy in both local and export markets Multotec manufactures a complete range of equipment for coal processing plants, from the Run of Mine (ROM) stockpile to the tailings Coal Processing Multotecscreen on raw coal screening, desliming before lump and slack coal separation, dehydration and sculping of slack coal are comprehensively introducedThe undersize fraction and the oversize fraction are simultaneously decreased because of the application of flip flow screen on raw coal screeningDue toApplication of flip flow screen in Sihe Coal Preparation PlantCoal stockpile Coal stacker Coal reclaimer Coal needs to be stored at various stages of the preparation process, and conveyed around the CPP facilities Coal handling is part of the larger field of bulk material handling, and is a complex and vital part of the CPP Stockpiles provide surge capacity to various parts of the CPP ROM coal is delivered with large variations in Coal preparation plant Wikipedia

Impact of screening coals on screen surface and multiindex

2018年6月20日 Coal is one of the most important fossil fuels, and accounts for 30% of the global primary energy resources (Kopacz et al, 2017)In 2016, China produced 341 billion tons of raw coal, and it provided 624% of total energy consumption (Liu et al, 2016)Coal beneficiation is the most effective method for obtaining cleaner coal with reduced ash content (Song et al, 2015)2018年3月1日 However, due to water spraying for dust control and coal seam seepage during the mining process, the raw moisture content of the mined coal is high, which has a serious impact on the depth Impact of screening coals on screen surface and multiindex 2024年4月15日 This paper presents the investigation of the dynamic mechanical properties of coal rock under complex stress conditions at depth, based on the improved Separate Hopkinson Pressure Bar Test SystemDynamic mechanical response and crack evolution law of raw coal 2016年10月22日 Flip flow screen, which is in the forefront of the domestic counterparts, has been comprehensive application in Sihe Coal Preparation Plant The application practice and effect of flip flow screen on raw coal screening, desliming before lump and slack coal separation, dehydration and sculping of slack coal are comprehensively introducedApplication of flip flow screen in Sihe Coal Preparation Plant

Coal mining Coal preparation Britannica

2024年10月11日 ROM coal is crushed to below a maximum size; undesirable constituents such as tramp iron, timber, and perhaps strong rocks are removed; the product is commonly called raw coal Level 2: The product from level 1 is Coal roller screen is a kind of equipment specially used for raw coal screening, which has the advantages of large processing capacity, no vibration, low maintenance cost and low operating cost 1 Problems Exist Coal is crushed to Upgrading Process And Result Of Coal Roller Screen As coal waste becomes increasingly more useful and fine coal recovery techniques develop, the market for coal waste continues to grow Coarse and fine material screening equipment allows the reuse of products in a variety of Material Screening Sizing Mobile Preparation Plants coal and, since the moisture content of the fine coal is relatively low, low final product moisture levels can be maintained Dry screening of fine coal at small screen sizes, 3 mm for example, is unfortunately not easy The problem experienced with dryscreening in practice is that the raw coal received from miningDRY SCREENING TESTS CONDUCTED WITH A BIVITEC SCREEN

.jpg)

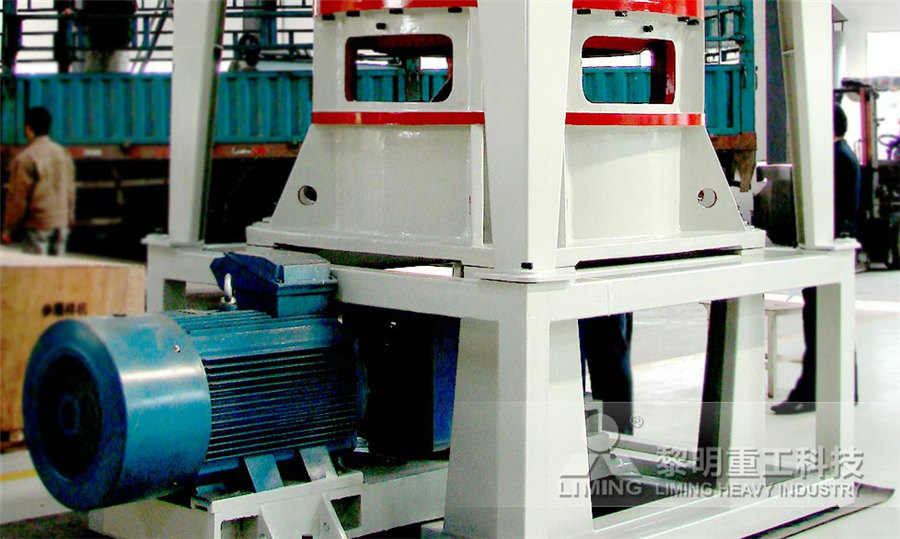

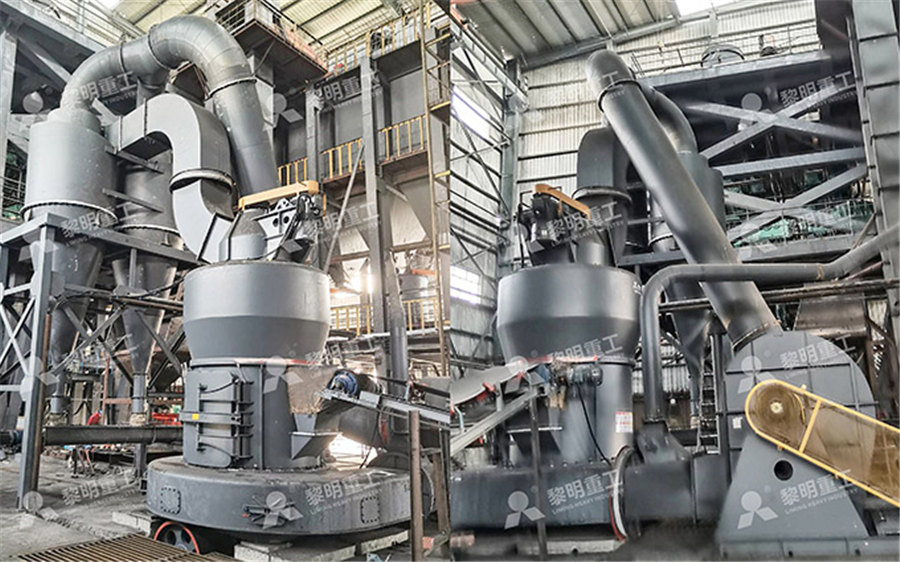

How to Process Coal into Pulverized Coal in 5 Steps?

2024年1月11日 With a vertical roller mill (VRM) VRMs consist of a rotating table or bowl and rollers 1 To grind the coal, feed raw or initially crushed coal into the mill which is then ground between the rotating components; 2 Finally, hot air removes moisture, carries the pulverized coal out, and a classifier segregates the particles; Here is all you need to know about the VRM:2023年10月31日 Coal is one of the important energy sources; however, the direct combustion of raw coals is discouraged due to their low calorific value and the production of harmful gasesCoal biotransformations under aerobic conditions: screening and 2023年10月8日 Each coal crusher can be combined with the screening equipment (such as vibrating screen) and loaded on the mobile crusher to form an efficient coal crushing and screening production line Capacity: 1700 t/h Feed size: ≤1,000 mm Output size: 2180 mm Advantages: Shorter installation time, lower transportation costs, environmentally friendly6 Types of Coal Crusher: Which Is Best for Crushing My Coal?McLanahan offers a variety of screening solutions to separate coal into products according to their size The screens employ tumbling or vibrating actions to size and separate the coal The larger coal particles remain on the screen for further processing, while the smaller coal particle fall through the openings in the screen mediaCoal McLanahan

.jpg)

Preparation and Transportation of Coal EOLSS

major coal cleaning devices are shown in Figure 1 Typical efficient separating gravity ranges are given in Figure 2 For below about 05 mm raw coal fines, the difference of surface property is utilized since conventional gravity dependent processes are inefficient for this size range Coal preparation plants are designed to suit theirFullwash thermal coal preparation plant (CPP) circuits in which typical +1 mm raw coal is processed in heavy media vessel (HMV) and/or cyclone (HMC), and 1 mm × 015 mm raw coal is processed in Dry screening versus Wet screening PSD comparisonCrushing Screening: Raw coal is transported to crushing workshop by belt conveyor First, it is pre screened by a circular vibrating screen with a sieve opening of 50 mm +50mm materials and extra large gangue enter the crusher and are crushed to – 50mm,Coal Preparation Plant Coal Preparation Process Coal WashingIn the initial preparation phase of coal cleaning, the raw coal is unloaded, stored, conveyed, crushed, and classified by screening into coarse and fine coal fractions The size fractions are then conveyed to their respective cleaning processes Fine coal processing and coarse coal processing use similar operations and equipment to1110 Coal Cleaning US EPA

Ore, Rock Aggregate Screening (Complete Guide)

2016年6月20日 Effective screening area Effective screening area is the area where material can drop down through the surface Effective surface area is about 0709 times the whole area The whole area is determined by the Coal Crushing and Screening Conveyor to Crushing Unit: Raw coal is fed into crushers to reduce its size Belt conveyors transport the crushed coal to the sizing equipment Belt Conveyor to Screens: After crushing, the coal may be sent to vibrating screens for further sizing Belt conveyors move the sized coal to the next stage of processingCoal Conveyor Belt Conveyor for Coal Preparation SKE Industries2019年4月1日 For the clean and efficient utilization of coal, coal preparation is an important measure to solve the problem of air pollutant emissions, solid waste generation and save coal resources in the world [1, 2]Screening is the basic process for cleaning and efficient utilization of coal, and is mainly realized via vibrating screen [3]A conventional largescale coal preparation A review on the advanced design techniques and methods of vibrating According to the annual census of coal preparation plants conducted by Coal Age [], the USA operates 286 coal preparation plants in 12 statesThis number is relatively small by comparison to the worldwide fleet which is estimated to be 2,283 plants []The capacity of the plants can range from less than 200 t/h for small operations to 6,000 t/h or more for large industrial plantsCoal Preparation SpringerLink

Mineral Screening: The Complete Guide Mining Pedia

2022年12月28日 Screening refers to the process of breaking up the material into different size pairs through one or several layers of screen surface In the screening process, the sieved raw material continuously into the screening machinery, then, less than the size of the screen hole material will be through the screen hole, this part of the material is the product of the screen; 2023年5月19日 2 used for ultrafine grinding of coal with a top size of 1 mm to produce a coal product with 95% passing 75 microns (200 mesh) Coarse and mediumduty breakers and crushers are used for primary size reduction purposes, ie for size reduction of runofmine or "raw" coal Medium and lightduty crushers are used for secondary size reduction with the Coal Preparation: Size Reduction and Screening for Efficient%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources352 Coal Screening '8 3521 Conventional Screens 3522 Heated Deck Screens 3523 Rod Deck Screens 3524 Probability Screens and that the Power Plant should be designed to burn blended raw coal It was therefore proposed that quality control should be achieved by means of mine planning and operational control, Materials Handlinq, Screening Crushing Scheme Gov

.jpg)

A novel vibration isolator for vibrating screen based on

2021年10月2日 A vibrating screen is widely used in raw coal screening, but intensive resonance in the startup and shutdown stages shortens the service life of the vibrating screen and generates vibration damage to surrounding buildings Therefore, we designed a novel vibration isolator based on a magnetorheological damper, aiming to improve the vibration isolation performance The quality of coal below 3 mm can be improved by decreasing the coal’s particle size, which reduces the ash percentage of coal Screening is one of the significant beneficiation techniques used Particle size composition of coal sample片語 raw coal reserve 原煤儲備 raw w coal 原煤 raw coal consumption detail 實物煤耗 rawcoal buffer silo原煤緩沖倉 raw coal screening 原煤篩選 raw material coal煤原料 comprehensive raw coal field 原煤綜合料場 run of mine coal [礦物] 原煤 raw coal size 原料煤粒度raw coal中文,raw coal的意思,raw coal翻譯及用法 英漢詞典Selective Crusher The equipment for raw coal roughing integrates breaking, screening and dressing, smashes large coal blocks through strength difference of gangue and coal, and separates coal and gangue through barrel wall gap, and is widely used for top crushing of large and medium coal preparation plantsSelective Crusher, Crusher, raw coal

.jpg)

Kinematics of a novel screen surface and parameter optimization for

2020年3月15日 This study provided technical support for the largescale, clean, and efficient utilization of steam coal and proposed a novel, efficient process for the separation of steam coal The −3 mm dry screening of raw coal and + 3 mm coal separated by a dense medium separator will become the new trend for the separation of steam coalCoal Screening Crushing Raw Coal Crushing Processing Coal is known as the black gold and the food of the industry, it is one of the main energy sources used by the human world since the eighteenth century + View Details Wet Sticky Coal ScreeningCoal Screening and Crushing plantCoal Sizer is a professional coal crushing equipment, mainly used for crushing raw coal, coal gangue, coal coke and other materials According to the crushing degree, coal sizers can be divided into onestage crusher and twostage crusher Our coal sizers has the characteristics of wear resistance, impact resistance, stable operation, convenient maintenance and so onCoal Sizers, Coal sizers Crusher, Coal Mineral Sizers —Henan 2018年11月20日 The declining quality of raw coal makes the control of coal product increasingly difficult and the beneficiation of raw coal more important, Council for Scientific and Industrial Research (CSIR Beneficiation of raw coal increasingly important – De Korte

.jpg)

Definition of raw coal mindat

Coal which has received no preparation other than possibly screening Synonym of: raw ore Click here to see list of references, authorities, sources and geographical terms as used in this glossary2022年10月10日 Crushing large raw coal: 2: Electronic scale – Weighing the raw coal: 3: Sample preparation commuter: HY 98: Pulverize fine coal: 4: Standard sieve: 01 mm: Raw coal screening: 5: Sulfur analyzer: SDS 516: Determination of total sulfur in coal samples: 6: Industrial analyzer: SDLA 618: Industrial analysis of coal samples: 7: Hightemperature Desulfurization mechanism of highsulfur coal by heating reduced