Investment requirements for lignite high calcium powder production line

.jpg)

Full Length ArticleTechnoeconomic implications of flexible

2020年11月15日 The coal and lignite supercritical power plants equipped with calcium looping system for plant decarbonization were evaluated in two operational scenarios The first operational scenario corresponds to base load conditions in which the power output is IFS has been developed for potential investors, partners and/or financial institutions that are willing to invest in a project for the production of calcium carbonate (very high purity), the INITIAL FEASIBILITY STUDY CORRECTEDA calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications Both dry grinding and wet grinding are Customize Suitable Calcium Carbonate Plant DASWELL2023年8月13日 Using lignite mines as a case study and a properly modified analyticalhierarchyprocessbased roadmapping methodological framework, the current study attempted to Fair Development Transition of Lignite Areas: Key Challenges and

Rugao calcium powder production line建冶重工机械官网

The project aims to process raw materials into 200 mesh calcium powder that meets the market demand through advanced production technology and equipment, providing stable and 2016年9月23日 This study highlighted a number of critical factors of lignite briquette production, ie, reduction of electricity consumption and transportation distances, optimization of lignite Future of lignite resources: a life cycle analysisThe lignite power industry produces low cost electricity but the associated pollutant emissions are higher than from other fossil fuels Tighter environmental legislation requires older facilities to Retrofitting lignite plants to improve efficiency and performance2021年11月19日 Analysing the results obtained, several key (hot spot) elements of the lignite mining operations were distinguished for modelling the environmental impact, ie: calorific Life cycle assessment of opencast lignite mining

.jpg)

Evaluating the enhanced flexibility of lignitefired power plants: A

2018年12月1日 Subsidies are still crucial for a profitable operation of lignite plants in Germany In this paper the authors develop a decision tool that is based on real options analysis and that In practice, lignite's calorific value is about 10 MJ/kg, depending on the EU Member State and the individual mine concerned, which is well below the maximum official gross calorific value (20 Production of lignite in the EU statistics Statistics ExplainedFujian Longyi Powder Equipment Manufacturing Co,Ltd is a national hightech enterprise specializing in researching, developing, manufacturing and marketing powder equipment manufacturing production lines, providing complete engineering services including drying, crushing, conveying, grinding, classifying, shaping, modifying and design, manufacturing, Powder Equipment Manufacturing Production Lines LongyiFrom highly specialized calcium hydroxide production line made to order with your exact powder needs To serve any market we offer calcium hydroxide plant with customized service, EPC service to satisfy your requirement, get Best Calcium Hydroxide Production Line

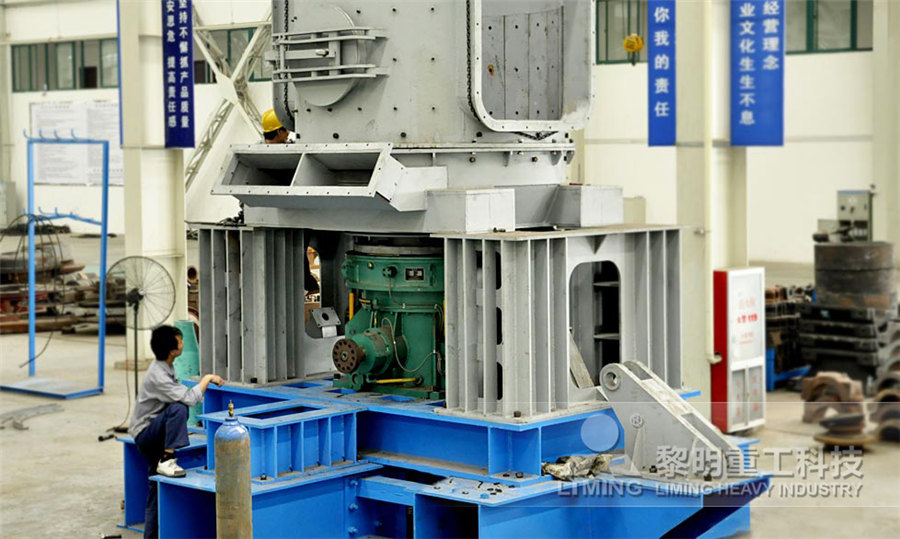

HQ large calcium hydroxide production line

HQ largescale calcium hydroxide production line is a highefficiency calcium hydroxide digester configured by Guilin Hongcheng, and a special machine for HC calcium hydroxide powder making Realize the intelligent water distribution 2016年11月16日 PDF This work explored the use of ashes of a lowsulfur, highalkali lignite coal for partially capturing the sulfur dioxide emissions from combustion Find, read and cite all the research (PDF) Utilization of a HighAlkali Lignite Coal Ash forCalcium carbonate ultrafine vertical mill, mainly used for the production of calcium carbonate powder Calcium carbonate powder can be widely used in cables, papermaking, toothpaste, cosmetics, glass, medicine, paint, ink and many other Calcium Carbonate Ultrafine Vertical Mill SBM Ultrafine Powder 2021年6月22日 The calcium carbonate production line with an annual output of 300,000 tons uses a vertical grinding mill production line to crush, grind, and classify calcium carbonatecontaining minerals such as limestone, marble, chalk, icelandite, stalactite, aragonite, vaterite, and semihydrated calcium carbonate A summary of the production line equipment for a 300,000 tons of calcium carbonate powder production line

China Calcium Chloride Production Line Wholesale Suppliers

1CaCl2 Process feature: Calcium chloride main processes of this production line include calcium liquid production and drying granulation; The purity of produced anhydrous calcium chloride can reach above 95%; the tail gas of production process can reach to emission standard after desulfuration and washingSOLUTION2: Lime Production Line With Vertical Kiln The vertical lime kiln is suitable for smallcapacity active lime production lines, lowcost, safe and environmentally friendly The vertical lime kiln uses the principle that the material’s own weight descends and the hot gas rises for heat exchange to burn lime We supply twin shaft lime kiln, double beam lime kiln, annular lime kiln Lime Production Line Active Lime Production Line Cement PlantFrom the total investment cost, the highest share (Birr 3933 million or 6519%) is accounted by fixed investment cost followed by initial working capital ( Birr 1566 million or 2596%) and pre operation cost (Birr 534 million or 885%) From the total investment cost Birr 1935 million or 3207% is required in foreign currencyPROFILE ON THE PRODUCTION OF CALCIUM CARBONATE AND 2005年7月1日 A new type of process for producing highpurity calcium carbonate from waste cement powder was developed The process consists of two main reactions; extraction of calcium in the form of calcium Development of a process for producing high‐purity calcium carbonate

.jpg)

Methanol Production from Solid Recovered Fuel and

2022年9月1日 The main purpose of this work is to examine the technoeconomics and environmental assessment of the Solid Recovered Fuel and Lignite to methanol pathwayEmerging Investment Opportunities in Hydrated Lime (Calcium hydroxide) Production from Limestone (Calcium Carbonate) Most Demanding Profitable Business Idea of Chemical Industry Hydrated Lime (Calcium hydroxide) is an Emerging Investment Opportunities in Hydrated Lime 2023年3月21日 Production project of 6 tons of heavy calcium powder per hour in Myanmar Production fineness: D97 10um (1250 mesh) Yield: Highend calcium carbonate production line with an annual output of 150,000 tons in Pakistan Phone: Detailed Requirements: Send Now Recommended products HGM superfine powder mill Fineness: 1502500meshThe advantages of ultrafine vertical mill in the processing and 2022年9月13日 The calcium treatments were lime application (A0) at 500 kg ha⁻¹ and four rates of eggshell powder application including A1 (200 kg ha⁻¹), A2 (300 kg ha⁻¹), A3 (400 kg ha⁻¹), and A4 (PDF) Eggshell powder as calcium source on growth and yield of

Utilization of a HighAlkali Lignite Coal Ash for Capture in Power

The research reported herein is concerned with the utilization of CFA as a potential sorbent for air pollutants from coalfired power plants Coal fly ash can serve as an inexpensive absorbent2020年1月1日 Till now, the RDF technology has been used for lignite upgrading and tar production, such as the 300 000 t/a Lignite Pyrolysis Industrial Production Process of Datang Huayin [79], the 1500 000 t/a Lignite Pyrolysis Project of Shenhua in Hulun Buir, and the 2 × 8500 000 t/a Lignite Pyrolysis Project of Shenyang Jinshan Energy Co,Bluecoke production technology and the current stateoftheart PDF On Sep 18, 2024, Alina Maciejewska and others published Lignite – a natural source of organic matter and its impact on soil health Find, read and cite all the research you need on (PDF) Lignite – a natural source of organic matter and its impact Gypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery

.jpg)

Inclusion variations and calcium treatment optimization in

2011年10月4日 SiCa line and SiCaBaFe alloy were injected into liquid pipeline steel at the end of LF refining as calcium treatment, and samples were taken from the ladles, mould, and slabs Analysis of Ca content and inclusions shows that Ca content in steel decreases obviously in the following process after calcium treatment; the compositions, morphology, and sizes of 2022年12月1日 Unit 4 /5 Tamric Park, 9 Calcutta Street, Paarden Eiland, Cape Town 7415Study of Investment Casting Process For 3D Printed Jewellery as high energy consumption and environmental pollution, slowed down its development Calcium acetylide production via ETMP is characterized by high energy consumption (ca 3500 kWh per t of calcium acetylide) required to reach the extreme reaction conditions required (Fortischem, 2014b) The process of acetylene production from calciumSimulation of calcium acetylide and acetylene production SciendoThe heavy calcium produced by the ball mill production line can be used in papermaking, plastics, rubber, ink, chemical building materials, sealing materials, daily chemicals, etc Calcium carbonate powder mainly plays the role of filling, Calcium Carbonate Ball Mill Plant DASWELL

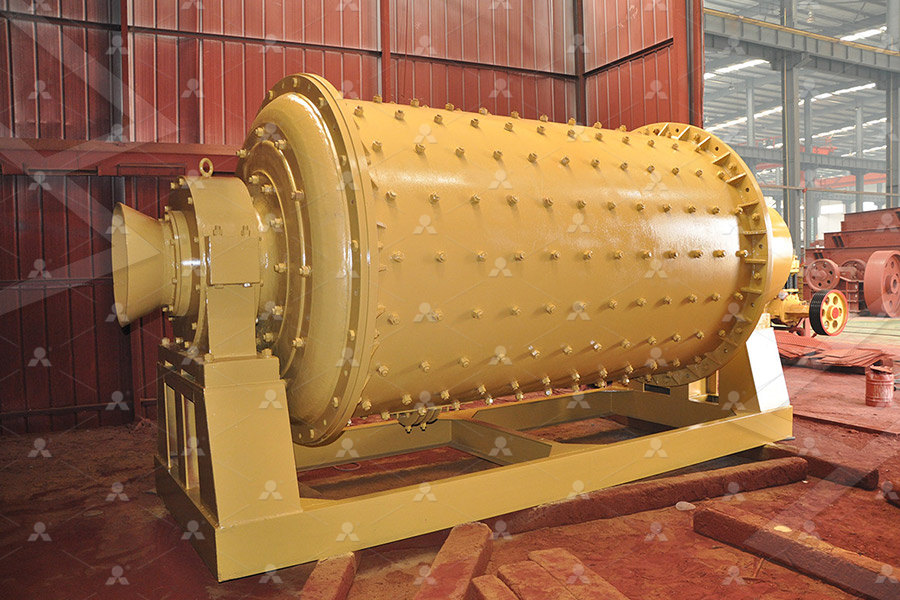

.jpg)

Calcium: Benefits, Requirements, and Supplements

2023年11月3日 Calcium is important for bone health and other body functions Learn how much you need, what foods contain the most calcium, and the pros and cons of supplements2Product features: medium and lowend products, suitable for the production of coarse powder; 3Energy saving; 4High yield Micro powder roller mill 545 1Applicable materials: medium and low hardness; 2Product features: midend product, suitable for the production of fine powder; 3Low energy consumption; 4Long service life Ball mill 522How to Choose a Calcium Carbonate Grinding Mill DASWELLIt is intended to prepare a Feasibility Report to install 600 MT/Year DiCalcium Phosphate (Powder) production facilities as a Brown Field Project 2 Uses /Applications • Dicalcium phosphate is mainly used as a dietary supplement in prepared breakfast cereals, dog treats, enriched flour and noodle productsDetailed Project Report on DiCalcium Phosphate (Powder)2020年3月7日 From the table above, if you have higher requirements for output, you can choose a ball mill or a vertical roller mill If the material humidity is low and the budget is not high, Raymond mill will be a good option The complete limestone powder production line Successful cases: 1 316tph limestone powder in Pakistan Material: limestoneLimestone Powder: Uses, Price and Production HongXing

.jpg)

Evaluation of Lignite Fly Ash for Utilization as Component in

2013年7月4日 Experimental program implied production of two refractory composites: “referent” concrete from 20 % of highaluminate cement and 80 % of corundum aggregate, “recycled” concrete from 10 % 2021年2月1日 Lignite is an important kind of coal resource which is widely distributed over the world Compared to other coals, lignite contains a high concentration of carboxyl groups [23]It was beneficial to load calcium cations or other metal cations which have high catalytic activity on the surface of ligniteThe evolution of catalytically active calcium catalyst during steam 2020年9月15日 Keywords:China Gypsum Powder Production Line, gypsum grinding mill, Gypsum Powder Machine Video of HLM Vertical Roller Mill Max feeding size: 50mm Capacity: 5700t/h Fineness: 200325 mesh (75 Gypsum Powder Production Line in High Productivity(ie 95% to 98%) of calcium carbonate The production of high quality and pure calcium carbonate is not highly developed in Croatia There is not much competition in the production of calcium carbonate, especially if we are talking about calcium carbonate with a very high purity > 98,9% Given the fact that it is a production of highqualityINITIAL FEASIBILITY STUDY CORRECTED

Production of High H2/CO Syngas by Steam Gasification of

2015年7月9日 The high steam gasification rate of Shengli lignite was achieved at a lower temperature range of 616750 °C compared to the demineralized lignite SLHCl and SLHF, indicating that the inherent GDFCL range of high performance Lignite Dispersants include Finely Ground Oxidized Leonardite, Cauticized lignite,chrome lignite, potassium lignite , Causticized Potassium Lignite for water Base Mud Systems and a range of High performance Organophilic Lignite for Oil Base Mud Systems and Polymerized Lignites which can be customized and manufactured according to Modified Lignite Drilling Lignite Leonardite Powder Oxidized LignitePRECIPITATED CALCIUM CARBONATE [CODE NO4246] Precipitated calcium carbonate (PCC) is an innovative product derived from lime, which has many industrial applications PCC is made by hydrating highcalcium quicklime and then reacting the resulting slurry, or “milkoflime”, with carbon dioxideDetailed Project Report on precipitated calcium carbonateCalcium carbonate is a chemical compound with the formula CaCO3 It is a common substance found in rocks as the minerals calcite and aragonite (most notably as limestone, which is a type of sedimentary rock consisting mainly of calcite) and is the main component of pearls and the shells of marine organisms, snails, and eggsCalcium carbonate, Micro powder production line material

制粉-10.25公众号.jpg)

Briquetting optimization method for the lignite powder using

2020年5月1日 Because young lignite is a type of coal with high plasticity and low elasticity and they are rich in highly plastic asphaltenes and humic acids Therefore, its moldability is good However, aged brown coal has a relatively high degree of coalification and the “selfbinder” substance cannot meet the molding requirements2017年9月1日 The high steam gasification rate of Shengli lignite was achieved at a lower temperature range of 616750 °C compared to the demineralized lignite SLHCl and SLHF, indicating that the inherent Direct production of high hydrogen syngas by steam gasification Quick Facts: Lignite is abundant and accessible Lignitegenerated electricity is reliable Lignitegenerated electricity is environmentally compatible Lignitegenerated electricity is lowcost Lignite is used in an environmentallyresponsible manner by power plants Lignite is a dark brown to black combustible mineral formed over millions of years by the partial decomposition of plant What is Lignite? Lignite Energy CouncilThe manufacture of hydrated lime starts by calcining high quality limestone (Calcium Carbonate) at elevated temperatures to supply quicklime (Calcium oxide) a volatile powder Hydrated lime successively is created by reacting Quicklime with a controlled amount Emerging Investment Opportunities in Hydrated Lime (Calcium

.jpg)

(PDF) INVESTMENT MATERIALS: A REVIEW ResearchGate

PDF On Feb 27, 2021, Prakhar Khurana and others published INVESTMENT MATERIALS: A REVIEW Find, read and cite all the research you need on ResearchGate2021年11月24日 The use of biomass to partially replace fossil fuels to produce syngas is an effective way to reduce net CO2 emissions The chemical looping cogasification of wheat straw and lignite with iron Chemical looping cogasification of wheat straw and lignite