Silver crushing machine working principle

.jpg)

Working Principle of Crushers 911Metallurgist

2016年2月18日 There are two main types of primary crushersgyratory crushers and jaw crushers Gyratory crushers are the most common for new operations Secondary crushers 2022年1月14日 Commonly used crushers include jaw crusher, impact crusher, hammer crusher, cone crusher, etc This article will introduce the working principles of these four types of crushing machines one by one to help you Working Principle of 4 Commonly Used CrushersOperating Principal • In a cone crusher the stones are crushed with both SPB and IPB as the material moves down through the chamber • The relative amounts of IPB and SPB depends Crushing Principles of Mechanical Crushing 911 MetallurgistThere are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ a combination of all these crushing methods Impact refers to Construction, Working and Maintenance of Crushers for Crushing

.jpg)

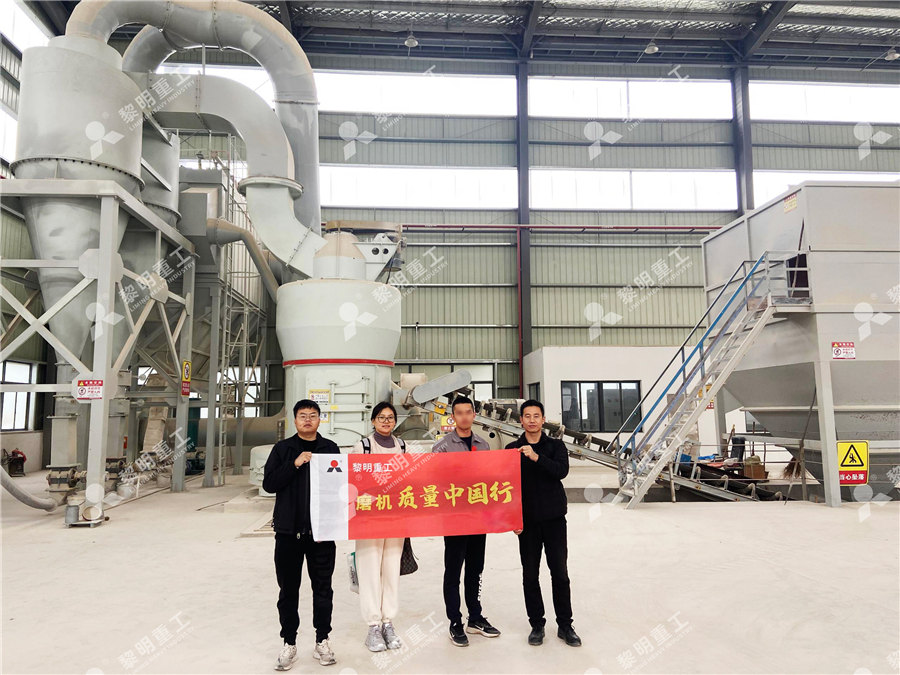

Grinding Mills — Types, Working Principle Applications

2018年8月17日 There are two end results that one is trying to achieve — either to get a crushed product that can be directly used for industrial application or to recover a metal from a complex ore Before we2024年1月1日 According to the structure and working principle, the commonly used crushing equipment can be divided into jaw crushers, gyratory crushers, cone crushers, roller crushers, Crushing Equipment SpringerLink2007年1月1日 Crushing is a size reduction process for particles of brittle materials It is characterized by particle diameters, volumetric equivalent diameters and by force releases on Chapter 4 The Principles of SingleParticle Crushing2016年1月1日 Roll crushers consist of two or more adjacent rolls placed parallel to each other and rotated in opposite directions Single roll crushers are also available which rotate a single Roll Crushers ScienceDirect

.jpg)

Industrial Solutions Jaw crushers ThyssenKrupp

thyssenkrupp jaw crushers are mainly designed to crush mediumhard to very hard materials When it comes to the crunch, crushing systems from thyssenkrupp Industrial Solutions offer 2023年6月29日 Pneumatic flotation machines, also known as column flotation machines, consist of a tall column filled with slurry and air bubbles The key advantage of pneumatic flotation machines is their ability to generate smaller Comprehensive Guide to Flotation Machines: 2020年7月24日 Also, when you want to select the adequate crusher machine for your needs, crushing machine online sale is made available for you And below are the ways to select the best crusher machine for your needs online Types And Working Principle Of Crushing Machine2023年2月23日 ¿Qué es una trituradora de impacto? Trituradoras de impacto, también conocidas como impactadoras o trituradoras de impacto de eje horizontal, son máquinas trituradoras que utilizan el principio de trituración por impacto para triturar materialesSe utilizan comúnmente en las industrias de minería, construcción y reciclaje para producir agregados Comprensión del principio de funcionamiento de la trituradora de

Working Mechanism of Stone Crusher Machines AGICO

2023年2月22日 Stone crusher machines are widely used in various industries for breaking down and crushing large rocks into smaller pieces However, understanding the working mechanism of these machines is critical to ensure safe and efficient operation In this comprehensive guide, we will explore the crushing process, power and performance, components and structure, safety 2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to improve the production capacity of the mill, cast iron balls were used as the medium, so normal gravel mills were evolved into ball mills and rod millsGrinding Machines: Types and Selection Principles Miningpedia2023年3月11日 In conclusion, while the basic working principle of an impact crusher is simple, its impact force can be quite significant This burst of energy is responsible for breaking materials into smaller pieces, making it an effective crushing machine However, limitations do exist, and it’s crucial to select the right machine for the specific How Impact Crushers Work: A Comprehensive Guide2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of the comminution The Complete Guide to Primary Crushing, Secondary Crushing,

.jpg)

Working Principle of 4 Commonly Used Crushers miningpedia

2022年1月14日 Jaw crushers are widely used in mining, smelting, building materials industry, highways, railways, water conservancy and chemical industries and many other sectors, crushing various materials with compressive strength within 320 MPa Working Principle Jaw crusher mainly consists of a frame, an eccentric shaft, a large pulley, a flywheel, a movable jaw, a side Working Principle of Gravity Separator The basic principle of a gravity separator is to use gravity and material density differences for separation When materials enter the separator, they are processed by forces such as vibration, airflow, or fluid flow, causing particles of different densities to layer accordinglygravity separator machine working principle advantages5 天之前 In this article, we’ll detail the advantages and disadvantages of 8 kinds of screening machines, and tell you how to choose the right screening machine for your processing operation This article explains the characteristics of 8 kinds of commonly used screening machines and the screening equipment suitable for different processing stages in the sand and gravel production Screening Machines Comparison JXSC Machinery2022年12月8日 Hydraulic Press Working Principle We manufacture the Hydraulic Press Working Principle to bend sheet metal edges Hydraulic Press Machines are used in metalworking industries The working principle of a hydraulic press is based on Pascal’s law, which states that when pressure is applied to a fluid in an enclosed system, the pressure is transmitted equally Hydraulic Press Working Principle Hydraulic Press Machine

marble processing machines working principle

Working Principle Of Marble Granite Crushing Machine gold, silver, copper or other mines, mining and other rights and using the latest improved machinery to the value of many thousands of dollars principle of dual wheel marble machine stone broken machine Working Principle: This kind stone crusher has two series: 3 Crushing Principle They are typically separated into three forces: impact, shear, and compression When analyzing a crushing machine, it is vital to know what types of breakage that are occurring in the machine In order to examine a crushing machine's characteristics, input, output, and performance,Influence of Crusher Machinery It’s Working Principle2019年8月14日 Working principle of ball mill When its own gravity is greater than the centrifugal force, it falls or rolls down from the inner wall of the cylinder, crushing the ore Beneficiation of Goldsilver Polymetallic Ore (09:04:47) 4 Siderite Ore Extraction Method (12:03:04)The Ultimate Guide to Ball Mills Miningpedia2023年2月20日 2 After crushing the plastic into flakes, it could be cleaned and then sold , or made granules with a higher price 3 The crusher machine can also be used with other equipment then form recycling line 4 Automatic feeding, convenient and manual power saving 5 The crusher machine is compact size,easy to crush and space saving 6 Stable Plastic Crusher Working Principle and Applications

Construction, Working and Maintenance of Crushers for Crushing

6 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials practicalmaintenance shown in above figure, a closed circuit crushing system is a means of controlling product top size by screening the product and then returning oversize material to the feed end of the crusher for another pass through the machine2023年12月11日 2 After crushing the plastic into flakes, it could be cleaned and then sold , or made granules with a higher price 3 The crusher machine can also be used with other equipment then form recycling line 4 Automatic feeding, convenient and manual power saving 5 The crusher machine is compact size,easy to crush and space saving 6 Stable Plastic Crusher Working Principle and Applications2024年9月4日 They play an irreplaceable role in the fine crushing of various ores and are currently the most effective, practical, and reliable stone crushing machines available This article will provide an indepth look into the applications, working principles, and outstanding features of VSI Crushers Vertical Shaft Impact Crushers ApplicationsVertical Shaft Impact Crushers:A Comprehensive Guide2022年7月4日 Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutterThe metal removal rate is higher very high as the cutter has a high speed and many cutting edges It is the most important machine in the tool room as nearly all the operations can be performed on Milling Machine: Definition, Parts, Operation, Working Principle

Jaw Crusher Working Principle StudiousGuy

Working Principle of a Jaw Crusher A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher The repeated movement of the jaws results in the development of compression force that further causes the breakdown of the rock or the ore placed between the two jaws into smaller piecesThe machine consumes less energy and hence reduces the cost of your electricity bill You can minimise Environmental pollution by using our Plastic bottle crusher Types of Plastic Crusher machines: Plastic bottle machines Plastic Crusher Machine Working Principle and It's 2021年12月22日 The invention of the hammer crusher greatly simplified material crushing We can increase our understanding and use of the hammer crusher by describing its working principles and characteristics This will help to improve BTMAThe working principle for a hammer crusherAccording to the working principle, crushing machines are divided into the following types: cone crusher; jaw crusher; impact crusher; These are the most basic distinctions There may also be subtypes of these machines For Types Of Crusher Working Principles of Crushers

.jpg)

A Guide to Types of Jaw Crushers for Crushing Rocks and Minerals

2023年2月15日 Discover the most common types of jaw crushers used in the stone crushing industry, including single toggle, double toggle, Blake, and Dodge jaw crushers Learn about their construction, working principles, advantages, and disadvantages to help you choose the right one for your mining or aggregate operations2023年8月15日 In conclusion, the working principle of a grinding machine involves rotating the grinding wheel at high speed, which causes the material to be cut or removed from the workpiece This process is achieved by the abrasive particles present in working and principle of grinding machineOptimization of a Final Crushing Stage This method applies to other crushers where a control variable is available The crushers are the last size reduction stage in the value chain Over crushing is common The connection between crusher setting and yield is often unknown The rock cannot be repaired We need to control the crusherCrushing Principles of Mechanical Crushing 911 Metallurgist2023年3月2日 The machine crushes the slag to the desired size, and the crushed slag is then separated and removed from the machine Working Principle of Slag Crusher Machine The working principle of a Slag Crusher Machine is straightforward The machine uses mechanical energy to break the slag into smaller piecesWhat is a Slag Crusher Machine and How Does it Work?

%3C1PGHL[2}HK_]YT.jpg)

Working Principle of Cone Crushers

Working Principle of Cone Crushers: Efficient Crushing Technology in Stone Crushing and Screening Facilities Before delving into the working principle of cone crushers, let’s discuss them briefly Cone crushers are crucial equipment widely used in mining and construction industries for crushing and screening operations2024年3月7日 At the heart of a gold shaking table is the principle of gravity separation The table consists of a flat, riffled surface that is set at an angle to the horizontal When fed with a mixture of water and mineral particles, the table's oscillating motion creates a thin film of The Ultimate Guide to Gold Shaking Table Miningpedia2016年2月18日 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and Working Principle of Crushers 911Metallurgist2023年3月10日 Si trabaja en la industria minera, de la construcción o agrícola, debe haber oído hablar de las cribas vibratorias Cribas vibratorias son ampliamente utilizados en la industria para Separar y clasificar materiales Principio de funcionamiento de la criba vibratoria:

Jaw Crusher Working Principle 911Metallurgist

2021年5月6日 A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the top of the crushing 2023年2月28日 The working principle of a jaw crusher is simple The jaw crusher uses a movable jaw plate and a fixed jaw plate to crush the material The material is fed into the jaw crusher through the top of the machine and is A Comprehensive Guide to Understanding the WORKING PRINCIPLE AND STRUCTURE ⅠWorking principle: The bigsized material is evenly sent into the clearance between two rollers Under the impact of two rollers’ contrary rotation, the materials are extruded and crushed to the desired size ⅡStructure: The roll crusher is mainly composed of fixed roller, movable roller, machine frame Onestop Turnkey ROLL CRUSHER FTM MachineryDiscover an indepth guide to stone crusher, including working principles, types, advantages, applications, maintenance tips, and the latest technologies and trends Stone Crusher Rock Crushing MachineStone Crusher Rock Crushing Machine

.jpg)

Jaw Crusher Working Principle

911metallurgistJaw Crusher Working Principle Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses the working principle of a singletoggle jaw crusher It describes the elliptical motion of the swing jaw and how it closes at the top of the stroke and opens at the bottom It also compares the motion and performance to other jaw crusher Ginger crushing machine working principle Driven by the motor, the flying knife rotates around its own axis in the gap between the fixed bottom knives, thereby crushing the fruits and vegetables There are four sets of flying knives on the rotor, and the bottom knife is a groupStainless Steel Ginger Crushing Machine Ginger Processing ExpertWorking principle:This machine is of vertical crushing structure, and the material is fed into the crushing chamber through a hopper, crushed by simultaneous cutting of both fixed and movable knives and rotating impact of rotating knife, and enters into the catcher automatically under the effect of rotating centrifugal force, and the dust is filtered and recovered by dust collector Fine crusher – 江苏宏达粉体装备有限公司2023年2月23日 Una trituradora de cono es una herramienta poderosa que se utiliza en las industrias de minería, agregados y construcción para triturar materiales en pedazos más pequeños pero como funciona? En este artículo, exploraremos el principio de funcionamiento de la trituradora de cono, incluido el movimiento excéntrico del eje principal, el proceso de Comprensión del principio de funcionamiento de la trituradora de

.jpg)

Grinding Mills — Types, Working Principle Applications

2018年8月17日 Stage 2 — Crushing Screening silver, alumina and nickel industries Working Principle Applications What is a Thickener? Aug 8, 2018 Savona Equipment