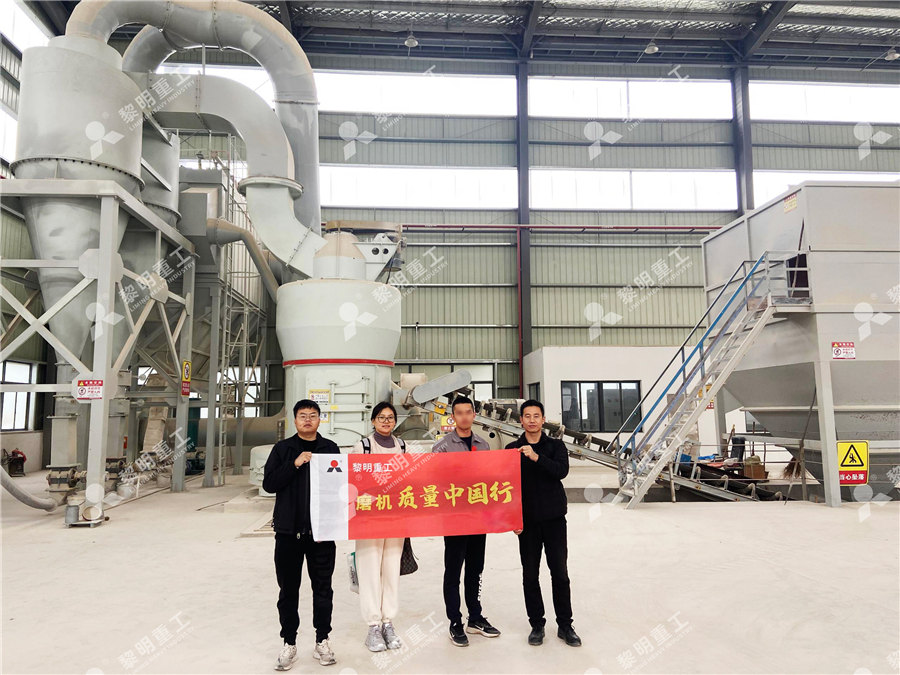

Gange ore grinding mill out of the furnace

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the top The intense heat generated by the combustion of coke reduces the iron oxides in the ore to metallic iron2023年7月20日 Ore grinding is completed in the cylinder of the grinding mill With a certain amount of grinding medium in the cylinder, when the cylinder rotates, the grinding medium is Ore Grinding SpringerLink2005年12月2日 Massive quantities of material, ie, ores, solvents, additives, and gangue, must be handled for separation procedures Most mined ore undergoes size reduction, ie, grinding (PDF) Minerals Recovery and Processing ResearchGate2017年10月17日 Unlike blast furnace pig iron, the siliceous gangue in the iron ore remains in reduced iron sponge and needs to be removed in the steelmaking process Extractive From Ore to Iron with Smelting and Direct Iron Reduction

.jpg)

The six main steps of iron ore processing Multotec

The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or Mineral processing is the process in which chemical or physical methods are used to separate the useful minerals in the ore from the useless minerals (usually called gangue) or hazardous Mineral Processing SpringerLinkModern iron ore pelletizing process operations may be divided into two main process sections: feedstock preparation and agglomeration processes In most plants, the required particle size Development of a Novel Grinding Process to Iron Ore Pelletizing 2019年6月11日 According to the US Environmental Protection Agency, the sintering process converts finesized raw materials, including iron ore, coke breeze, limestone, mill scale, and Sintering: A Step Between Mining Iron Ore and Steelmaking

Iron ore pelletization ScienceDirect

2015年1月1日 In a study (Wang, 2003) to investigate the effect of damp milling on the balling ability of a magnetite concentrate, the drop number was found to increase first with milling grinding mills Water is added at this point to transport it (94 percent of the water is recycled, while the rest is lost through evaporation) Each primary mill contains several 4" steel balls that grind Iron Ore Processing The Welding HandbookA crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsGrinding Mill an overview ScienceDirect Topics2015年6月15日 Playing DW20, I've just set up simple automated ore processing using EnderIO's Sag Mill and Alloy Furnace I'm trying to decide what to do about the other potential uses of the Sag Mill such as clay blocks for making silicon, etc I've got a general dumpallthethings chest that goes to storage or to the Sag Mill based on a whitelist advanced filterLooking for Advice on EnderIO Auto Ore Processing Logic

(PDF) REHEATING FURNACES IN THE STEEL INDUSTRY

2020年11月16日 The reheating furnace of the steel industry was evaluated in the present study, which uses the gas mixture from coke oven (COG), steelmaking process “LinzDonawitz” (LDG) and blast furnace (BFG)DOI: 101016/JMINENG201804015 Corpus ID: ; Effect of frictional grinding on ore characteristics and selectivity of magnetic separation @article{Wang2018EffectOF, title={Effect of frictional grinding on ore characteristics and selectivity of magnetic separation}, author={Shaoyan Wang and Ke Guo and Qi Shuokun and Liming Lu}, journal={Minerals Engineering}, Effect of frictional grinding on ore characteristics and selectivity of 2019年2月5日 Companies such as KHD, who deal in dry separation equipment, have produced several commercially used airbased classification systems including the V separator and SKS dynamic cage wheel separatorCase Study of Dry HPGR Grinding and Classification in Ore Processing2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of LOESCHE vertical roller mills for the comminution of ores and minerals

Grinding Mill Liners 911Metallurgist

2015年8月6日 There are basically two groups of Grinding Mill Liners The amount of unground material will slowly increase until the mill can no longer grind the bigger ore wear past a critical size the efficiency of the mill will slowly deteriorate until the liners are completely worn out requiring replacement Grinding Mill Rubber Liners2020年6月17日 Abstract The study results of the effect exerted by steel grade and heat treatment of grinding balls with a diameter of 100 mm on the hardness, wear and impact resistance, as well as on the tendency to quenching crack embrittlement, are presented The following effects have been studied: alloying carbon steel (06–15% of C) with 09–50% of Cr; Grinding Balls for the First Stage of Iron Raw Grinding in Tumbling 2011年1月1日 Knowledge of the constraints imposed on the iron blast furnace by the First and Second Laws of Thermodynamics can be used to formulate a conceptual model of the processCalculating the value of iron ores in ironmaking and steelmaking2023年2月23日 The modern world uses shocking amounts of steel The input requirements for 16th century blast furnaces were large Though fuel consumption had fallen to roughly the level of the bloomery furnace (initially it used much more fuel than a bloomery), producing a ton of pig iron still required roughly 455 tons of charcoal, and 557 tons of iron oreThe Blast Furnace: 800 Years of Technology Improvement

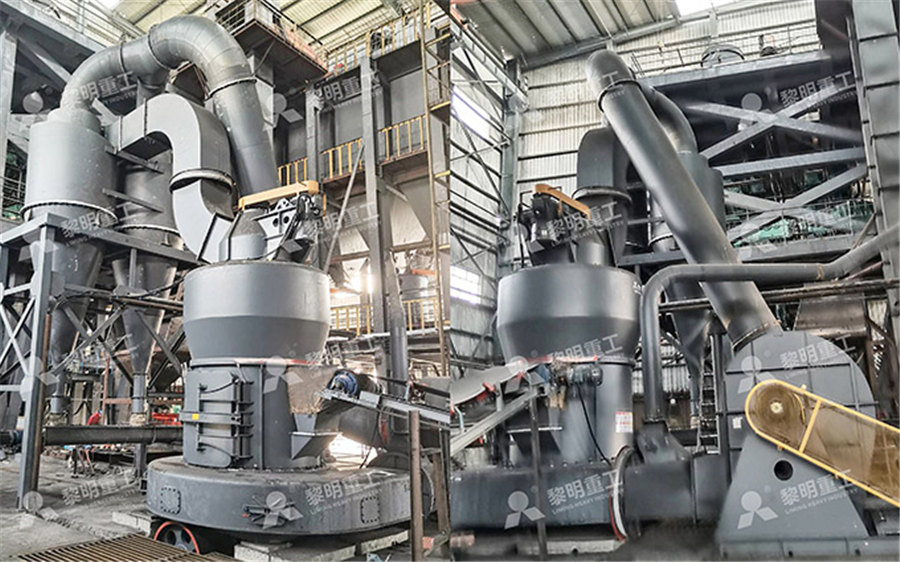

Magnesite Grinding Equipment Production Line

2021年10月29日 Highpressure mill: can produce 50325mesh magnesite ore powder HGM ultrafine grinding mill: can produce 1503000mesh magnesite powder, the powder quality is medium and high CLUM vertical roller mill: can 2022年7月18日 With respect to the mechanical properties, durability and thermal behavior, groundgranulated blastfurnace slag (GGBS) delineates a rational way to develop sustainable cement and concreteA Comprehensive Review on the Ground Granulated 2020年10月18日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesThe effects of iron ore concentrate grinding methods (HPGR and 2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution behaviour and

.jpg)

Grinding Mills and Their Types – IspatGuru

2015年4月9日 The mill is normally used for grinding of ores There is little wear as the grinding is often carried out by the material itself Autogenous mills are more suited to large installations ie more than 50 tons per hour and have a power requirement ranging from 40 kW up to hundreds of kW1 Grindability: The grindability of the ore affects the efficiency of the grinding mill Harder ores require more energy and longer grinding times, which can impact the mill's performance and operational costs 2 Media andliner Wear: The condition of the grinding media and liners affects the mill's efficiencyUnderstanding the operation of grinding mills in the mining and It is in the blast furnace that extraction of iron occurs The extraction of iron from its ore is a long and subdued process, that helps in separating the useful components from the waste materials such as slag What happens in the Blast Furnace? The purpose of a Blast Furnace is to reduce the concentrated ore chemically to its liquid metal stateExtraction of Iron Metallurgy Blast Furnace and ReactionsThe performance of grinding mills depends on many operating factors among which are the time of grinding, mill speed, grinding media–toore ratio, (Gallen Kamp muffle furnace), , the average grindability value was obtained and this was carried out for both iron ore and granite rock 59 mwe‐journal Journal of Mining World Comparative Analysis of Grindability of Iron‐ ore and Granite

.jpg)

Gold Ore Roasting Techniques 911Metallurgist

2016年7月14日 Straight pyritic ores, where the pyrite is present in small quantities, usually yield their gold to fine grinding and cyanidation alone Silver ores containing the values as polybasite, stephanite, pyrargyrite (the antimony sulphide), and proustite (arsenic sulphide) usually require roasting Tetrahedrite is often refractory even after roasting2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral ProcessingWhile developing most of the above techniques the use of rotary hearth furnace (RHF) (Fig 15) has been kept in view due to its merits: – – It can use wide variety of feed Flexible to use Additives mixed ore pellets J MET MATER SC, Vol (PDF) The utilisation of iron ore fines Academia2020年3月28日 The grinding product t10 is negatively correlated with the feed sizes of ore when the grinding force is applied to the ore At the same time, it has a simple positive linear relationship with the Development of a Novel Grinding Process to Iron Ore

.jpg)

Basic oxygen furnace slag: Review of current and potential uses

2020年4月1日 During the steel making process, CO 2 is generated as a byproduct in either one of the following two processes: (i) reduction of iron ore with coke in a blast furnace (BF) to produce pig iron, or (ii) from the decarbonisation of limestone (CaCO 3) and dolomite (MgCO 3) which are added together with coke as fluxing materials to strip oxygen and other impurities 2007年2月1日 But nowhere in the world have so many roller mills for granulated blast furnace slag grinding been sold as in China during the last 6 years First Polysius slag roller mill in China The first Polysius roller mill for slag grinding in China is in operation since 2002 in Anshan in the province of LiaoningSlag grinding with the Polysius Roller Mill in ChinaFind your ore mill easily amongst the 42 products from the leading brands (Fritsch chemical industry, etc, it has two ore grinding Compare this product Remove from comparison tool ball grinding mill horizontal for ore ball grinding mill Suitable for carrying out grinding tests or simple wet process mixing tests on ceramic glazes Ore mill, Ore grinding mill All industrial manufacturers2017年6月15日 Additionally, the wear out of the grinding media represents another significant factor that influences the grinding kinetics and reduces the overall milling efficiency [76]Friction and wear of liner and grinding ball in iron ore ball mill

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 2016年2月29日 In this way, we can insure complete decomposition of the ore One of the components is a lead oxide that is reduced to metallic lead This metallic element collects gold and silver The weight of flux is 25 grams Basically, the flux must be able to control viscosity, degree of acidity, change the melting point of the ore and decompose the oreGold Smelting Refining Process 911Metallurgist2022年3月19日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesGrinding iron ore concentrate by using HPGR and ball mills and 2019年7月2日 Iron and steel making is one of the most intense energy consuming in the industrial sectors The intensive utilization of fossil carbon in the ironmaking blast furnace (BF) is related directly to Modern blast furnace ironmaking technology: potentials to

.jpg)

Ball Mill Is Indispensable For Lithium Ore Processing

2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common mill scale, LD sludge and BF dust are more attractive in comparison with low iron bearing materials like slags One such attractive material to explore is mill scale obtained from hot rolling mill operations Mill scale, generally obtained in the size range of 1–5 mm, comprises of about 70% iron in the form of hematite (Fe 2O 3), magnetite (Fe 3ODirect Reduction Recycling of Mill Scale Through Iron Powder 2020年3月31日 This laboratory study investigates selective grinding and beneficiation options for a Greek bauxite ore First, a series of batch grinding tests were carried out in order to investigate the Grinding Behavior and Potential Beneficiation Options 2016年2月5日 The quality of raw materials (iron ore, coal, and coke) has a clear impact on the carbon emissions of the hot metal production in steel making So far, very little work has been done to measure and quantify this impact Yet for benchmarking, technology choice and general carbon optimization are important elements The total slag production of a blast furnace gives The Carbon Cost of Slag Production in the Blast Furnace: A

(PDF) A short history of mineral processing ResearchGate

2006年1月1日 Crushing and grinding of ores and their beneficiation by washing away gangue minerals has been practiced since ancient times Primitive crushing was done by hand pounding the ore with a hard stone 2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant2020年3月3日 In the blast furnace process, ironbearing materials (eg lumps iron ore, sinter/pellets, mill scale and steelmaking slag), coke (fuel as well as reducer) and flux (limestone and/or dolomite) are charged by the skip car or conveyor belt from the top of the furnaceBlast Furnace Process SpringerLink2019年6月11日 World resources are estimated to be greater than 800 billion tons of crude ore containing more than 230 billion tons of iron The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering process Sinter is the primary feed material for making iron and steel in a blast furnaceSintering: A Step Between Mining Iron Ore and Steelmaking

.jpg)

Metallurgists Mineral Processing Engineers 911Metallurgist

911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables 2018年9月24日 In this paper, the sand casting process was evaluated using ProCAST simulating software and practical experience for manufacturing of the high chromium stainless steel outlet diaphragms used in iron ore ball mill In the simulation practice, the effects of feeding and gating designs on the liquid flow, heat transfer and solidification phenomenon were Simulation of casting process: case study on the gating and