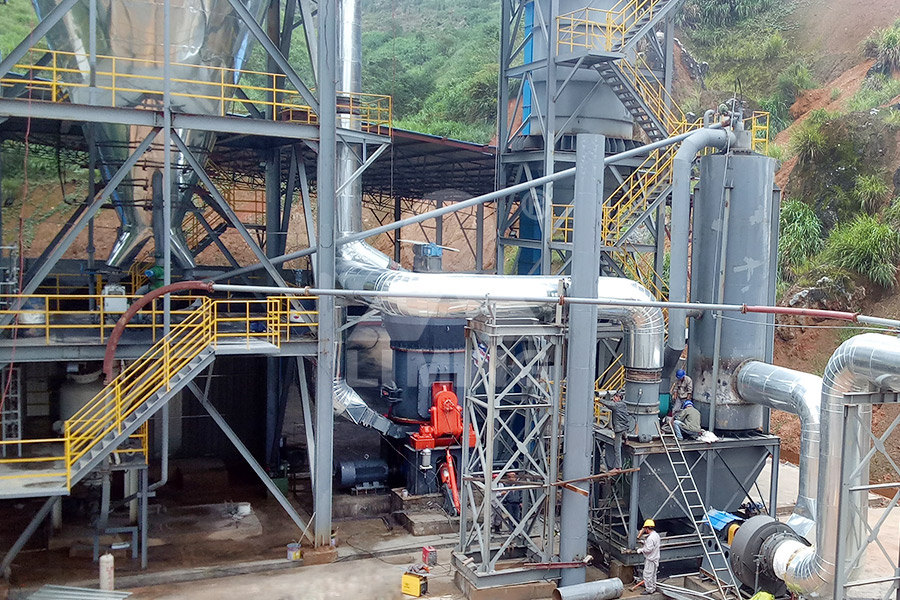

Dyke core backfill limestone construction

.jpg)

Dyke Walls: Design, Construction, and Applications

2024年7月2日 The construction of dyke walls involves a blend of traditional methods and modern engineering practices, tailored to the specific type of dyke being built The process A λframe dyke generally consists of foundation, λframes, wingwalls and slabs It is a reinforced concrete hydraulic, detachable structure across a small stream valley to impound water for λframe dyke construction technique Purdue UniversityFills include conventional compacted fills; hydraulic fills; and uncontrolled fills of soils or industrial and domestic wastes, such as ashes, slag, chemical wastes, building rubble, and refuse An Intro to Fill and Backfill for Structures R CED EngineeringIn civil engineering and water engineering, dyke structures are special hydraulic installations designed to protect developed areas and infrastructure against flooding and against tidal BECO BERMÜLLER Dyke construction

.jpg)

Secondary aggregates and seawater employment for sustainable

2016年6月15日 According to technical recommendations the blocks produced with 100% of recycled aggregates were too light for use in dyke construction The concrete blocks produced 2016年1月1日 In this paper a technical option for safe back filling practices by constructing embankment in the decoaled area is discussed This paper throws a light on the scheme for (PDF) Design of embankment for safe back filling in opencast 2016年3月4日 Different types of backfill materials are used in construction industry Backfill materials that are commonly used are described below with their engineering properties 1 6 TYPES OF BACKFILL MATERIALS USED IN CONSTRUCTIONpermitting the use of locally available soils for the construction of dykes are very attractive Costeffective and competitive solutions can be achieved by using geosynthetic clay liners and RECONSTRUCTION AND IMPROVEMENT OF DYKES BY USING

.jpg)

Construction of flood protection dyke using poor draining backfill

This paper elaborates on the innovative approach chosen to design the 12m high 2400m long peripheral flood protection dyke using composite geosynthetic reinforcement materials with Terre Armée has forged an unrivalled level of expertise and experience in reinforced backfill applications and soilstructure interaction Our technical solutions are defined by four functions Dams and dykes Terre Armée's engineered solutions RECo 2021年8月31日 CA6 base stone: This is another popular option in construction and is used in both commercial and residential projects Trench backfill: This backfill material consists of small aggregates and is known for its good What Is Backfilling in Construction? Foundation structural backfill zone (sometimes called the critical backfill zone) Appropriate granular materials are selected based on structure shape, live load, cover and other site conditions Granular materials that meet the AASHTO M145 Classification for SoilAggregate Mixtures for Highway Construction are normally acceptable These materials canBACKFILL REQUIREMENTS

Backfilling in Foundation: Types and Procedures The

2024年5月27日 Backfilling is a critical process in construction, particularly in laying foundations for buildings It involves refilling an excavated site with soil or other materials to provide support and stability to a structure Proper Understanding the importance of backfill in construction is paramount to ensuring the stability and longevity of any structure Why Is Backfill a Cornerstone in Construction? Backfill is more than just refilling excavated sites; it’s about providing a solid foundation that supports the entire structureUnderstanding Backfill in Construction ProjectsIts natural properties, coupled with a global push for environmentally friendly construction materials, position limestone as a critical player in the future of construction As we look ahead, the exploration of limestone’s benefits and applications will likely continue, with innovations aimed at enhancing its performance and minimizing its environmental footprintThe Impact of Limestone Uses in Construction Kemper EquipmentIn the construction, backfilling stands as a pivotal process, essential for fortifying and supporting the foundations and structural components of buildings Compaction of Backfill: Proper compaction of backfill material is imperative to prevent Backfilling in Foundation : Types and Procedure

Excavation and Backfilling of Soil – Work Sequence and

Excavation and backfilling of soil is a very important part of construction process, and care must be taken while excavation in safety perspective Different soil layers may be encountered while excavation, dewatering may be needed sometimesIncorporating limestone into construction projects offers a holistic approach to building design, where functionality, aesthetics, and occupant comfort are all considered For foremen and contractors, it presents an opportunity to meet the growing demand for buildings that not only look good and last long but also offer a superior living experienceThe Top 5 Benefits of Using Limestone in Construction2024年10月20日 Learn what backfill is in the construction industry and how it plays a crucial role in building construction Find out its importance and methods used for proper backfilling Join for Free: Get Help Insights Little Household Additions For What Is Backfill In Construction Storables2016年7月29日 Existing practice for construction of large lakefills is to construct the core of the spine with earthen materials and to later protect or armour the spine with quarry rock or concrete rubble The protection is commonly advanced along with the filling such that active filling occurs only along a 15 metres exposed faceB6 Guidelines for Evaluating Construction Activities Impacting on

.jpg)

Construction of flood protection dyke using poor draining backfill

9m from the existing ground levels which made the authorities to propose a protection dyke of 12m height An Earthen embankment of inclination 1H:3V with stone pitching on the slopes had been initially Construction of flood protection dyke using poor draining backfill materials on the banks of river Ganges, India2017年5月30日 Crews used imported 4 to 8inch crushed angular limestone for the backfill for the pads and the gabions “Not a lot of backfill was needed due to the cut of the slopes,” says Fee “It averaged approximately two feet” They Preventing erosion with riprap and gabion walls2016年10月1日 The purpose of this study is to assess the coupled effects of limestone powder (LP) and waterreducing admixture (WRA) dosages (by dry total mass) on the properties of cemented paste backfill (CPB Utilization of limestone powder and waterreducing admixture in Also called Washed Rock, Clean Rock, or Crushed Limestone Concrete Aggregate due to its uniformity and wide range of use in construction applications, particularly in Concrete and Asphalt mixes Thanks to its availability, versatility, and ability to be produced into a wide range of products, limestone is the most utilized rock for production of crushed stone in the US Crushed Limestone Rock Gulf Coast Limestone

.jpg)

ANCHOR DIAMOND ANCHORPLEX™ RETAINING WALL CONSTRUCTION

the structural backfill attaches itself to the wall facing, effectively extending the depth and mass of the facing In addition, the structural backfill zone also serves as the required drainage zone The Anchorplex construction method completely eliminates the need for the construction of a mechanically stabilized earth zone behind the188 Chaoyang Fang et al / J Rock Mech Geotech Eng 2011, 3 (2): 186–192Stressstrain analysis of Aikou rockfill dam with asphaltconcrete coreThis manual presents fundamental principles underlying the design and construction of earth and rockfill dams The general principles presented herein are also applicable to the design and construction of earth levees The construction of earth dams by hydraulic means was curtailed in the 1940's due to economicDesign and Construction of Earth and RockFill Dams CED 2024年4月29日 Discover the crucial role of backfilling in construction projects, from supporting foundations to enhancing drainage Explore the selection of materials, compaction techniques, and environmental considerations involved Learn best practices and insights to ensure the stability and durability of structuresWhat is Backfilling and How It Shapes Construction Projects DOZR

.jpg)

What is Backfill in Construction? A Guide to Types and Uses

2021年7月6日 Backfill is an essential part of construction and landscaping projects But what exactly is backfill, and why is it important? In this guide, we’ll explore what backfill is, the different types available, and their various uses We’ll also discuss an important concept called the clay bowl effect, which can lead to foundation issues in some 2016年10月12日 This study presents results from a fully instrumented fieldscale load test on a 02mdiameter micropile socketed 42 m into limestone layers (27 m into weathered limestone and 15 m into hard Bored Pile Construction Challenges in Highly Variable Limestone A backfill calculator provides you with precise measurements for the fill material, allowing you to assess soil stability and ensure your foundations are built on solid ground Retaining Wall Construction If you’re constructing a retaining wall, a backfill calculator helps you ascertain the volume of material needed behind the wallBackfill Calculator – Accurate Volume Cost Estimation2020年7月31日 Ponds, lakes, reservoirs, and dams are essential parts of stormwater management efforts in Maryland and throughout the country While there are many differences between the various structures that can be used Construction Basics: What Is A Clay Core?

7 Types of Sand Used in Construction BuilderSpace

2020年1月6日 The main types of sand used in construction range from concrete sand to pit sand, natural or river sand, manufactured sand gneiss, or limestone This sand has angular granules and works best when mixed with cement 2018年8月30日 According to the Chinese standard for construction sand, the highest limit value of stone powder content in sand and gravel is 10 % [6]But after grinding the stone powder finelyIts mechanisms of A review on use of limestone powder in cementbased materials The governance zone of the water element covers an area of 21207 km 2 , with Town accounting for 3880%, Datong Town accounting for 3178%, and Ganshu The governance zone of the mountain element Advantages and disadvantages of rock backfill systemsEngineering Construction Services Division Standard Specifications for Road Works TS 1010 September 2017 Amendment to OPSSMUNI 1010 (Apr 2013) – Material Specification for Aggregates – Base, Subbase, Select Subgrade, and Backfill Material Page 1 of 8 TS 1010 – September 2017 Amendment to OPSSMUNI 1010 (Apr 2013) –TS 1010 Aggregates – Base, Subbase, Select Subgrade, and Backfill

Ultimate Guide to Structural Backfill: Tips Best Practices

2023年7月24日 Following proper compaction techniques is crucial to ensuring a stable and longlasting construction project By layering the backfill material, maintaining appropriate moisture levels, and using mechanical compaction methods, you can help prevent settling and shifting and ensure the success of your project2022年11月14日 House Construction Vlog! Using Limestone To BackfillHouse Construction Vlog! Using Limestone To Backfill Basement2022年4月22日 Backfilling means the process used refilling soil (or) sand an excavated area, backfilling quantity usually calculating in m³ (Cubic meter), basically There are two type of backfilling method used in construction work 1Handmade Backfilling – The Soil is refilling by Humans 2 Machinery made Backfilling – The Soil is refilling machineryHow to Calculate Backfilling Quantity (or) Volume of Backfilling PDF On Jan 1, 2021, 功祥 陈 published Numerical Simulation of Tunnel Group Excavation with Reserved Core Soil Method in Deep Backfill Area Find, read and cite all the research you need on Numerical Simulation of Tunnel Group Excavation with Reserved Core

.jpg)

15″ Screened Limestone Outdoor Solutions

15" Screened Limestone used for driveways and backfill material behind retaining walls Outdoor Solutions Lincoln, NE 4024201477 Virtual tour Products; About; Contact; Employment Opportunities; Home 15″ Screened Crushed limestone is perfect as a driveway stone, walkway stone, or in drainage applications Available in 1", 1 1/2", 3" Get a free quote today! 5 Best Stones for Backfill Construction projects typically require a vast amount of digging Crushed Limestone Driveway Stone Walkway 2024年8月17日 After the completion of underground work, backfilling helps in returning the land to its original contour, which is crucial for the visual appeal of the site and for facilitating subsequent landscaping or construction activities What is Backfilling in Construction?2018年10月27日 Conference: 5th INTERNATIONAL SYMPOSIUM on DAM SAFETY AND EXHIBITION; At: Istanbul, Turkey; Volume: 2, Proceedings for dam safety 2018, ISBN: 9789444The Effect of Clay Core Specifications On the Seepage Behavior

Limestone Base Gulf Coast Limestone

Also referred to as Caliche, Road Base, Crushed Stone Base, or Flex Base Limestone Base is a versatile crushed stone aggregate that can be used in applications ranging from landscaping and other home applications to largescale road and highway construction Limestone base is produced to be in 15 inches in size down to fines (small particles of rock) and comes in A) Pile Core Conform to Section 206 of the Standard Specifications Provide pile core material consisting of the same material as the adjacent embankment except the material in the pile core area shall be free of boulders or particle sizes larger than 4 inches in any dimension or any other obstructions that may hinder pile driving operationsSPECIAL PROVISION FOR EMBANKMENT AT BRIDGE END BENT Socalled dyke defence paths are constructed on and next to the dyke for maintenance purposes and for defence in case of a disaster The main objective of the dam structures is to protect the hinterland from flooding Along coasts, dyke structures are also of crucial importance for permanent coastal protectionBECO BERMÜLLER Dyke constructionConstruction measures to prevent hazards in karst cave ground under soft sand strata QingLong Cuii), HuaiNa Wuii), YeShuang Xuiii) and ShuiLong Sheniv) i) PhD Student, State Key Laboratory of Water or stone Karst cave Karst cave Tunnel ResearchGate

The Ultimate Guide to Trench Backfill Material

2020年7月6日 Proper backfill processes require knowledge of the specifications and the soil conditions to ensure optimal performance We put together this guide of general considerations to keep in mind and help you better understand backfill Trench Backfill Basics Let’s start at the beginning: Why should you care about your trench backfill material?Chapter 10 – Embankment Construction is an existing chapter within Design Standards No 13 and was revised to include: Experience and information that have been gained since the initial versionDesign Standards No 13 Embankment Dams Bureau of