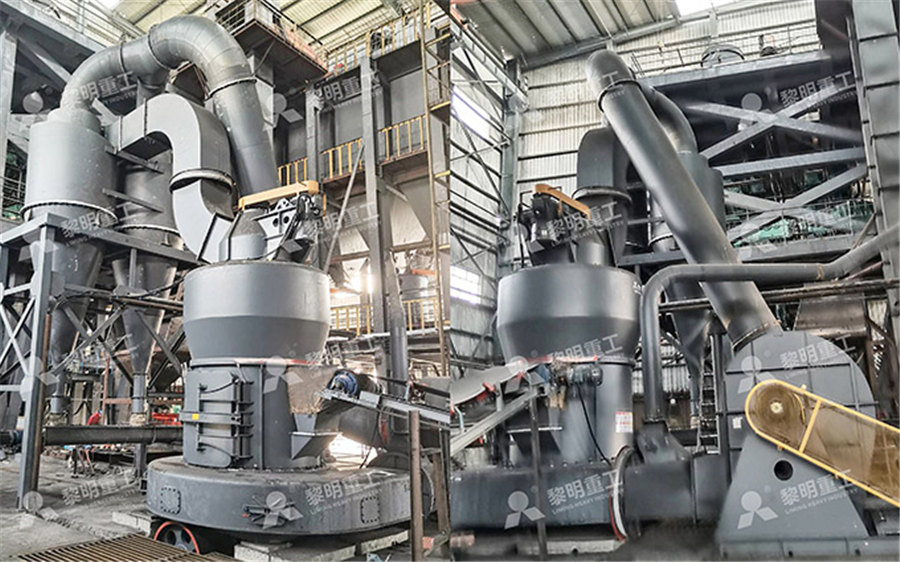

Ore grinding machine installation plan

.jpg)

Crushing Plant Design and Layout Considerations 911 Metallurgist

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design 2023年12月16日 The first step in designing an iron ore crusher plant is to define the project requirements This includes the following: The type of iron ore that will be processed; The iron ore crusher plant design step by step CM Mining Machinerythe HPGR Pro, our latest generation high pressure grinding roll HPGR Expertise 35+ years of experience supplying HPGR’s to mining customers More than 150 machines installed across HPGR / HPGR Pro The next level in grinding FLSmidthWe specialise in grinding mills, crushers, feeders, conveyors, pumps, screens and a variety of power transmissions Our installation services include feasibility consulting services on size and appropriate equipment to scale for the Mining Equipment Installation Construction HMR

Crushing Screening Plant Design Factors

2016年4月14日 We should consider how the work is done by crushing machines, hammermills and pure impact crushers lift the kinetic energy of the material to a level where on sudden impingement against a stationary plate Depending on the ore characteristics, it is possible to optimize the mineral dissociation, grain distribution and throughput for each deposit The versatile concept behind OGPmobile enables Mobile grinding mill for ore LoescheThe use of HPGR machines in minerals processing plants requires special attention to these issues: » Pilot plant HPGR tests are necessary to evaluate the ore performance and to assess HighPressure GrindingDesigning a grinding plant to facilitate maintenance activities such as relining provides an excellent return on investment Not only are the relining times reduced which increases mill DESIGNING GRINDING PLANTS FOR MILL RELINING TO MAXIMISE

Your iron ore beneficiation solutions Downer Group Site

Our testing uses state‐of‐the‐art iron ore beneficiation equipment for crushing, grinding, classification, gravity and electrostatic separation as well as high and low intensity magnetic 2024年9月25日 A copper ore selection plant encountered problems during the production and commissioning phaseThe design production capacity of the selected plant is 4500t/d, and the processing capacity is 1875t/h at Taiwan timeIn the early stage of commissioning, when the processing capacity of the ball mill was 140t/h, the indicators were better, but when the Copper ore flotation plant optimizes grinding and grading The main objective of the study was to design, develop and install a solar powered peanut grinding machine Specifically, the project aimed to attain the following objectives: 1 To evaluate the existing peanut grinding machine in terms of: 11 Design; 12 Construction; 13 Operation; 14 Areas of Improvement 2DEVELOPMENT AND INSTALLATION OF A SOLARPOWERED PEANUT GRINDING MACHINEFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchasesOre mill, Ore grinding mill All industrial manufacturers

HPGR 911Metallurgist

2016年7月14日 A case study illustrating the optimization of a conventional gold ore grinding circuit is shown in the attached Table 3 Operating Modes of the Polycom HPGR in a Gold Plant The grinding circuit applications of Polycom HPGR units for mining applications have been described previously by Patzelt (1987), Otte (1988), and Otte Patzelt (1991)At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where technology and excellence converge Ore Crushing, Sand Making, Grinding Machinery Bellian Mining 2021年9月9日 Diatomite ultrafine grinding mill is an efficient ore stone powder making machine Diatomite ultrafine grinding mill is an efficient ore stone powder making machine It can grind 100+ kinds of ores into a fine powder (1503000mesh) our designers will directly configure the equipment in the production line planDiatomite Ultrafine Grinding Mill SBM Ultrafine Powder 2019年8月14日 Ball mill is a common grinding equipment in concentrator : hm@gmail Toggle navigation Home it falls or rolls down from the inner wall of the cylinder, crushing the ore At the same time, from the prepurchase consultation, to the smooth installation, and to the test run of the ball mill Moreover, The Ultimate Guide to Ball Mills Miningpedia

World’s largest sorting plant now in operation – Nextore

2022年5月26日 First Quantum Minerals’ Kansanshi mineral processing plant finalised commissioning and undertook verification testing in May of 2022 of a bulk ore sorting system The bulk sorting system has been retrofitted to the existing primary crushing circuit, with MR analyser located after the primary crusher and hydraulic diverter installed at a transfer chute ahead of DOVE Hard Rock Plants and recovery methods vary depending on several factors, including the size of the rock, the rock’s condition, the hardness of the materials, minerals composition in the ore, specific gravity and other characteristics and specification of the elements to insure the efficient recovery of 100% of the minerals Production, with no lossHard Rock Mining Equipment Crushing Plants DOVEMineral Processing Wet Ore Grinding and Classifying Plant, According to the plan of grinding product size and capacity, grinding flowchart should be designed reasonably, and grinding machine is properly selected according to the size of ore and other properties Common grinding process may be one stage, two stage or three stageMineral Processing Wet Ore Grinding and Classifying PlantThe ball mill machine is known as a ball grinding machine It is a wellknown ore grinding machine and is widely used in mining, construction, and aggregate application JXSC started manufacture the ball mill grinder since 1985, supply Ball Mill JXSC Mineral

Understanding the SAG Mill in Copper Ore Mining

The Grinding Laws and Machines Grinding is an essential process in the mining industry, and it involves breaking down large pieces of ore into smaller fragments The grinding laws are fundamental principles that guide the design and 2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration Grinding Modeling and Energy Efficiency in Ore/Raw 2023年11月13日 Selecting the appropriate feeder for a mineral processing plant ensures efficient and effective operations Feeders are responsible for transferring material from storage to the processing equipment, and their performance can significantly impact the plant’s overall productivity Factors Affecting Feeder Selection: Particle size Feed rate Moisture content How to Select the Best Feeder for Your Ore Processing Plant?2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

.jpg)

Quick Pick: Compare 4 Top Barite Grinding Mills for Your Needs

2024年4月17日 Grinding machine Ф2700×4500 Ball Mill Finished barite powder 100 mesh Customer feedback The cooperation with FTM Machinery is very good this time Before designing for us, it specially arranged professional technicians to visit the site to provide us with a suitable production plan The equipment runs stably in production2020年7月27日 #BallmillBall Mill Installation In Africa For Grinding Ore 2020 Ball mill installation is a must step before it is put into production, which will affect thBall Mill Installation In Africa For Grinding Ore 2020 YouTubeOre processing is the process of separating valuable minerals from its ores by ore beneficiation equipment Mineral processing plant is recovers or extracts minerals through a range of ore dressing solutions, including washing, crushing, grinding, gravity concentration, flotation magnetic separation, electrostatic separation and more JXSC provide full mining process Mineral Processing Plant Beneficiation Solutions JXSC MachineryDasen provides gold ore CIP CIL processing plant and also equipment manufacturing solution with benefits of ultra low power ensuring the complete monomer dissociation of fine gold particles during grinding is crucial for enhancing the gold leaching Xi’an Dasen Mining Machinery Equipment Co, LTD Tel: +86 29 8113 7393 Gold Ore CIP CIL Processing Plant Equipment Solution Dasen

.jpg)

Leadzinc Process Refinery: Ore Sorting Machine Upgrade

This accounts for 2,600 tons of ore, rejecting 400500 t/d of waste rock After preconcentration, the lead and zinc content in the waste rock is below 03%, and the sulfur and iron content is below 38% Therefore, the ore sorting process enriches the ore grade by 108% for lead and zinc and 2% for sulfur and iron2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Pretreatment Methods for Grinding: Journey and ProspectsWet pan mill is the most widely used gold milling machine in African countries, the most popular model is 1200, 1100 is mainly applied for grinding rock gold ore In Sudan, at least 85% of gold miners are using the Gold Milling Machine (wet Wet Pan Mill For Gold Pineer Mining MachineryBall mill working principle The ball mill operates based on impact and abrasion effects Step 1 Loading: First, the material to be ground and grinding media (such as steel balls or ceramic balls) are loaded into the ball mill cylinder Typically, Ball Mill FTM Machinery

.jpg)

Installation Preparation Checklist General Kinematics

2018年10月26日 How you will store it if installation can’t take place the same day; Also,communication is critical Prepare your team for delivery and possible shutdown during this time Create an installation plan After you’ve planned how the equipment will be delivered, you’ll need to know how you (and your manufacturer) are going to install it2021年5月31日 the ore blending plan’s adjustment to form a closedloop control the particle size of the ore, and the grinding time Machines to Classify Dephosphorization in BOF Steelmaking(PDF) A Method of Ore Blending Based on the Quality of 2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLinkCrushing Circuit and Equipment The crushed ores must to be grinded to meet the liberation condition to meet the next operation stage Wet grinding is often used in the mineral processing plants to improve efficiency, reduce consumption of Mining Industry Mineral Processing Wet Grinding and Classifying

.jpg)

AusIMM – Leading the way for people in resources

%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 3 Separation stage The separation stage is the core link of the iron ore beneficiation plant We select suitable magnetic separation equipment according to the magnetic characteristics of the oreEquipment Configuration Plan and Process of Iron Ore Dressing2019年8月23日 JXSC Mine Machinery Company in China has more than 30 years experience in chrome ore equipment manufacturering, and ore processing flow design optimization Have already built many chrome ore processing plant in South Africa, Zimbabwe, Madagascar, Albania, India, Philippines, kazakhstan, Russia, China, etcChromium Processing Process Flow, Cases JXSC Machine2021年8月17日 The Mohs hardness of gypsum is 235, and it can be ground with an SBM industrial grinding mill (gypsum industrial ultrafine powder mill machine) SBM is a professional manufacturer of mining ore grinding Gypsum Industrial Ultrafine Powder Mill Machine

Report Business Plan Iron Ore PDF Iron Ore Mill

Report Business Plan Iron Ore Free download as PDF File (pdf), Text File (txt) or read online for free The document is a prefeasibility report submitted to the Ministry of Environment and Forests for an iron ore beneficiation plant to be 2022年3月22日 The ball mill is the key equipment for the grinding of iron ore after crushing, and the grinding process is the important process of iron ore sorting Ball mill can grind iron ore from 25mm to 150250 mesh, and with high 10 Most Popular Iron Ore Beneficiation Machines HXJQMain machines in ore grinding process are Iron ore mill equipment The most common Iron ore mills in mining are ball mill, raymond mill and high pressure suspension mill The selection of is according to customers’ requirements and the nature of the minerals Ore grinding can be divided into grinding with media and withoutIron ore grinding plant for ores milling process SBMSUPPLY, INSTALLATION, COMMISSIONING OF THE WORLD'S LARGEST GRINDING MILL by Alan Boughey Project Engineering Manager Newcrest Mining Ltd Australia Vytas Svalbonas Director of Engineering Technologies Svedala Industries, Inc York, PA, USA Stuart M Jones Director of Sales Marketing Svedala Industries, Inc York, PA, USA 1 ABSTRACT In June SUPPLY, INSTALLATION, COMMISSIONING OF THE WORLD'S LARGEST GRINDING

Crushing Plant Design and Layout Considerations 911 Metallurgist

monitor costs and promote methods of reducing total installation costs In some locations, for example, labor and material costs could make a gabion wall more expensive than a poured concrete wall, which has minimal structural backfill Ore Characteristics Ore characteristics are a critical element in both crusher selection and plant design In ore dressing, the purpose of crushing ore is: (1) supply the most reasonable ore feeding size for rod grinding, ball milling, or provide qualified grinding medium for autogenous mill and gravel grinding; (2) make coarsegrained embedded minerals monomer preliminarily dissociated, create convenience for the coarse grain dressing methods, such as heavy medium separation, jig Crushing Plant Design and Layout Considerations JXSC MinePrater Industries, Inc does not install your machine It is your responsibility to provide lockout switches, guards, and other safety devices and safety procedures to protect the machine operator or maintenance personnel 24 Before Operation 3/24/14 3/24/14 Prater Prater Prater, FINE GRINDER INSTALLATION, OPERATION, AND MAINTENANCE 2019年8月29日 estimation and mine plan based on applicability of a sensor ‐ based ore sorting machine; downstream, with adequate mill and circuit design based on the properties of a sorted material stream(PDF) Sensor‐Based Ore Sorting Technology in Mining—Past,

.jpg)

CHROME WASH PLANT Pineer Mining Machinery

Pineer mining machinery company could supply a full list of chrome wash plant machinery and help customers to install up whole wash plant Skip to content Call Us Today! +87 info@pineerminingmachinery Home; About Us; Mining to grinding ore into about 100200 mesh, and liberate out useful mineral ore contained by quartz