Iron tailings for cement making

Utilization of iron ore tailings with high volume in green concrete

2023年8月1日 In this study, the potential of converting iron ore tailings (IOTs) into sustainable building materials was explored IOTs were combined with fly ash (FA) and ground granulated 2021年6月21日 This paper specifically points out three directions for the use of iron ore tailings in construction and building materials, namely production of cementitious materials, preparation of bricks as well as preparation of concreteCementitious activity of iron ore tailing and its 2019年10月18日 This paper reviews the potential utilization of tailings as a replacement for fine aggregates, as supplementary cementitious materials (SCMs) in mortar or concrete, and in the Utilization of tailings in cement and concrete: A review2023年4月11日 In this study, the iron tailings from different regions in Hebei Province of China were selected to investigate the application of iron tailings in cementbased materials as fine aggregate and mineral admixture Moreover, Effect of Iron Tailings as Fine Aggregate and Mineral

Concrete Made with Iron Ore Tailings as a Fine

2022年9月8日 Concrete containing iron tailing sand had enhanced performance in agglomeration, as shown by the 12% loss value of concrete with 45% for 1 h Owing to the tailing mixes’ poor solubility, cement paste and aggregate quickly 2021年4月7日 In this research, iron ore tailing (IOT) is utilized as the cementitious material to develop an ecofriendly ultrahigh performance concrete (UHPC) The UHPC mix is obtained according to the modified Andreasen and Utilizing Iron Ore Tailing as Cementitious Material for 2023年12月13日 The purpose of this research is to determine how well sand can stand in as a partial substitute for iron ore tailings without negatively impacting the microstructure, strength, Effect of iron ore tailings as partial replacement to fine aggregate 2024年4月8日 The compressive strength, hydration products, and microstructure of the iron tailings–cementbased supplementary cementitious materials were investigated using ICPOES, XRD, TG, FTIR, and SEM The Mechanical Properties and Hydration Mechanism of

.jpg)

Utilisation of iron ore tailings as aggregates in concrete

2015年12月31日 Sustainable handling of iron ore tailings is of prime concern to all stakeholders who are into iron ore mining This study seeks to add value to the tailings by utilising them as acement, sand, and sodium silicate to obtain or valueadded product out of iron tailing waste which is suitable for use in the construction industry Bricks were made using a variety of compositions of iron tailings, Ordinary Portland Cement, sodium silicate, and sand in cuboid mould (9″X 5″X 3″)Utilization of Iron Ore Tailings for Brick Manufacture from 2023年12月13日 After the beneficiation of iron ore, the waste is generated, which arise many environmental issues for both living and nonliving components Iron ore tailings are a byproduct of the mining and processing of iron ore, and their potential use as a replacement resource is the emphasis of this study The purpose of this research is to determine how well sand can stand Effect of iron ore tailings as partial replacement to fine aggregate 2022年8月26日 Iron Ore Tailings as Partial Replacement for Fine Aggregate in Concrete Production – Review August 2022 International Journal of Engineering and Management Research 12(4):6471(PDF) Iron Ore Tailings as Partial Replacement for Fine

2FD{P}PC]854]XQ.jpg)

Utilization of iron ore tailings with high volume in green concrete

2023年8月1日 In this study, the potential of converting iron ore tailings (IOTs) into sustainable building materials was explored IOTs were combined with fly ash (FA) and ground granulated blastfurnace slag (GGBFS) to prepare IOTsbased supplementary cementitious materials (SCMs) A concrete mix using 100% IOTsaggregate was also prepared2024年1月12日 When the raw material ratio of molybdenum ore tailings, iron ore tailings and waste glass powders was 6:2:2 and the sintering temperature was 1120 °C, the pore structure of the ceramsite as prepared was uniform and rich and mostly closed The density was low and the mechanical propertities were excellentUse of iron ore tailings as partial replacement for cement on cement, sand, and sodium silicate to obtain or valueadded product out of iron tailing waste which is suitable for use in the construction industry Bricks were made using a variety of compositions of iron tailings, Ordinary Portland Cement, sodium silicate, and sand in cuboid mould (9″X 5″X 3″)Utilization of Iron Ore Tailings for Brick Manufacture from 2022年12月1日 The two prominent methods for mine wastes management or storage are dams and dumps, according to Blight []Mine tailing impoundments and dam failures are very common, and many literatures have reported this [13, 14] as a cause due to the geotechnical behaviour of tailingsThe Fundao dam failure in 2015 [], Brumadinho dam disaster at Corrego do Feijao iron A Critical Review on Potential Use of Iron Ore Tailings as

Utilization of Iron Ore Tailings as Raw Material for Portland Cement

2016年3月16日 Currently, all the cement consumed in Northwest Territories (NWT), Canada, is imported from other provinces (eg, Alberta) by longdistance (∼1,800 km) truck freightPDF On Mar 11, 2021, Ranjeet Kumar Singh and others published Utilization of Iron Ore Tailings for Brick Manufacture from Donimalai Mines of Karnataka, India Find, read and cite all the (PDF) Utilization of Iron Ore Tailings for Brick Manufacture from 2015年12月31日 A concrete mix of grade 40 MPa was prepared in the laboratory with water–cement ratio of 05 The concrete were cured silicate minerals in the iron ore tailings, making it possible for the Utilisation of iron ore tailings as aggregates in concrete2016年4月1日 Waste and tailings from iron ore mining plants are utilized for the manufacture of construction materials (Sreekant et al 2016) The ores and coke used for reduction of Fe contain heavy metals (PDF) Utilization of Iron Ore Waste in Brick Making For

.jpg)

Investigating the hydration characteristics of iron tailings powder

2024年1月1日 However, the hydration characteristics of ITP were still inferior to that of cement, making it difficult to eliminate the dilution effect caused by substituting cement with iron tailings [15]In reality, the dilution effect actually increases the effective watertocement ratio, disrupts the pore structure, enhances porosity, and reduces the strength of the cementitious materialcement and lime to make it economical Some studies has made an attempt to utilize the industrial wastes such By mixing optimum proportions of Iron ore tailings to lateritic soil, the physical properties of soil samples are studied by conducting the laboratory tests such as Sieve analysis, Specific gravity, STABILIZATION OF LATERITIC SOIL USING IRON ORE TAILINGS 2024年4月1日 Fig 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings Due to the characteristics of iron ores and the conditions during beneficiation, it is inevitable that approximately 25–3 tons of IOTs are generated for every 1 ton of iron ore concentrate produced [7]A critical review on metallurgical recovery of iron from iron ore tailings2022年6月25日 It can also be used to produce cement mortar coating and noise reduction plate filler; In terms of making filling materials, iron tailings are applied to the pavement base, LUO L Experimental study on preparation of portland cement clinker from iron tailings[D] Wuhan: Wuhan University of Technology, 2016 Google ScholarResearch Progress on Comprehensive Utilization of Iron Tailings

.jpg)

Production of Construction Bricks Using Iron Ore Tailings and

PDF On Jan 1, 2019, K Behera and others published Production of Construction Bricks Using Iron Ore Tailings and Clay: Proceedings of 6th IconSWM 2016 Find, read and cite all the research you 2019年4月15日 Iron ore tailings (IOTs) are a form of solid waste produced during the beneficiation process of iron ore concentrate In this paper, iron recovery from IOTs was studied at different points during a process involving preconcentration followed by direct reduction and magnetic separation Then, slagtailing concrete composite admixtures were prepared from Recovering Iron from Iron Ore Tailings and Preparing Concrete 2020年2月26日 World is pound with million tonnes of industrial wastes such as ground granulated blast furnace slag (GGBS), flyash and mine tailings as a various industrial waste The best way to make use of these wastes is to incorporate these materials as structural elements, which in turn minimizes the carbon foot print In this contest, this study focuses on using iron Geopolymer Bricks Using Iron Ore Tailings, Slag Sand2024年2月2日 Upstream tailings dams are highrisk structures that have experienced several failures worldwide, particularly with iron ore tailings (IOT) In this study, new disposal methods/techniques, such as cementstabilized dry stacking, are discussed that provide enhanced mechanical behavior while reducing failure risks Alkaliactivated materials are used Iron ore tailings stabilization with alternative alkaliactivated

-2.jpg)

Feasibility Study of Developing Green ECC Using Iron Ore Tailings

IJESC, 2019 Iron Ore Tailings (IOT) are the waste slag resulted from iron ore mines Large amount of Iron Ore Tailings (IOT) have been generating every year posing serious environmental problems, large production of cement everyday resulting the emission of CO 2 and increase in the consumption of river sand for construction activities making the river beds overexploited2022年8月1日 Iron ore tailings is a potential alternative material for the pavement sector • Iron ore tailings were dredge from a dam failing accident in Brazil • Soilcement mixtures with iron ore tailings up to 20% were studied • The mixtures met the Brazilian standards for a Use of iron ore tailings and sediments on pavement structure2024年2月23日 Investigators [17], [18], [19] developed a new type of cementitious material by taking advantage of the synergistic effect of blast furnace slag and steel slag The required amount of new cementitious material in the fulltailings backfill was only 50% of the crude cement amount The strength of the backfill with a cementitious materialsand ratio of 1:4 was 576 Rheological and mechanical properties of fulltailings backfill 2024年8月14日 Iron TailingsBased Masonry Cement: It is composed of iron tailings, high calcium coal ash, slag, sodium sulfate, early strength agents, fly ash, or coal cinder This method involves mixing these materials, offering benefits like reduced investment, lower costs, and simpler technologyMasonry Cement: Composition, Properties, and Applications

.jpg)

Assessment of iron tailings as replacement for fine aggregate in

2023年3月9日 Additionally, the active substances in iron tailings promote the hydration reaction of cement, leading to the formation of an increased amount of CSH gel and other hydration products in the Feasibility Study of Developing Green ECC Using Iron Ore Tailings Powder as Cement Replacement Xiaoyan Huang1; Ravi Ranade2; and Victor C Li, FASCE3 Abstract: This paper reports the results of an initial attempt of using iron ore tailings (IOTs) to develop greener engineered cementitiousFeasibility Study of Developing Green ECC Using Iron Ore Tailings 2017年10月14日 The iron ore tailings which is the waste product of industries [5] is refined, reuse and recycle to extract valuable resource ingredients which in turn lead to economic benefits and address (PDF) A Study on Utilization of Iron Ore Tailings as Partial IJESC, 2019 Iron Ore Tailings (IOT) are the waste slag resulted from iron ore mines Large amount of Iron Ore Tailings (IOT) have been generating every year posing serious environmental problems, large production of cement everyday resulting the emission of CO 2 and increase in the consumption of river sand for construction activities making the river beds overexploited(PDF) UTILIZATION OF IRON ORE TAILINGS AS REPLACEMENT

.jpg)

UTILIZATION OF IRON ORE TAILINGS AS REPLACEMENT TO

314 Iron Ore Tailings Tailings are the materials left over, after the process of separating the valuable fraction from the worthless fraction of an ore Tests on Iron Ore Tailings procured from Kudremukh, Lakya Dam site were conducted The properties of the IOTs are indicated in table 34 Fig 32 Iron Ore Tailings2020年9月1日 Request PDF Experimental investigations on the mechanical behavior of iron tailings powder with compound admixture of cement and nanoclay In order to examine the mechanical performance of Experimental investigations on the mechanical behavior of iron tailings 2024年10月30日 AbstractIron tailings (IT) are byproducts of iron ore mining, which have the characteristics of high stockpile and low cost Recycling IT as alternatives for high “Effects of natural zeolite and sulfate environment on mechanical properties and permeability of cement–bentonite cutoff wall” Eur J Environ Civ Eng 27 (3 Converting Iron Mine Tailings into Composite Aggregates for 2022年9月8日 The need for lowcost raw materials is driven by the fact that iron ore tailings, a prevalent kind of hazardous solid waste, have created major environmental issuesConcrete Made with Iron Ore Tailings as a Fine

.jpg)

On the grinding effects of highsilicon iron tailings

2022年5月27日 The main chemical component of highsilicon iron tailings (HSITs) is SiO2; HSITs also include some oxides such as Al2O3 and CaO Mechanical activation can reduce the particle size of HSITs and enhance their pozzolanic activity such that they can be used as a type of mineral admixture for cementbased materials (CBMs) This study aims to investigate the 2023年12月22日 The construction industry is affected due to a shortage of river sand, besides, the production of cement releases large amounts of CO2 into the atmosphere which leads to global warming There is an imperative to identify viable replacements for river sand and cement Various industrial byproducts have been used in earlier studies as sand and cement Enhancing sustainability in concrete: synergistic effects of used For the tailings concrete being studied, iron ore tailings were used together with the cement to make the new concrete The iron ore tailings were obtained from Mount Gibson Iron Extension Hill Operations in Perenjori of Western Australia (WA) The particle–size distribution curve of the original tailings as obtained is shown in Figure 1Utilisation of iron ore tailings as aggregates in concrete2023年2月25日 The use of high amounts of Portland cement insertion (75 and 150 kg / m 3) caused an alteration in the ultimate condition of the studied tailings, and M tc changed to 236 Finally, the insitu addition of Portland cement to tailings deposited behind upstream dams is an important alternative for the safe decommissioning of such structuresCementEnhancing Mechanical Behavior of Tailings Behind

.jpg)

Comprehensive Utilization of Iron Tailings in China

2018年12月19日 PDF Iron tailings are the main component of industrial solid waste, grade B06 with 60% iron tailings, 25% lime, 10% cement and 5% g yps um 33 Microcrystalline glass Iron Ore Tailings as Partial Replacement for Fine Aggregate in Concrete Production – Review Abdulaziz Alhassan 1 , Kudirat O Yusuf 2 , Adavi Aliyu Abdulazeez 3 and Salihu Usman 4Iron Ore Tailings as Partial Replacement for Fine ResearchGate2024年5月18日 Iron ore tailings used should be analyzed to have enough SiO 2 content for ensuring the attainment of strength to the GPC produced Though the addition of Iron ore tailings does not provide strength equal to the control mix, the attained strength surpasses the design mix making it usable in production of precast blocksFeasibility of Iron Ore Tailings in Geopolymer Concrete for lower, indicating a chemical reaction occurred between the iron tailings and cement paste Generally, the iron tailings sand with higher SiO 2 content and ner particles tend to have higher activity In addition, the pozzolanic activity of iron tailings powder could be greatly promoted by chemical activation, especially by acid activationEffect of Iron Tailings as Fine Aggregate and Mineral Admixture

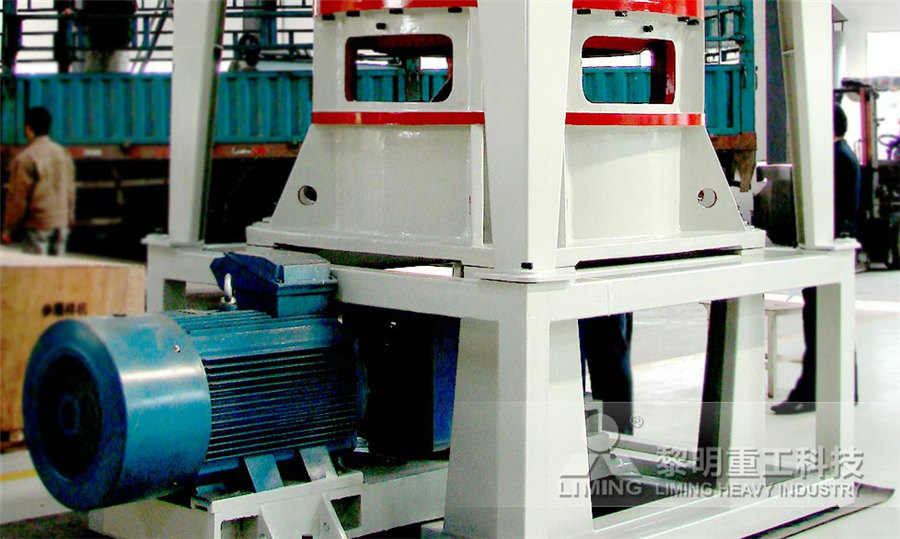

CFB石灰石脱硫剂制备64.jpg)

Basic characteristics and environmental impact of iron ore tailings

2023年5月8日 Keywords: iron ore tailings (IOTs), mineralogical characteristics, grindability, Particle size distribution, particle morphology, composite cementitious material (CCM) Citation: Wang C, Jing J, Qi Y, Zhou Y, Zhang K, Zheng Y, Zhai Y and Liu F (2023) Basic characteristics and environmental impact of iron ore tailings Front