Doubleshaft particle crusher

.jpg)

titan® DoubleShaft Hammer Crusher thyssenkrupp

Crushes materials in just one stage to the required product particle size for either vertical mills or ball mills The titan® DoubleShaft Hammer Crusher is used for crushing mediumhard rock For wet limestone, wet marl, clay, chalk, gypsum 2024年4月19日 There are two types of jaw crushers: single or double shaft In the single shaft crusher, the movement of the mobile plate occurs in a circular manner, making it more compact and with greater capacity In the double Crushers: 5 types and their main failures DynamoxThe double shaft bone crusher transforms the bones of cattle into particles suitable for heat treatment, thanks to its highly wearresistant blades Yemmak double shaft crusher makes the heat treatment process more cost effective Yemmak Double Shaft Crusher [Meta=> Site Name]A highcapacity, heavyduty, single or double shaft crusher, reduces large wet or dry materials to a freeflowing size Learn moreParticle Sizers, Industrial Shredders, and More

Double Shaft Crusher, PDWB Pallmann Industries

Production of powders with narrow particle size distributions from brittle and crystalline materials The ORIGINAL PALLMANN Horizontal Knife Mill, type PSRH, called ,Biber“, with an hydraulic TITAN® doubleshaft hammer crushers are the perfect crushers for the cement industry Typical feed materials are moist limestone, moist marl, clay, chalk, gypsum and similar raw materials doubleshaft hammer crushers ThyssenKruppDoubleshaft breakers are arranged at the outlet side of dryers, centrifuges, agitators and bag and drum emptying devices Typical applications are crushing of organic and inorganic materials in Double Shaft Crushers SolidsWikiThe double shaft bone crusher transforms the bones of cattle into particles suitable for heat treatment, thanks to its highly wearresistant blades Yemmak double shaft crusher makes the DOUBLE SHAFT CRUSHER Yemmak

.jpg)

Dynamics in double roll crushers ScienceDirect

2017年4月1日 Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably Doubletoggle jaw crushers are equipped with a doubletoggle system, which is con trolled by a pitman that moves up and down under the influence of an eccentric shaft, causing the toggle Industrial Solutions Jaw crushers ThyssenKrupp2024年11月7日 The UBC small production line uses a combination of a dualshaft shredder and a hammer crusher It can be seen that the UBC is broken into spherical particleDouble Shaft Shredder + Hammer Crusher UBC Recycling LineDouble Shaft Crushers are used in crushing of mediumhard, brittle products in all branches of industry The unit is often used as a coarse crusher for subsequent fine crushing or as a control crusher in pipes It is manly chemical industry where these units are required as a result of the wide range of productsDouble Shaft Crushers SolidsWiki

doubleshaft hammer crushers ThyssenKrupp

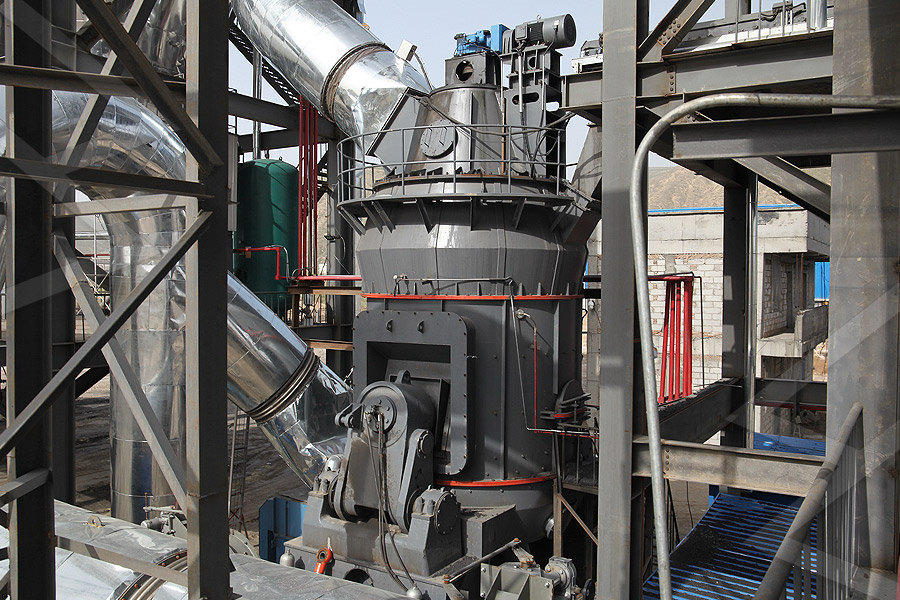

TITAN® crusher, type 80D160, with hammer axle extraction device Grate basket trolley Fiveaxle rotor for a TITAN ® crusher, type 80D160 TITAN® doubleshaft hammer crusher with grate basket carrier Pentagonal rotor shaft for a TITAN ® crusher, type 60D160 Perfect material thanks to rotating hammers 4 ®TITAN doubleshaft hammer crushers 5DOUBLE ROLL CRUSHER DR13 Features Solution for mediumhard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc) Weldon hardfaced crushing teeth with various configurations for most difficult applications Integrated flywheel equalizing torque peaks, thus reducing required motor power Permanent parallel position of crushing rolls due to hydraulic Double Roll Crusher CPC GmbH Crushing ProcessingPlastic shredder is a machine that turns used plastic bottles to smaller particle sizes to enhance portability, easiness and readiness for use into new products While in operation, Evaluation of Double Shaft Plastic Bottle Crusher for Small Scale Industrial Application Turkish Journal of Agricultural Engineering Research (TURKAGER), 4(2): Development and Performance Evaluation of Double Shaft Plastic DOVE Roll Crusher also referred to as Double Roller Crusher, or Twin Roll Crusher is highly efficient crushing machine, used in certain applications for primary, secondary and tertiary crushing applications DOVE Roller crushers are highly practical crushers for soft to mediumhard ore and where the final crushed out put is required to be of uniform grain sizes, with minimum Roll Crusher Double Roller Crusher DOVE DOVE Equipment

Single Shaft vs Double Shaft PVC Shredder Machine

2024年10月16日 The choice between a single shaft and double shaft shredder depends on the nature of the PVC material, the required particle size, and the processing volume Single shaft shredders are ideal for lighter PVC materials and precise shredding needs, while double shaft shredders excel in highcapacity, tough material processing2013年2月3日 TITAN® Double Shaft Hammer Crusher ThyssenKrupp EN English Deutsch Français Español Português Italiano Român Nederlands Latina Dansk Svenska Norsk Magyar Bahasa Indonesia Türkçe Suomi Latvian Lithuanian česk TITAN® Double Shaft Hammer Crusher ThyssenKrupp2024年2月7日 Particles in the vertical shaft impact crusher absorb and dissipate collision energy in the impact breakage The distribution of the collision energy determines the breakage rate of materials and Collision Energy Analysis within the Vertical Shaft Impact Crusher Since the doubleshaft shredder has more shredding blades and more complex shredding actions, the output particle size of the doubleshaft shredder may be more uniform and can adapt to a wider variety of materials, but the output size is larger than that of the singleshaft shredderAluminum Scrap Recycling: Single Shaft Shredder VS Double Shaft

CPC Double Roll Crusher SIEBTECHNIK TEMA

CPC Double Roll Crusher Application Coarse size reduction of hard and mediumhard material (lime stone, magnesia, salt, fertilizer, coal etc) Throughput up to 2500 mt/hr, depending on material characteristic and particle size; Feed 2023年11月1日 Feed particle size distribution has a substantial impact on DRC mass throughput The core of the test plant is a double roll crusher DRC 450x450 toothed rolls Fig 3 shows a 3D view of the crusher without the drive units and inlet hopperNew insights into double roll crushing ScienceDirect2024年8月20日 Single shaft and dual shaft shredders are two commonly used technologies, each offering distinct advantages depending on the specific requirements of the task This article explores the key differences between single shaft and dual shaft biomass shredders, focusing on aspects such as output, particle size, and operating modes 1 OutputSingle Shaft Biomass Shredder vs Dual Shaft Biomass ShredderDouble shaft crusher TGMachines have the right to change design/specification of the machine at any time TECHNICAL DATA: Meat and Bone Crusher Model Capacity raw material [ton/h] Particle after crusher [mm] Weight [kg] Power [kW] Dimensions [mm] L W H MBC08 8 : 25/30 3700 45 2900 : 1150 1800 : MBC22 22 25/30 5200 75 3900 1200 Meat and Bone Crusher TG MACHINES

(PDF) Numerical Simulation of a Single and DoubleRotor Impact Crusher

2022年1月25日 Energy spectra comparing singlerotor at 2080 rpm and doublerotor at 510 rpm, particle size 190 + 16 Particles in the vertical shaft impact crusher absorb and dissipate collision energy in Tramp can also refer to inclusions in the material feed to a machine (ie crusher) that the machine is not designed to handle For example, a large particle of hard rock would be considered tramp for a Double Roll Crusher since Double Roll Crushers are not typically designed toSampling Sizers/Roll Crushers McLanahan2024年7月17日 Vertical Shaft Impact Crusher (VSI) / Sand Making Machine The VSI, also known as a sand making machine , is used to produce highquality manufactured sand, with output capacities up to 703 t/h It is suitable for materials of various hardnesses, especially hard and abrasive materials like granite and river pebblesTypes of Crushers: Choosing the Right One for Each Stageiv List of Publications Appended papers: Paper A Simon Grunditz, Magnus Evertsson, Erik Hulthén, Magnus Bengtsson, Prediction of Collision Energy in the VSI Crusher, proceedings of European Symposium on Comminution and Classification 2015, Gothenburg, September 2015 Paper B Simon Grunditz, Magnus Evertsson, Erik Hulthén, Magnus Bengtsson, The Effect of Modeling of Vertical Shaft Impact Crushers

.jpg)

Simulation of particle flows and breakage in crushers

2015年4月30日 Request PDF Simulation of particle flows and breakage in crushers using DEM: Part 1 – Compression crushers Discrete Element Method (DEM) simulation using a breakage model is applied to study After the successful delivery and installation of an titan® doubleshaft hammer crusher to Semen Bima, the Indonesian cement producer has decided on another crusher of this series The additional crusher ensures the supply of High Grade Limestone to Crushing Technologies thyssenkrupp Polysius2016年1月16日 In the history of crushers, both chronologically, and by virtue of its standing in the field of heavyduty crushing, the Blake jaw crusher stands first in the list All of the large, heavyduty primary crushers of the jaw type are built around the Blake principle which, for simplicity and brute strength, is unsurpassed by any mechanism thus far devised for rock and Blake Jaw Crusher 911Metallurgist2024年10月10日 A double shaft shredder, also known as a twinshaft shredder, is a robust and versatile piece of equipment used in the processing and size reduction of various solid waste materials It is widely employed across multiple industries for its efficiency and ability to handle tough and bulky materialsdouble shaft shredderZchMachinery

.jpg)

Collision Energy Analysis within the Vertical Shaft

2024年2月7日 Particles in the vertical shaft impact crusher absorb and dissipate collision energy in the impact breakage The distribution of the collision energy determines the breakage rate of materials and breakage energy consumption Request PDF On May 25, 2016, Egbe EAP and others published Design, Fabrication and Testing of a Double Roll Crusher Find, read and cite all the research you need on ResearchGateDesign, Fabrication and Testing of a Double Roll Crusher2 Stoneonstone cavity type, stone material selflining (stoneoniron cavity type): The vertical shaft impact crusher has a large crushing ratio and a high sandforming rate and is suitable for material crushing and building aggregate shaping The Vertical shaft impact crusher Advanced Machinery Manufacture This type of mobile crusher plant mainly consists of jaw crusher, cone crusher, impact crusher, vibrating screen, conveyor Belt and control system It integrates the functions of a variety of crushing and screening equipment and is suitable for crushing, screening and pulverizing of raw materials of different types and hardness, such as rocks, ores, construction waste, etcWhat Is Mobile Crushing Plant AIMIX GROUP

.jpg)

What Is A Jaw Crusher MEKA

In doubletoggle jaw crushers, the pitman is mounted on fixed noneccentric shaft that situated at the top of the crusher There are two toggle plates, one on the left and one on the right, are linked to the pitman that is hinged to the driven camshaft2023年2月21日 The double toggle jaw crusher is designed for crushing hard and abrasive materials, with its unique features including a double toggle plate and a large feed opening One of the advantages of a double toggle jaw crusher is that it is capable of crushing materials with a higher compressive strength than other types of jaw crushersThe Ultimate Guide to Jaw Crushing Machines: Types More TipsVersatile – The Double Roll Crusher crushes a wide range of material types reaching compressive strengths of up to 150 MPa and higher It is less sensitive to wet and sticky material than RollSizers and can take in larger feed sizes, The ERC features an eccentric shaft positioned above the crushing chamberRoll crushers – ERC and double roll crusher – FLSOur shredders work as oneway and reversible machines, with optional controlled airflow Machines vary in speed, depending on the material being shredded and the required finished particle size High speed shredders from Williams are designed to handle any material you need to dispose of They also function as industrial crusher machinesIndustrial Shredders Equipment Williams Patent Crusher

G[R.jpg)

Which Equipment to Choose for Plasterboard and

2023年9月17日 The choice of equipment should be based on your production scale, desired particle size, budget, and specific application For smallscale operations, a hammer mill or jaw crusher may suffice, while largerscale Particle Size (mm) Feed Material Final Product for Basalt,Gravel at Moderate Speed 46m/s (9,000 FPM) Best Tertiary Impact crusher Fehmi Soner Mazlum VERTICAL SHAFT IMPACT CRUSHERS (VSI) MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONALVERTICAL SHAFT IMPACT CRUSHERS2023年12月31日 Plastic shredder is a machine that turns used plastic bottles to smaller particle sizes to enhance portability, easiness M A, Ogunlade, C B, Oluwagbayıde, S D (2023) Development and Performance Evaluation of Development and Performance Evaluation of Double China Double Shaft Crusher wholesale Select 2024 high quality Double Shaft Crusher products in best price from certified Chinese Crusher manufacturers, Mining Machinery suppliers, wholesalers and factory on MadeinChinaDouble Shaft Crusher MadeinChina

How to produce a doubleshaft shredder? WANROOETECH

2023年12月29日 Here is a general guide on how you might approach building a doubleshaft shredder: 1 Define Requirements: Clearly define the purpose and specifications of your doubleshaft shredder, including the types of materials it will handle, the desired throughput, and the particle size of the output 2 Conduct Research:2023年9月13日 Singleshaft shredder: suitable for smallscale particle board recycling, with low output and fine output, suitable for customers with fine crushing needs Doubleshaft shredder : It has higher output, wide applicability of materials, and does not have too strict requirements on the fineness of the outputParticle Board Shredder Model Selection Guide GEP ECOTECH2019年11月1日 The coefficient of restitution and rolling friction for both interparticle and particlecrusher were 05 and 005, respectively The coefficient of static friction for interparticle was 06, while the value for particlecrusher was 04 Individual metaparticle modelled in Laboratoryscale validation of a DEM model of a toothed double Shunzhi vertical shaft impact crushers ensure uniform cubic particle size and low consumption Quote low price VSI crusher now! Skip to content Menu Vertical Shaft Impact Crusher Mobile VSI Crusher Plants In Large Stock! Feeding Size: 060mm Power of double motor (KW) 2×75 (100) 2×110 (150) 2×160 (220) 2×220 (300) Overall Vertical Shaft Impact Crusher For Sale Shunzhi Machinery

(PDF) The Influence of the Structure of Double Toothed Roller Crusher

2018年11月7日 To represent the particle behaviors and to predict the product size distributions of coal breakage products by a doubleroll crusher, a new combined breakage–agglomeration model has been The double shaft aggregate crusher eliminates this type of movement and allows the material to be crushed not only by crushing but also by rubbing The result is a synchronized movement of the mobile jaw over the entire surface and consequently less and uniform jaw wearDOUBLE SHAFT CRUSHER