Principle of mining ball

Ball Milling an overview ScienceDirect Topics

Ball milling: The main principle of mechanical milling can be described as the exploitation of high energy grinding to reduce the particle size In general, the high energy ball milling route is 2019年8月14日 Ball mill is a common grinding equipment in concentrator, the main role is to provide qualified grinding products for the subsequent dressing process The ball grinding The Ultimate Guide to Ball Mills MiningpediaA ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls The working principle is simple; impact and attrition size reduction take Ball Mill an overview ScienceDirect TopicsExplore the working principle, types, parts, applications, advantages, and recent developments of ball mill grinding machines Discover how these versatile tools optimize grinding efficiency in various industriesBall Mill Grinding Machines: Working Principle, Types,

.jpg)

Ball Mill (Ball Mills Explained) saVRee saVRee

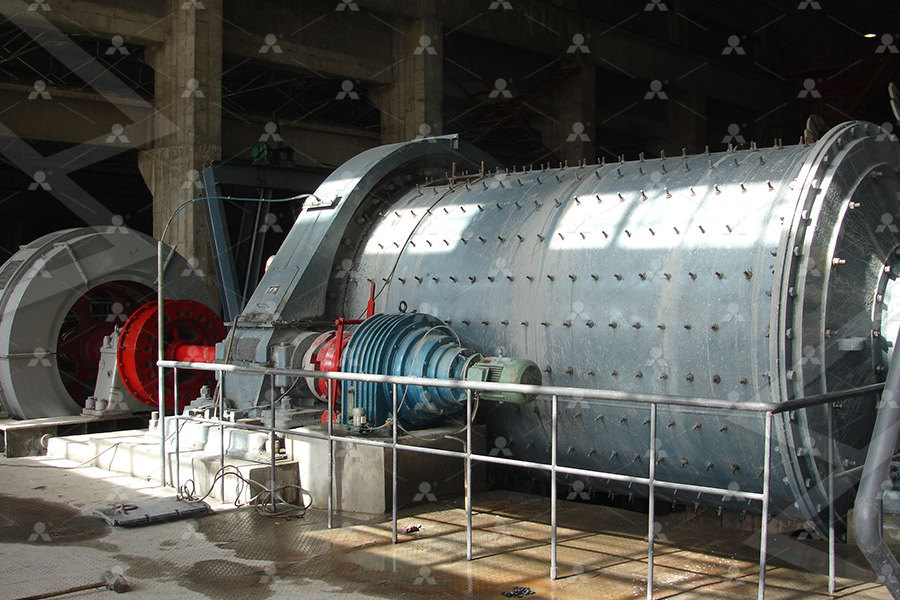

Ball Mill Introduction There are three main stages to mineral processing in the mining industry These are: Comminution (crushing and grinding) Beneficiation (separation and concentration) Smelting and refining Ball mills are employed 2023年4月30日 Ball mill is the key equipment for crushing materials after they are crushed It is widely used in cement, silicate products, new building materials, refractories, chemical Ball Mill SpringerLinkBall milling is a highenergy operation of repeated welding and fracturing of sample powders [13] It is well known as a novel synthesis technique to prepare materials in nanometer scale and Ball Milling an overview ScienceDirect TopicsExplain the role of ball mill in mineral industry and why it is extensively used Describe different types of ball mill design Describe the components of ball mill Explain their understanding of ball mill operation Explain the role of critical AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

.jpg)

Ballmilling – Nanoscience and Nanotechnology I INFLIBNET

Ball milling is an economic and facile technique to produce nanosized materials It is a topdown approach of nanoparticle synthesis which includes mechanical breakdown of large substances 2023年10月20日 Operating a ball mill requires a deep understanding of its components, principles, and operational procedures By following the guidelines provided in this comprehensive guide, operators can optimize the Comprehensive Guide on Operating a Ball MillBall Mill Principle Ball mills are a type of grinder used to grind and blend materials for use in various industries The basic principle of ball mills involves two or more grinding media, such as balls or rods, rotating in a container to Ball Mill Principle, Application, Uses, Critical Speed, 2017年2月13日 The capacities, power requirements, etc, of the various sizes of Marcy Ball Mills are given in Table 11 It should be noted that the first figure of the number of a mill represents its diameter, and the second one its length The Ball Mills 911Metallurgist

.jpg)

Ball Mill; Principle, Working, and Construction » Pharmaguddu

2022年10月17日 Ball: The ball lies in cylinders, which are made up of stainless steel, the size of the ball depends on the cylinder diameter The ball covers 30 to 50% area in the cylinder Working: Open the lid and Feed the materials into the cylinder; Introduced the fixed numbers of balls and closed the lid; Run the machine and adjust the speed as per requiredMining and Mineral Processing: Ball mills are commonly used in the preparation of ores for mineral beneficiation, as well as in the production of metals and minerals 2 Ceramics: Ball mills are essential in the production of ceramics, where fine particle size and uniform particle distribution are crucial for highquality productsBall mill principle: An explanation of operation and importance in 2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and The basic principle of a ball mill is very ancient However, the machine itself could be produced only after the industrial revolution Typically, ball mill is a grinder and is often employed blend materials by grinding/crushing them, for potential applications in mineral dressing processes, paints, pyrotechnics, ceramics as well as selective laser sinteringBallmilling – Nanoscience and Nanotechnology I INFLIBNET

.jpg)

Ball mill PPT Free Download SlideShare

2015年4月24日 Ball mill consist of a hollow cylindrical shell rotating about its axis Axis of the shell horizontal or at small angle to the horizontal It is partially filled with balls made up of Steel,Stainless steel or rubber Inner surface of the shell is lined with abrasion resistant materials such as Manganese,Steel or rubber Length of the mill is Specification of high energy ball mill: • Principle: Milling to be done using friction and repeated impact of shots and balls • Applications: Mechanical alloying, homogenization, size reduction, colloidal grinding These application are the domain of chemistry, civil engineering, recycling of wastes, metallurgy, mining, chemicals, ceramics, and oxides etcCRF Ball Milling NITKDownload scientific diagram Different types of ball milling and its working principles: (a) Planetary ball milling, (b) Tumbler ball milling, (c) Attrition ball milling, and (d) Vibration ball Different types of ball milling and its working principles: (a This manual provides a comprehensive guide to operating, maintaining, troubleshooting, and repairing ball mills Operating Principles of Ball Mill Description of How a Ball Mill Works A ball mill operates by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be groundA Comprehensive Guide to Ball Mill Manual

Exploring Ball Mill Diagram: A Comprehensive Guide

2024年4月28日 Through careful assessment of the mill’s working principles, construction, operation, and efficiency determinants, operators and engineers can make wellinformed decisions to ensure the maximum grinding efficiency and 2024年1月1日 According to the discharge methods of the ball mill, it can be divided into overflow ball mill, and discharge is through the hollow shaft Grate ball mill (Fig 3), the discharge end of the mill is set with a gratePeripheral discharge ball mill, and the products are discharged through the discharge port around the cylinderBall Mill SpringerLinkHow Ball Mill Works The working principle of a ball mill is mainly based on impact and wear During its operation, the ball mill cylinder rotates at a certain speed, and the grinding medium inside the cylinder (such as steel balls, ceramic balls, etc) rotates to a certain height under the action of centrifugal force and frictionBall Mill Working Principle Ball Mill Types MCA ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes It is a cylindrical device filled with balls, which rotate on a horizontal axis to pulverize the material The working principle of a ball mill is based on the impact and friction between the balls and the powder material 1 Ball Mill Exploring the working principle of ball mills

.jpg)

A Comprehensive Guide to SAG Mill Operation ball mills supplier

SAG mills are often used in conjunction with ball mills, but they are not the same The purpose of this article is to provide a comprehensive guide on SAG mill operation, including its components, working principle, and maintenance2019年6月20日 Want to continue learning about engineering with videos like this one? Then visit:https://coursessavree/ Want to teach/instruct with the 3D models shownHow Ball Mills Work (Engineering and Mining) YouTube2024年4月28日 A ball mill is a kind of grinder that grinds and blends materials for the purpose of mineral processing, paint production, pyrotechnics, ceramics, and selective laser sintering It works on the principle of impact and attrition: the balls are released from the top of the shell and then crush and grind the material to fine powdersWhat is a Ball Mill Explained: InDepth Guide JXSC2024年7月12日 From mining operations to pharmaceutical labs, The ball mill works on the principle of impact and attrition Size reduction occurs as the small balls drop from near the top of the shell What is the difference between a ball mill and a tumbling mill?What Is a Ball Mill and How Does It Work? Certified MTP Blog

Working Principle of Crushers 911Metallurgist

2016年2月18日 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and Batch Ball Mill: Operated in batches, suitable for smallscale production or testing Continuous Ball Mill: Designed for continuous operation, ideal for largescale production Ball Mill Working Principle The working principle of a ball mill involves several steps: 1 Material Feeding: The raw material is fed into the drum 2The Role of Ball Mill in Mexico's Mining Industry2024年6月3日 This article presents an overview of the fundamental principles underlying ball milling technology, encompassing aspects such as ball milling pretreatment, biochar pyrolysis temperature, Research progress on synthesis mechanism and performance2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral

Ball Mill an overview ScienceDirect Topics

In its simplest form, the ball mill consists of a rotating hollow cylinder, partially filled with balls, with its axis either horizontal or at a small angle to the horizontal The material to be ground may be fed in through a hollow trunnion at one end and the product leaves through a 2020年9月22日 Grinding machine has been widely used in gold mines in South Africa since 1905 At that time, the grinding machine used river pebble as the grinding medium, which was essentially a gravel mill Later, in order to improve the production capacity of the mill, cast iron balls were used as the medium, so normal gravel mills were evolved into ball mills and rod millsGrinding Machines: Types and Selection Principles MiningpediaThe efficiency of copper ball mills can be enhanced by optimizing factors such as the rotational speed, ball size, and pulp density Factors to Consider When Selecting a Copper Ball Mill: Several factors should be considered when selecting a copper ball mill for a specific mining operation: 1Copper Ball Mill: A Comprehensive Guide Bellian Mining 2019年10月17日 1 Working principle 2 Structure Let's dive right in! 1 Working Principle of Rod Mill Rod mill is a common equipment for grinding operation in mineral concentrator, which is mainly suitable for rough grinding operationThe Working Principle and Structure of Rod Mill

.jpg)

China Ball Mill Manufacturers Suppliers Factory Customized Ball

A: If a ball mill uses little or no water during grinding, it is a 'dry' mill If a ball mill uses water during grinding, it is a 'wet' mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than 2012年12月15日 2 Nano materials can be defined as those materials which have structured components with size less than 100nm at least in one dimension Nanotechnology is an advanced technology, which deals with the synthesis of nanoparticles, processing of the nano materials and their applicationsNano Ball Milling PPT Free Download SlideShare2022年3月30日 There are different types of ball mill that exists They may differ in operating principle, maximum capacity of the milling vessel, ranging from planetary ball mill, mixer mill, or vibration mill to several 100L for horizontal rolling ball mill How does Ball Mill Work? Materials used to grind include iron ore and ceramics are added to the ball Introduction to HighEnergy Ball Mill: Working Principle, Tumbling mills are machines used in mining, chemical, and construction industries to reduce the size of solid materials by using the principle of impact and attrition They consist of a rotating cylinder, which contains a charge of loose grinding mediaAs the cylinder rotates, the grinding media falls, collides, and crushes the materials inside the cylinderUnlocking the Secrets of Tumbling Mill Principle ball mills supplier

.jpg)

Ball Mill Mining Grinding Mill JXSC Machinery

Types: Mining ball mills are divided into two categories, Overflow ball mills: center discharge ball mills; Lattice type ball mills: Peripheral row ore type ball mills Batch small ball mill: control the particle size of the material by adjusting the 2017年6月2日 Heavy mining, quarried materials, sand gravel, recycling: Gyratory crushers: Soft to very hard: Abrasive: Dry to slightly wet, not sticky: 4/1 to 7/1: Ball mills use a tumbling process with stone or metal balls as the How it Works: Crushers, Grinding Mills and Pulverizers2024年11月24日 Miningpedia is a valuable and professional communication platform who focuses on providing mineral This article provides a detailed overview of the spiral classifier, its working principles, design considerations, types, applications, and its significance in mineral Rod Mill VS Ball Mill: Which is Best for Your Miningpedia Mineral Extraction, Mineral Processing, A ball mill is a crucial equipment used for grinding materials into fine powders in various industries It operates on the principles of impact and attrition, where the grinding media are balls to be fed into the mill The ball mill diagram visually represents the use and efficiency of the millThe Ultimate Guide to Understanding Ball Mill Diagrams

.jpg)

Exploring the functionality: What is a ball mill?

Applications of Ball Mills 1 Mining: Ball mills are widely used in the mining industry for the grinding and separation of ores They are essential in the preparation of ore for concentration and extraction processes 2 Ceramics: Ball mills are used in the ceramics industry for the fine grinding of clays, glazes, and other ceramic materialsPrinciples of Random Walk Download book PDF Overview Authors: Frank Spitzer 0; Frank Spitzer Department of Mathematics, Cornell University, Ithaca, USA View author publications You can also search for this author in PubMed Google Scholar Covers almost all Principles of Random Walk SpringerLinkBall mills operate on the principle of impact and attrition The drum of the mill is filled with grinding media, typically steel balls, and the ore or material to be processed Base Metal Mining: Ball mills are also essential in base metal mining, such as copper, zinc, and leadThe role and importance of ball mills in the mining industryPractical Applications: Leveraging Ball Mill Insights for Success The insights derived from understanding the ball mill working principle can be applied across various sectors—ranging from mining and cement production to manufacturing of chemicals and pharmaceuticalsHow Does Understanding The Working Principle Of A Ball Mill