Small vertical ball mill

.jpg)

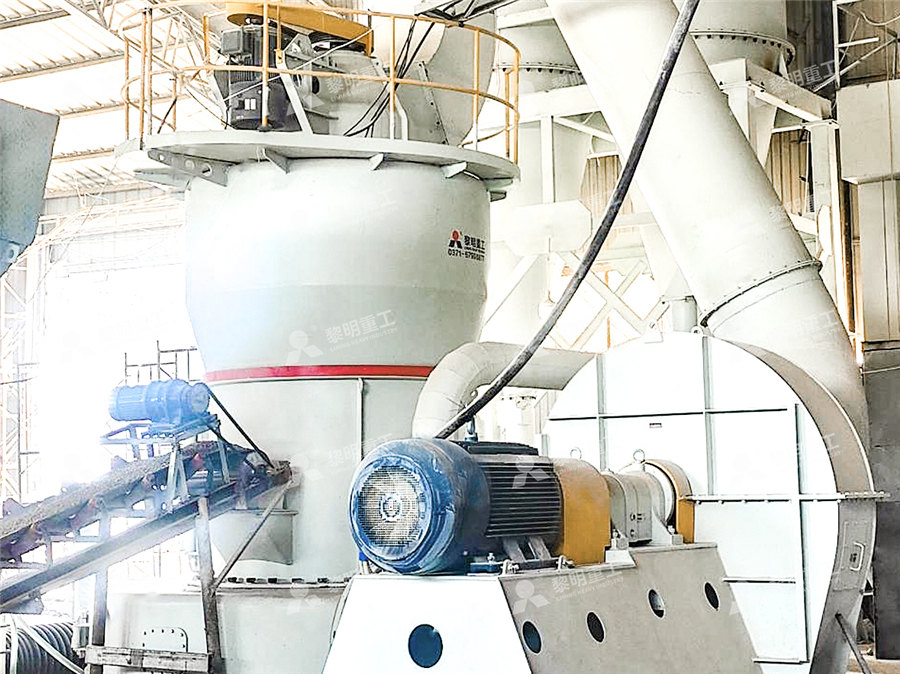

Vertical Ball Mill

The vertical ball mill has stable performance, supports dry and wet grinding, and has unique performance for coarse and thickened materials Vertical ball mill Mini vertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production Tencan planetary ball mill owns small volume, high efficiency, low Mini Planetary Ball Mill XQM04A from China Sherline vertical mini milling machines are made in the USA and feature either precisionrolled ball screws or leadscrews, and handwheels graduated in thousandths of an inch (001") or hundredths of a millimeter (01 mm)Sherline Vertical Milling MachinesThe small vertical Ball mill features a unique vertical structure with the ball mill cylinders arranged in the vertical direction This design allows for a more uniform distribution of grinding media Small vertical Ball mill NBCHAO

.jpg)

Mini Mills Haas Automation Inc

Haas Mini Mills are the industry standard for compact machining centers They are perfect for schools, startup shops, or as a first step into CNC machining Loaded with fullsize features, they are valuable additions for shops needing a Vertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production Tencan planetary ball mill owns small volume, high efficiency, low planetary ball mill, buy ball mill, laboratory ball millingVertical planetary ball mills offer several advantages over traditional horizontal ball mills, including higher energy input, better mixing and grinding efficiency, and the ability to process smaller sample sizesVertical Planetary Ball MillThe OTMT 0T2213 mini mill is a small, compact benchtop milling machine with 1/2 HP and a 35” x 15” work table This benchtop milling machine has some great features that make it a useful addition to your workspace For example, 10 Best Benchtop Milling Machines 2024 (All Prices)

.jpg)

Planetary Ball Mill PM 100 RETSCH highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg Wet grinding is used to obtain particle sizes below 5 µm, as Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD institution, university, enterprises laboratory to get samples ( you can get four samples from each planetary ball mill, buy ball mill, laboratory ball millingFeatures of 4L (4 x 1L) Vertical High Energy Planetary Ball Mill with Touchscreen Controller Touchscreen controller for easy operation and problem fixing Special gear design for low noise and vibration Stable rotation speed Programmable milling Planetary Ball Mills MSE Supplies LLC2022年6月24日 Ball mills and vertical roller mills are common mining machinery that can grind ore into powder and are used in all walks of life there is no direct metal contact with each other during the operation of the vertical grinding mill, the metal wear is small, and the pollution to the finished material is smallHow to choose between ball mill and vertical roller mill?

Vertical roller mills FLSmidth Cement

Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceB Vertical Ball Mills Small vertical ball mills are about the size of a blender and are intended for laboratory or shop use They are small enough to fit on a lab table or workbench and only big enough to process the small quantities need for desktop applications Design and Analysis of Ball Mill For Paint Industries IJSRDVertimill® requires a simple and small foundation, which means less floor space is required In fact, in the same application a Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, Vertimill® MetsoMSE PRO Bench Top Mini High Energy Vertical Planetary Ball Mill, 04L Size (4 x 100ml or 4 x 50 ml) Designed for holding four 50 ml size milling jars or 100 ml milling size jars (to be ordered separately) Can be placed in a glove box Should not be used in an Argon atmosphere as it can cause arcing due to a 110V voltage power supply to this equipmentPlanetary Ball Mills MSE Supplies LLC

How does Vertical Roller Mill Work? ball mills supplier

Vertical roller mills (VRM) have become increasingly popular in recent years, as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localized rises in cement demand The demand for cement has grown rapidly in recent years, creating a need for a more efficient way to grind clinker and other raw materials used in Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball millsA ball mill is a crucial piece of machinery used in grinding and mixing materials in various industries It works by rotating a cylinder with steel or ceramic balls, causing the balls to fall back into the cylinder and onto the material to be groundA Comprehensive Guide to Ball Mill ManualVertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD institution, Vertical Laboratory Planetary Ball Mill Korea Process Technology

Ball Mills Suitable for every application Retsch

Ball mills are tools for reduction of hard, brittle or fibrous materials vast range variable effective world leading manufacturer Learn more Figure 2: Examples of different jar and ball sizes used in laboratory ball mills: small metal cups of 2 ml capacity used in Retsch mixer mills;Vertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production Xiangyi planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD institution, university, enterprises laboratory to get samples (each experiment can get Vertical Laboratory Planetary Ball Mill (Semicircle Model)Comparison of Ball Mills and Vertical Roller Mills The choice between ball mills and vertical roller mills depends on several factors, including the particle size distribution of the coal material, the coal hardness, and the moisture contentWhat is a Coal Grinding MillThere are small vertical planetary ball mills for lab use,04L,2L,4L,6L, 8L, 12L etc and big type for production, 20L, 40L, 60L, 80L,100L A vertical planetary ball mill is a specialized milling machine used for grinding and mixing various materials in research laboratories and industrial settingsVertical Planetary Ball Mill

.jpg)

Vertical Planetary Ball Mill (Semicircle Type) BIOBASE

Application: Planetary Ball Mill has four ball grinding tanks installed on one turntable When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder Various kinds of different materials can be ground by the mill with dry or wet method The cement industry has long been a major consumer of energy, contributing to approximately 5% of global CO2 emissions In order to address this issue, the industry has been exploring new technologies and innovations to improve energy efficiency, reduce emissions, and lower production costsVertical Roller Mill in Cement Plant ball mills supplierThe 5000series tabletop mills come with two standard 15/8″ (41 mm) laser engraved aluminum handwheels and one 25″ (65 mm) handwheel, while the 5500, 5400, 2000, and 5800series mills come with deluxe adjustable zero handwheels 5400, 2000, and 5800 mills include a 1/4” drill chuck 5400series tabletop mills also include a #1291 headstock spacer blockSherline Vertical Milling MachinesThe small grinding chamber volume (4 to 6 times smaller than other ball mills) enables a fast cleaning Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and Nova S Ball Mill Bühler Group

Ball Mill Hosokawa

Ball mill for dry hard comminution, especially in the finest range below 10 µm, in circulation with ALPINE fine classifier Storage of the grinding drum in watercooled, oillubricated neck bearings Grinding drum lined with hard metal armor Small scale ball mills are a costeffective solution for material processing in various industriesHow to choose the right one for your business, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for grinding in a variety of industries and materials ContactCostEffective Solution for Small Scale Ball Mill Material ProcessingVertical mill Vertimill® 7000 roller mineral wool for metals Lower capital cost Vertimill® requires a simple and small foundation, which means less floor space is required In fact, in the same application a Vertimill® has 50% less footprint than a ball millVertical mill Vertimill® 7000 Metso Corporation DirectIndustryVertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD institutionVertical Planetary Ball Mill (Square Type) from China

Ball Mill an overview ScienceDirect Topics

In its simplest form, the ball mill consists of a rotating hollow cylinder, partially filled with balls, with its axis either horizontal or at a small angle to the horizontal The material to be ground may be fed in through a hollow trunnion at one end and the product leaves through a Vertical Laboratory Planetary Ball Mill Feature: Stable revolving speed of the gear transmission ensures the consistency and repeatability of the experiment Planetary movement principle is adopted in the machine, which has high speed, large energy, high efficiency, small GranularityVertical Laboratory Planetary Ball Mill, Semicircle ModelJM series vertical stirred ball mills is a kind of high efficiency ultrafine ore grinding equipment (also called tower mill or vertical spiral stirred ball mill), mainly adopted for the ultrafine grinding test research, also for the small scale industry grinding production, to provide reliable technical parameters for industrial productionVertical Stirred Ball Mills – ZJH minerals2023年1月19日 The CNC mill will certainly become a fixture in your shop Our CNC Mill Recommendations First and foremost, we would just like to add that this recommendation is strictly based on our reviews and may not be your preference Second, we will break these down into two categories Those being Desktop CNC Mill and Small CNC Mill The Best Desktop CNC Mill for a Small Shop Top 10 BudgetFriendly Options

.jpg)

Benchtop Ball Mill LBBMA21 Ball Mill Lab Labtron

Benchtop Ball Mill LBBMA21 features a 15L drum capacity for versatile sample milling, Vertical Planetary Ball Mill LPBMA10 COMPARE and businesses for a variety of purposes and is built to handle small to mediumsized batches of materials 4CLS Attritors – Stirred Vertical Ball Mill Lime Slaker The patented CLS Attritor Stirred Vertical Ball Mill Lime Slaker operates in continuous processing mode and has been used successfully in power generating plants for flue gas Vertical Ball Mill Vertical Media Mill Union ProcessBy choosing to use a miniature ball mill for smallscale grinding tasks, you can enjoy the benefits of precision grinding, versatility, costeffectiveness, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for grinding in The Benefits of Miniature Ball Mills for SmallScale GrindingVertical Ball Mill Slakers Carmeuse Systems has partnered with Metso to integrate the VERTIMILL® vertical ball mill slaker into our complete system package Eliminate Grit Disposal Problems When lime or water quality is poor Verticall Ball Mill Slaker Carmeuse Systems

.jpg)

Vertical Roller Mill for Sale AGICO Cement Plant

AGICO vertical roller mills can be used as cement mills, raw mills, and slag mills AGICO also supplies vertical roller mill components and parts, we can customize machines according to customers’ needs Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish []The Planetary Ball mills, the Mixer Mills MM 500 nano and MM 500 control, as well as the High Energy Ball Mill Emax, offer greater versatility compared to Bead Mills All these mills are suitable for both dry and wet grinding Unlike bead mills, RETSCH ball mills can also process larger sample pieces using larger grinding ballsBead Mills for ultrafine grinding RETSCHCement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich experience in the designing and Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill If you’re in the market for a ball mill, you’re likely looking for a reliable and highquality machine that can handle a wide range of materials and processesBall mills are used for grinding and mixing materials, and they can be found in a variety of industries, from mining and construction to pharmaceuticals and ceramicsA Comprehensive Guide to Finding the Best Ball Mill for Sale

.jpg)

What is a Miniature Ball Mill and How does It Work?

The miniature ball mill is a smallsized mill that is used to grind various materials It is widely used in the laboratory and smallscale production because of its low cost, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for grinding in a variety of industries and materials ContactVertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD institutionSemicircle Round Vertical Planetary Ball Mill