Parameters of trm4541 vertical mill

TRM SERIES CEMENT VERTICAL ROLLER MILLTRM SERIES CEMENT

The followings are the main characteristics of TRM series Raw Vertical Roller Mill in aspect of structure, operation and maintenance To be of horizontal and inclined grinding table In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The identification and (PDF) Operational parameters affecting the vertical roller mill 2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Design parameters of vertical roller mill Table diameter (m) 46 (PDF) Performance Evaluation of Vertical Roller Mill

Calculating breakage parameters of a batch vertical stirred mill

2017年9月1日 Calculating breakage parameters of a batch vertical stirred mill Author links open overlay panel Maruf Hasan, Sam Palaniandy, Marko Hilden The general shape of vertical stirred mill breakage function is shown in Fig 12 where the model based simulated breakage function is compared with the standard breakage function to 2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills Loesche GmbH “Operational parameters affecting the vertical roller mill performance”, 2016 Google Scholar [13] India Brand Equity Foundation report “Cement Industry in India 2020”,2020Review on vertical roller mill in cement industry its DOI: 101016/japt2023 Corpus ID: ; Operation parameters multiobjective optimization method of large vertical mill based on CFDDPM @article{Huang2023OperationPM, title={Operation parameters multiobjective optimization method of large vertical mill based on CFDDPM}, author={Rongjie Huang and Yao Ma and Hao Li and Chunya Sun and Jun Liu and Operation parameters multiobjective optimization method of Operational parameters affecting the vertical roller mill performance (PDF) Operational parameters affecting the vertical roller mill performance Namik Aydogan Academia Academia no longer supports Internet Explorer(PDF) Operational parameters affecting the vertical roller mill

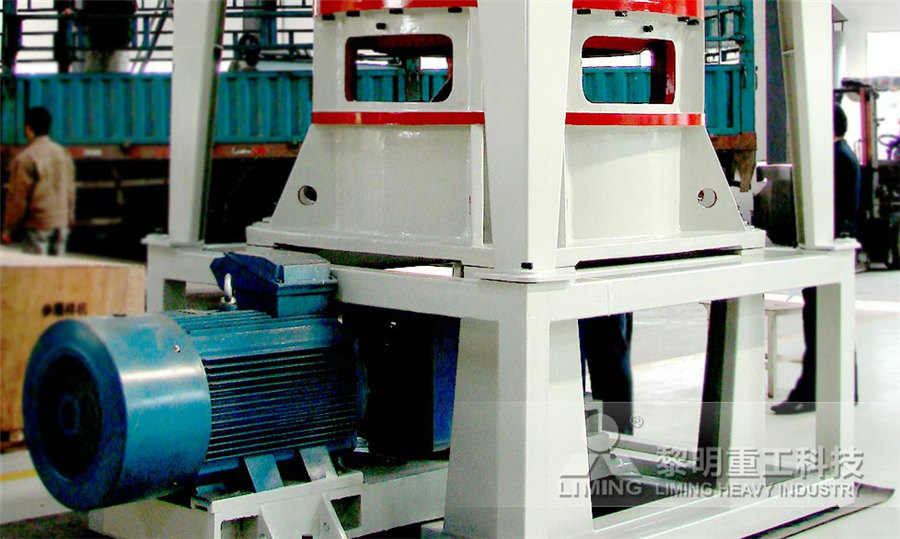

.jpg)

Parameters for the Grinding Process in Vertical Mills Using

2024年1月17日 VRM construction, its process and parameters which affects the performance and productivity of vertical roller mill are discussed Also the consequences of variations in parameter explainedbe used, which are: a ball mill or a VRM vertical roller mill The ball mill makes use of grinding bodies and they have been the main tool for more than 100 years, although they have a low efficiency, while the vertical mills are much more modern tools that are capable of saving between 45 to 70% of the power consumed [4]Parameters for the Grinding Process in Vertical Mills Using this investigation were Aluminum alloy 6082 and Cemented carbide end mill of 12mm diameter and 30° helix angle was used They concluded that The Regression Milon D Selvam al et(2012) had optimized the process parameters levels on Vertical CNC Milling for face milling operation using mild steel material They have planned experiments OPTIMIZATION OF MILLING PROCESS PARAMETERS A REVIEW2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics The capacity of the VRM depends not only on the grinding material properties but also on the operational parameters of the VRM This study investigatedNumerical Investigation of Vertical Roller Mill Operation Using

Operational parameters affecting the vertical roller mill

2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance model2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and 2023年1月1日 This work includes the calibration of DEM parameters to simulate a planetary ball mill using EDEM Altair 20212 software, (PRM) for modelling grain breakage in a vertical rice millEffect of Milling Parameters on DEM Modeling of a This work named “Investigation of Effect of Operational Parameters on Vertical Roller Mill Performance” by HULUSI KONURAY DEMİR has been approved as a thesis for the Degree of MASTER OF SCIENCE IN MINING ENGINEERING by below mentioned Examining Committee Members Prof Dr Ali İhsan AROLINVESTIGATION OF EFFECT OF OPERATIONAL PARAMETERS ON VERTICAL

PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED

2021年6月17日 Abstract The authors analyze the influence of the semiautogenous (SAG) mill parameters on the mill grinding efficiency, energy consumption and the tangential cumulative contact energy This paper provides a new liner parameter design and optimization method, which offers theoretical guidance for the optimization design of liner parameters2017年4月1日 DOI: 101016/JMINENG201608015 Corpus ID: ; Operational parameters affecting the vertical roller mill performance @article{Altun2017OperationalPA, title={Operational parameters affecting the vertical roller mill performance}, author={Deniz Altun and Hakan Benzer and Namık A Aydogan and Carsten Gerold}, journal={Minerals Operational parameters affecting the vertical roller mill DOI: 101016/JMINENG201706024 Corpus ID: ; Calculating breakage parameters of a batch vertical stirred mill @article{Hasan2017CalculatingBP, title={Calculating breakage parameters of a batch vertical stirred mill}, author={Maruf Hasan and Samayamutthirian Palaniandy and Marko Hilden and Malcolm S Powell}, journal={Minerals Engineering}, Calculating breakage parameters of a batch vertical stirred mill2021年1月6日 Download Citation Review on vertical roller mill in cement industry its performance parameters India is the world's second largest producer of cement and produces more than 8 per cent of Review on vertical roller mill in cement industry its

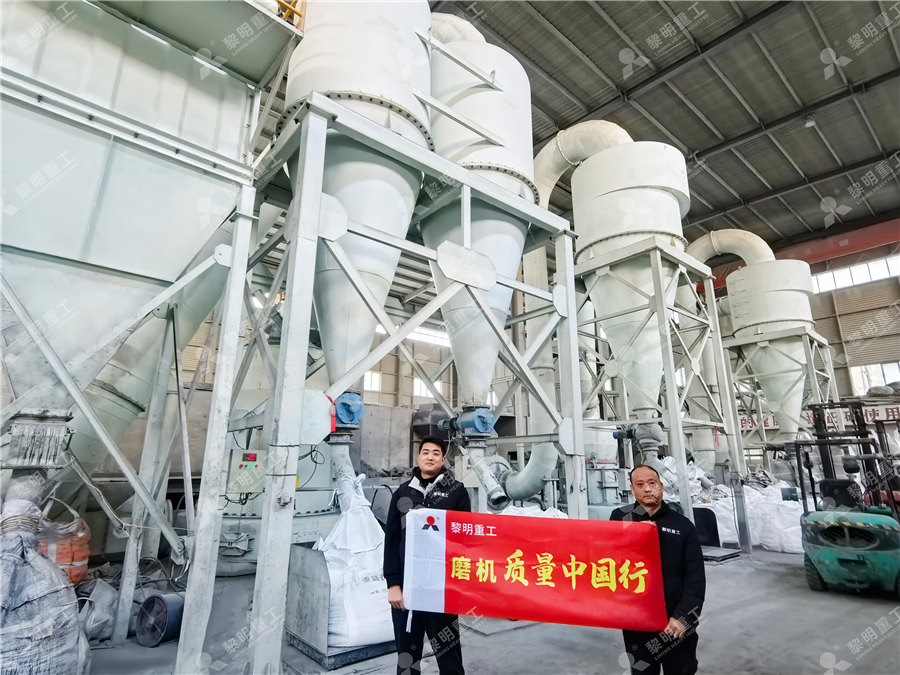

.jpg)

Effects of Blade Parameters on the Flow Field and Classification

2020年11月4日 Effects of Blade Parameters on the Flow Field and Classification Performance of the Vertical Roller Mill via Numerical Investigations November 2020 Mathematical Problems in Engineering 2020(4):1年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on the energy Analysis and Optimization of Grinding Performance of Vertical 2021年1月29日 design parameters It was a Vertical Roller Mill is designed for rated capacity 215 TPH but its output was very low so specific power consumption was higher and contributing to loss in terms of Increase productivity of vertical roller mill using seven 2015年3月15日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projectsVertical Agitated Media Mill scaleup and simulation

Effect of operating parameters on fine particle

2017年1月10日 This paper evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different 2022年5月31日 Analysis of vertical roller mill performance with changes in material properties and operating conditions using DEM Author links open overlay panel Chang Liu a, Operational parameters affecting the vertical grinding roller millstone performance Miner Eng, 103 (2017), pp 6771 View PDF View article View in Scopus Google ScholarAnalysis of vertical roller mill performance with changes in 1 Introduction The vertical roller mill (VRM) is heavy mechanical equipment that used in the cement materials industry to process cement, slag, and coal cinder (Pani Mohanta, Citation 2015)The equipment always needs to work in the environment of heavy load, high temperature, high pressure, high corrosiveness, electromagnetic radiation interference, and multifield Full article: Reliability assessment of the vertical roller mill based 2017年9月1日 Request PDF Calculating breakage parameters of a batch vertical stirred mill The paper discusses the outcome of a series of test work carried out in a screw type batch vertical stirred mill to Calculating breakage parameters of a batch vertical stirred mill

.jpg)

(PDF) Optimization of Operation Parameters of a Vertical

2016年7月1日 In this study optimum operation parameters of a newly developed sterilizer of the medium‐scale oil palm processing mill were investigated for maximum oil yieldDownload scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller Technical specifications of vertical roller coal mill2020年11月4日 1 Introduction The vertical roller mill, integrating various processes including crushing, grinding, drying, conveying, and powder selection [1, 2], is broadly employed in many fields like cement, electric power, metallurgy, chemical, and nonmetallic ore industriesHowever the vertical roller mill, as a common choice due to its multiple functions, always consumes Effects of Blade Parameters on the Flow Field and Classification dem simulation and analysis of operating parameters on grinding performance of a vertical stirred mill by yu hou ba, university of science and technology beijing, 2011 a thesis submitted in partial fulfillment of the requirements for the degree of master of applied science in the faculty of graduate and postdoctoral studies (mining engineering)DEM SIMULATION AND ANALYSIS OF OPERATING PARAMETERS

OPTIMIZATION OF OPERATION PARAMETERS OF A VERTICAL

OPTIMIZATION OF OPERATION PARAMETERS OF A VERTICAL STERILIZER OF MEDIUMSCALE OIL PALM MILL USING TAGUCHI METHOD T AFOLABI MORAKINYO1,3 and A ISAAC BAMGBOYE2 1Department of Food Science and 2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Modeling and Parameter Identification of Coal Mill2014年5月1日 The estimated parameters of the Austin selection function for a particular ball size (317 mm) Vertical roller mill (VRM) is a largescale grinding equipment, (PDF) Matrix Model Simulation of a Vertical Roller Mill 2020年9月1日 The present work analyzes the effect of several design and operating variables on the breakage rates of a pilotscale batch vertical stirred mill estimated on the basis of a mechanistic mill model Mechanistic modeling and simulation of a batch vertical stirred mill

Performance Evaluation of Vertical Roller Mill in Cement

Design parameters of vertical roller mill Table diameter (m) 46 Table speed (rpm) 2421 Number of master and slave rollers 2 M+ 2 S Max working press (bar) (Mroller) 年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 16(PDF) Performance Comparison of the Vertical and ResearchGate2024年11月15日 In order to improve the crushing efficiency of highpressure roller mill and reduce energy consumption, the optimal parameter combination of highpressure roller mill is sought, GM160140 high Optimization of working parameters of highpressure roller mill 2018 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are givenCEMENT RAW MATERIAL GRINDING ; VERTICAL ROLLER MILL OPERATION PARAMETERS

.jpg)

Important operation parameters in Vertical mill

Important operation parameters in Vertical mill TO DOWNLOAD THE EXCEL SHEET AND ALL THE OTHER USEFUL BOOKS AND RESOURCES KINDLY CLICK HERE Feed rate to mill, production rate [t/h] Mill differential pressure [mbar] Grinding bed thickness with span [mm] Amount of external material recirculation [t/h, or BE current A] Gas flow through mill [act 2024年7月29日 Setting your CNC machining parameters ensures the utmost perfection of your It is a crucial parameter in CNC machining, especially for operations involving drilling or vertical cutting The plunge rate is usually measured in inches Shape of the Cutting Edges of the Mill Bit: Different shapes, such as flat, ballnose CNC Machining Parameters: 11 Types, Setup and Adjustment