New dry process cement raw meal roller mill

From Virtual to Reality KHD Humboldt Wedag

The new dry process cement production line, Pervomaysky, was erected next to Novorossiysk in the southern region of Russia, achieving compliance with European and international 2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, Review on vertical roller mill in cement industry its performance 2010年11月1日 The new MVR vertical roller mill for grinding cement raw material, cement and granulated blast furnace slag has a modular design, which enables operation to be continued The new pfeiffer MVRR vertical roller mill for producing raw meal2023年3月1日 This work aims to develop a soft sensor for raw meal fineness in a vertical roller mill of a cement plant In previous research, some key indicators of the process were ignored Efficient machine learning model to predict fineness, in a vertical

.jpg)

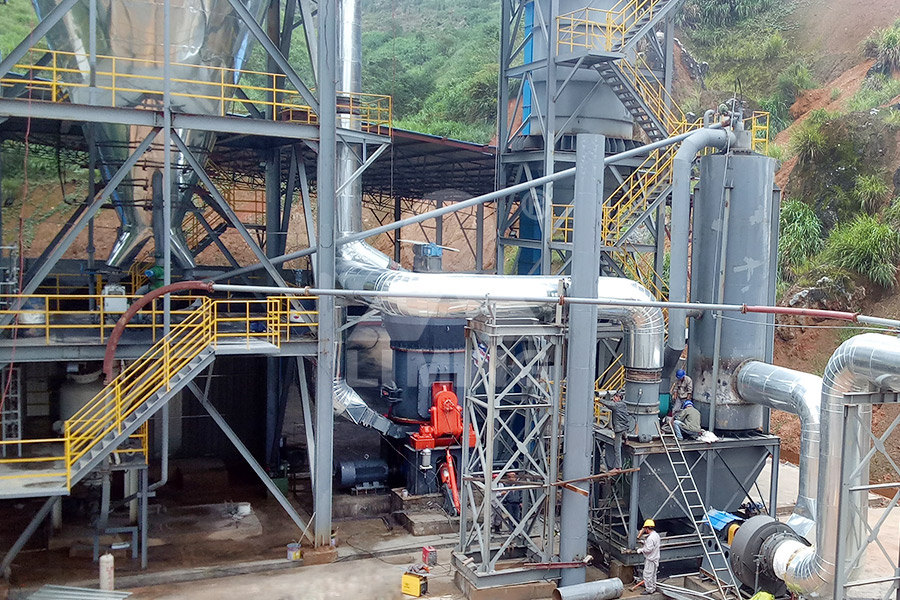

QUADROPOL® roller mill

The QUADROPOL® roller mill integrates three work operations into a single unit: drying, grinding and separating The ground material spills over the grinding table rim and is entrained by the 2015年1月1日 Vertical cement mill (vertical mill) is a machine that plays an important role in the raw meal production process of the newtype dry cement, and it is a set breakage, drying, Modeling Based on the Extreme Learning Machine for Raw 2014年4月1日 The newly developed modular roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to (PDF) The latest innovative technology for vertical roller mills Vertical roller mills have been used successfully for the combined drying and grinding of cement raw material, coal, cement clinker, blastfurnace slag and composite cements for manyGrinding Process Optimization Featuring Case Studies and

.jpg)

ModelFree Adaptive Controller Design Based on DataDriven ILC

Based on the analysis of the process of cement raw meal vertical milling system, this paper points out the key control output in the process, the mill vibration, and designs a controller to control it 2015年4月1日 Production capacity of a fully airswept industrial scale twocompartment KHD Humboldt Wedag® cement ball mill was optimized with the aid of simulation It was proposed Optimization of a fully airswept dry grinding cement raw meal 2016年10月5日 Vertical roller mills are developed to work as airswept grinding mills Roller mills are operated with throughput capacities of more than 300 t/h of cement raw mix (Loesche mill, Polysius® double roller mill, Pfeiffer® MPS EnergyEfficient Technologies in Cement Grinding2021年1月1日 The wet process requires 028 tons of coal and 110 kWh to produce one ton of cement, while the dry process requires only 018 tons of coal and Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units Review on vertical roller mill in cement industry its

Cement Raw Mill in Cement Plant for Cement Raw

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process Raw mill is mainly used for grinding cement raw meal in the cement factory Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical raw mill Cement PlantOptimization of a Fully Airswept Dry Grinding Cement Raw Meal Ball Mill Closed Circuit Capacity With the Aid Free download as PDF File (pdf), Text File (txt) or read online for free This document discusses optimizing the production capacity of a fully airswept industrial scale twocompartment cement ball mill through simulation The mill has two compartments, with the first Optimization of A Fully AirSwept Dry Grinding Cement Raw Meal The 2500t / d cement clinker production line adopts a new dry process, with an annual output of 775,000 tons of cement clinker and a total cement output of 105 million tons / year Tel:+86513 Email: 2500TPD new type dry process cement clinker production line

.jpg)

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Part Three: Raw Mill Process of Raw Mill The proportioned raw material is feed first to a grinding mill In the mill, particles ground in to very fine sizes In the grinding unit, drying, grinding and mixing takes place simultaneously Hot gas from clinker burning unit is passed into the grinding unit to assist the drying and grinding processThis paper introduces the large raw material roller press finish grinding system developed by Tianjin Cement Industry Design Research Institute Ltd, which adopts newly developed equipment and process technology, such as the large raw meal roller press, new combined separator, lowresistance and highefficiency cyclone, highefficiency fan, and intelligent Industrial application of large raw material roller press finishCement Ball Mills Manufactured By AGICO Cement ball mill: the cement ball mill grinding system produced by AGICO merges drying, grinding, classifying into a single It can both grind the raw material and finished cement product in the cement plant, has the advantages of strong adaptability to materials, continuous production, large crushing ratio, easy to adjust the speed, Dry Process Of Cement Manufacturing Dry Cement AGICO2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality How Does a Raw Mill Work in a Cement Industry

.jpg)

Vertical Cement Mill, Vertical Roller Mill Buy

AGICO Cement provides vertical cement mill, vertical roller mill used for cement manufacturing, powerful grinding and homogenization, customdesign cement mill, onschedule delivery Skip to content +86 For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our Vertical roller mills FLSmidth CementAbstract: Based on the analysis of the process of cement raw meal vertical milling system, this paper points out the key control output in the process, the mill vibration, and designs a controller to control it by iterative learning and modelfree adaptive control methods Firstly, the PPD state observer is designed for dynamic linearization, and the controller design is based on the MFAC ModelFree Adaptive Controller Design Based on DataDriven ILC Cement Cement Mill; Vertical Roller Mill; Cement Mill Separator; Steel Balls for Ball Mill; Others Menu Toggle Highquality rotary dryers for cement raw meal drying and the drying of other bulk materials In the new dry process of cement manufacturing, the raw meal must be preheated in the preheater before entering the rotary kiln for calciningCement Manufacturing Equipment for Sale AGICO Cement

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsGRMK3041 Vertical Cement Mill : 1000 t/d : GRMR2231 Vertical Raw Mill : GRMC1231 Vertical Coal Mill : Φ33×52m Rotary Kiln : Φ26×13m Cement Mill : 1500 t/d : GRMR3031 Vertical Raw Mill : GRMC1621 Vertical Coal Mill Φ35×54m Rotary Kiln : Φ35×13m Cement Mill : 2500 t/d : GRMR3841 Vertical Raw MillCement Production Line2022年1月23日 Among these devices, VRM plays an important role in cement, accounting for more than 55% of China’s cement raw meal market , and its performance directly affects the cost of producing cement VRM has the functions of grinding and powder selection, including a grinding unit and an air classifier, and can be divided into two categories, one airswept and Analysis and Optimization of Grinding Performance of Vertical Roller A cement roller press is also referred to as a roller press cement mill, or cement roller press machine TRP220160 roller press is the largest roller press in raw meal and cement grinding system in China: (New Type Dry Process) cement production lines SolutionsRoller Press In Cement Plant Roller Press Cement Mill CNBM

From Virtual to Reality KHD Humboldt Wedag

The new dry process cement production line, Pervomaysky, was erected next to Novorossiysk designed for 800 tph z A raw material grinding system with a vertical roller mill (VRM), designed for 550 tph z A pyroprocessing line, with a daily production rate of 6000 tpd, consisting of the following raw meal quality control systemTable 1 Energy Efficiency Measures and Technologies for the Cement Industry Raw Materials Preparation All Kilns Efficient transport systems (dry process) Improved refractories Raw meal blending systems (dry process) Kiln shell heat loss reduction Process control vertical mill (dry process) Highefficiency roller mills (dry process)Energy Efficiency Improvement Opportunities for the Cement Biege, Neal W, and Bartholomew, Leslie, “Low cost, low power, high efficiency raw meal blending and silo withdrawal,” International Cement Review, April 1998, pages 8690 Birch, Erik, and Keefe, Brian P, “Experience with the OK roller Everything you need to know about cement Materials 2022年5月9日 Lin, X Liang, J Modeling based on the extreme learning machine for raw cement mill grinding process in Proceedings of the 2015 Chinese Intelligent Automation Conference 129–138 (2015)Modeling of energy consumption factors for an industrial cement

.jpg)

New Type Dry Process Cement Production Line

2016年9月28日 Since the raw meal grinding work takes up more than 30% labor force in the whole dry process cement production line, it is quite important to choose appropriate grinding equipment and technological process so that high 2023年3月1日 β [1 − α; p 2; n − p − 1 2] = (1–α) th quantile of β [p 2; n − p − 1 2] distribution For α = 005, the number of outliers is 44 among 280 data corresponding to an upper limit control U C L M a h a l a n o b i s = 455 as illustrated in Fig 3The results of these outliers have been carefully analyzed by a process expert from the cement plant Indeed, if an outlier carrying Efficient machine learning model to predict fineness, in a vertical raw In the new dry process of Portland cement production, the raw material must be homogenized before it can stably enter the kiln Our homogenization equipment uses the funnel effect generated by gravity to make the raw material powders cut as many raw material layers as possible while falling down, so they can be fully mixedPortland Cement Plant for Sale New Dry Process of Portland Cement New Type Dry Process Cement Production Line Slag final grinding and raw meal final grinding system Slag combined grinding system Pengfei high pressure roller mill Cement combined grinding system PFG170100 high voltage roller press PFG12045 Roller pressJiangsu Pengfei Group Co,Ltd

.jpg)

Everything you need to know about clinker/cement Grinding

Max hot gas temperature 450°C for roller and 350°C for ball mill trunnion bearing 4 stage preheater systems are generally able to dry raw meal up to 8% moisture 5 stage 65%, Mill type: cement mill, dry process raw mill, wet process raw mill Diaphragm location:2020年11月25日 Cement equipment list This is a dry process cement plant customized by a client from Shenyang, Liaoning province To meet the cement production requirement, the cement production line is equipped with raw mill, cement mill, cement dryer, cement rotary kiln, MBS rod mill, cement packing machine, belt conveyor and other related cement equipment5000tpd Dry Process Cement Plant Project In LiaoningVertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMA2019年8月26日 The new dryprocess cement production line technology was developed in the 1950s So far, cement production Each production – ton of clinker requires about 13 tons of limestone, and more than 80% of the raw meal is limestone 2 and is crushed by the grinding roller under the action of the centrifugal force, New dry process cement production line process LCDRI CN

.jpg)

Cement Mill for Sale Buy Cement Ball Mill Vertical

Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish cement mills since their history in cement production is no more than 20 years, but So the vertical raw mill particularly suitable for the grinding of cement raw meal in cement factory The vertical raw mill in cement industry has been applied in the field of medicine and food because of its high grinding efficiency, can dry up to Vertical Raw Mill for Cement Raw Meal Grinding in Cyclone preheaters are also called suspension preheaters In the new dry process of cement manufacturing, the raw meal must be preheated in the preheater before entering the rotary kiln for calciningThe quality of the Cement Plant Cyclone PreheaterIn the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40% Therefore, the ball mill should have a drying function besides grindingCoal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

.jpg)

Cement Manufacturing Equipment for Sale AGICO Cement

Cement Ball Mill; Vertical Roller Mill; Cement Mill Separator; Cement Mill; Others Menu Toggle Conveying System; Highquality rotary dryers for cement raw meal drying and the drying of other bulk Cyclone Preheater In the new dry process of cement manufacturing, the raw meal must be preheated in the preheater before entering the rotary 2015年3月21日 Vertical grinding mill is the main grinding equipment for the newtype dry cement raw meal production, raw material grinding process in cement industries accounts for approximately 50–60 % of Modeling Based on the Extreme Learning Machine for Raw Cement Mill The cyclone preheating system Phase IV: Calcination The calcination is the core phase of the cement making dry process The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinkerHow Is Cement Produced in Cement Plants Cement Making ProcessOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOK™ Raw and Cement Mill

.jpg)

The new pfeiffer MVRR vertical roller mill for producing raw meal

2010年11月1日 The trend in the cement industry is towards ever increasing kiln capacities that have now reached clinker outputs of up to 12000 t/d This requires mills that are capable of producing raw meal at In the past 40 years, the international cement industry has made remarkable progress in technology, which is embodied in the development of new dry process cement production technologyThe new dry process cement production technology has attracted the attention of the whole industry because of its high yield, high quality and low consumptionNew dry process cement production technology homogenization of raw