MMD7061150 ore mill

.jpg)

Grinding mills for mining and minerals processing Metso

Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchasesOre mill, Ore grinding mill All industrial manufacturersThe dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant Mills for minerals and ores LoescheMt Baker Mining and Metals is focused on providing a costeffective and durable ore processing plant that includes a jaw crusher, hammer mill, size classification equipment, and sluice/shaker Ore Milling Mt Baker Mining and Metals

SAG milling grinding pilot plants alsglobal

Integrated with a classification tower and feed/discharge conveyor system, the mill can be setup to facilitate open circuit, single stage closed circuit, AG/SAG and ball mill circuit (SAB), and Mine to Mill, which links aspects of mining and mineral processing in order to optimise the combined mining and processing stages, has been under development and use for the last 20 UNDErsTaNDINg MINE TO MILL 911 MetallurgistWe design and supply mineral process equipment and solutions Easily adjust stroke and speed to optimise performance and increase efficiency Convenient access to replaceable parts and MechProTech MPT – Designers And Suppliers Of: Mineral Process Metso Outotec HIGmillTM is an advanced and energyeficient fine and ultrafine grinding solution that relies on proven technology The mill takes advantage of gravitational forces and Stirred mills Metso

.jpg)

High voltage motors for mills More for mining ABB

Mills require high starting torque, low speed and overload capability There are many options for starting, controlling and driving mills, with the optimum choice depending on the size of mill or Highly reliable mill drive systems to power mega mills that can handle immense process capacity and challenging ore characteristics under extreme environmental conditions Scope: 1 x 28 GMD system for Toromocho mine ABB2017年9月1日 Mandatory documents and records required by ISO 14001:2015 in Copper ore mill The transitional change on the implementation of It is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill ore The importance of mills cannot be understated since no money was made until the minerals were stripped of their metal Winning the Metal: Ore Mills of the West Western

How to choose a suitable ore powder grinding mill?

2023年10月17日 Type of Ore powder grinding mil 1 Raymond mill Raymond mill feed particle size ≤30mm, production capacity 8176 tons/day, production fineness 80325 mesh, the main transmission device adopts sealed gearbox 2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills MiningpediaDefinition and Overview of Gold Ore Mill A gold ore mill is a facility where the raw mined goldbearing ore is crushed into fine particles through various mechanical means These particles are then further processed to extract the valuable metal within them Gold ore mills have evolved over time to improve efficiency and increase recovery ratesUnlocking the Secrets of Gold Ore Mill: A Comprehensive Guide2016年6月6日 Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughputSAG Mill Grinding Circuit Design 911Metallurgist

¿Quién fue John Stuart Mill y cuáles fueron sus aportes a la

John Stuart Mill (20 de mayo de 1806 a 7 de mayo de 1873), generalmente citado como J S Mill, fue un filósofo, economista político y funcionario británico Fue uno de los pensadores más influyentes en la historia del liberalismo clásico, contribuyó ampliamente a la teoría social, la teoría política y la economía política2016年6月6日 Once the process metallurgist has thoroughly tested the ore body and determined the optimum method of mineral recovery; and the plant designer has efficiently and economically laid out the circuit, instrumentation, equipment installation, and building design; and the mill manufacturer has completed his stress analysis and reliability engineering for mill design, the SAG Mill Liner Design 911MetallurgistOre Mill Bar Grille 17 Lake Tarleton Road, Warren, New Hampshire 03279, United States (603) 7646069Ore Mill Bar GrilleCrushing, a form of comminution, one of the unit operations of mineral processing Mineral processing is the process of separating commercially valuable minerals from their ores in the field of extractive metallurgy [1] Depending on the processes used in each instance, it is often referred to as ore dressing or ore milling Beneficiation is any process that improves (benefits) the Mineral processing Wikipedia

.jpg)

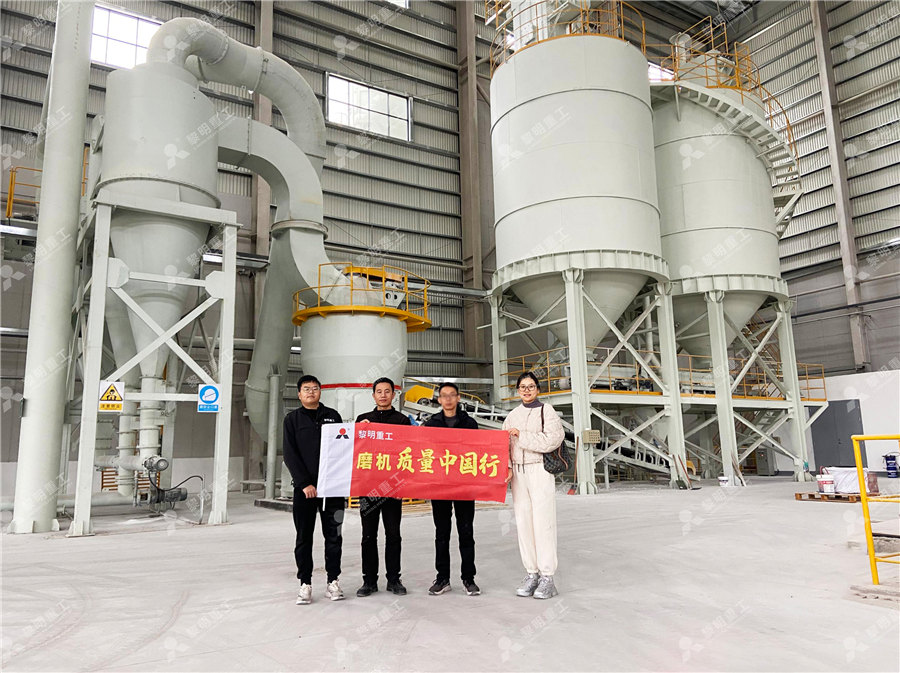

Ore Grinding Mill

Rod Mill The rod mill is loaded with steel bars as grinding media and comprises five parts: cylinder shell, feeding system, discharge system, main bearing, and transmission system It is suitable for both dry and wet grinding to meet customer needs Materials with a Moh's Hardness of 5512 can all be handled by our mill2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Ball Mill Design/Power Calculation 911MetallurgistHowever, ore below the pay limit adds variation to the mill grade as increased mill throughput will be required to make up for the loss of gold, and that impacts on the recovery in the plant It is against these perspectives and findings of this Monitoring ore loss and dilution for minetomill 6 天之前 2845 Ore Mill Rd, Colorado Springs, CO 80904 This Industrial space is available for lease • Visible from Hwy 24 • Drivein doors • Flexible sizes • Ju2845 Ore Mill Rd, Colorado Springs, CO 80904 LoopNet

.jpg)

What Ore Testing is Required For Mill Selection

2015年4月15日 Discharge from each mill Feed to each classification stage Oversize from each classification stage Fines from each classification stage, k Power drawn by each mill (motor input) Motor and drive efficiency of each mill, Size of and type of grinding media used in each mill Speed in RPM for each mill Liner design and condition in each mill2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage Ball Mill Is Indispensable For Lithium Ore ProcessingSAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: FO VERRET, G CHIASSON AND A MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is SAG Mill Testing Test Procedures to Characterize Ore GrindabilitySMALL MULEBACK BALL MILL Small (Muleback Type) Ball Mill is built for “muleback” transportation in 30″ and 3′ diameters (inside liners) A 4′ (Muleback Type) Ball Mill is of special design and will be carefully considered upon request Mankind’s search for valuable minerals often leads him far away from modern transportation 05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

(PDF) Control of ball mill operation depending on ball load and ore

2023年12月12日 In addition, the ore properties are one of the important parameters for the optimal utilizing of the ball mill Ore can have various properties, such as hardness, density, Nestled in the heart of “Ontario’s most beautiful village”, the Elora Mill Hotel Spa is a oneofakind destination that offers our guests access to bespokeElora Mill Hotel Spa Anything but Ordinary2014年10月20日 Rio Paracatu regrind circuit Santos Júnior et al (2011) presented some data on the Paracatu Vertical Mill circuit process, as well as its comparison to the plant's conventional ball millRegrind of metallic ores with vertical mills: An 2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the Ball Mills 911Metallurgist

.jpg)

Ball Mill JXSC Mineral

High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding 911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgist2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Mineral Processing and Ore Mineral Processing and Ore Dressing 911MetallurgistGet more information for 2845 Ore Mill Rd in Colorado Springs, Colorado See reviews, map, get the address, and find directions2845 Ore Mill Rd, Colorado Springs, Colorado MapQuest

YGM Industrial Raymond Mill

YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, quartz stone, marble and other materials with Mohs hardness below 7Store your belongings at Extra Space Storage on 2755 Ore Mill Rd in Colorado Springs, CO today! Our large selection of storage units, drive up access, drive up units, allhours access, manager living on site, exceptional security, deliveries accepted, non climate controlled units available, parking spaces, golf carts available, meeting room available, wide drive isles, Extra Space Storage, 2755 Ore Mill Rd, Colorado Official 2024年11月17日 Address: 2755 Ore Mill Rd, Colorado Springs, CO 80904; More public record information on 2755 Ore Mill Rd, Colorado Springs, CO 80904 The Flex Property at 2755 Ore Mill Rd, Colorado Springs, CO 80904 is currently available For Lease Contact Quantum Commercial Group for more information2755 Ore Mill Rd, Colorado Springs, CO 80904 LoopNetThe steel mill is a large complex of furnaces and channels of molten SteelIt produces the steel from Iron Ore which is delivered by a transport company The steelmaking process is sufficiently interesting that the mill can in fact become a tourist attraction if you place a Steel Mill OpenTTD

AG Autogenous Grinding 911Metallurgist

2015年8月6日 The test mill was fed plant run ore with an average Work Index of 16 Critical size buildup occurred in the first series of tests run, with a feed 80% passing 1¼ in The size of media required for this size feed could not be The rock is then dumped into an ore bin until being fed through ore bin gates into an ore feeder , then into the stamp mortar When the rock runs through the stamp battery, the finely crushed mixture is washed over a series of copper plates Detail Parts Mining Wild West Scale Model Builders2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeA guide to SAG Mill management3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for Population balance model approach to ball mill optimization in iron ore

BUILDING A GOLD ORE HAMMER MILL Part 2 YouTube

2021年12月25日 In this episode we complete the Hammer Mill to crush gold bearing ore Once the mill was almost complete we run a test, the quartz was left overs from quart2021年11月8日 As potencialidades da orapronóbis (Pereskia aculeata Mill) no Programa Nacional de Alimentação Escolar November 2021 Research Society and Development 10(14):e1As potencialidades da orapronóbis (Pereskia aculeata Mill) no View detailed information about property 2655 Ore Mill Rd Apt 203, Colorado Springs, CO 80904 including listing details, property photos, school and neighborhood data, and much more2655 Ore Mill Rd Apt 203, Colorado Springs, CO 80904Savona Equipment is your source for mill components and accessories for large primary ore process concentrating through secondary and tertiary fine material as well as complete ore processing facilities All our reconditioned mill components will be supplied ready for service We can supply SAG mill parts and Ball mill wearparts including ball mill liners and shell linersGrinding Mill Parts for Sale Ball Mill Parts SAG Mill Parts

.jpg)

Rod Mills: Efficient Grinding Solutions for Mining

2016年6月1日 The Steel Head Rod Mill (sometimes call a bar mill) gives the ore dressing engineer a very wide choice in grinding designHe can easily secure a standard Steel Head Rod Mill suited to his particular problem The successful operation of any grinding unit is largely dependent on the method of removing the ground pulpIf you’re looking for a reliable and efficient gold ore mill that can handle the demands of hard rock mining, the Stutenroth Impact Mill should be at the top of your list Purchase the Stutenroth Impact Mill: https://montanagoldoutfitterStutenroth Impact Mill – GameChanging Gold Mining Machinery