vsi5*1145 ore grinding mill weight

.jpg)

SAG Mill Optimization using Model Predictive Control Andritz

SemiAutogenous Grinding mills can be optimized for maximum ore throughput or maximum grinding energy efficiency In both cases, precise control of the mill weight is critical Model predictive control provides an additional tool to improve the control oSemif Autogenous 2021年1月14日 Six samples were tested by Hazen Research, Inc (HRI) to obtain the JK parameters using the JK Drop Weight Test, standard Bond crushing, and rod mill work indices, Comparison of Ore Hardness Measurements for Grinding Mill 2015年6月19日 Use this online calculators for Motor Sizing and Mill sizing as well as mill capacity determinators In extracting from Nordberg Process Machinery Reference Manual I Ball Mill Design/Power Calculation 911MetallurgistNowadays, conducting grindability tests requiring only a few kilos of material on several samples, is a more typical approach to grinding mill design This paper summarises the requirements SAG Mill Testing Test Procedures to Characterize Ore Grindability

.jpg)

VSI mill Wikipedia

A VSI mill (vertical shaft impactor mill) is a mill that comminutes particles of material into smaller (finer) particles by throwing them against a hard surface inside the mill (called the wear plate)2021年1月1日 Calculate load mass from mill crashstop and grindout filling measurements Spreadsheet calculator and procedure pdf supplied as supplementary material The fraction of An improved method for grinding mill filling measurement and Ore hardness is measured through benchscale comminution (grindability) testing, and these test results are used to design comminution circuits Several grindability tests have been COMMINUTION SGS2018年10月1日 This paper, proposes an approach to extend the standard JKMRC drop weight testing method to quantify the breakage variability of an ore domain for impact breakage In Quantifying variability of ore breakage by impact ScienceDirect

.jpg)

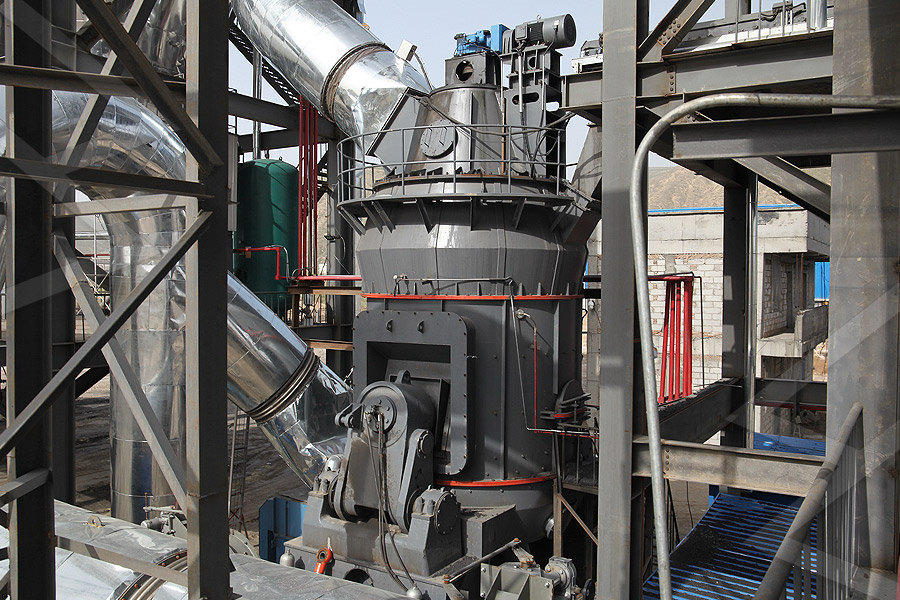

Mobile grinding mill for ore Loesche

Depending on the ore characteristics, it is possible to optimize the mineral dissociation, grain distribution and throughput for each deposit The versatile concept behind OGPmobile enables 2022年12月31日 The grinding process was carried out in a cylindrical ball mill with a diameter and length of 186 cm and 215 cm, respectively, as well as a steel ball with a diameter of 25 cm and a weight of OPTIMIZATION OF LATERITE ORE GRINDING SBM Ore Ultrafine Grinding Mill Discharge fineness: 1503000 mesh Feed size: 20 mm Output: 120 T/H Product features: Safe and reliable, high efficiency and energy saving, low carbon and environmental protection, stable operation, SBM Ore Ultrafine Grinding Millvariations in unmeasured ore properties, material transport delays, and nonlinear response characteristics Control of SemiAutogenous Grinding(SAG) mill weight is an example of an important process that exhibits many of these aspects Maintaining the SAG mill weight at the optimum value is critical forSAG Mill Optimization using Model Predictive Control Andritz

Intel Core i51145G7 vs Intel Core i71165G7 Versus

What is the difference between Intel Core i51145G7 and Intel Core i71165G7? Find out which is better and their overall performance in the CPU ranking1 Population balance model approach to ball mill optimization in iron ore grinding Patricia M C Faria1,2, Luís Marcelo Tavares2 and Raj K Rajamani3 1 Vale SA, Brazil 2 Department of Population balance model approach to ball mill optimization in iron ore 2017年8月26日 By doing so, although the wear rate does not change, metal use efficiency increases when liner scrap weight is reduced and liner cost per ton ore ground is minimized Improve Mill Operating Conditions In practice, operating conditions of the grinding mills are optimized for maximum ore throughputHow to Reduce Steel Consumption in Grinding MillsContact Us Tel: 8621; Office Add: Pudong New Area, Shanghai, China Postcode: ; Email: [ protected] Random Read » alsaka iron ore production » dunlop mine conveyor design software » technical details of batch type bead mill » layout of coal handling plant and washery equipment crushers, feeders, screens » 800 tph iron ore process plant with iron ore weight per cubic meter Grinding Mill China

.jpg)

Understanding the SAG Mill in Copper Ore Mining Process

The Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for grinding materials, the Autogenous Mill relies on the material being ground to break itself into smaller piecesBased on 14,196 user benchmarks for the Intel Core i51145G7 and the Core i71185G7, we rank them both on effective speed and value for money against the best 1,468 CPUsUserBenchmark: Intel Core i51145G7 vs i71185G72018年4月17日 SAG Mill Charge Defining the charge weight and height for fully autogenous grinding mill requires allowance for the ore specific gravity (and its variations) and accounting for the water content and the fine ore which will fill the interstitial spaces between the Autogenous and SAG SemiAutogenous Mill Design Calculations2017年7月3日 On account of the lifting effects of the ends, a mill 2 feet long is expected to take a little more than half as much power as a mill 4 feet long Correction for length was made in a recently developed formula for power, but other variables, such as the amount of ore in the mill, were too intangible to be correctedVariables Affecting Grinding Mill Power 911Metallurgist

Study on Grinding Additives in Cassiterite–Polymetallic

2022年4月12日 Polyacrylamide with a 5 × 106 molecular weight was better than that with a 3 × 106 molecular weight in aiding the grinding of the (denoted as the weight of ore in the mill as a percentage of 2021年1月14日 Key Words: Comminution Tests, Bond Work Indices, JKTech, Grinding Mill Design, Database, Ore Hardness Measurements, JK Drop Weight Test, SAGDesign Test Weight of ore in mill, grams 6739 6608 6921 7359 7087 6634 6889 6891 Pinion kWh/t to T 80 17mm 339 343 224 185 167 355 427 291 Bond BM Wi, Comparison of Ore Hardness Measurements for Grinding Mill 2017年5月8日 Coming now to a study of the effect of the density of the grinding media upon the power required to drive a mill it follows that since the mass of grinding bodies has a definite configuration, as suggested by Fig 33, then the torque to drive the mill will be proportional to the weight of the charge; that is, without powder, proportional to the density of the material of the Grinding Mill Power 911MetallurgistWhat is the difference between Intel Core i51135G7 and Intel Core i51145G7? Find out which is better and their overall performance in the CPU rankingIntel Core i51135G7 vs Intel Core i51145G7 Versus

Study on Grinding Additives in Cassiterite–Polymetallic Sulfide Ore

than that with a 3 × 610 molecular weight in aiding the grinding of the discussed ore It was also found that 6the aid action of the polyacrylamide with a 5 × 10 molecular weight was related to grinding concentration and that a low grinding concentration Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show Grinding Mills 911MetallurgistDownload scientific diagram Standard Bond mill properties and grinding conditions from publication: Correlations of Bond and Breakage Parameters of Some Ores with the Corresponding Point Load Standard Bond mill properties and grinding conditions2021年4月16日 In comparing wet and dry grinding the tests were paired so that all the set variables were the same, except pulp consistency (wet or dry) With an intermediate weight of ore charge, selective grinding was of the same degree; with a heavy ore charge, wet grinding was more selective, and with the light ore charge, dry grinding was more selectiveBall Mill Grinding 911Metallurgist

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 2015年8月6日 Rubber liners absorb the impact of the larger grinding media and thus protecting – the mill structure and prolonging it’s life Weight: Rubber weighs about 15% of an equivalent volume of steel This means that a rubber liner Grinding Mill Liners 911Metallurgist2023年7月20日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Ore Grinding SpringerLink2017年10月26日 The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a Factors Affecting Ball Mill Grinding Efficiency

(PDF) Reducing Grinding Energy and Cost Magnetite Iron Ore

The performance of grinding mills depends on many operating factors among which are the time of grinding, mill speed, grinding media–toore ratio, – 29571 Table 1 Ore Design Parameters Ore Grade % FeT 322 Drop Weight Index (DWi) Ore SG kWh/m3 111 340 Concentrate SG Bulk Density t/m3 430 201 Bond ball mill work index (BBWi 2023年4月23日 grinding media in a grinding mill with about 2630 wt% chrome by Chen et al [37] using a phosphate ore in a modified ball laboratory ball mill whose electrochemical potential could be controlled(PDF) Grinding Media in Ball MillsA Review ResearchGateBond Rod Mill 0305 127 Any 118 15 10 Lockedcycle Y Y Bond Ball Mill 0305 335 Any 0149 10 5 Lockedcycle Y Y Mod Bond 0305 335 Any N/A 2 12 Batch N Y Table 1 – Summary of Grindability Test Procedures 1Weight requested for the test, for typical ores (SG = 28g/cm3) Denser samples require more weight, proportional to the SGSAG Mill Testing Test Procedures to Characterize Ore GrindabilityThe process variables that are linked to the SAG mill are used in clustering, such as weight or bearing pressure, power draw, feed size, is developed for a runofmine ore grinding mill circuitRelationship between SAG mill power draw, bearing pressure and

.jpg)

EVALUATION OF THE ALTERNATIVES FOR GOLD ORE GRINDING

2018年12月24日 EVALUATION OF THE ALTERNATIVES FOR GOLD ORE GRINDING Standard drop weight, It is therefore surprising that in all this time there have been no published models for predicting grinding mill 2023年7月1日 This study aimed at investigating the grinding and classification behaviors of elements found in the copper ore grinding circuit Such expertise is beneficial for a real plant to foresee the fluctuations in the performance of the circuit that is Element based ball mill and hydrocyclone modelling for a copper ore 2021年2月9日 It had been reported by the management that BGM grinding circuit was designed to produce final product size of 125 μm, which had not been achieved for a long period of time under both, low to (PDF) Assessment of the Performance of Grinding Circuit for The weight is less, which facilitates transport, installation and dismantling; Reducing the total weight also reduces the energy consumption of the operating mill by 10%; No corrosion; Rubber lining significantly reduces the noise level, Rubber Lining for Ore Grinding Mills and Mining and

.jpg)

Grinding media characteristics, a total weight of each

Download Table Grinding media characteristics, a total weight of each set: 15 kg from publication: Grinding Kinetics Adjustment of Copper Ore Grinding in an Innovative Electromagnetic Mill 2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material When choosing primary autogenous grinding, run of mine ore up to 200300 mm in size is fed to the mill When calculating the weight of the grinding medium charge weight, Grinding Mill Design Ball Mill Manufacturer 911Metallurgist2010年3月10日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral (PDF) Optimization of mill performance by using online ball and *Corresponding author: The study of the lining layer abrasing wear in the semiautogenous grinding mill Mykola Sokur1, Volodymyr Biletskyi2,*, Mykhailo Fyk2, Oleksandr Fyk3, and Igor Zaselskiy4 1Kremenchuk Mykhailo Ostrohradskyi National University, Marketing Department, 20 Pershotravneva Str, Kremenchuk, 39614, Ukraine 2National Technical The study of the lining layer abrasing wear in the semiautogenous

.jpg)

A guide to SAG Mill management

2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeBond Rod Mill 0305 127 Any 118 15 10 Lockedcycle Y Y Bond Ball Mill 0305 335 Any 0149 10 5 Lockedcycle Y Y Mod Bond 0305 335 Any N/A 2 12 Batch N Y Table 1 – Summary of Grindability Test Procedures 1Weight requested for the test, for typical ores (SG = 28g/cm3) Denser samples require more weight, proportional to the SGSAG Mill Testing Test Procedures to Characterize Ore 2017年11月6日 Their function is crushing and grinding ore rocks weighing up to 45 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral between 175 and 2 kg (385 and 440 lb) depending on source and lot In 127 mm (5 in) balls received at the Henderson mill, weights of 79 and 88 kg (174195 lb Grinding Ball Design 911Metallurgist2022年5月23日 Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to Modeling and application of stirred mill for the coarse grinding

The formula for calculating the weight of grinding mill steel balls

2023年7月24日 Formula for calculating the weight of forged steel balls: Diameter (mm) × Diameter (mm) × Diameter (mm) × 41 / = kg This formula gives the weight of each corresponding diameter steel ball Formula for calculating the weight of cast steel balls: Diameter (mm) × Diameter (mm) × Diameter (mm) × 3865 / = kg