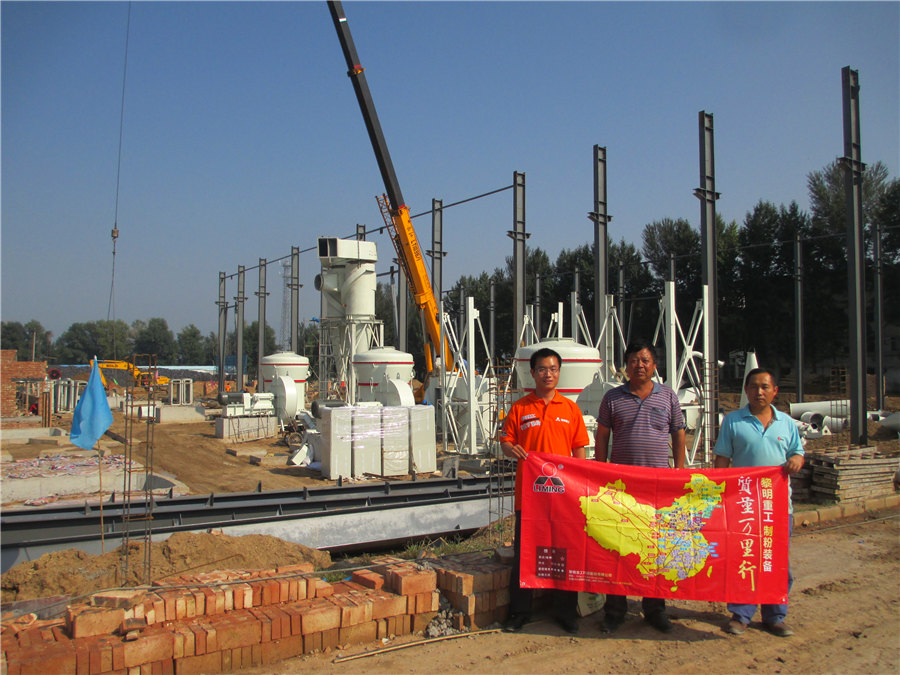

Huxian coal ash bidding unit

Fly ash properties, characterization, and applications: A review

2021年9月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides Gasification of lowgrade, subbituminous coal with a highash content above 45% is carried out in a pilotscale bubbling fluidized bed reactor using air and steam as the fluidizing gasesHighAsh LowRank Coal Gasification: Process Modeling and 研究工作具体围绕重金属形态解析及高温迁移转化、有机固体废弃物低温热解、飞灰熔盐温和热处理、有机固体废弃物熔盐预处理及高值化利用等方面展开。 相关研究成果发表SCI论文60余 胡红云( 博 导 ) 2018年6月21日 Accordingly, this study presents results of the cogasification experiments conducted in a fluidizedbed gasifier (FBG) pilot plant using as a feed the blends of high ash Cogasification of High Ash Coal–Biomass Blends in a Springer

TVNL Tenughat Vidyut Nigam Limited

2024年10月5日 Annual maintenance operation contract of all electrical equipment`s of Coal handling plant and Ash handling plant of 2 X 210MW units at Tenughat Thermal Power Station 2022年1月15日 Coal bottom ash (CBA) shows great potential to produce valueadded materials The basic properties and potential hazards of CBA were systemically reported Recent Towards sustainable coal industry: Turning coal bottom ash into 2023年2月15日 Field monitoring combined with laboratory leaching characterization and geochemical speciation modeling were used to identify important geochemical parameters and Leaching and geochemical evaluation of oxyanion partitioning 2022年8月16日 In this paper, the ash chemistry of coals from the Huainan–Huaibei mining area (Zhuji and Taoyuan) was analysed to investigate the mechanisms of the composition Regulation of Ashfusion Behaviors for High Ashfusion

.jpg)

Observations and Assessment of Fly Ashes from HighSulfur

ABSTRACT: Fly ash was investigated with a variety of chemical, mineralogical, petrographic, and microbeam techniques from three coalfired units at two Kentucky power plants2018年9月1日 The comprehensive analysis of 63 test samples of coal concentrates from Ukraine, the Russian Federation, and countries outside the former Soviet Union (the United States, Canada, Australia, and Method for Calculating the Gross Calorific Value of 2006年4月1日 Conventional floatsink testing is considered the standard test method for generating coal washability data (Temel, Majumder, and Bakır 2015, Galvin 2006, Callen et al 2002, Callen et al 2008 (PDF) Coal preparation plant optimization: A critical 2024年9月26日 Improperly constructed or managed coal ash disposal units have been linked in cases to harm to groundwater, and this final rule addresses the risks identified in these cases leaking of contaminants into groundwater by adding new requirements for coal ash surface impoundments and landfills including:Frequent Questions about the 2015 Coal Ash Disposal Rule

.jpg)

Ballari Thermal Power Station (BTPS) Karnataka

2024年11月14日 Bellary Thermal Power station is located in Kudatini Village, Bellary District in the Indian state of KarnatakaTwo coalfired units of 500 MW each are in operation with generating capacity of 12 million units per day and a 700 MW coalfired unit with operation The thermal electric power generating station is run by KPCL a government of Karnataka undertaking2023年4月10日 Coal fly ash (CFA) management has become a global environmental concern due to their impact on the environment and the quantities of the waste generated However, the utilization of CFA as feedstock in industrial processes is considered a promising option for managing the waste sustainably The physical, chemical and mineralogical properties of CFA Valorization of coal fly ash (CFA): a multiindustry review2024年8月26日 Sale of fly ash, bottom ash, and pond ash for all users of ash Publication Date: 29th May 2024 Last Date for Submission of Bid: 2nd June 2024 Tender Document Size : 31029 KB EOI Advertisement MSE buyers for fly ash for ashbased product New Tender Updates by Vedanta Aluminium2020年10月8日 The SEFA Group developed the STAR process to change the chemical composition of the ash so that it’s suitable for use in concretebased construction materials After SEFA introduced the technology in South Carolina, Duke Energy commissioned three STAR units in North Carolina, making Buck the second such facility in the world to process ash from pondsAdvanced technology recycles coal ash for use in concrete

.jpg)

ASH POLICY 2015 NTPC Limited

Fly Ash: Ash Extracted from flue gases by any suitable process Bottom Ash: Ash collected separately at the bottom of the boiler furnace Pond Ash: Fly ash or bottom ash or both mixed in any proportion and conveyed in slurry / paste form and deposited in pond / lagoonoverheads) When higher volumes of ash are utilised, causing decreased handling, a proportion of the fixed costs may become avoidable (grey regions) The variable cost (blue) indicates the costs that vary with each unit of ash handled (Fuel etc) Figure 2: Avoided OPEX cost calculationEskom’s revised Coal Ash Strategy and Implementation Progress2016年5月12日 The Barapukuria 2 × 125 MW Coal Fired Thermal Power Plant generates significant quantities of solid byproducts which are conventionally known as fly ash These quantities are about 008 million metric tons per year which is currently disposing into two designated ash ponds as a waste material Nowadays, this ash disposal process with its safe A study on physicochemical properties and uses of coal ash of 2023年2月15日 On average, 47 % (by mass) of the coal ash (CA) produced in the US over the decade from 2011 to 2020 was stored in disposal sites, including landfills and surface impoundments [1]The US Environmental Protection Agency (US EPA) has identified several constituents in CAs that can pose risks to human health and the environment [2] Leaching and geochemical evaluation of oxyanion partitioning

.jpg)

A Primer on Coal Ash Handling Systems

2015年11月23日 In 2007, the United States produced over 131 million tons of coal combustion products from the nation’s 1,308 coalfired power plants This 131 million tons of residuals must go somewhere, and has to be handled in a coal imports in the year 201920, on about 250 MT of coal Dependence on coal imports need to be reduced if we have to build an Aatmanirbhar Bharat In June 2020, more than 45 years after the nationalisation of coal mines in the country, Government of India opened the coal sector for commercial mining by private players While thereCOMMERCIAL MINING OF COALIn the past two decades, large coal ash spills (eg, Tennessee Valley Authority Kingston plant in Tennessee in 2008, the Dan River Coal Ash spill in North Carolina in 2014) spurred a national interest in regulating how the coal combustion residuals, CCR, (ie, coal ash) impoundments (ie, ash basins/ash ponds) are managed across the United States (US) These events were a Sustainable Approaches for Closure of Coal Ash Impoundments: A PDF On Mar 30, 2020, Salmi Samsudin published Sub Bituminous Coal Blended Analysis Find, read and cite all the research you need on ResearchGate(PDF) Sub Bituminous Coal Blended Analysis ResearchGate

Coal Ash IspatGuru

2018年12月17日 Coal Ash satyendra; December 17, 2018; 3 Comments ; Boiler slag, Bottom ash, Coal ash, FGD waste, fly ash, Geo technical properties, Gradation of slag, Coal Ash Coal ash is the mineral matter present in the coal It is a waste which is left after coal is combusted (burned) It is the particulate material which remains after coal is burned2022年6月4日 This research aimed to explore the potential of untreated coal ash for the manufacturing of building units (coal ash unburnt bricks) Coal ash unburnt bricks were manufactured at an industrial brick plant by applying a preform pressure of 3 MPa and later curing them via water sprinkling in a control shed Various proportions of Manufacturing of Sustainable Untreated Coal Ash Masonry Units 2020年5月19日 Thus, the use of small aggregates in the form of ash and slag waste components has a positive effect on the strength characteristics of artificial stone on alternative types of binder [36][37][38 Coal ash use as a cement replacement in concrete production2023年2月15日 Leaching and geochemical evaluation of oxyanion partitioning within an active coal ash management unit Author links open overlay panel Xinyue Wang a, Andrew C Garrabrants a, Hans A van der Sloot b, Zhiliang Chen a, For example, as a result of a coal ash spill of 37 million cubic meters of CAs at the Kingston Fossil Plant, Leaching and geochemical evaluation of oxyanion partitioning

Coal combustion products Wikipedia

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), [1] are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: Diagram of the disposition of coal combustion wastes Fly ash is captured after coal combustion by filters (), 2021年5月17日 There is a large demand for nonrenewable energy, and the annual consumption is more than half [1][2] The thermal power system of the thermal power plant is connected by steam and water pipes in Performability and maintenance decisions for coal ash 2022年5月30日 In this research study, environmentally friendly unburnt coal ash (CA) bricks were investigated as an alternative to conventional burnt clay bricks In this research study, various physical and mechanical properties of unburnt Feasibility of Using Coal Ash for the Production of 2021年6月1日 Coal ash is a material from coal combustion and recently is an economical source for the extraction of valuable elements such as rare earth elements and Yttrium (REY) and base metals(PDF) Coal and coal ash characteristics to understand

2FD{P}PC]854]XQ.jpg)

Cost and CO2 emission of concrete incorporating pretreated coal

2023年12月8日 Coal bottom ash is a promising material for use as alternative fine aggregates and is produced worldwide in coal power plants [1]However, in most countries, the utilization of bottom ash as an aggregate for structural concrete remains extremely low, with rates falling below 1 % in both the EU and US [2], [3], [4], [5]This limited adoption can be attributed to the 2022年9月1日 Cofiring ammonia in coal units is a promising approach for the phasedown of coal power In this paper, we demonstrate the feasibility of burning ammonia with coal and biomass in a 25 kW down Experimental investigation of NOx emission and ashrelated issues Lanco Anpara power Limited Group Company of Megha Engineering Infrastructures Ltd (MEIL) is a Coal fired thermal power project won through Competitive bidding under Electricity Act 2003, with two subcritical units of 600 MW each, located near Anpara in Uttar PradeshAbout Us MEIL ANPARA POWER2020年5月8日 Abstract Coal fly ash is a lightweight incombustible particulate generated during coal combustion Alumina content in the fly ash is present in the mullite phase, and its high stability calls for alternative processing for conversion to reactive phase before leaching Mechanical activation with sodium hydroxide was found unsatisfactory for the breakdown of Processing of Coal Fly Ash for the Extraction of Alumina Values

.jpg)

Coal Ash Management: Understanding Your Options Power

2014年2月14日 The Agency has defined economizer ash as bottom ash when “it is collected with the bottom ash” (40 CFR 42311f) and as fly ash when “it is collected with fly ash” (40 CFR 42311e)Bidding on Unclassified Unit prices shall be used to calculate the net change to the contract amount by means of multiplying the volume of rock excavation determined under Section 2b by the Unit Price determined under Section 2g less the value of earth excavation Materials such as coal ash, wood chips, stumps, branches Bidding on Unclassified Excavation, Bidding Pittsburgh AIA2021年9月1日 As shown in Fig 1, the byproducts of coal ash combustion include fly and bottom ash, boiler slag, and flue gas FA particles, the main byproduct, are fine powdery particles, and heterogeneous During coal combustion, FA particles were carried usually aside by the aid of flue gas and detained by precipitators either electrostatic or mechanicalFly ash properties, characterization, and applications: A reviewFor covering of ash filled low lying site, compliance with circular no FNo 2213/2019IAIII dated 28th August 2019, has to be ensured Refer to schedule 06 for details Cleaning of ash spillage from roads inside/outside plant will be in the scope of Bidder(s) Ash to be transported according to approved carrying capacity of trucksNOTICE INVITING TENDER ASH TRANSPORTATION TO LOW

Huxian power station Global Energy Monitor

Huxian power station (大唐户县热电厂) is an operating power station of at least 600megawatts (MW) in Yuxia Town, Hu, Xi'an, Phase I Unit 5 retired coal: bituminous 50 subcritical 1978 2008 Phase II Unit 1 operating coal: bituminous 300 subcritical 2005 – Phase II 2018年6月21日 Cogasification (COG) is a cleancoal technology that uses a binary blend of coal and biomass for generating the product gas; it is environmentfriendly since it emits lesser quantities of pollutants compared to the coal gasification process Although coals found in many countries contain high percentages of ash, cogasification studies involving such coals, and Cogasification of High Ash Coal–Biomass Blends in a Springer2020年5月14日 Also, the calorific value of coal increased from 5,486 cal/g to 5,53538 cal/g However, the volatile matter and ash content of coal was eliminated View Show abstract (PDF) Coal quality characterization in East Kalimantan Province 2022年8月16日 Abstract To produce coal with a high ash fusion temperature (AFT) as the raw material for gasification, the addition of fluxes is often adopted In this paper, the ash chemistry of coals from the Huainan–Huaibei mining area (Zhuji and Taoyuan) was analysed to investigate the mechanisms of the composition modulation and, subsequently, the ash melting behaviour of Regulation of Ashfusion Behaviors for High Ashfusion

.jpg)

Thermal power plants allowed to use coal with high ash content

2020年5月26日 NEW DELHI: The environment ministry has decided that it will no longer regulate the ashcontent of coal used by thermal power plants On Thursday, the ministry issued a notification that overturned its January 2014 regulation that made it mandatory for all coalbased power plants located 500 kilometres or more from the pithead or coal mine to use raw or Coal ash pollution poses grave risks to health and the environment worldwide1 Each year, the world’s coal plants generate more than 500 million tons of coal ash2 Coal ash is a toxic waste product generated by burning coal, and the world extracts about 75 billion tons of coal each year3 Approximately 655% of the coal producedCOAL ASH PRIMER EarthjusticeBidder Unloading of Coal at NSPCL Bhilai power station end from Railway Wagons shall be arranged by NSPCL Bhilai The detailed Scope of Work shall be as per VolumeIII of Bidding Documents 30 TECHNICAL SPECIFICATIONS OF IMPORTED COAL Parameters UNIT Specified Range Total Moisture (ARB) % Upto 32% Ash (ADB) % Upto 20% MaxCORPORATE CONTRACTS MATERIALS DEPARTMENT DETAILED words “coal ash” were replaced with “soil” Such graphics are even more misleading where they suggest that any exposure to coal ash (and, really, soil) will result in these adverse health effects This is just not true The information provided here demonstrates that: • Coal ash is not toxic—even at the high exposure levels used inHealth and Safety Coal Ash Is Not Toxic Haley Aldrich

Coal Ash Texas Department of Transportation

Coal Ash The following sources are qualified in accordance with DMS4610, “Coal Ash,” or DMS4615, “Fly Ash for Soil Treatment” This Material Producer list applies to the June 2020 letting and prior The Department reserves the right to conduct random sampling of qualified materials for testing and to perform random audits of test reports