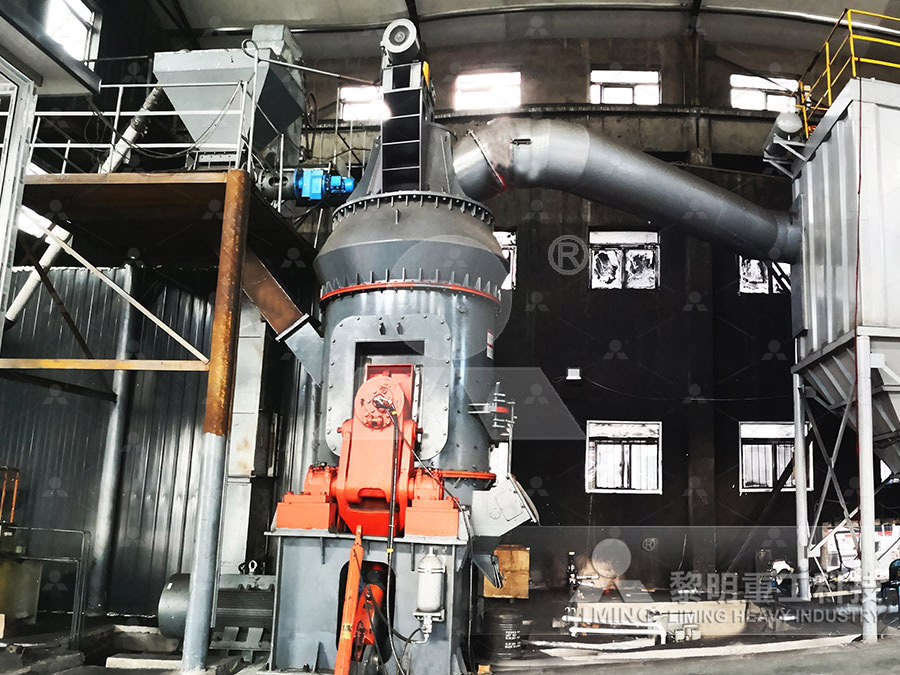

GZV200 mesh coal powder mill

200 mesh coal powder mill/coal powder preparation production line

A 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh or smaller The production of 200 mesh coal powder requires the selection of an appropriate vertical mill that meets the specific requirements of the application The choice of vertical mill should be based Choosing the right vertical mill for 200 mesh coal powder 2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to Coal mill pulverizer in thermal power plants PPTCoal vertical mills are designed to achieve the maximum rated capacity grinding a design coal with a grindability of 55 HGI and 812 percent moisture and achieving a discharge fineness of 70 per cent passing a 200 mesh screen (74 micron) Coal Vertical Mill

.jpg)

HighEfficiency Vertical Coal Mill Enhancing Coal

Our coal vertical mill utilizes advanced dynamic and static separators for efficient particle separation during coal grinding The advanced control system and grinding structure precisely control key parameters, ensuring the desired The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and Raymond Bowl Mill designed and built for flexibility QlarPulverized coal production line is widely used in power plants, steel works, industrial boilers, textiles, heating centers, steam power centers, etc Capacity: 6110tons/hrPulverized Coal Production LineThe BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in A Comparison of Three Types of Coal Pulverizers Babcock Power

.jpg)

200 Mesh partical pulverizer coal mill

200 Mesh partical pulverizer coal mill All categories Featured selections Trade Assurance Buyer Central Help Center Get the app Become a supplier 200 Mesh partical pulverizer coal mill No ONLINE COAL FLOW MEASURING AND BALANCING (CONTROL) AND ONLINE COAL FINENESS MEASURING SYSTEM FOR COMBUSTION OPTIMISATION IN A THERMAL BOILER Suresh G Chandwani1, Dr Francesco Turoni2, Reinhardt Kock2, Dr Michael Haug2, Dr Michael Schreiber2 1NSGuzder Company Pty Ltd, Neville House, Currimbhoy Road, CPRI Online Coal Flow Balancing and Fineness AdjustmentMESH and MICRON SIZES coal dust 1 to 100 coffee (ground) 5 to 400 concrete dust 3 to 100 flour (wheat milled) 25 to 212 gelatin powder 5 to 90 giardia cysts 8 to 14 ginger (ground) 25 to 40 human hair 70 (40 to 120) human vision (lower limit) MESH and MICRON SIZES Industrial Spec1200 Mesh micro silica fume powder production line, HLMX600 superfine mill This 1200 Mesh micro silica fume powder production line uses HLMX600 superfine mill, which has the output of 115t/h, and 10001200 mesh 1200 Mesh Micro Silica Fume Powder Production,

.jpg)

WorldProven Coal Pulverizer Technology Debuts in the US

Wyoming Hanna Basin coal, Rosebud seam, having a heating value 913% below that of the original coal; analysis is shown in Figure 2 This fuel change did not affect Unit 5's load carrying capability Then during 198384, OPP D began procurement of a significantly lower cost Wyoming Powder River Basin coal for their two coalfired plants This coal,2011年10月1日 A sample set of results from a vertical air swept pulverizer with a static classifier might be 9925% passing 50 mesh (297 µm), 8738% passing 100 mesh (149 µm), 7212% passing 140 mesh (105 µm Improved Coal Fineness Improves Performance, Reduces EmissionsThis calcite powder mill plant using our HCQ1290 grinding mill, which has the output of 5t/h, and 100200 mesh fineness Calcite is a calcium carbonate mineral that main component is CaCO3 It is generally transparent, colorless or white, some may contain mottled colors with vitreous lusterCalcite powder mill 100200 mesh 5TPH, HCQ1290 Raymond millDivided into: vertical roller mill, vertical slag mill vertical coal mill, and ultrafine vertical mill (ultrafine powder processing) One machine is multipurpose, it can be used for grinding, grading, crushing, drying, etcvertical roller mill, vertical coal mill, vertical slag mill, superfine

.jpg)

A Comparison of Three Types of Coal Pulverizers Babcock Power

Mill Speed Capacity Desired Coal Properties Feed Size Total Moisture Grindability (HGI) Abrasiveness Prod Fineness thru 200 Mesh Standard Screen Typical Air to Coal Ratio at 100% Mill Load Specific Power @ 100% Mill Load Typical Conditions CrusherDryer Mill PA Fan Total StartUp Time NoiseMill Only Approx Dimensions Mill Dia (D)2023年5月17日 Coal hammer mill is a type of industrial equipment used to grind or pulverize coal into fine particles for combustion in We can do this using sieves or sieves with various mesh sizes We can add limestone powder to soil for agricultural purposes or as a raw material for making cement Gypsum: Gypsum is a mineral used to What Is Coal Hammer Mill? SBM Mill CrusherWhile all these are regarding the mill performance, the coal fineness and mill out let temperature also affect the boiler performance The coal fineness has an effect on the combustion performance like the bottom ash percentage combustibles when the plus 50 mesh percentage goes up It has been very well established that in the case of tangential firing system, the Boiler Performance and Mill Outlet Temperature Bright Hub The whole grinding line is used for processing coal to 200 mesh, our technicians configure one set of LM150M in order to meet customer's demand for production MTW European Type Grinding Mill for limestone powder making Output size:200mesh MTW European Type Grinding Mill for limestone powder making Output size:200meshLM150M Coal mill , 200mesh D90 25tphLIMING HEAVY

.jpg)

Coal gangue ultrafine powder mill

2022年9月13日 Coal gangue can be made into coal gangue powder by grinding with an ultrafine powder mill Coal gangue powder is widely used in the construction field +17 [ The particle size of the finished 2015年8月7日 Petroleum coke (PC) blend with coal is an attractive feedstock for combustion process The present work investigates the grinding characteristics of PC blend with coal in a laboratory ball mill to Grinding Characteristics of Coal and Petroleum Coke/Coal 2 Steps for using coal powder for boilers 1)Coal powder preparation: Select suitable coal as raw material based on the combustion requirements and coal quality characteristics of the boiler; The raw coal is crushed into small pieces by a crusher and then sent to a coal mill for grinding to prepare coal powder that meets the requirements of boiler combustionGuilin Hongcheng HMM Series Bowl Coal Mill Promoting Efficient, Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee

.jpg)

How is pulverized coal processed? SBM Ultrafine Powder

2022年2月24日 Coal is an important energy source in my country and is widely used in metallurgy, 100 mesh Suitable coal types: lignite, weathered coal, peat, HGM superfine powder mill Fineness: 1502500mesh Yield: 0245t/h see More >> Clum ultrafine vertical mill2019年8月1日 Design and Modify of Mill Discharge Valve Using in pulverizing the coal to required fineness of about 70 microns coal powder are embedded with a stainlesssteel wire mesh Design and Modify of Mill Discharge Valve Using inFinished particle size: 10–40 μm (370–1,250 mesh) Capacity: 245 t/h Other types include ore vertical mills and pregrinding vertical mills For Customer case—Vietnam clean coal powder production line 3 sets of HLM1900M coal vertical mill Auxiliary equipment: Jaw crusher, conveyor belt, Energysaving and Efficient Vertical Roller Mill Fote MachineryMill connection: the circulating fan is connected to the explosionproof bag dust collector and the inert gas supplement pipe: the inert gas supplement pipe is connected to a heat source system that supplements the low oxygen content heat source gas to the pulverized coal vertical mill to control the low oxygen in the extracorporeal circulation system The limiting oxygen content What is the process flow of vertical mill to produce pulverized coal?

Quartz Industrial Powder Grinder Machine SBM Ultrafine Powder

2021年10月11日 Quartz industrial powder grinder machine can be used to further grind quartz sand into quartz powder, and its fineness can be adjusted freely between 1503000 mesh The industrial grinding mills independently developed and produced by SBM have the advantages of stable operation, high efficiency, energysaving, and environmental protection, and long 2011年8月1日 Adequate fineness for both western and eastern fuels (Powder River Basin or bituminous) is a minimum of 75% to 80% passing 200 mesh and zero to 01% remaining on a 50 mesh screen (Figure 10)Pulverizers 101: Part I POWER Magazine2015年11月1日 Dynamic coal mill model based on conservation laws and empirical relations The coal mill grinds the raw coal into fine powder and hot air entering the mill dries and carries the pulverized coal to the burners of the furnace 75% of the pulverized coal passing a 200 mesh screen is optimal for the mill and combustion performanceA unified thermomechanical model for coal mill operation2017年6月9日 The minus 325mesh coal was ground for 30 minutes using the same conditions as were The clay was ground batchwise in the Bureau’s 20inchdiameter mill using minus 14 plus 28mesh Ottawa sand as the minus 325 mesh zirconia powder sintered at 1,400° C The average particle size of the attritionmilled zirconia Attrition Grinding Mill Design 911Metallurgist

HighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

Our vertical coal mill is designed to enhance the process, maximizing energy Coal vertical mills are widely used in cement production, calcium carbonate crushing processing, coal powder preparation stations, gypsum powder processing, power plant (200 mesh pass %) 80: Coal moisture content (%) ≤1: Main motor Power (kW) 55: 110: 132 Coal mills, essential components in power generation and various industrial processes, pose significant safety risks if not properly managed These mills, used to grind coal into a fine powder for combustion, present potential hazards such as fire, explosion, and mechanical failures This article outlines best practices and precautions to ensure thBest Practices and Precautions Coal Mill Safety, Explosion and Analysis of Coal Mill Operation Free download as PDF File (pdf), Text File (txt) or read online for free This document analyzes the comilling of coal and wood biomass in a ringball mill It describes tests conducted pulverizing hard coal with additions of 8% and 16% pine sawdust at different moisture contents Key findings include: 1) Biomass has weaker grinding properties Analysis of Coal Mill Operation PDF Mill (Grinding) ScribdThis Coal Powder Making Plant in Bhutan utilizes our CLRM1300 Raymond grinding mill to achieve 80400 mesh coal powder production with high capacity The customer celebrated the factory’s commencement with prayers for a bright and successful future Raymond Mill for Coal Powder Making The Raymond mill is widely used for grinding coal into SBM Ultrafine Powder Technology Industrial Grinding Mill,

Pulverized Coal Boiler an overview ScienceDirect Topics

Fuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200mesh (74μm) screen Figure 2 shows a particlesize distribution from a bowlmill grinder typically used in power plants A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200mesh screen, which is equivalent to 70% Phrase one: raw material crushing Coal blocks will be crushed to 15mm50mm fineness by crusher Phrase two: drying and grinding 1Coal material with low moisture will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding The hot air in the mill will dry the coal This will reduce drying cost 2For high Coal Mill Manufacturers Powder Making Machine PriceThe “M” Series fine grinders are designed to grind dry, freeflowing material down to 400 mesh with extremely tight particle size distribution This highly efficient machine ensures easy access to all internal areas and is perfect for heat Particle Size Reduction Solutions Prater Industries2021年11月3日 Materials: limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc CLUM ultrafine vertical roller mill SBM specially designed a unique roller shell and liner grinding curve, which can Phosphate Mineral Powder Grinding Mill SBM

Charcoal Raymond Mill Coal Powder Milling Machine

Its adjustment range is between 30400 mesh Therefore, in order to improve the quality of charcoal products, Such as Raymond mill, and coal powder mixer Welcome to contact us for a business consultation charcoalraymondmillfor 2022年9月20日 Coal gangue grinding powder can be used in coal gangue making bricks, cement making, light aggregate production, coal gangue blocks and so on (4) Brick making with coal gangue powder The process of making bricks from coal gangue is basically the same as that of clay bricks, mainly including the preparation, molding, drying and baking of raw materialsCoal Gangue Vertical Roller Mill SBM Ultrafine Powder 3 天之前 Low Ash Coal Powder: 1400: MANGAL INDUSTRIES: INR: 989% Pure 223 G/Cm3 Density Carbon Coal Powder For Industry Fuel: 10: MEHTA MANUFACTURING AND TRADING CO INR: 95% Methane Content Hydrogen 5800 Kcal/Kg Industrial Fuel Black Coal Powder: 56: Purushottam Traders: INR: FragranceFree Black Coal Powder Used As A Cooking Fuel: 150: Coal Powder Manufacturers, Suppliers, Dealers Prices TradeIndiaWorking Principle of HD DBM Series German Type Coal Mill Machine: DBM Series German Type Coal Mill Machine is a coal powder making machine It is also named pulverizer mill The whole structure of pulverizer millis composed of crushing equipment a roller mill,Driving system, Classifier, pipeline device, blower, finished cyclone collector , jaw crusher, bucket elevator, Coal Mill Machine 400 mesh 50TPH HD DBM Series German

.jpg)

Graphite Grinding Machine Powder Mill Equipment

2021年10月26日 For the production of coarse powder (under 325 mesh), you can choose a highpressure powder mill or Raymond mill; for the production of fine powder above 1000 mesh, you can choose an ultra fine grinding mill, vertical roller mill, wet mill, etcCLUM series ultrafine vertical roller mills have a large capacity, stable operation, low wear, long life, environmental protection and energy saving, simple operation, intelligent control system, easy maintenance, and the fineness can be freely adjusted between 1503000 meshesVertical Roller Mill SBM Ultrafine Powder TechnologyThe MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking systemMPS ZGM Coal MillGrinding Equipment YingYong Machinery