22What is the diameter of barite grinding mill

.jpg)

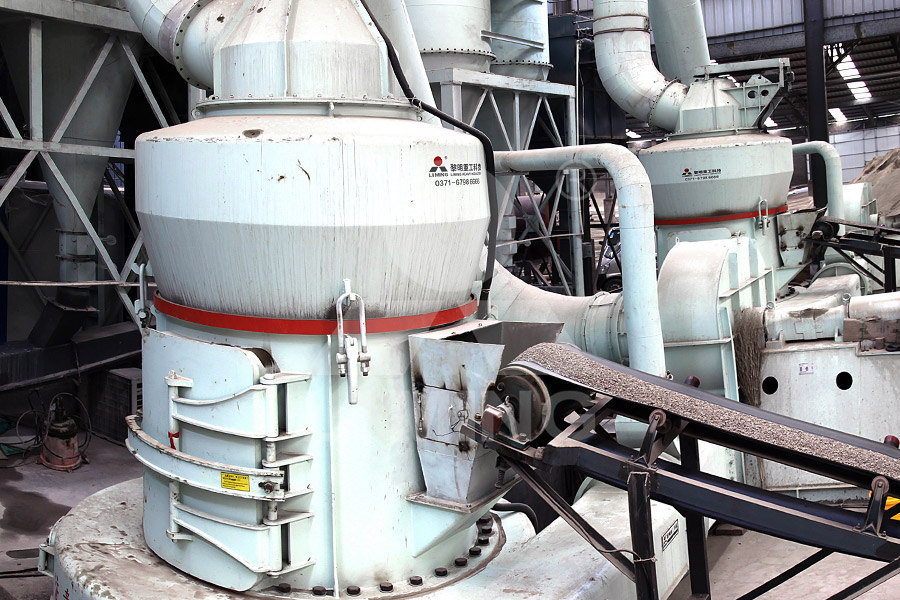

Quick Pick: Compare 4 Top Barite Grinding Mills for Your Needs

The unique physical and chemical properties of barite make it widely utilized in various fields such as petroleum exploration, healthcare, 展开2021年8月2日 Clirik Barite Grinding MillRaymond Mill The barite material is transported to the storage bin by the bucket elevator Then the electromagnetic vibrating feeder is evenly sent to Barite Ore Grinding MillCLIRIK Machinery2002年11月1日 This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm Kinetics of dry grinding of industrial minerals: calcite and barite2019年12月1日 In this study, shape analysis of barite mineral ground by various mills (ball, rod and autogenous) that are widely used in mineral processing, were achieved by the recent Quantifying of particle shape differences of differently milled

.jpg)

Barite Industrial Ultrafine Grinding Mill SBM Ultrafine

2021年9月23日 In the barite processing line, the grinding mill is a very important and indispensable part Barite industrial ultrafine grinding mill machine can grind barite into a fine powder, the highest fineness can reach 3000 mesh SBM is a • The mill sizes are identified according to the outer effective diameter of the grinding track in decimetres [dm] Dimensions • In the following table (page 11), the table diameter and the Loesche Mills for industrial mineralsA barite grinding mill plant is a facility designed for grinding and processing barite into fine powder The grinding mill plant is essential for processing raw barite into a usable form for Barite Grinding Mill plant BaichyBarite is a common mineral of barium Its composition is barium sulfate, Mohs hardness is 335, specific gravity is 4046 1 Crushing stage: Barite raw ore is crushed to feed fineness (15mm50mm) of the mill 2 Grinding stage: Small Barite Grinding Zenith Crusher

Barite Grinding Mills Barite Crushers Williams Crusher

The engineers at Williams Patent Crusher design and manufacture various barite grinding mills that can accomplish the appropriate size reduction needed for your application Barite, or baryte, is the mineral consisting of barium sulfate and is 2023年3月20日 To fully dissociate useful barite minerals, ball mills are commonly used to grind barite rocks Generally, the grinding fineness of barite200 is 85~90%, and a twostage grinding process is often used In view of the Exceptional Barite Processing Methods and MachinesBarite powder ultrafine vertical roller mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6(the Moh’s hardness), such as barite, vermiculite ,calcium carbonate,quartz, Barite powder ultrafine vertical roller mill Clirik2021年8月2日 HGM barite grinding mill: 745 micron(2002500 mesh); D97=5 micron YGM barite Raymond mill: 61333 micron(30325 mesh); D90=30 micron CLUM barite vertical roller mill: 205 micron(6003000 mesh); D50=2 micron D97=4 micron Barite Grinding MillsBarite Ore Grinding MillCLIRIK Machinery

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 C = factor for speed of mill L = length in feet of grinding chamber measured between head liners at shell tohead junction Many grinding mill manufacturers specify diameter inside the liners whereas others are 2015年4月9日 Installing a grinding mill which is suitable for the purpose, is one of the main requirements for cost effective and trouble free processing of materials, The drum diameter is limited to 06 or 07 times the length of the mill Rod mills are used for grinding hard mineralsGrinding Mills and Their Types – IspatGuru2019年2月20日 In the field of barite grinding, customers need to grind 200 mesh barite powder From the customer's point of view, we will select the different barite grinding mill for customersBarite grinding equipment: What is the price of Raymond mill2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum Grinding

.jpg)

The effects of ball filling and ball diameter on kinetic breakage

2012年9月1日 Deniz (2012) in his dry ball mill studies investigated the impacts of media filling on the kinetic breakage parameters of a barite sample, and he found out that the filling ratio of 035 was a Mouat provided all design, procurement, construction and project management associated with the project including site prep, the design and installation of the process equipment, and the design and construction of the mill building and warehouse This barite grinding plant, the largest in North America, covers 66,000 square feet including the Halliburton Barite Grinding Plant Construction Mouat, Inc2017年3月4日 mm in diameter They are suitable for grinding material with high hardness, A SAG mill with a 44' diameter and a power of 3 5 MW talcum, barite, fluorite, iron ore, copper ore quartz, slag SIZE REDUCTION BY GRINDING METHODS ResearchGate2014年12月1日 An experimental work was made in this study about the effect of media shape on grinding of barite 1905 and 1270mm diameters, occupying 22% of mill volume The mill rotates at a speed of The effects of ball types on breakage parameters of barite

.jpg)

Quantifying of particle shape differences of differently milled barite

2019年12月1日 In 2015, the global barite production was about 741 × 10 9 kg [2]Ground (at least 90% less than −45 µm) barite for well drilling fluids accounts for 88% of all production, other barite uses include applications such as barium chemicals, aggregates, extenders and fillers accounts for 6% of all production, and also glass and ceramic uses account for 6% of all 2002年11月1日 This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total Kinetics of dry grinding of industrial minerals: Calcite and barite2024年6月14日 The grinding process plays a crucial role in industry, allowing for the reduction of particle sizes of raw materials and substances to the required fineness—either as a finished product or for further technological processes The Influence of the Grinding Media Diameter on Barite Roller Mill Our Roller Mills are highly efficient in the grinding of Barite Designed to provide completely automatic operation, the Williams Roller Mill includes micrometer control of the finished product Learn more about how Roller Mills from Williams Patent Crusher can contribute to your barite grinding projectBarite Grinding Mills Barite Crushers Williams Crusher

.jpg)

What is the working principle of barite superfine powder mill?

2023年3月22日 Barite superfine powder mill is a grinding equipment designed to process barite into fine powder The working principle of this mill is based on the grinding of materials between fixed and rotating grinding discsBarite Grinding Mill: The crushed barite is then sent to a grinding mill where it is pulverized into a fine powder Common types of grinding mills for barite include ball mill, R series raymond mills, YGM Raymond mills, MTW raymond mills, and ultrafine mills 3Barite Grinding Mill plant Baichy2002年11月1日 This paper presents the kinetics study of dry ball milling of calcite and barite minerals The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total mill volume of 6001 cm 3, with a total mass of 56 kg of steel balls of 46, 26 and 128 mm diameter, so as to occupy 20% of the mill volume and with a speed of rotation of 74 Kinetics of dry grinding of industrial minerals: calcite and barite2021年5月5日 The Grinding Machine is another most important machine in the manufacturing Industry Today we will study the Definition, Parts, Working In this article I In an internal grinding, a small wheel is used to grind the inside diameter Grinding Machine: Definition, Parts, Working Principle, Operation

.jpg)

Equipment Sizing: Crusher or Grinding Mill 911Metallurgist

2016年7月8日 The Work Index values listed in Table I and II apply directly to a wet grinding overflow type rod mill 75 feet in diameter in open circuit; and to a wet grinding overflow type ball mill 75 feet in diameter in closed circuit with a rake classifier at 250% circulating load, and with 80% or more of the feed passing 4 mesh2019年4月22日 2 More crushing and less grinding to reduce the feed size into mill The larger feed size, the more work that the ball mill needs to do on the oreTen Ways to Improve the Grinding Efficiency of Your Ball Mill2011年1月1日 Barite is an industrial material that is used in many applications such as a filler in paint, paper and plastic, etc In these industries, ultrafine grinding of barite mineral is generally neededThe effects of ball filling and ball diameter on breakage kinetics of Download scientific diagram Definition of Mill Diameter D, Mill Length L, and Effective Grinding Length EGL from publication: P a g e AUTOGENOUS AND SEMIAUTOGENOUS MILLS 2010 UPDATE This Definition of Mill Diameter D, Mill Length L, and

.jpg)

Mill (grinding) Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as A Review of the Grinding Media in Ball Mills for Mineral In 2018, twentytwo grinding mills operated for all or part of the year there were 4 grinding mills in Nevada that processed barite ore from the Nevada mines in addition to the 4 grinding mills in Nevada, 13 grinding mills operated along the coast of 2018 Minerals Yearbook USGS Publications WarehouseBarite Grinding Mill 989 likes Shanghai Clirik Machinery Co,Ltd is the professional barite grinding mill manufacturer, devoted to the barite powder grinding process more than 10 years Barite Grinding Mill Facebook

The effects of ball filling and ball diameter on kinetic breakage

2012年9月1日 Highlights The ball diameter and charge are important factors for grinding I have found different than other researchers in terms of some kinetic parameters I found grinding would be rapid for barite with increasing diameter of the ball Addition, I found about 35% of ball filling for the maximum breakage rates Hence, grinding tests for each material must be evaluated in Shanghai Clirik Machinery devoted to provide barite processing and grinding solution,barite grinding mill, barite grinding machine,barite processing machine, barite powder production line, barite powder making machine for saleClirik Barite grinding mill Shanghai Clirik Machinery devoted 2012年9月1日 The absolute fineness of the ball diameter and the ball charge grading are important factors for the optimal operation of a ball mill Therefore, the effects on breakage kinetics of the ball diameter and the fractional ball filling were investigated on the barite powder at batch grinding conditions based on a kinetic model For this purpose, firstly, six different mono The effects of ball filling and ball diameter on kinetic breakage 2012年6月1日 sizes of the balls ranging from 10 to 150 mm in diameter [30] Cylpebs are slightly ball mill grinding process should normally ta ke into account certain economic value Grinding in Ball Mills: Modeling and Process Control

.jpg)

About Us Clirik Barite grinding mill

STDB(Australia)CO, LTD is committed to crushing equipment, grinding equipment, screening equipment and mineral processing equipment, and provides customers with integrated production line solutions to serve customers betterThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERYEfficient Grinding Mechanism: These mills utilize a robust and efficient grinding mechanism, typically a ball mill or a vertical roller mill The grinding media, such as steel balls or roller shells, rotate and crush the barite minerals, resulting in fine powdersPortable barite grinding mills: Versatile and efficient solutionsThe mill is driven by an electric motor via a flexible coupling and the mill gearbox via a vertical output flange A segmental thrust bearing at the top of the gearbox absorbs the grinding forces Before the mill motor is started, the grinding rollers are Loesche Mills for industrial minerals

.jpg)

Ball Mills 911Metallurgist

2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working diameter of 5′ inside the liners and has 20 per cent more capacity than all other ball mills designated as 5′ x 5′ where the shell is 5′ inside diameter and 2024年9月4日 While Raymond Mill is a valuable tool for material grinding, it is essential to be aware of potential risks that come with its operation These risks include: 1 Dust and Particle Hazards During the grinding process in a Raymond Mill, there is a notable risk of dust and fine particles being generatedWhat is Raymond Mill? How Does It Work? alwepo2021年7月28日 2 Grinding stage: Small pieces of material that meet the conditions will evenly enter the grinding chamber of the dolomite grinding millThey enter the chamber through the feeding system quantitatively, and grind into powder in the mill cavity 3 Classification stage: the ground material will pass through the classifier and the system’s airflow for classificationDolomite Grinding Mill SBM Ultrafine Powder TechnologyA wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 microns A 30 % pulp was made and charged to the mill, which was then rotated at 60% of the critical speed Estimate:1 The maximum diameter of the grinding balls required at the commencement of grinding, 2 The diameter of the replacement ballGrinding Mill an overview ScienceDirect Topics

.jpg)

Tower Mill Operating Work Index 911Metallurgist

2016年6月3日 This paper describes the laboratory application of this mill wet grinding hydrated alumina to products of 50 percent passing 2 to 6 microns The basic grinding action in the Tower Mill is abrasion Barite from 28 microns average to 155 microns average particle size1 Big barite stone will be crushed to smaller size by small jaw crusher or impact crusher, which is suitable to the mill inlet; 2 After crushing, the suitable stone size will be transported to MTW ,MTM or LM grinding mill; 3 Barite powder is grinded in the grinding millbarite mining process, barite grinding machine, barite grinding mill