Bentonite ore mill

Mining and processing Bentonite

Bentonite production process features ore mining, sodium activation – if required , drying, and milling Sodium activation is performed to convert calcium bentonite to sodium bentonite, in which calcium ions are exchanged for sodium carbonate5 天之前 Bentonite processing methods are mainly dry and wet beneficiation, crushing, sieving, and grinding Contact us for a complete bentonite processing plant and equipment with high added valueBentonite Processing Methods And Required Equipment2021年12月14日 With the development of science and technology, the consumption of bentonite has been extended from the traditional drilling mud and iron ore pellet casting industries to Bentonite processing technology ALPA Powder Equipment2006年1月1日 Wyoming bentonites are used to clarify water because it is easily dispersed and has good adsorptive properties Dye manufacturers use the sodium bentonite to preferentially Chapter 6 Bentonite Applications ScienceDirect

Effects of bentonite fiber formation in iron ore pelletization

2002年7月1日 Bentonite is a significant cost item in iron ore pelletization, and also contributes undesirable amounts of silica to the finished pellets If the binding effectiveness of bentonite is MTW175 Grinding Mill The investor has its own bentonite ore Due to the increase of supply and the consideration of large equipment, two sets of MTW175 have been purchased from SBM 120,000 Tons Bentonite Grinding Plant sbmchinaBentonite for Drilling Mud is the second largest user of bentonite Bentonite is a clay mineral with montmorillonite as the main component It has strong water absorption and can absorb water equivalent to 8 times its volume The volume BentoniteA combination of 04% CaLS with 5% LDS addition can prevent strength deterioration at 300–350°C during drying and gives a goodquality pellet in terms of strength, thermal shock An innovative approach to replace bentonite in hematite ore

An innovative approach to replace bentonite in hematite ore

Bentonite is suitably used as a binder for iron ore pellet ma (LD) sludge and mill scale have been added FeO and Fe 3 O 4 in these materials will be oxidized at the mild oxidizing atmosphere of 04% CaLS with 5% LDS shows its good application potential to replace bentonite in hematite ore pelletizing KEYWORDS: Calignosulphonate; Na The reducing gas hydrogen, the inert gas argon, and the inert gas nitrogen were purchased from Nippon Gases Iron ore pellets, which were delivered by voestalpine Stahl GmbH, were used as a reference in the reduction tests Use of Bentonite and Organic Binders in the HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding MillThe quantity of Bentonite Powder Lumps used is variable depending upon the depth of the hole to be drilled Generally one tonne of Bentonite Powder Lumps is used to prepare about 100 barrels of mudBENTONITE Lumps is also used in Iron Ore Palletization Advantages: Optimum results; Affordable; Superior qualityBentonite Nilkanth Exports

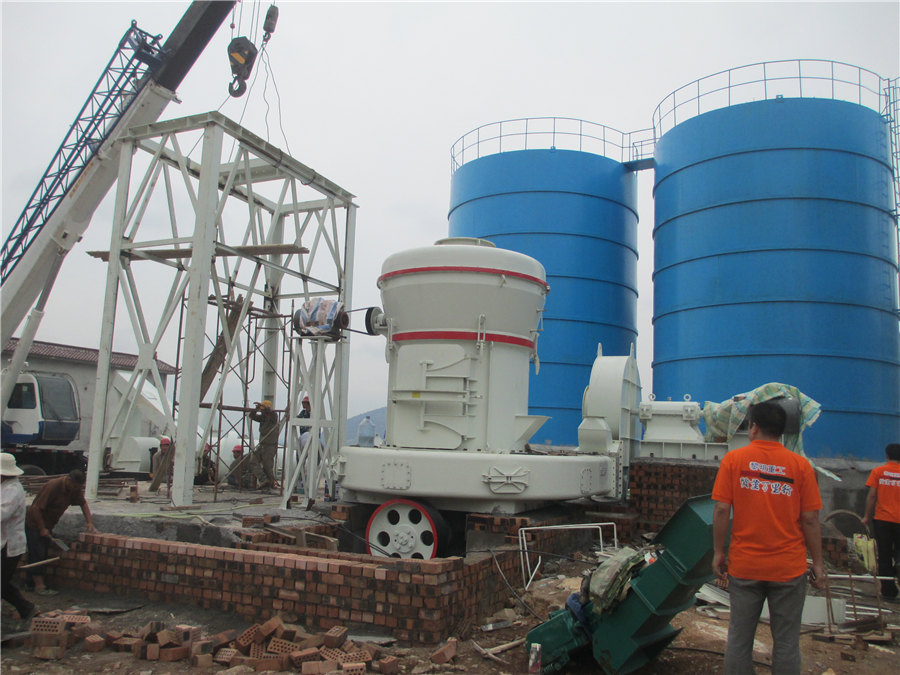

Competitive Advantages Of Raymond Mill For Grinding 300 Mesh Bentonite

Which factory has to sell professional bentonite grinding mill equipment? HCMilling (Guilin Hongcheng) is an ISO certified enterprise We are a professional manufacturer of ore grinding machine The newly upgraded 300 mesh environmentfriendly Raymond mill has outstanding competitive advantages, 2024年4月26日 Iron ore processing is a crucial step in the production of steel, one of the most essential materials in modern society Iron ore, a naturally occurring mineral composed primarily of iron oxides, is mined and processed to extract iron for various industrial applicationsIron Ore Processing: From Extraction to ManufacturingStabilization of iron ore tailings with cement and bentonite: a case study on Golgohar mine 4153 TheGolgoharironoredeposit,comprisingsixmainanomalies (~40 km2) and an annual output of 148 million tons of iron ore concentrate and pellets (Soltani et al 2017),is one ofStabilization of iron ore tailings with cement and bentonite: a DOI: 101080/2022 Corpus ID: ; An innovative approach to replace bentonite in hematite ore pelletizing with organic binder @article{Pal2022AnIA, title={An innovative approach to replace bentonite in hematite ore pelletizing with organic binder}, author={Jagannath Pal and A Ammasi and Brati S Bandyopadhyay and Srinivas Dwarapudi An innovative approach to replace bentonite in hematite ore

An innovative approach to replace bentonite in hematite ore pelle

An innovative approach to replace bentonite in hematite ore pelletizing with organic binder Buy Article: $7100 + tax (LDS) is a better additive than mill scale A combination of 04% CaLS with 5% LDS addition can prevent strength deterioration at 300–350°C during drying and gives a goodquality pellet in terms of strength, MTW Grinding Mill LM Grinding Mill LUM Grinding Mill XZM Grinding Mill MTM Bentonite is a nonmetallic mineral with montmorillonite as its main mineral component and its content is 8590%,the hardness is 12 and the density is 23g/m³,because of the change of iron Bentonite Powder for Iron ore pellets Industry Standard(GB/20973 Bentonite2016年3月1日 Bentonite is the most common binder used in iron ore pelletisation owing to its good bonding properties in green and dry pellets at both ambient and elevated temperatures However, due to its high alumina and silica content, it increases the slag volume and energy consumption in downstream processes Organic binders may be used to replace bentonite; Replacement of bentonite in hematite ore pelletisation using a Bentonite is a nonmetallic mineral with montmorillonite as its main mineral component and its content is 8590%,the hardness is 12 and the density is 23g/m³,because of the change of iron contentthere are different kinds of Bentonite Processing Plant, Bentonite Mill

Dry Grinding of Bentonite by Stirred Media Mill

2021年12月30日 In this study, a pintype vertical stirred media mill was used to perform the dry grinding of bentonite Grinding time and stirring speed were investigated for effect on the particle size 9 Apr 2024; Mobile bentonite crusher and mill plants are used to crush and grind bentonite ore into a fine powder The plants are typically mounted on trailers or skids, making them easy to transport from one location to anotherMobile bentonite crusher and mill plants CM Mining Machinery2022年4月1日 In order to improve the practical value of bentonite and expand the scope of application of natural bentonite, it is necessary to modify the natural inorganic bentonite into organic bentonite In the modification process of bentonite, it is necessary to add modifier to make bentonite have the ability to adsorb organic compounds, so as to reach the standard of organic Properties, Processing and Modification of Bentonitepoint out the possibility of activating ore bentonite of Ain AlBeida utilizing sodium carbonate powder and to Samples were crushed by a Jaw crasher, then grinded by a disc mill and then sieved The samples were washed and dried at 100˚C, activated by sodium carbonate at Activation of Jordanian Ore Bentonite by Sodium Carbonates

Bentonite Uses, Status and Processing in India FTM Machinery

2020年3月14日 After the mining of bentonite raw ore, it is generally irregular in shape and contains about 25% ~ 28% water After being milled by Raymond mill, more than 95% of bentonite can reach 200 mesh, which can meet the requirements of general application fields2017年12月21日 Surface morphologies of hematite ore fines and mill scale fines (a) Hematite 04% CaLS with 5% LDS shows its good application potential to replace bentonite in hematite ore pelletizing (PDF) Mill scale as a potential additive to improve the quality The 100mesh bentonite Raymond mill can achieve an output of 625t/h using an HC pendulum mill If a traditional Rtype Raymond mill is used, the output can be Home; limestone, feldspar, phosphate rock, marble,quartz sand,bentonite, graphite, manganese ore and other nonmetallic mineral materials with hardness below Mohs level 7 Which mill should be used to grind bentonite clay to 100 mesh?Journal of Characterization Table 2 Chemical composition of the bentonite sample Component SiO2 Al2O3 Fe2O3 MgO Na2O CaO K2O LOI Content, wt% 6223 1906 363 270 261 205 065 630Dry Grinding of Bentonite by Stirred Media Mill ResearchGate

.jpg)

Chapter 6 Bentonite Applications ScienceDirect

2006年1月1日 The mixtures of bentonite, iron ore, and water are commonly tested for wet drop strength, wet compression strength, plastic deformation, and dry compression strength 4 Bentonite is also used to adsorb paper mill wastes, sewage, and certain industrial wastes (Olin et 2023年2月23日 In the first step, the large bentonite ore is crushed to about 20mm, soft bentonite does not need to be crushed or dried by passing hot air into the mill to dehydrate it in the grinding powder The third step is manual The Definitive Guide to Bentonite Miningpedia2013年8月1日 Bentonite is the traditionally used binder in iron ore pelletization However, it consists of up to 85% silica and alumina which are undesired acidic gangue in ironmakingStudy of Organic and Inorganic Binders on Strength of Iron Factory Supply Cement Gypsum Ball Mill for Mineral Ore Stone Clinker Grinding silica sand grinder mill Machine Cost ball mill xkj small diesel 600x1200 ball mill grinding machine for gold for sale Laboratory Size Wet Ore Material Grinding Miller Experiment Mineral Sample Analysis Rod Mill Graphite Lime Gypsum Activated Carbon Black Chalk Powder Crushing Production Line 3 Mineral stone gold ore rock wet ball grinding mill machine for

.jpg)

Bentonite Powder Manufacturer, Calcium Bentonite Exporter

Our products of Bentonite its Variants comprises of Bentonite Activation Powder, Bentonite Horizontal Drilling Grade, Bentonite Lumps, Bentonite Pilling, Bentonite Powder, Calcium Bentonite Ore, Foundry Grade Bentonite etc along with other industrial minerals etc are suited for specific applications customized as per client requirements and international specificationsBentonite was ground in a Raymond laboratory mill, hand operated, screw feeder In Table 1, some of the properties of bentonite samples are shown Table 1 Properties of bentonite samples used for agglomeration Bentonite property Bentonite A Bentonite B Bentonite C Plate Water Absorption (4h,0,5g) (%) 691 835 933 Swelling (2g/100ml) 31 38 38PLATE WATER ABSORPTION METHOD FOR BENTONITE Bentonite is used as a binding agent in the production of iron ore pellets Through this process, iron ore fines are converted into spherical pellets, suitable as feed material in blast furnaces for pig iron production, or in the production of direct reduction iron (DRI) If you []Bentonite for IronOre Pelletizing BPN International LLCEgyptian bentonite was crushed, grinded by a ball mill, purified using magnetic separation, treated with 01N acetic acid, and finally activated by Acid activation (HCl, H2SO4) Bentonite Nanoparticle Synthesis Scheme Download Scientific

Effects of Bentonite Fiber Formation in Iron Ore Pelletization

2001年1月1日 In the production of iron ore concentrate pellets, binders are required to improve pellet green strength The most popular binder for this purpose is bentonite clay, which is added at a rate of Pintype vertical stirred media mill used for the grinding experiments The grinding experiment was performed as a batch process First, the raw bentonite sample dried at 50oC for 24 h and then crushed under 1 mm using a roll mill 350 mL of preground bentonite sample (300 µm) and 530 mL grinding media were placed into the mill chamberDry Grinding of Bentonite by Stirred Media Mill Academia2023年3月20日 Bentonite raw ore is generally in irregular lump shape after mining, and contains about 25%~28% water Bentonite grinding mill Generally, the application field of bentonite requires a powder fineness of 200 meshes Items You Must Know About Bentonite Processing 2024年5月1日 Bentonite is commonly used as a binder in iron ore pelletizing Its primary phase is montmorillonite, characterized by a layered crystal structure capable of absorbing large amounts of water Consequently, bentonite exhibits favorable water absorption and high thixotropy [[5], [6], [7], [8]]Reducing bentonite usage in iron ore pelletization through a

.jpg)

Drop number of green pellets with different types of

Activation of mixed bentonites with soda in the amounts of higher than 1% also enhanced the compressive strengths (dry and fired pellets) On the other hand, soda dosages less than 1% on the 2015年3月1日 The use of excessive bentonite also leads to the production of pellets with very plastic properties, which are undesirable for further processes due to high and easy deformation [6]Effect of Blaine Fineness on the Quality of Hematite Iron Ore This is further complicated by bentonite’s significant variation – even within the same deposit As such, bentonite process development testing is a key aspect of developing a successful processing operation Bentonite Characteristics Bentonite is a member of the smectite group of minerals and is primarily made up of montmorilloniteProcess Development Essential to Bentonite Processing Operations2024年4月22日 Effect of bentonite grinding powder air separation by Raymond mill After grinding, the Raymond grinder fan blows up the bentonite powder into the main machine shell Separating the powder by an analyzer above the grinding chamber Some bentonite materials with coarse fineness fall into the grinding chamber for regrindingBentonite Processing Plant And Grinding Machine

.jpg)

Bentonite Performance Minerals Lovell Chamber of Commerce

2024年5月29日 Bentonite Performance Minerals is proud to be the first Wyoming bentonite supplier to receive ISO 90021994 certification for a bentonite BPM closed its Osage mill and mines due to the low quality of the remaining Pet Absorbents, Iron Ore Pelletizing and Oil Field Services BPM is committed to new markets, products and The raw materials used for the preparation of the green pellets are iron ore, mill scale, limestone, bentonite and Corex sludge and their chemical composition is given in Table 1 Iron ore fines of –10 mm size and mill scale of –6 mm were ground together in laboratory ball mill to get the required finenessRecycling of steel plant mill scale via iron ore sintering plant2024年10月31日 Beneficiation: mining bentonite ore from natural coal mines to remove stones, There are many varieties of mills, such as Raymond mill, airflow mill, ball mill and so on After grinding, the bentonite should do a particle size test and test its percentage through a variety of mesh sieves, such as 80 mesh, 200 mesh, 325 mesh, etc Your Bentonite Clay Manufacturer and Supplier in ChinaSanding2014年9月1日 It is shown that the manganese ore possesses good ballability after being pretreated by HPRG twice, and good green balls were produced under the conditions of blending 20% bentonite in the feed Strengthening pelletization of manganese ore fines containing