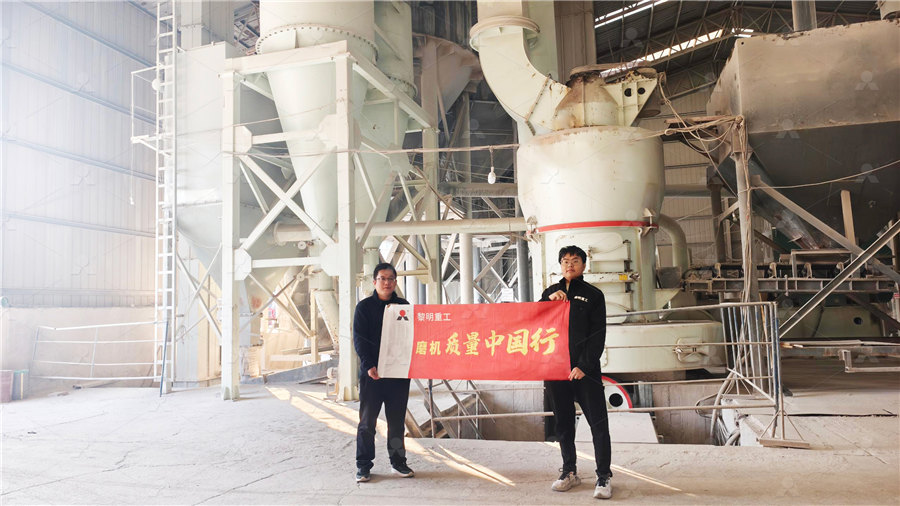

Sijiaying Phase II powder processing plant ball mill

.jpg)

Silicon Powder Properties Produced in a Planetary Ball Mill as a

2020年1月15日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding 2021年7月21日 In order to explore the impact of different ball milling technical parameters on the grain size of nano silicon powder, this paper adopted the orthogonal experimental design in The Impact of Ball Milling Process Parameters on the Preparation 2020年10月1日 In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding Silicon Powder Properties Produced in a Planetary Ball Mill as a 2019年4月8日 The phase evolution, phase composition and grain size of ball milled SiW alloys were quantitatively measured during the ball milling process Ball milling was found to proceed Ball Milled SiW Alloys: Part I Microstructural and Phase Evolution

.jpg)

Planetary Ball Mill Process in Aspect of Milling Energy

2014年4月28日 From the results obtained, it was determined that the energy transferred by means of the control of balls size and high milling speeds allowed the particles of Mg powder 2013年2月7日 Processes inside planetary ball mills are complex and strongly depend on the processed material and synthesis and, thus, the optimum milling conditions have to be Process Engineering with Planetary Ball Mills ResearchGate2021年2月19日 The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L while the optimum speed of the ball Comparative Study on Improving the Ball Mill Process Parameters 2015年4月22日 SEM micrograph of the ballmilled mixture of boron carbide and graphite powders at milling time of 0 h (manual mixing) at magnification of (a) 500Â and (b) 2000Â, respectivelyOn the Use of Ball Milling for the Production of

Silicon Powder Properties Produced in a Planetary Ball Mill as a

2020年10月1日 The current study investigates the type of ratio for ball mill jars listed in Table 3 and [63,80,168,181,183] Different balltojar ratios can affect the milling kinetics, the size, and 2020年2月1日 Rather than huge expansion, most industries will focus on maximizing resources for maximum pro tability Consequently, a study of the impact of operational parameters on ball mill energy e ciency Energy and exergy analyses for a cement ball mill of a new 2013年2月7日 Processing in planetary ball mills the purest phase of both Gd 3 Fe 5 O 12 and ZnFe 2 O 4 was chosen and rewelding of powder particles in a highenergy ball millProcess Engineering with Planetary Ball Mills ResearchGate2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties(PDF) Grinding Media in Ball MillsA Review ResearchGate

.jpg)

Ball Mills Agitated Media Mills

Overview of our ball mills and agitated media mills The classic ball mill Super Orion SO is suitable for dry hard crushing and achieves finenesses of under 10 µm For superfine dry grinding: The energyefficient Pulvis combines a vertical agitator bead mill with a highperformance classifier and is also suitable for grinding hard materialsPowder Technology 211 (2011) 19–27 Contents lists available at ScienceDirect Powder Technology j o u r n a l h o m e p a g e : w w w e l s ev i e r c o m / l o c a t e / p ow t e c Grinding in an air classifier mill — Part I: Characterisation of the onephase flow Petya Toneva a,1, Philipp Epple b, Michael Breuer c, Wolfgang Peukert a,⁎, KarlErnst Wirth a a b c Institute of (PDF) Grinding in an air classifier mill Academia2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral Processing2023年6月27日 Nevertheless, parameter factors, such as the type of ball milling, balltopowder ratio (BPR), rotation speed, grinding period, size and shape of the milling media, and process control agent (PCA (PDF) Producing Metal Powder from Machining Chips Using Ball

.jpg)

Physicochemical Problems of Mineral Processing Investigation

2017年3月20日 Ball mill process parameters for five ground samples with ball load J = 050, particle filling U = 053, mill speed N c = 71% and mill factor F c = 069 Shape and size factors equation and Manufacturer of Ball Mill Batch Ball Mill, Call 76% Response Rate SEND Our Products » Cement Plant; Ball Mill; Packing Machines; Industrial Crushers; Feeder Machines; Grinding Plant; Industrial Conveyors; Ball Mill Batch Ball Mill Manufacturer from Jodhpur2006年1月10日 The pilot setup of a horizontal high energy ball mill (Simoloyerk) that has been successful in reactive milling, mechanical alloying, and formation of ductile metalflakes is used for semi (PDF) Influence of formulation and processing variables on ball mill 2007年12月1日 The refining product and the balls are then agitated by a rotating shaft with arms The product can also be recycled through the ball mill several times (Alamprese, Datei, Semeraro, 2007)During Optimization of processing parameters of a ball mill refiner for

.jpg)

Ball Mill an overview ScienceDirect Topics

The history and necessity of mechanical alloying M Sherif ElEskandarany, in Mechanical Alloying (Second Edition), 2015 2515 Planetary ball mills The Planetary ball mills are the most popular mills used in MM, MA, and MD scientific researches for synthesizing almost all of the materials presented in Figure 11 In this type of mill, the milling media have considerably high AllisChalmers ball mills (mineral processing) for sale Includes 5 HP, 3 phase, 60 cycle, 230 volt TEFC motor, bull gear and pinion drive Includes dust cover Ore Processing Plant (Including Jaw Crusher) All assets are ready to be loaded and go !!Used Ball Mills (mineral processing) for sale Machiniogeneration in the ball mill decreases The correlation is depicted in Figure 3a, from which it can be seen that the Performance optimization of an industrial ball mill for chromite processing VOLUME 117 77 Table III 864(89 40+8193/95)89*638119*464,9!8#Performance optimization of an industrial ball mill for chromite processing2024年8月8日 In this process, a powder mixture is placed in a rotating drum, along with grinding media such as balls The kinetic energy imparted by the balls' motion breaks the powder into smaller pieces, making it a critical technique in various industries In mining, it's used for ore processing, enabling the extraction of valuable mineralsBall Mill Success: A StepbyStep Guide to Choosing the Right

.jpg)

Charge behaviour and power consumption in ball mills: sensitivity

The experimental assessment of ball mills type MCB 45x6 (МШЦ 4,5х6) operating in copper ore processing plant and SAG mill 85x53 operating in gold ore processing plant are presented The experimental results are statistically processed and some 2019年8月14日 Ball mill is a common grinding equipment in concentrator Common Types of Ball mill back to top The common industrial ball mills mainly include cement ball mill, tubular ball mill, ultrafine laminating mill, cone ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill, wind discharge ball mill, double bin ball mill, energy saving ball millThe Ultimate Guide to Ball Mills MiningpediaPowder Particle Processing Powder Particle Processing Powder Particle Processing Powder Particle Processing Ball Mills Agitated Media Mills Pulvis Pro Simplify your processes The spiral jet mill AS 200 II Baseline is designed to combine a wellknown and proven technology with high economic efficiencyAS 200 II Baseline Hosokawa Alpine2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a (PDF) Effects of Ball Size Distribution and Mill Speed and Their

Ball Mills in the Mineral Processing Industry

2024年5月27日 Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger Investing in cuttingedge 1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, including Ball Mill Mining Grinding Mill JXSC MachineryBall mill is the cement crushing equipment in the cement plant Compared with open circuit ball mill, the closedcircuit ball mill has high efficiency, high output, low cement temperature, and good comprehensive benefit It is the best choice for a cement plantBall Mill In Cement Plant Cement Ball Mill AGICO Cement2022年3月15日 These mills consume enormous amounts of electrical energy (5060%); consequently, comminution costs roughly 60% of the overall investment in a beneficiation plant [2,3](PDF) Power consumption management and simulation of

Controlling the Ground Particle Size and Ball Mill Load Based on

2023年9月23日 Controlling the Ground Particle Size and Ball Mill Load Based on Acoustic Signal, Quantum Computation Basis, and Least Squares Regression, Case Study: Lakan LeadZinc Processing Plant September Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys In fact, ball milling process is not new and dates back to more than 150 years It has been used in size comminutions of ore, mineral dressing, preparing talc Ball Milling an overview ScienceDirect Topics2020年1月15日 Mechanical milling is a promising route for production of submicron and nano sized silicon powders, but it is challenging to predict and control the product properties In this study a metallurgical grade silicon quality was milled in a planetary ball mill and the properties of the powder were investigated as a function of grinding time, grinding bead size (20 mm, 2 mm, Silicon Powder Properties Produced in a Planetary Ball Mill as a 2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 inGrinding Mills Common Types 911Metallurgist

.jpg)

Grinding Mills Mineral Processing Equipment CITIC HIC

High costeffectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product CITIC HIC is responsible for setting the national standards of semiautogenous mills (SAG mills) and ball mils, supported by powerful database, optimized process technology, cuttingedge design concept, and 60 years of experience in developing Find your powder mill easily amongst the 104 products from the leading brands (Fritsch GmbH, NETZSCH, BOHLE, FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Mill Powder mill, Powder grinding mill All industrial 2023年3月15日 One of the very first B 4 C products synthesized by a superb Dow scientist (A) was made using a laserheated reactor with boron trichloride as one of the reactants (Fig 1) [[1], [2], [3]]The powder averaged 34 nm in size and could be fabricated to make a quality part, provided that it was not exposed to air which would result in surface oxidationFrom a laboratory curiosity to a commercial powder processing plant 2015年11月30日 If the rate of feed increased, coarser product will be obtained and if speed of rotation is increased the fineness for a given capacity is increases During grinding, the balls themselves wear and are continuously replaced by Ball Mill PPT SlideShare

Zhengyuan Powder Equipment

LHMB Ball Mill The ceramic media ball milling production line is the best solution for processing highpurity materials It is specially designed for highpurity materials: the grinding lining and media are made of corundum, cobblestone, quartz, zirconia, etcRevolutionize your experience with our cuttingedge grinding solutions Explore our range of best chilli processing plant now Enquire Now ! Industries 3rd Stage: Grader – Grader arrests the smaller stones mud ball through screen coarser dusts collected through Cleaned chillies are cut into flakes or pizza cut size in Hammer MillBest Chilli Processing Plant Grinding Solutions Enquire Now2003年2月15日 The highenergy ball mill processing can be divided in three main groups Fe 2 O 3 NPs prepared by plant extract and attained after 10 h milling at constant balltopowder (PDF) High Energy Ball Mill Processing ResearchGate2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Ball Mill Critical Speed 911Metallurgist

.jpg)

Improving the Morrell Cmodel's accuracy in predicting the ball mills

2023年3月1日 This paper investigates grinding media's dynamic voidage to improve the MorrellC model's accuracy in predicting the ball mills’ power draw Using a three installed in the Sarcheshmeh copper complex processing plant on grinding effect in horizontal planetary ball mill Adv Powder Technol 25:983–990 Crossref Web 2013年12月1日 Percent passing of milled Al 2 O 3 powder as a function of particle size for varying ball diameter Rotation speeds are (a) 50 rpm, 100 rpm, and (c) 153 rpmEffect of ball size and powder loading on the milling efficiency 2019年5月20日 The manufacture and preparation of charge powders are the first and one of the most important stages of producing composite materials by powder metallurgy []Processing in planetary ball mills is often used to synthesize composite powders []The main parameters that characterize the efficiency of planetary mill processing are the input energy (fraction of the Simulation of the Energy–Force Parameters of Planetary Ball Mill