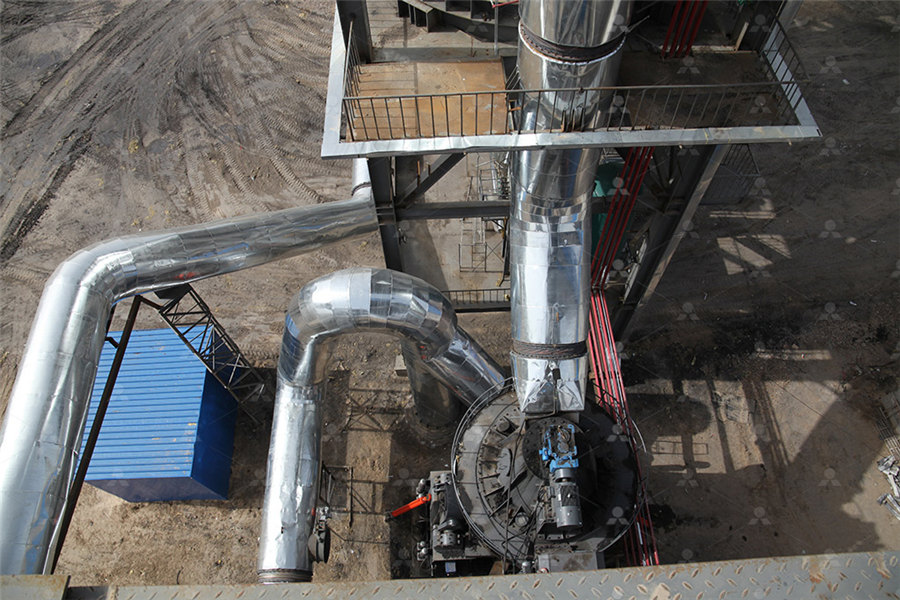

Performance of mediumspeed mill and its powder making system

.jpg)

Mill Speed an overview ScienceDirect Topics

2011年8月1日 Milling speed is one of the most important milling parameters that controls the milling process because it provides the mill with the energy required for (1) powder particles Through the detailed analysis and research of medium speed pulverizer and pulverized coal pipelines, the crux was found and the optimization measures of pulverizer and dynamic Research and Application of Optimization Technology of Medium 2021年6月29日 Optimum performance of ball mill could potentially refine Blaine fineness, thereby improving the cement quality This study investigates the effects of separator speed and mill speed onEffects of Mill Speed and Air Classifier Speed on 2015年8月6日 To investigate the vibration performance of mediumspeed mills, eight mediumspeed mills in the Yuzhou, Yaomeng, Xinyang, Sanmenxia, and Hebi power plants in Henan Study on dynamic response and vibration reduction of medium

Study on dynamic response and vibration reduction of medium

2015年1月22日 Mills can be divided into three types: low, medium, and highspeed mills The mediumspeed mills operate within 50 and 300 r/min, the lowspeed mills within 15 and 25 2020年6月25日 Mechanical testing of the produced bulk composites resulted in achieving superior mechanical properties, characterized by 92% higher hardness, 180% higher yield Superior Mechanical Performance of Inductively Sintered Al/SiC 2017年8月1日 An identification method of the model of the ballandrace coal mill motor power signal with the use of machine learning techniques is presented, aimed at simulation of the Modeling of a medium speed coal mill Semantic Scholar2020年1月1日 The research results show that lower ball mill speed is beneficial to achieve the effect of uniform mixing of powder, excessive rotation speed of ball mill will lead to Effect of ball milling speed and sintering temperature on

制粉项目-2023.11.17.jpg)

(PDF) Effects of Ball Size Distribution and Mill Speed and Their

2020年7月2日 A comprehensive investigation was conducted to delineate the effect of ball size distribution, mill speed, and their interactions on power draw, charge motion, and balls segregation in a The milling and mechanical alloying (MA) performances of a new high energy ball mill with functions of the powder layer formation onto inner wall of revolving vessel and the intensive impact of medium ball on the layer were studied The high intensive mill is capable to decrease of powder size under 5 μm at 18 ks of treatment time for glass, bottom ash and tourmaline, and Basic Performance of High Speed, High Purity and High Intensive Ball MillPDF On May 28, 2019, Girisha Lakhman Naik and others published Design and Performance of Ball Milling for Powder Metallurgy Composites Find, read and cite all the research you need on ResearchGate(PDF) Design and Performance of Ball Milling for 2018年7月19日 The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screen(PDF) Design, construction and performance evaluation of a

Effective Ball Mill Media for Superior Black Powder Production

2024年8月1日 Operate the ball mill at the recommended speed for the specific media and material The critical speed of the mill should not be exceeded to avoid inefficient grinding and potential hazards Use appropriate cooling methods, such as cutting oil, to manage heat buildup and reduce wear on the media and mill Maintenance and Monitoring:2010年3月10日 ball, while breaking the material grain, causes in it stress which is higher than the grain hardness Therefore, for the biggest grain size, it is necessary to have a definite number of the (PDF) Optimization of mill performance by using online ball and The mediumspeed coal mill system is mainly composed of raw coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and cold air regulating valves View in fulltext Similar The structure of MPS mediumspeed coal mill system2017年5月1日 Download Citation Modeling of a medium speed coal mill This paper presents a coal mill model that considers the effect of coal moisture on its accuracy This mathematical model is derived Modeling of a medium speed coal mill ResearchGate

Mill Steam Inerting System Review and Performance Validation

In addition to the requirement by NFPA 85 for inerting a tripped mill system, coal mill OEMs usually recommend that a mill system be inerted during both the normal mill startup and shut down process Steam is commonly employed in the power industry for coal pulverizer system inerting, due to its ready availability and cost effectivenessTaking hp1103 medium speed roller disc coal mill as the carrier, this paper mainly describes the common faults in the normal operation of this type of coal mill, and analyzes and judges each type ofSHPHGLXP VSHHGFRDOPLOO ResearchGateThese mills enable the production of highquality powders with precise particle sizes, making them indispensable in various industries Consider factors such as mill size, grinding media, mill speed, screening system, and maintenance to optimize the performance of powder grinding millsPowder grinding mills: Revolutionizing the manufacturing industry 2018年12月13日 The large amount of calculation and iteration for manual thermal calculation are easily lead to errors In this paper, based on the direct fired systems with medium speed mill, a common computing (PDF) Program Design and Calculation Example of Direct Fired

.jpg)

Superfine Grinding Mill for Making Tea Powder by feng li Medium

2017年12月28日 Superfine Grinding Mill for Making Tea Powder The tea through the instant grinding method, crushed into more than 600 mesh of tea powder, to maximize the retention of the original2017年8月15日 According to the equation, the yield of fine powder can be improved by increasing rotation speed and the diameter of the electrode, which has also been shown in experiments42 It was reported that the yield of fine Ti alloy powder can be increased to ~16% using an electrode rod with a diameter of 100 mm and a rotating speed of 30,000 rpm42 It Review of the Methods for Production of Spherical Ti and Ti Alloy Powder2024年9月1日 To improve vertical mill performance, a vertical stirred mill is used as the research object Firstly, an electromechanical multibody dynamic model (EMBD) of the vertical stirred mill is established, followed by the establishment of a discrete element method (DEM) analysis model of the grinding media, and then the DEMEMBD coupling model is formedPerformance analysis of vertical stirred mill based on multi 2023年10月30日 By conducting this comparative analysis, the aims of the study was to examine the impact of the new lifter's geometry and rotational speed of the mill on torque, power draw, particles behavior Analyzing the influence of lifter design and ball mill speed on

Analysis and Optimization of Grinding Performance of Vertical

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on the energy 2020年4月7日 Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis methods often result in low fault recognition rate or even misjudgment due to the imbalance between fault data samples and normal data samples In order to obtain massive fault sample data effectively, based on the Modeling of Coal Mill System Used for Fault Simulation MDPI2011年8月1日 13112 Mediumspeed mill Mediumspeed mills are smaller than lowspeed units and are generally of the vertical spindle construction The speed of the grinding section of these mills is usually 75–225 rpm They operate on the principles of crushing and attrition Pulverization takes place between two surfaces, one rolling on top of the otherMill Speed an overview ScienceDirect Topics2017年8月1日 This paper presents a coal mill model that considers the effect of coal moisture on its accuracy This mathematical model is derived through the analysis of mass flow, heat exchange, and energy transferring balances in which all heat input into or output from the coal mill are calculated quantitatively to reduce the number of unknown parameters that need to be Modeling of a medium speed coal mill ScienceDirect

.jpg)

Modeling and simulation of MPS medium speed coal mills

2015年1月15日 The coal mill used in the coalfired power plants is modeled in view of the controller design rather than the educational simulator The coal mass flow and the outlet temperature are modeled by 2006年7月14日 The milling and mechanical alloying (MA) performances of a new high energy ball mill with functions of the powder layer formation onto inner wall of revolving vessel and the intensive impact of Basic Performance of High Speed, High Purity and High Intensive Ball MillWith the ongoing development and deployment of mediumlow speed maglev vehicles in China, it has become common to increase operational speeds from 100 km/h up to 140 km/h or even 160 km/h, necessitating further studies and simulation models to understand the implications of these changes This paper analyzes mediumspeed maglev vehicletrackgirder coupling dynamic Dynamic Performance of Medium Speed Maglev Train Running able condition assessment, and decision making of mediumspeed mill, the measuring points should be placed on the locations that re ect abundant structural information of mediumspeed mill So the OSP for vibration test on mediumspeed mill is extremely necessary In this paper, a reliable nite element model (FEM) of mediumspeed millSensor Placement Optimization of Vibration Test on Medium‐Speed Mill

An investigation of performance characteristics and energetic

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose 2015年1月22日 To investigate the vibration performance of mediumspeed mills, eight mediumspeed mills in the Yuzhou, f0000 É4150 100 2350 330 50 7000 10000 1450 1150 2400 2400 1150 1450 Spring vibration isolators Upper bedplate Buttress Figure 1 Spring vibration–isolated foundation for a mediumspeed mill (mm) 2 Advances in Mechanical Study on dynamic response and vibration reduction of mediumspeed 2021年7月1日 Our findings show that decisionmaking in discrete MS is established temporally based on strategic, operational, and control definitions, influencing firms’ operational performanceKey factors for operational performance in manufacturing systems 2017年8月1日 In this study, the lumped parameter modeling method is adopted with the following assumptions: 1) the parameters of the medium in the coal mill are uniform; 2) the media in the coal mill are incompressible; 3) the parameters of the medium in the coal mill change along the axial direction only; 4) the change in the flow power in the coal mill is ignored; 5) the coal Modeling of a medium speed coal mill ScienceDirect

Design, Fabrication, and Performance Evaluation of a Hammer Mill

2019 The performance of a hammer mill fabricated in Uganda was evaluated and the optimal performance conditions were determined The evaluation was done with screen hole diameters (S) of 15, 20, and 30 mm, hammer tip speeds (H) of 6812, 8181, 10217 m s and hammer thicknesses (T) of 40, 50, and 60 mm for determination of energy consumption and 2023年4月11日 For the speed and tension system of the reversible cold strip rolling mill with output constraints, parameter perturbations and load disturbance, a fixed‐time prescribed performance optimization Fixed‐time prescribed performance optimization control for the speed 2019年12月1日 OPTIMIZATION AND PERFORMANCE EVALUATION OF BLENDERHAMMER MILL CO Ajayi1*, FA Oyawale1, S A Afolalu1 1Mechanical Engineering Department, College of Engineering, Covenant University, Ota Optimization And Performance Evaluation Of BlenderHammer MillIt can crush materials into powders at level of 20006000 mesh or even finer through scientific grinding medium ratio, longyi wet mill works continuously by feeding materials from the base through pump, after which frequency Top 5 Powder Manufacturing Machinery Industry in

Superior Mechanical Performance of Inductively Sintered Al/SiC

2020年6月25日 Superior Mechanical Performance of Inductively Sintered Al/SiC Nanocomposites Processed by Novel Milling Routeroute composites The performance test on the fabricated ball mill for the aluminum in powder form and blended with alumina shown proper distribution through scanning electron microscope images for different weight percentages of alumina The ball mill is used for different speed, timeDesign and Performance of Ball Milling for Powder Metallurgy Composites2019年7月28日 The performance of a hammer mill fabricated in Uganda was evaluated and the optimal performance conditions were determined The evaluation was done with screen hole diameters (S) of 15, 20, and (PDF) Performance evaluation of a hammer mill during2024年6月3日 Biochariron based material has been recognized as an important soil and underground water remediation material, which successfully achieves by adsorption, reduction, and mediating advanced oxidationResearch progress on synthesis mechanism and performance

.jpg)

High Performance Low Cost Size Reduction with the Mikro

The Mikro Pulverizer® Hammer Screen Mill combines a high speed mechanical impact mill with an outlet screen to control particle size These hammer and screen mills are used in the production environment to provide continuous size reduction at high capacities for a variety of materials This type of mill is used widely for themedia filling, media size, mill speed, and mill diameter, significant effort and time is required (Kano et al, 2000) However, operating parameters are critical indicators influencing the performance (energy efficiency, fineness, surface area, capacity, fluidity, etc) of a ball millInfluences of operating parameters on dry ball mill performance2015年8月6日 Many engineering technicians have accumulated extensive experience in the longterm design of dynamic machine foundations; thus, many designs are created by simply matching dynamic characteristics of a system to those of previous systems 8 For example, in the design of foundations for mediumspeed mills in thermal power plants, the mass ratio of the Study on dynamic response and vibration reduction of mediumspeed 2010年8月18日 Request PDF Effects of disc rotation speed and media loading on particle flow and grinding performance in a horizontal stirred mill IsaMill™ is a highspeed stirred mill used in the mineral Effects of disc rotation speed and media loading on particle flow