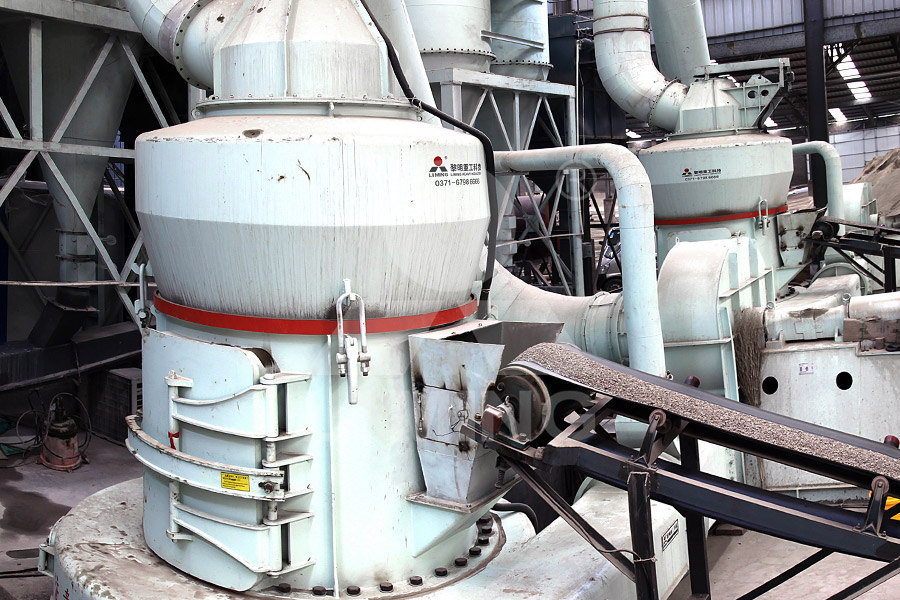

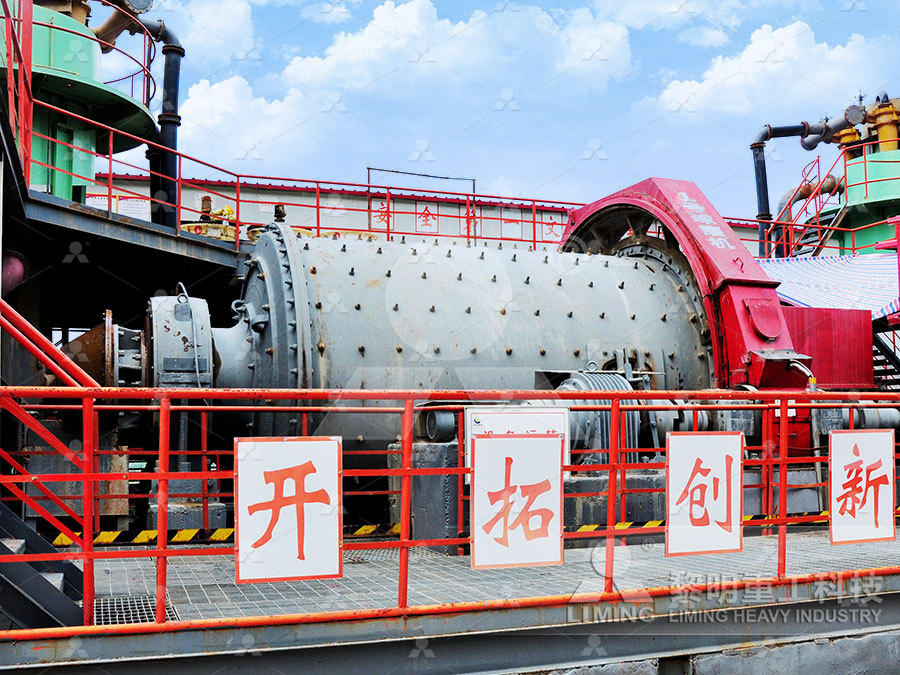

Rare earth ore stripping and crushing

.jpg)

A review on complex utilization of mine tailings: Recovery of rare

2024年6月1日 Strategies like extracting rare earth elements and making geopolymers from tailings were explored Techniques like bioleaching and mechanical activation can improve 2020年3月26日 The production of rare earth oxides from beach sand involves several steps such as mining, preconcentration of the heavy minerals, separation of monazite, and finally, Mineral Processing of Rare Earth Ores SpringerLink2019年5月20日 Highly efficient separation of rare earths from nickel and cobalt by solvent extraction with the ionic liquid trihexyl (tetradecyl) phosphonium nitrate: a process relevant to A review on the recovery and separation of rare earths and 2015年8月31日 Present review reports the commercial processes based on pyro–hydro or hybrid techniques as well as systematic research for process development to recover rare (PDF) Process development to recover rare earth metals from

.jpg)

Mineral Processing and Extractive Metallurgy of the

2015年12月25日 This chapter is about mineral processing of the rare earths (making the mined ore into a concentrate of the valuable minerals), and extractive metallurgy of the rare earths (how to get the metals out of the concentrate) 2020年9月1日 To remove thorium and uranium to the highest degree requires separate solvent extraction or ion exchange steps designed to specifically extract these impurities by anion Recent progress in impurity removal during rare earth element In the paper, the ore properties of these REE deposits are introduced and the renovation and progress on the beneficiation techniques including flowsheets, flotation and leaching reagents CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION2017年11月10日 Rare earth elements (REEs) have unique physicochemical properties that make them indispensable in many emerging critical and green innovations The performance of REE in the hightechTechnospheric Mining of Rare Earth Elements from

.jpg)

[PDF] Development of a physical separation preconcentration

2024年11月19日 DOI: 1017159/24119717/695/2024 Corpus ID: ; Development of a physical separation preconcentration process for the extraction of Rare Earth bearing ore 2017年7月3日 The technology is used in applications as diverse as ore processing, pharmaceuticals, agriculture, industrial chemicals, petrochemicals, the food industry, the purification of base metals, and the (PDF) Solvent Extraction and Its Applications on Ore 2023年11月9日 Step 1 Crushing The mined rare earth ores enter the jaw crusherthrough a vibrating feeder and are initially broken into smaller particles A cone crusheris then used for secondary crushing After screening, the Unlocking Potential: Rare Earth Elements Processing 2024年9月29日 Electronic waste (ewaste) contains valuable rare earth elements (REEs) essential for various hightech applications, making their recovery crucial for sustainable resource management This review provides A Review of the Occurrence and Recovery of Rare

.jpg)

Material and Energy Requirement for Rare Earth Production

2013年8月21日 The use of rare earth metals (REMs) for new applications in renewable and communication technologies has increased concern about future supply as well as environmental burdens associated with the extraction, use, and disposal (losses) of these metals Although there are several reports describing and quantifying the production and use of REM, there is still a First, the old rareearth mines can be reopened but this will take some time2 Secondly, rare earths can be substituted by other less expensive rare earths or dblock metals, but this o en results in products which are less effective and usually requires a new product design2 Thirdly, recycling of rare earths from scrap produced throughout theFrom NdFeB magnets towards the rareearth oxides: a recycling Handbook on Rare Earth Metals and Alloys (Properties, Extraction, primary crushing, secondary crushing, wet grinding, dry grinding etc The rare earths are silver, silverymwhite, or gray metals; they Ion Adsorption Type Ores 5 Other Rare Earth Sources Commercially important Rare Earth Minerals 1 Monazite 2 Bastnasite 3Handbook on Rare Earth Metals and Alloys (Properties, Extraction Footnotes 1 Based on Mineral Resource Estimate announced on 20 March 2023 2 Based on public disclosure from owner 3 TREO includes Y 2 O 3 Historical processing at Phalaborwa, including initial flotation by Foskor followed by further processing in Sasol’s phosphoric acid plant, deposited a gypsum residue with upgraded rare earth elements in the stacksPhalaborwa — Rainbow Rare Earths

.jpg)

CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION

ERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sina2021年10月15日 Rare earths include the chemical elements of the third Reasons are the different ore inputs/t REO (Tables 2, 3) as well as different stripping used by Sprecher, is based on the production of phosphate rock from phosphate ore (Althaus et al, 2007a), where after crushing and sieving, the phosphate ore is calcined to Life Cycle Assessment studies of rare earths production Findings 2024年11月21日 Rare earth ore, also known as rare earth element ore or rare earth metal ore, contains various rare earth elementsIt mainly contains lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, lutetium; it is also a general term for 17 metal elements such as Rare Earth Ore Beneficiation Is Difficult, What Are The Methods?Round Top2 Ionic Clay US Rare Earths/TMRC 0063% 39 45 179 La Paz2 Ionic Clay American rare Earths 004% 80 1 7 Makuutu2 Ionic Clay Ionic Rare Earths 008% 232 10 30 Mount Weld2 Hard rock Lynas Rare Earths 790% 18,833 30 750 Bear Lodge2 Hard rock Rare Element Resources 308% 7,059 113 472 Longonjo2 Hard rock Pensana plc 143% 3,170 29 967UNLOCKING SECONDARY SOURCES OF CRITICAL RARE EARTHS

.jpg)

A review on the recovery and separation of rare earths and

2019年5月20日 Recovery of rare earth oxides from spent rechargeable batteries using SiO 2 slag was investigated and reported (Tang et al, 2013) Two slag systems CaO SiO 2 Al 2 O 3 and CaO CaF 2 were used to recover REEs from EOL permanent magnet wastes (Yang et al, 2013a) The rare earth rich slag is further subjected to hydrometallurgical process2023年12月14日 Efficient waste management practices can utilize waste as a resource for the recovery of valuable metals Rareearth metals have significant economic importance and are currently in high demand because of their strategic industrial applications These metals are critical to the development of advanced devices However, the supply of critical metals from Novel devices for the extraction and recovery of rareearth metals 2020年3月26日 The major rare earth minerals are found as monazite and/or bastnaesite In addition to the above existing source, trace amounts of rare earths including lanthanides, scandium and yttrium are found in other sources such as red mud of Bayer’s process, deepsea nodules, fly ash and illuminate (Hidayah and Abidin 2018)The concentration of rare earth Fundamental Principle and Practices of Solvent Extraction (SX) and 2009年4月1日 Rare earths are essential constituents of more than 100 mineral species and present in many more through substitution They have a marked geochemical affinity for calcium, titanium, niobium, zirconium, fluoride, phosphate and carbonate ions Industrially important minerals, which are utilized at present for rare earths production, are essentially three, namely Handbook on Rare Earth Metals and Alloys (Properties, Extraction

(PDF) A Review of Rare Earth Mineral Processing Technology

2017年9月10日 Rare Earth Ores Processing Steps Most of the literature has been reviewed by several authors including beneficiation process 22 and solvent crushing and grinding) 2018年11月30日 Rare Earth Element Deposits – aspects of their evaluation, diversity, geochemistry and genesis Phillip L Hellman There has been a significant growth in exploration activity for rare earth Evaluating Rare Earth Element Deposits ResearchGate2023年7月28日 The beneficiation process can vary depending on the specific composition of the rare earth ore and the desired end products Below are the general steps involved in the beneficiation of rare earth ore: Crushing and Grinding The rare earth ore is first crushed into smaller particles to increase the surface area for further processingRare Earth Ore: From Mining to Application JXSC MineralAt Skorpion Zinc mine, in southwest Namibia, zinc oxide ore is refined through sulphuric acid leaching, solvent extraction, electrowinning and casting of the final 99995 % Zn metal Over the Chapter 6: Stripping rare earth elements from the organic phase STRIPPING RARE EARTH ELEMENTS AND IRON FROM D2EHPA

Reclaiming rare earth elements from endoflife products: A

2015年7月1日 The rare earth elements (REEs) are presently regarded as being among the most critical chemical elements Their importance for the advancement of technology has been widely discussed and this is acknowledged in many recent reports (European Commission, 2011, UN Environment Programme and UN University, 2009, US Department of Energy, 2011)Bastnaesite is a rare earth fluorocarbonate mineral1, RE(CO3)F, which primarily contains light rare earth elements After physical upgrading, bastnaesite ore concentrates contain between 40 to 60% REE2 One of the main concerns in past bastnaesite Leaching of rare earths elements (REE) past and present2024年6月18日 It could be seen that the concentration of RE in the stripping solution was 278 g/L, displaying all the rare earth elements were stripped into the stripping solution The concentrations of Bi(III) and Fe(III) in the stripping solution were only 6 mg/L and 0 mg/L, indicating that the effective separation of RE(III) from Bi(III) and Fe(III) was achievedEfficient separation and comprehensive recovery of rare earth, Abstract A solidphase extraction resin SIRsP227/XAD7HP was prepared by impregnating extractant P227 onto macroporous resin XAD7HP beads SIRsP227/XAD7HP beads were characterized by Fourier transform infrared spectroscopy (FTIR) and scanning electron microscopy (SEM) equipped with energydispersive spectroscopy (EDS) The adsorption Solidphase extraction and separation of heavy rare earths from

(PDF) Economic analysis of rare earth element processing

2022年8月22日 Although rare earth deposits are found on all continents, China produces more than 90% of all globally used rare earth metals Besides its economic dominance, China has also gained a monopolistic 2020年9月23日 A Review of RareEarth Elements Extraction with Emphasis on Nonconventional Sources: Coal and Coal Byproducts, Iron Ore Tailings, Apatite, and Phosphate ByproductsA Review of RareEarth Elements Extraction with Emphasis on 2018年11月5日 Rare earth elements are widely found in many minerals, some of which, such as bastnaesite, monazite, and xenotime, are of great commercial value Cerium (Ce) is the rare earth element with the highest content in light rare earth ore Solvent extraction is the most effective and efficient method to recover and separate Ce from other light rare earth elements After acid Extraction and Recovery of Cerium from Rare Earth Ore by 2024年3月15日 Separating rare earth oxides from the mined REE ore is a multistep process that includes crushing, grinding, chemical leaching, and solvent extraction Production of refined REEs is highly localized, with China currently producing 87% of the global refined REE supplyRare earth elements facts Canada

.jpg)

Rare Earth Elements: Overview of Mining, Mineralogy, Uses

2014年10月29日 Rare earths are used in the renewable energy technologies such as wind turbines, batteries, catalysts and electric cars Current mining, processing and sustainability aspects have been described in this paper Rare earth availability is undergoing a temporary decline due mainly to quotas being imposed by the Chinese government on export and action PDF On Jan 23, 2019, Kai Li and others published Extraction and Recovery of Cerium from Rare Earth Ore by Solvent Extraction Find, read and cite all the research you need on ResearchGateExtraction and Recovery of Cerium from Rare Earth Ore by2024年2月2日 The Balzhe rare earth mine, renowned for its rich reservoirs of niobium, zirconium, and rare earth elements, poses a unique challenge due to its diverse and interbedded mineral compositionGravitybased preconcentration strategies for complex rare earth ore 2022年3月29日 The demand for highefficiency, lowenergy consumption materials, with high durability and stability, has led to the rapid increase of the demand and prices of Rare Earth Elements (REE) The REE monopoly of Sustainable Recovery, Recycle of Critical Metals and

.jpg)

Separation of uranium and thorium from rare earths for rare earth

2015年6月1日 The rare earth ores were from Mountain Pass deposit in the USA with the main rare earth minerals of bastnasites However, the stripping of U(VI) and Th(IV) from D2EHPA and EHEHPA is difficult Only sodium carbonate is efficient for their stripping (Ritcey, 2006, Zhang et al, 2010, Dinkar et al, 2012)2022年6月30日 Among them, monazite, bastnaesite and xenotime are found to be the superior primary source of REM Weathered crust elution deposited rare earth ore (Jun et al, 2010) also known as ionabsorbed clays are a very important primary source in which 60% of rare earth oxides are from the heavy rare earth element group (Jha et al, 2016)A systematic review on leaching of rare earth metals from primary 2016年10月27日 Neodymium and dysprosium are two rare earth elements (REEs), out of a group of 17 elements Due to their unique properties, REEs gained increasing importance in many new technologies, like wind turbines, batteries, etc However, the production of REEs requires high material and energy consumption and is associated with considerable environmental Environmental Impacts of Rare Earth Mining and Separation Based PDF On Nov 1, 2020, Jiaming Xia and others published Rare earth elements deposits in China: Spatiotemporal distribution and oreforming processes Find, read and cite all the research you need (PDF) Rare earth elements deposits in China: Spatiotemporal

.jpg)

(PDF) Stripping and recovery of U and Th from EHEHPA in rare earth

PDF On Oct 1, 2023, Zheng Li and others published Stripping and recovery of U and Th from EHEHPA in rare earth separation plant Find, read and cite all the research you need on ResearchGate2024年11月1日 Ionadsorption type rare earth ores (IATREOs) are a crucial rare earth resource with significant economic and strategic value, widely distributed throughout southern China 1, 2, 3 These ores comprise fifteen rare earth elements (REEs), categorized into three groups: light REEs (LREEs, including La, Ce, Pr, and Nd), medium REEs (MREEs, including Sm, Eu, Gd, Efficient enrichment and selective recovery of rare earths from Ionabsorbing Type Rare Earths Ore mining is also present which Beneficiation of a beach placer sand deposit from Malawi is Ore CRUSHING/ GRINDING CONCENTRATION (Flotation Fig 7 Flowsheet illustrating the successive extraction and stripping stages to separate middle rare earth concentrate Na2CO3, 50 vol% 1 M NaOH and (PDF) Process development to recover rare earth metals from Ionadsorption type rare earth (RE) ore mainly distributes in Southern China, which contains 005–02 wt% REO adsorbed on the surface of aluminosilicate clay minerals, is strategic mineral resource especially for heavy rare earth elements (Nie et al, 2020, Wang et al, 2023)The main form of REEs in the ore is the ionexchangeable phase adsorbed on clay mineralA novel extraction process for efficient recovery of rare earth

Rare earths: A review of the landscape MRS Energy Sustainability

2018年6月26日 Production and use The United States Geological Survey produces annual statistics on various aspects of rare earths in its Minerals Yearbook16 The yearbook is the source of information in this section, unless otherwise stated The global production of rare earths have increased dramatically since the 1950s (Fig 1 17)The United States was the primary