The weight of PCB100 ore mill

.jpg)

Cross Beater MILLS

Net Weight 120kg MRC723 PCB100 Features and Advantages: It can be fixed on the floor and equipped with casters to move easily With quick locking device and motor braking, it has high safety performance The grinding process is rapid and produces less heat The size of the This tool helps you to calculate weight, area, volume and freigth cost for several types of printed circuit boards (PCBs) Material thickness, copper thickness, material type and layer quantity PCB weight calculator » Standard, multilayer aluminum PCBsEach gram of crushed router PCB contained at least 333 ppm of copper (Cu) according to the initial test with aqua regiaMetal content of ores and PCBs Download Table ResearchGate2016年3月21日 Example: A mill in closed circuit with a classifier receives 300 dry tons of crude ore per day, and the percentages of solid are respectively 25, 50, and 84% in the classifier overflow, feed to classifier, and sand, equivalent Common Basic Formulas for Mineral Processing

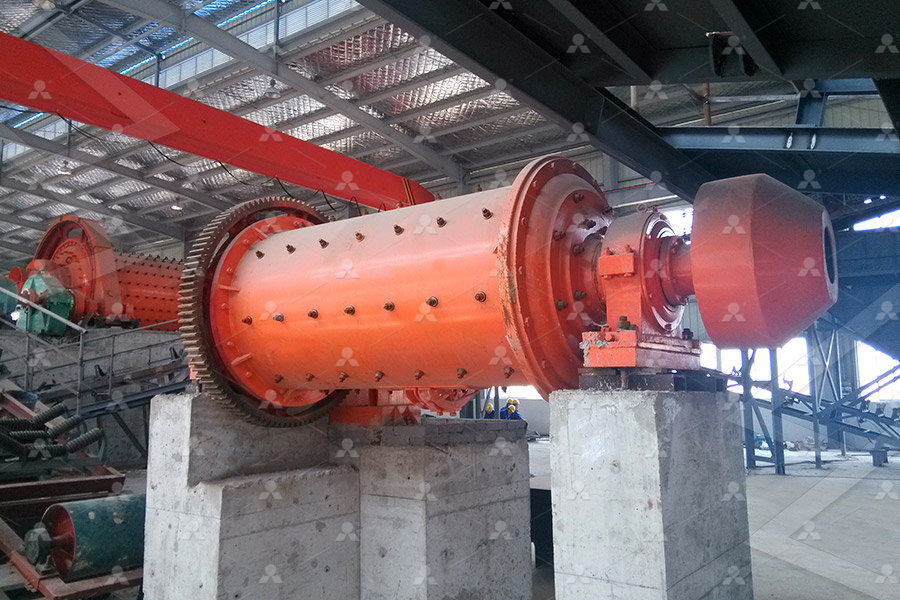

Ball Mills Mt Baker Mining and Metals

Our ball mills are industrial grade and designed for continuous operation, equipped with oversize roller bearings and a complete drive system All wear parts are highly abrasion resistant and replaceable The capacity, or Custom designed brushless DC motor dynamically balanced to G25 grade for minimal vibration All materials listed here are merely a sampling of what can be used on the Bantam ToolsTM Bantam Tools™ Desktop PCB Milling Machine Specifications Digi 2015年11月1日 In this paper, a novel mechanical process is proposed for enriching metal content of computer Printed Circuit Boards (PCBs) The PCBs are crushed and divided into Characterization and mechanical separation of metals from Custom designed brushless DC motor dynamically balanced to G25 grade for minimal vibration All materials listed here are merely a sampling of what can be used on the Bantam Tools Bantam Tools Desktop PCB Milling Machine Specifications

Bond Work Index Procedure and Method

2015年6月6日 Add a prepared 500 g charge slowly, in 100 ml increments, to the cylinder on a vibrator until 700 ml is obtained Vibrate two minutes between additions Vibrate an additional five minutes Add additional ore and vibrate to 2024年6月28日 To convert this to copper thickness, you would divide by the width of the trace For instance, if the trace is 0100 inches (100 mils) wide, the required copper thickness would be 2652 / 100 = 2652 mils However, PCB The Significance of Copper in PCB Designs: Decoding 1 2022年4月8日 Ore A has goethite[FeO(OH)] as the main phase, and contains 006 wt pct of sulfur But, Ore B has Fe 2 O 3 as the main phase, and contains 003 wt pct of sulfur Since iron ores contain sulfur, the content of sulfur in the iron ores was considered when evaluating the conversion ratio of sulfur to SO 2In sinter mix condition, Ore A and Ore B were mixed in the Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix mill weight during the test from the empty mill weight, including the ball charge, at the start of the test The pulp Ore solids density 31 31 31 Dry feed rate (kg/h) 289 288 287 Speed (rpm) 3531 3511 3500 % Vcrit 7559 7517 7492 Absorbed power (kW) 5335 5628 5338The influence of mill speed and pulp density on the grinding

.jpg)

A comparison of wear rates of ball mill grinding media

2016年1月1日 In wet grinding practice, highstress abrasion occurs over a small region when ore particles are trapped between the grinding balls and the mill liner, and the load is sufficient to fracture PCB weight calculator » Calculate weight, area, volume and freight cost☑️ material and copper thickness / material type / layer quantity all adjustable☑️ YOU DESERVE PCB+ 892 Ratings: 49 von 5 Login Contact Prices Online calculator; Overview Online Calculators;PCB weight calculator » Standard, multilayer aluminum PCBsThe weight loss of the PCB samples after various heat treatments was also determined and is presented in Fig 3B; the weight loss may be attributed to the loss of volatiles/organic mat ter(A) Thermogravimetric analysis of PCB samples (B) Weight loss of PCB Revised: Mill scale is one of the byproducts which produced during the processing of 11 Mar 2021 Accepted: 28 Apr 2021 ore substitution by mill scale at 3%, the rate of production increases from 2194 to 2550 Keywords mill scale; sintering process; iron ore Abstract steelIt is richEffect of Partial Replacement of Iron Ore by Mill Scale on the

(PDF) Study On The Performance Of High Chromium Cast

2002年8月16日 content and the type of matrix of the cast irons, and using two ores and silica sand as According to many authors [5,8,1214,16], the rate of weight loss of a mill ball at a given 2021年1月14日 was surprising that the Bond Rod Mill Wi average was 113 kWh/t Since the ore is unusually soft, the Rod Mill Wi is probably irrelevant in determining required power for the SAG mill Drop Weight Tests Drop Weight tests were done at Hazen and analyzed by Contract Support Services, Inc Table 4: Summary of 6 JKTech Drop Weight TestsComparison of Ore Hardness Measurements for Grinding Mill 2023年12月12日 of the ball mill Ore can have various properties, su ch as behavior of Portland cement in laboratory ball and vibrating disk mills when added at the same amount of 006 % by the weight of the (PDF) Control of ball mill operation depending on ball Bond Rod Mill 0305 127 Any 118 15 10 Lockedcycle Y Y Bond Ball Mill 0305 335 Any 0149 10 5 Lockedcycle Y Y Mod Bond 0305 335 Any N/A 2 12 Batch N Y Table 1 – Summary of Grindability Test Procedures 1Weight requested for the test, for typical ores (SG = 28g/cm3) Denser samples require more weight, proportional to the SGSAG Mill Testing Test Procedures to Characterize Ore Grindability

(PDF) Recycling of mill scale in sintering process

2011年1月1日 Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction 2012年4月1日 Adding mill scale as an ingredient into the iron ore sintering or pelletizing process is the main utilization approach for mill scale because of its high iron content and positional advantages [10 Recycling of steel plant mill scale via iron ore sintering plant2021年5月31日 Qualified ore dressing gradient descent method to continuously adjust the network’s weight and JM Kinetics of DryBatch Grinding in a LaboratoryScale Ball Mill of Sn–Ta (PDF) A Method of Ore Blending Based on the Quality of performance of a large diameter sag mill is shown in Figure 4 page I208 The top size data has been plotted in both raw and smoothed form It clearly shows that as top size increases the mill weight increases as the mill finds it increasingly difficult to break down the bigger rocks Power responds to the increased mill weight by also increasingI203 I204 INTRODUCTION SMC Testing

.jpg)

The effects of iron ore concentrate grinding methods (HPGR and

2020年10月18日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles2012年1月1日 PCDD/F and WHO12 PCB congener profiles, expressed as percent contribution of each individual congener to the overall WHOTEQ at the BOS plant and the iron ore sintering plantAssessment of exposure to PCDD/F, PCB, and PAH at a basic 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911MetallurgistHigh Output of Ore Metal Refining Ball Mill Grinding Machine 100 Ton, Package Gross Weight 1500000kg Product Description High output of ore metal refining ball mill grinding machine 100 ton FSY Ball Mill is a type of grinder used to grind materials into an extremely fine powder mainly for use in the mineral processing industryHigh Output of Ore Metal Refining Ball Mill Grinding Machine 100

Population balance model approach to ball mill optimization in iron ore

3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for 2020年10月20日 One of the feed ore properties which can affect the grinding charge of an AG mill is particle size distribution Bergstedt and Fagremo (1977) studied the effect of feed size distribution on the performance of an AG during a series of pilot plant tests They reported that the ideal feed ore to an AG mill should have 10–15 wt% materials coarser than 100 mm Bouajila The performance improvement of a fullscale autogenous mill by setting 2023年6月21日 What are PCB Weight Calculators? PCB weight calculators are practical tools used in PCB design and manufacturing to estimate the weight of a printed circuit board They provide engineers and designers with valuable PCB Weight Calculators For Precision and ControlFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchases Machine weight max kg lb min Submit exhibit your products reach your Ore mill, Ore grinding mill All industrial manufacturers

Standard Bond Ball Mill Grindability Test MethodProcedure

2015年12月14日 It is screen analyzed and packed by shaking in a 1000cc graduated cylinder, and the weight of 700 cc is placed in the mill and ground dry at 250 per cent circulating load The mill is 12 in x 12 in with rounded corners, and a smooth living except for a 4 in x 8 in hand hole door for charging2015年6月16日 Weight and transfer ore to the ball mill Grind dry for 100 revolutions Empty the ball charge and ore through a coarse screen to separate the balls from the ore After mill and balls are swept clean, screen and ground ore through the mesh screen to be tested, using coarser protective screens if necessaryBond Grindability Test Procedure 911MetallurgistThe primary components of the PCB Processor are: Hammer Mill – Using the screen with holes, this machine breaks up the components to ; 1/8” pieces and discharges them onto the shaker table to separate the larger metal from the board material; Using the screen with slots, the board material is fully pulverized to liberate the metals from the plastics and fiberTurnKey PCB/EWaste Processor Mt Baker Mining and MetalsFor instance, from 1997 to 2015, the average life of a personal computer decreased from 46 to 23 years (Yazici and Deveci 2013) This trend results in the production of significant amounts of e (PDF) Challenges and opportunities in the recovery of gold

A guide to SAG Mill management

2024年5月17日 A SAG (SemiAutogenous Grinding) mill is a giant rotating cylinder filled with grinding media and the ore being reduced As the mill rotates, the grinding media lifts and the impact crushes the feed material SAG mill control refers to the practice of managing the mill load, which is the amount of material inside the mill at any given timeWet Pan MillWet Pan Mill, also called Wet Pan Mill, is mainly working for preliminary grinding for gold, silver, lead, zinc, iron, and copper ore concentration, but also one of 3After adding into ore,the materials are under the extrusion of grinding roller weight to revoluting and rotating with runner wheels,when twisting that coming into Wet Pan Mill Hengcheng Mining Equipment Co,ltd2017年7月26日 Soft ore Work Index 13 = 100,000/90,000 = 11 kwh/t Hard ore Work Index 16 = 100,000/65,000 = 154 kwh/t For the purposes of this example, we will hypothesize that the the crushing index of the hard ore with the increased energy input of 154 kw/t reduces the ball mill feed size to 6,500 micrometersHow Ball Mill Ore Feed Size Affects Tonnage Capacity2015年10月20日 When the charge volume of cylpebs is between 20% and 35% in the wet ball mill, cylpebs can be replaced by ceramic balls of the same single mass, with the total weight of the ceramic balls being INVESTIGATION OF EFFECTS OF GRINDING MEDIA

Determine the Proper Grind Size for Gold Ore 911Metallurgist

2016年9月15日 In one case known to the writer the product obtained from a bucking table, putting everything through a 100mesh sieve, only contained 50% of — 200 material whereas the finished mill pulp on the same ore contained 5% of + 100 mesh material and 75% of —200Revised: Mill scale is one of the byproducts which produced during the processing of 11 Mar 2021 Accepted: 28 Apr 2021 ore substitution by mill scale at 3%, the rate of production increases from 2194 to 2550 Keywords mill scale; sintering process; iron ore Abstract steelIt is richEffect of Partial Replacement of Iron Ore by Mill Scale on the Calculate the volume and weight, in English or Metric units, for over 40 geometric shapes and a variety of materials Select from such metals as Aluminum, Cast iron, or Steel, or from such thermoplastics as ABS, Nylon, or PolycarbonateVolume and Weight Calculator exhibits many of these aspects Maintaining the SAG mill weight at the optimum value is critical for achieving maximum grind rate efficiency and mill production (Powell, MS, van der Westhuizen, AP, Mainza, AN 2009) However, SAG mill weight is difficult to control as the dynamic response changes as the mill approaches maximum capacitySAG Mill Optimization using Model Predictive Control Andritz

Population balance model approach to ball mill optimization in iron ore

2014年1月1日 The mill product, due to its physical properties, determines the efficiency of subsequent stages of classification, filtration and pelletizing, thus impacting the quality of iron ore pelletsThe second primary function of a liner is to transfer rotary motion of the mill to the grinding media and charge After all, it is the interface between the mill and the grinding charge Although work on the grinding action in mills was published 100 years ago (White 1905 and Davis 1919), the firstThe Selection and Design of Mill Liners 911 Metallurgist2016年6月6日 Simple repeatable work index tests are usually sufficient for rod mill and ball mill tests but pilot plant tests on 50100 tons of ore are frequently necessary for autogenous or semiautogenous mills A Mill Charge Charge Weight/Volume/Percent Filling Ore Specific Gravity Percent Rock or Ore Charge Percent Ball Charge (if SAG Mill Grinding Circuit Design 911Metallurgist