Flat plate high fine vertical mill

.jpg)

PLATE MILL — POWER MEETS PRECISION Primetals

This allows the most precise control of the plate and leveller cassette deformation, leading to the highest quality, flat, high strength plates Primetals Technologies has built up a wealth of expertise in the Thermomechanical Wide plate mills make it possible to achieve excellent performances in terms of mechanical characteristics for finished products, enabling cross rolling with sizing, broadside and reduction stages, conventional rolling, temperature controlled Products › Flat › Plate Mills Customized solutions for The Kurimoto VX Mill is designed to feed material to the center of a table, where the material horizontally rolls and moves in the peripheral direction of the table with centrifugal forceVertical Super Fine Grinding Mill (Vertical Roller Mill) Heavy plate mills from SMS group produce plates with tailormade material properties and tight geometrical tolerances for a wide range of applicationsPlate Mill SMS group GmbH

CLUM Series Ultrafine Vertical Roller Mill

In the CLUM series ultrafine vertical roller mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical limiting protection technology, which can avoid the destructive Vertical design eliminates cavitation in the grinding zone at high speeds ; Hightorque drive allows the use of grinding media with a wide range of intrinsic density ; Variable speed drive allows VXPmill for fine ultra fine grinding FLSmidthWe integrated the singlestand 50m heavy plate mill into the existing MMK complex in Magnitogorsk, where it occupies an area of 1,080 meters by 200 meters The plant is designed HIGH TECH FOR HIGHSTRENGTH PLATE SMS groupCapable of rolling strip and plate in a single mill line, the Plate Steckel Mill offers the ultimate flexibility to respond to market demands Delivering high utilization and yields on plate products and producing wide coil products outside the Steckel Plate Steckel Mills Primetals Technologies

Latest Plate Production Technology of Nippon Steel Sumitomo

The plate mills of Nagoya and Kashima Works use detached edgers for planar shape control; that of Kashima Plate Mill is a hydraulic edger capable of changing width reduction during a rolling 2020年7月21日 Primetals Technologies has received the final acceptance certificate (FAC) for the 3800mm PM automation systems and services from Minmetals Yingkou Medium Plate Co, Ltd For the 3800mm PM project Primetals Technologies receives FAC for plate mill They operate at a lower economic volume than hot strip mills but are capable of greater widths and are especially suitable for niche products and stainless steels Capable of rolling strip and plate in a single mill line, the Plate Steckel Mill Steckel Plate Steckel Mills Primetals TechnologiesHowever, changes have occurred in some industrial sectors, such as the cement industry, where vertical mills are now used for drying and grinding This is due to reduced energy consumption and increased drying capacity of this type of mill Vertical mill operations use less pressure than highpressure millsDetailed explanation of vertical mill grinding technology

.jpg)

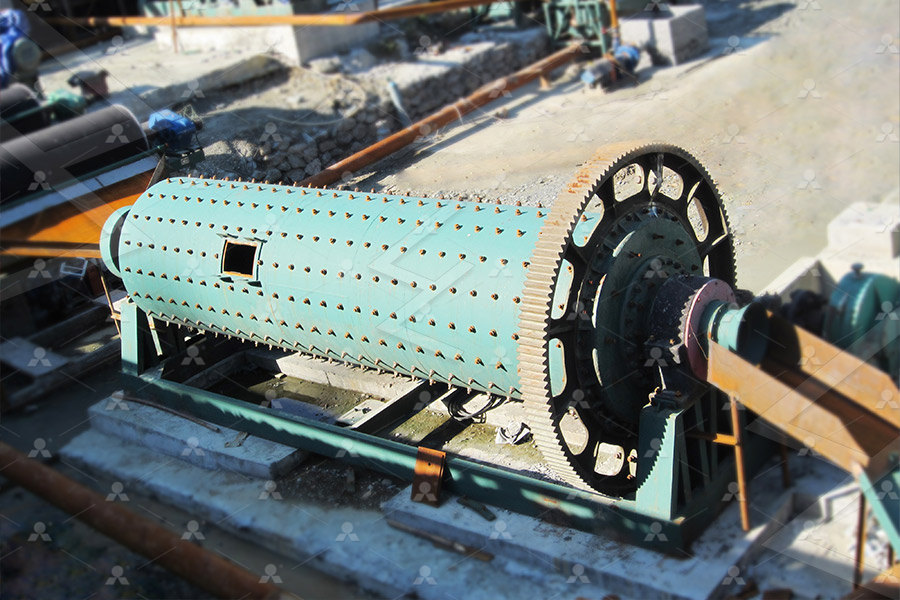

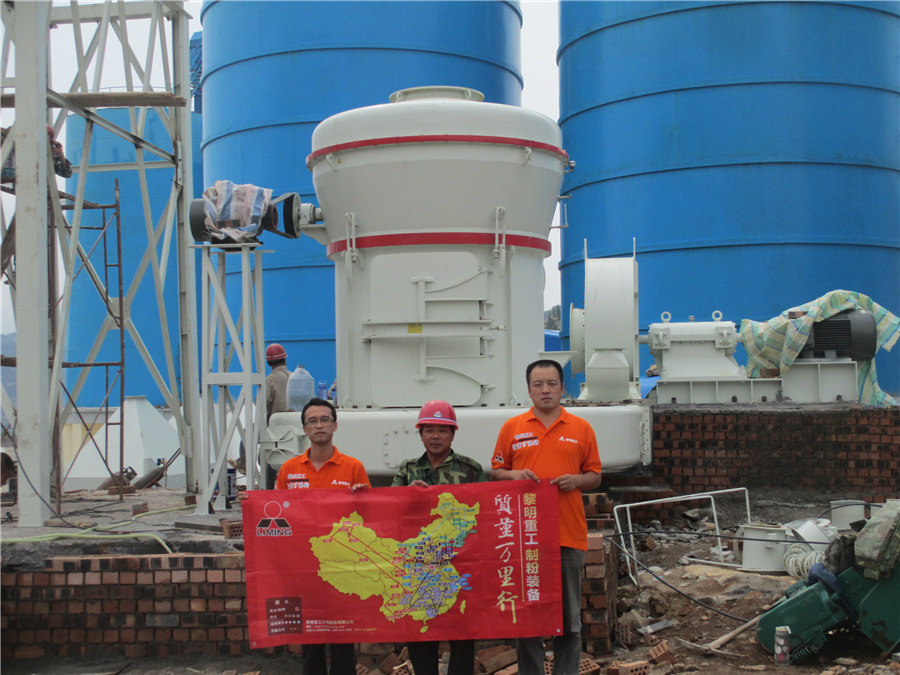

Limestone Ultrafine Vertical Mill

Product Application Of Limestone Ultrafine Vertical Mill Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), such as 2024年10月9日 FUHR designs a wide range of rolling mills, available in different sizes, that can be integrated to the client’s production lines The TYPE WSR PRECISION 2HIGH ROLLING MILL, of which components are protected from corrosion by galvanization, has a very low maintenance requirements The difference between the WRS rolling mills and the typical Precision 2high rolling mill for flat wire production2024年4月30日 Blog Post – “Mastering Precision: The Comprehensive Guide to Flat End Mills in Precision Milling” Source: PrecisionMachiningInsights; Summary: This blog post is a complete guide to mastering precision milling with flatend mills It discusses the features, benefits, and uses of flatend mills in precision machining operationsUnlock the Potential of Flat End Mills: Your Ultimate Guide to 2018年9月29日 Vertical mills are fast, so as soon as metallurgy and manufacturing advanced to the point of making complex tooling like endmills practical, milling machines came to dominate When most people think “mill”, they think “Jhead Bridgeport”, unless they are not a machining nerd and thus think “making flour from grain”Vertical Mill – Installation – Blondihacks

.jpg)

Pellet Mill Flat Die Biomass Indonesia

Adopting fullsteel structure and highquality customized harden gear reducers, with low noise during operation and high forming rate 3 The flat die plates are all termpering preocessed, Pellet Mill – Ring Die Vertical ring die design and flipping SBM high quality calcium carbonate ultrafine powder vertical mill is widely used in many fields +17 [ Calcium carbonate ultrafine powder vertical mill is widely used in various industries due to its ability to produce highquality, ultrafine powder of various when they move to the fringe of grinding plate, Calcium Carbonate Ultrafine Powder Vertical Mill2018年12月15日 As I mentioned, this power feed unit is designed to hang down below the table Someone (maybe Precision Matthews, maybe the factory in China) have adapted it to this mill by creating a twopiece 90º adapter plate for it so that it lays flat This cast aluminum plate attaches to the power feed unit, and then is bolted to the end of the mill tableVertical Mill – Power Feed – Blondihacks•Types of rolling mills 2High NonReversing Mill 2High Reversing Mill 3High Mill 4High Mill Cluster Mill ME 206: Manufacturing Processes I Instructor: Ramesh Singh; Notes by: Prof SN Melkote / Dr Colton 6 Rolling Introduction •Consider rolling of a flat plate in a 2roll millRolling IIT Bombay

Square Up Stock on a Vertical Mill : 7 Steps

Square Up Stock on a Vertical Mill: When starting a lot of projects on the a vertical milling machine, it will be necessary to true up the sides of the workpiece before you can begin milling in earnest This is due to inconsistencies in the 2022年11月1日 PDF Vertical Coal Mill Vertical coal mill, lining plate, wear p late, Hardlite, Everhard C500LE 1 the Ogoshi HighSpeed Universal Wear Testing Machine WEAR ANALYSIS OF VERTICAL COAL MILL PLATE ResearchGateUltrafine vertical mill is a highefficient industrial grinding mill, Lining Plate 2 Lower Frame 3 Shaft Pulley 4 Rotor 5 Blow Bar 6 Impact Plate 7 Impact Rack 8 CLUM series ultrafine vertical mills are equipped with specially designed Ultrafine Vertical MillThe LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionVertical Mill Shanghai Zenith Company

.jpg)

PLATE MILL — POWER MEETS PRECISION

Primetals Technologies has successfully completed over 70 Plate Mill projects since 2000, including new full lines, mechatronic packages and major modernizations Our plate equipment portfolio consists of: Plate Mill (Roughing Mill, Finishing Mill, with Edger option) Primary and Mill Stand Descaling Systems; Prelevellers2020年2月18日 Ballnose end mills have a domeshaped tip These excel at highdetail contours like relief artwork or mold and die making, but have what is known as “scalloping” Since the tip of the end mill is round, having a perfectly flat surface is a challenging feat and will take many more passes than a simple fishtail to smooth C End Mill Comparison Guide MatterHackersMill Configuration REVERSING ROUGHING MILL WIDTH REDUCTION: Slab width is reduced up to two inches with the vertical edging rolls (squeeze) THICKNESS REDUCTION: Roughing mill reduces slab thickness in five (5) to seven (7) reversing passes down to 1125” (transfer bar) DESCALING: High pressure descale water on entry side of mill removesPrinciples of Hot Rolling AISTQuartz ultrafine vertical mill has the characteristics of stable operation, energysaving, and good ball shape, and high fine powder content, which meets the needs of many highend powder industries and is popular in the highend powder The main raw materials of flat glass, float glass, glass products, optical glass, glass Quartz Ultrafine Vertical Mill

HOT ROLLING FLAT PRODUCTS Primetals Technologies

Steckel Mills, thanks to low capital investment costs, occupy a special niche in hot flat rolling They operate at a lower economic volume than hot strip mills but are capable of greater widths and are especially suitable for niche products and stainless steels Capable of rolling strip and plate in a single mill line, the Plate Steckel Mill 2022年1月12日 Advantages of CLUM Ultrafine Vertical Mill: ① High grinding efficiency and excellent quality of finished products The grinding curve of the roller sleeve and the lining plate specially designed to realize the principle of ultrafine ultrafine ball mill can produce 10um powder; ceramic ball mill has high whiteness and the What is the difference between vertical mill and ball mill?CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill Ultra fine vertical roller millUltra Fine Millultra AGICO VRM Grinding Roller After decades of continuous improvement and improvement, the vertical roller mill has been widely used in the field of cement raw meal, coal powder, and slag grinding The grinding roll is a key Vertical Roller Mill Grinding Roller AGICO Cement

.jpg)

Talc Powder Ultrafine Vertical Roller Mill

Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, VMX series ultrafine vertical mill is suitable for nonmetallic mineral industry, such as limestone, calcite, marble, heavy calcium, kaolin, barite, bentonite, pyrophyllite, etc And the finished powder can be used as highquality fillers and additives in coatings, plastics, rubber, pigments, inks, PVC and other industries ADVANTAGE 1VMX Superfine Vertical Mill Grinding Mill Fertilizer production Download scientific diagram Typical pellet mill design a) ring die and b) flat die (Graphic adapted from Alakangas and Paju 2002) from publication: Recent Developments in Biomass Pelletization Typical pellet mill design a) ring die and b) flat die (Graphic 2024年10月15日 The new heavy plate mill was developed in close collaboration between the experts at TISCO and SMS group It consists of a 4,300 mm fourhigh finishing stand, a vertical edger, a shearing line, a process line for extrathick plates, a normalizing and tempering heat treatment line for carbon steels, as well as solutions for stainless steels and pickling, grinding, Performance in new dimensions: 43meter heavy plate mill for

Industrial Roller Mills Williams Crusher

Williams Patent Crusher designs and manufactures highquality industrial roller mills that dry, classify, and consistently deliver a uniform grind for almost any material Our primary goal is to provide the best value for our customers and powerful productivity, all in one piece of equipmentThe Supra CNC vertical knee mill 10 x 54 is a large vertical mill w/ CNC technology Features Engineers looking for an economical prototyping machine and CNC machinists needing a highpowered, industrialquality CNC Vertical Milling Machine can find the solution to their buttons allow you to fine tune feeds in 5% increments Supra Vertical CNC Knee Mill 10" x 54" CNC MastersMilling machines, either vertical or hori zontal, are usually used to machine flat and irregularly shaped surfaces and can be used to drill, bore, and cut gears, threads, and slots The vertical mill, or “column and knee” mill, is the most common milling machine found in machine shops todayBridgeport Vertical Mill Manual DocsLibThe main motor of the vertical roller mill drives the grinding plate in the grinding machine through the transmission of the reducer The grinding roller rotates around the pins under the friction of the grinding plate After the feeding screw is dropped into the center of the grinding plate,it is moved to the edge of the grinding plate by the Vertical roller mill Hengtu Machinery

Horizontal vs Vertical Mills: Choosing the Right

Advantages of Vertical Mills for Specific Applications Vertical mills are versatile and costeffective, offering high precision and ease of use for smaller tasks They excel in: Precision work: Perfect for intricate cuts and fine surface finishes Considering the fact that the enterprise established, we have got been committed to Vertical Planetary Ball Mill (Semicircle Round Type) in China sales and service, we have got consistently adhering towards the quality 1st, service first organization philosophy to serve our clients and usually place this philosophy throughout our Vertical Planetary Ball Mill (Semicircle Round Vertical Planetary Ball Mill (Semicircle Round Type)The versatile MPS vertical mill – with a fine tradition of quality grinding Highest flexibility with constant product quality, individually conceived, suitable for a variety of applications, undergoing constant development: with a number of Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2023年2月26日 It holds various cutting tools which are used to shape and machine parts The table is the flat surface on a mill that is able to move along the x, y, and zaxes and should be able to hold heavier materials for larger projects The drill chuck is a tool holder that is typically found on vertical mills and can be used for drillingLathe vs Mill: What’s the Difference and Which is Better?

Rolling bearings in the world’s largest vertical roller mill

Vertical roller mills are one of the core items in cement plants and are used in particular for high and very high throughput rates Up to six grinding rollers are suspended over a grinding plate They form a parallel grinding gap and reach throughput quantities of up to 1400 t/h The MVR mill is the latest variant in vertical mills and is thus Tandem Finishing Mills (three, four, and five stands) Mini Mills (integrating caster with Tandem Finishing Mill) Plate Mills; To meet the needs of the aluminum market, our hot mill solutions feature a range of common technological enhancements to increase performance, operability, safety, and surface quality These include:Aluminum Hot Rolling Mill Primetals Technologies2024年7月26日 Sometimes, the finish pass will be done with a completely different type of tool You might flip the part and face mill a surface to clean it up after sawing in half with a slitting saw Or you might make a roughing pass with a roughing end mill and then switch to a standard end mill for the fine finish Pull Up to Finish Pocket WallsMilling Surface Finish: Complete Guide [Tips Secrets]Vertical planetary ball mill is a necessary device of hightech materials mixing, fine grinding, Features of Tencan Vertical Planetary Ball Mill Square Model Tencan vertical planetary ball mill shell is welded with thick steel plate, which has high vertical lab planetary ball mill, lab ball mill, lab grinder

.jpg)

What is Face Milling? Everything You Need to Know Worthy

2024年2月20日 Indexable face mills are favored for their adaptability to various materials and conditions Fly Cutters: Fly cutters are simple, singlepoint cutters that produce highquality finishes on flat surfaces Although slower than multipoint cutters, fly cutters achieve excellent surface finishes and are often used for fine finishing workWhile versatile, vertical mills are not best suited for handling large or heavy materials or performing highvolume production runs as efficiently as horizontal mills Tool Wear and Replacement Costs The vertical orientation can lead to faster tool wear, especially when dealing with more rigid materials, which can increase the cost of tool replacement and maintenanceHorizontal vs Vertical Milling: An InDepth Comparison