Working principle of silica powder making process

Analysis of silica production and drying processes IOSR Journals

In the production of silica by precipitation and dissociation, drying is an essential part of the process, and the design of a reasonable silica drying method is essential to improve the production efficiency and economic effectiveness of silica1995年1月1日 Various phases may be formed, depending on temperature, pressure, and degree of hydration The most documented method for the preparation of silica is the solgel route In Chapter 1 Silica: preparation and properties ScienceDirect2023年3月20日 Silica (SiO2), a component of the earth’s crust, has been in use for many nanotechnological applications This review presents one of the newest methods for safer, Methods for the Preparation of Silica and Its Nanoparticles from 2009年8月15日 A method was proposed for the preparation of silica powders using inexpensive material of sodium silicate (Na 2 SiO 3) and carbon dioxide (CO 2) by pressured carbonation, Synthesis of silica powders by pressured carbonation

Synthesis of silica powder with high pore volume by skeleton

2022年2月1日 In this paper, a method composed of gelation of basic skeleton (first step) and skeleton reinforcement process (second step) was introduced to synthesize silica powder with Schematic showing the generally accepted pathways to silica formation from orthosilicic acid through oligomers to particles and aggregated structures Annotations to show where in the An overview of the fundamentals of the chemistry of silica with 2020年7月17日 Several principle approaches in these methods to the synthesis of silica nanoparticles are of significant attraction: Stöber process [6], precipitation method [7], and The combined method to synthesis silica nanoparticle by Stöber 2016年8月3日 The biomimetic method and microemulsion methods of synthesis provide a superior level of surface chemistry and morphological control than current industrial processes Colloidal Silica Particle Synthesis and Future Industrial

Synthesis of Monodispersed Silica Powders I Particle Properties

scribe the formation of monodispersed silica parti cles by the controlled hydrolysis and condensation of tetraethylorthosilicate (TEOS) in mixtures ofThe main principle of the Stöber method is to control the hydrolysis and condensation process of tetraethyl orthosilicate (TEOS) in alcohol–water system with certain amount ofControlled synthesis of monodisperse silica particlesSilica (SiO2nH2O) is an inorganic chemical material, also known as nanosilica, amorphous white powder or flocculent powder, nontoxic, odourless, nonpolluting[1]Silica microstructures are spherical with porous, flocculent and reticulate quasiparticle structures, and are widely used in industry, agriculture, medicineAnalysis of silica production and drying processes IOSR Journals2008年4月1日 Since its first production in the early forties of this century, fumed silica has found widespread use in industrial applications Due to its pyrogenic manufacturing process by combustion of Fumed Silica ‐ Production, Properties, and Applications

(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals

2022年1月23日 Chemical Processing of Bauxite: Alumina and Silica Minerals—Chemistry, Kinetics and Reactor DesignLab personnel working with silica powder/silica gel are required to be provided with appropriate PPE, ensure compliance, and ensure safety training Principal investigators are required to maintain accurate training records 5 Engineering Control: Designate a Fume Hood (FH) for Silica work (see section 7 of this SOP)WORKING WITH SILICA University of Toronto Department of The cope and drag (top and bottom halves, respectively) of a sand mold, with cores in place on the drag Two sets of castings (bronze and aluminium) from the above sand mold Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand—known as casting sand—as the mold material The term "sand casting" can also refer Sand casting WikipediaThe first step in the overall powder metallurgy process is making metal powders There are four main processes used in powder production: solidstate reduction, atomization, electrolysis, In principle, the technique is applicable to all metals that can be melted and is used commercially for the production of iron; copper; alloy steels Making Metal Powder MPIF

Powder Detergent: Ingredients Manufacturing Process Explained

2021年6月21日 Powder detergent is a broad term encompassing all kinds of soap manufactured in powder form However, it’s commonly used as a synonym for laundry detergent While most formulas are suitable for both machine and hand washing, Indeed, products like instant milk or instant coffee are produced thanks to this process The possibility to avoid degradation during drying makes it also a process of choice for pharma Examples of applications for spray drying are given below : Instant milk; Whey powder; Instant coffee; Non dairy creamer; CaseinSpray drying process : overview, fundamentals of spray dryingThe silica sand production line is composed of vibrating feeder, jaw crusher, sand making machine, vibrating screen and belt conveyor According to different process requirements, various types of equipment are combined to meet the different process requirements of customersSilica sand making production line working principleIn addition, silica gel, alumina, cellulose, or Sephadex are used as stationary phase, whereas the mobile phase is liquid The process begins by packing 30g of silica gel (70/35) into a transparent glass column (80cm long, 5cm diameter) without introducing air bubbles Subsequently, the extract to be partitioned is added from the topPreparation of Medicinal Plants: Basic Extraction and Fractionation

.jpg)

Air ClassifierSinonine

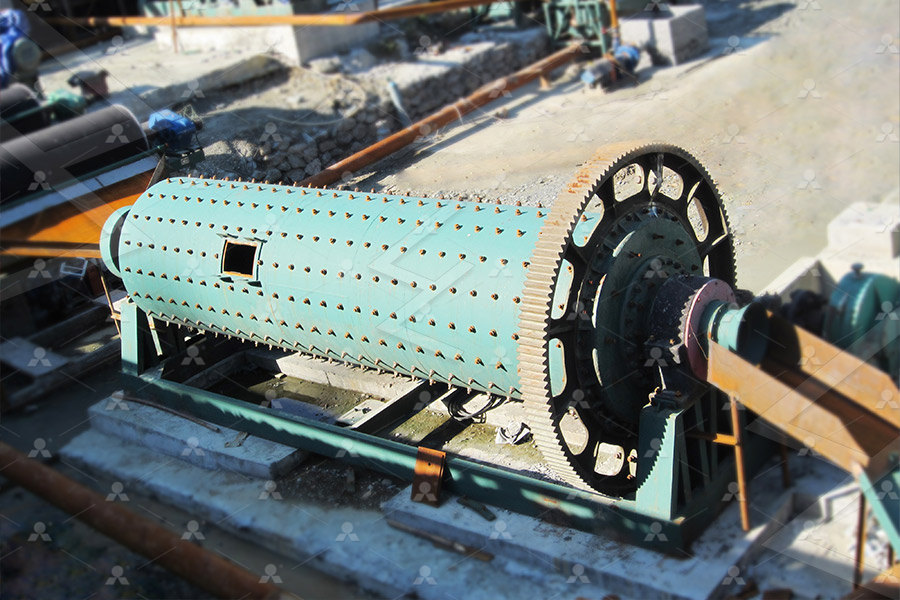

Sinonine has fully considered the process needs of silica powder in the whole system, and modified the traditional equipment to meet the needs of processing silica powderThe working efficiency of Sinonine silica sand ball mill and air 2023年11月14日 The whole total after summarizing the working principle and process of the automatic powder granule packaging machine, is from the feeding machine for material conveying, multihead scale for weight measurement, Working Principle Of Automatic Powder Granule of the network growth and powder precipitates, which can be used in particulate processes described below Stober et al [18] devised a method of making monosized silica particles in highly diluted basic solutions of TEOS; the particles may be as large as 1 mm Grader et al [19] repeated this experiment and found that particles, asSOL GEL PROCESSING GENERAL PRINCIPLES2023年7月12日 High Melting Point: Silica quartz powder boasts an exceptional melting point, making it ideal for foundry and refractory applications With a melting point of around 1700°C (3092°F), it can withstand extreme temperatures without melting or deforming, ensuring excellent performance and durability in highheat environmentsThe Importance of Silica Quartz Powder in Foundry and

.jpg)

Metal casting processes

%PDF15 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/ExtGState >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 720 540] /Contents 4 0 R/Group 2019年10月30日 Also known as sand molding casting, sand casting is a castingbased manufacturing process that involves the use of a sand mold It’s used to create metal products and components in a variety of sizes and shapes To put its popularity into perspective, statistics show over half of all metal castings — about 60% — are produced using sand The 6Step Process of Sand Casting Molding OneMonroe121 Principle of atomization The working principle of the atomizers is governed by the liquid disintegration phenomenon explained by several researchers It is worth understanding the progression in the concepts on atom ization phenomenon across the years This will also help in appreciating the science of droplet formation from an atomizer1 Introduction to spray drying WileyRoller presses are used to process bulk solids (powder, granules) in order to perform a dry granulation by compaction They can typically produce a compacted sheet of material that is later milled, even if some models have specific rollers whose shape allows to produce some briquettes This page is focusing on the design of roller presses, the mechanisms behind the Roller compactors : basic principles and technology overview

.jpg)

Effect of Silica Fume on Humidity Resistance of Sodium Springer

sodium silicate accounts for 20% of the silica sand mass This figure suggests that the tensile strength of sand core increased first and then decreased with the rise in silica fume content The reason was that the appropriate amount of silica fume can enhance the bond strength, whereas when there is overly high amount of silica fume, it is2020年6月4日 This is the socalled “pineffect” As coatings sit on the shelf, defoamers can lose their effectiveness as the active ingredients become solubilized into the resin Hydrophobic particles (silica, urea or polymeric) will Understanding Defoamer Chemistry 2023年3月20日 According to the results of surface area and elemental analysis, calcium silica aerogel powder produced at pH 70 (CSA7) had the best results compared to that produced at pH 90 (CSA9)Production and Characterization of Calcium Silica Properties of PPT High Surface Area and Porous Structure: Precipitated silica possesses a high surface area, which is a result of its porous structureThe high surface area allows for increased adsorption and absorption capacity, controlled release of substances in various applications, making it effective in applications such as desiccants, drying agents, and adsorbentsWhat is Precipitated Silica? A Comprehensive Overview Sinoxe

Spray Drying: An Overview IntechOpen

2017年12月20日 Spray drying is a wellknown method of particle production which comprises the transformation of a fluid material into dried particles, taking advantage of a gaseous hot drying medium, with clear advantages for the fabrication of medical devices In fact, it is quite common the production of microspheres and microcapsules designed for drug delivery systems1 Steel: Steel structures are one of the most popular substrates for powder coating It's durable, strong, and versatile, making it a prime choice for various industries Powdercoated steel is commonly seen in automotive parts, appliances, outdoor furniture, and industrial equipmentPowder Coating Process Explained – A Detailed BreakdownHallHeroult Process The HallHeroult process is widely used in the extraction of aluminium In HallHeroults process, pure Al 2 O 3 is mixed with CaF 2 or Na 3 AlF 6 This results in lowering the melting point of the mixture and increases its ability to conduct electricity A steel vessel with a lining of carbon and graphite rods is usedExtraction of Aluminium (Aluminium Ore) HallHeroults Process by adding more material in solid powder form followed by sintering or soldering, in fluid form followed by solidification, or in gaseous form followed by chemical reactions or physical deposition These techniques mostly work on the socalled layer manufacturing principle A close control of the layerbased addition processChapter 1 Introduction to Chemical Vapour Deposition Springer

.jpg)

Silica sand washing plant process flow and equipment cost

The process of cleaning silica sand is crushing, washing/, magnetic separation, acid leaching, washing, dehydration, and drying water washing Washing sand recycling machine working principle After the natural silica sand is classified and filtered by the screening equipment, the qualified products flow into the spiral sand washing machine 2016年8月22日 I hope it helpful for users If you are intrested in our Micro Powder Grinding Mill, please connect with me by: :sales@clirik Phone(WhatsApp): +86 Related News >> Basalt Rock Powder Making Machines >> Calcite Powder Manufacturing Process >> Silica Powder Grinding Mill Machines >> Granite Powder Grinding Mill MachinesWorking Principle of Micro Powder Grinding MillWorking with silica and silica containing products 9 2 Who has health and safety duties? Duty holders with a role in managing the risks of silica dust when working with silica containing products include: − PCBUs − officers − designers, manufacturers, importers, suppliers − workers, and − other persons in the workplaceWorking with silica and silica containing products Safe Work 2020年9月1日 Due to the delayed gelation process of silica gel at higher pH values, it could be concluded that the formed silica gel at pH = 8 which has the highest relaxation exponent value, is relatively soft This is confirmed by the visual inspection of the formed silica gels at different pH values, shown in Fig 1 A comprehensive study on the gelation process of silica gels

Solgel process applications: A minireview

2018年6月19日 Solgel process is categorized as a wellknown and reliable coating process The useful characteristics of this method are composition selection, easy to coat complex mechanical parts, geometries 2022年12月30日 Digital light processing (DLP) is an emerging additive manufacturing technique due to its inherent advantages Though DLP is similar to stereolithographybased techniques which works on principle of vatphotopolymerization and curing layer by layer to form the object, it offers faster printing rate, accuracy and higher resolution In recent years, the technique is Digital light processing of ceramics: an overview on process, 2024年6月8日 What is Powder Bed Fusion? Powder bed fusion is one of seven Additive Manufacturing techniques, in which either laser, heat or electron beam is used to melt and fuse the material together to form a threedimensional object Figure 1 Powder bed fusion ( source:GE) Types of Powder bed fusion Both metal and plastic parts can be made using this Powder Bed Fusion types SLS, DMLS, EBM MJF Pros Cons2020年1月8日 In this study, an inorganic sand core that exhibited high tensile strength was fabricated by sodium silicate, silica sand, as well as silica fume The effects of the silica fume on the properties of the sand core were studied According to the optimal hardening process of sand core material, the mold was first heated to 175 °C and the compressed air purging Effect of Silica Fume on Humidity Resistance of Sodium Silicate

Schematic of the working principle of the powder atomization process

Download scientific diagram Schematic of the working principle of the powder atomization process from publication: Manufacturing Methods, Microstructural and Mechanical Properties Evolutions of 2024年9月13日 Latest innovations of Silica Powder Novel Amorphous Silica Powder Synthesis and Modifications Renewable BiomassDerived Amorphous Silica: Innovative methods extract amorphous silica from plant biomass like rice straw and chaff, providing an ecofriendly and sustainable sourceThe silica is extracted through combustion or gasification processes below Silica Powder: Essential Mineral for Construction and Beyond2018年9月15日 To prepare a 2% agarose gel, weigh 20 grams of agarose powder and put it in a flask Add 100ml of 1X TAE buffer (or TBE) in the flask and shake well until the agarose powder will mix into the buffer To prepare a 10X stock buffer and 1X working buffer, read our previous article: Agarose gel electrophoresis bufferAgarose Gel Electrophoresis: Definition, Principle, Process, Protocol Cement production process overview clay, and sands Raw materials are milled into a fine powder, which is then blended and heated to form cement One type or making sure that the heat can be recovered from the kiln and be used to pre Cement Production Demystified: StepbyStep Process and

Chemical Processing of Bauxite: Alumina and Silica

The Bayer process is a chemical process for refining aluminium hydroxide, Al(OH) 3 from bauxite; this aluminium hydroxide is subsequently calcined to produce alumina, Al 2 O 3The basis of the Bayer process is an understanding of the characteristics of the sodiumhydroxide—sodiumaluminate solution relationship, namely its ability to keep sodiumaluminate in a dissolved state