mgs4366 type double inlet and double outlet steel ball coal mill

MGS Doubleinlet Doubleoutlet Steel Ball Coal Mill

There are various high quality and durable mgs doubleinlet doubleoutlet steel ball coal mill here in our factory As one of China's leading mechanical equipment manufacturers and suppliers, we also support customized service on mgs MGS Doubleinlet and Doubleoutlet Steel Ball Coal Mill has been widely used for pulverized coal preparation system in electric power, metallurgical, building materials, chemical industry and environmental protection industriesChina SHENYANG Heavy Machinery Mining 2019年12月12日 SEPHS is able to supply whole series of coal mills with high reliability The MGS double inlet double outlet ball mill is aimed to fit for power plant conditions from the 上海电气上重碾磨特装设备有限公司Based on this, the invention provides a kind of doubleinlet and doubleoutlet steel ball coal mill, by reducing the ball load of coal pulverizer, reduce the gross mass of mill ball inCNA Doubleinlet and doubleoutlet steel ball coal

System dynamic flow diagram of the output of doublein and

At present, the economic benefits of double inlet and double outlet ball mills, which are commonly used in coalfired power plants, need to be improved Based on this, this paperAccording to the load requirements, the double in and double out ball mill can operate in three working conditions: double in and double out, single in and double out, and semi mill BBD double In/Out steel ball millspower plant equipmentMgs4360 Double Inlet and Outlet Coal Grinding Mill, Find Details and Price about Coal Fired Power Plant Coal Grinder from Mgs4360 Double Inlet and Outlet Coal Grinding Mill Jinan Mgs4360 Double Inlet and Outlet Coal Grinding Mill2016年8月1日 A duplex inlet and outlet ball mill pulverize system model is established by considering the effect of raw coal moisture on the dynamic characteristic of the mill The EKF Modeling and control of ball mill system considering coal moisture

System dynamics model of output of ball mill ResearchGate

2021年2月15日 At present, the economic benefits of double inlet and double outlet ball mills, which are commonly used in coalfired power plants, need to be improved Based on this, this 2019年3月7日 At last, the HPAPSO method is combined with MPC, named HPAPSOMPC, and is applied to solve the control problem of duplex inlet and outlet ball mill system 2 Process Description 21 Duplex Inlet and Outlet Ball Mill System The system structure of duplex inlet and outlet ball mill system is shown in Figure 1Model Predictive Control of Duplex Inlet and Outlet Ball Mill 15 Operation principle of double inlet and double outlet ball mill The air powder flow of double inlet and double outlet ball mill is shown in figure 233 The raw coal is discharged from the hopper into the mixing box through the coal feeder BBD double In/Out steel ball millspower plant 2019年11月7日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before modificationTransform the Optimization and transformation of 300MV units steel ball coal mill

Applied Mathematics and Nonlinear Sciences ResearchGate

of double inlet and double outlet ball mill output system is established, and SPSS is used to fit the model data with the real data The fitting degree is above 08, and the authenticity is high2016年8月1日 The established coal mill model is based on the following assumptions: (1) the process of coal grinding is simplified by disregarding the separation of coal particles; (2) the grinding and delivery of pulverized coal are divided into two stages in the mill; and (3) pulverized coal sizes at the outlet is neglected in the model, and only raw coal and pulverized coal exist in Modeling and control of ball mill system considering coal moisture2024年11月2日 38 Flue gas desulfurization booster fan (FGDP fan or BUF) DL/T 4682018 A fan installed behind the induced draft fan to overcome the resistance of the flue gas desulfurization system 39 Seal air fan Fans that supply air for sealing in mediumspeed coal mills, doubleinlet and doubleoutlet steel ball coal mills and coal feedersDL/T 4682019 English PDF Chinese StandardM No Page 2 / 5 PUR No 1、 Application The doubleinlet and doubleoutlet coal mill is used for the pulverization of coals, and is the main device in the direct pulverizedcoal system The mill is mainly assembled with the boiler in large thermal power plant, and can also be used as the pulverization device in territories of chemical VA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet and Double

.jpg)

Mechanism Modeling and Simulation for Coal Pulverizing System

2017年12月15日 To improve the safety and economy of a pulverizing system for doubleinlet doubleoutlet coal mills, a mathematical prediction model was established to study the relationship between the ball wear This document provides instructions for the MGS4766 doubleinlet and doubleoutlet coal mill It includes specifications and performance parameters, an outline drawing, descriptions of the structure and operation principle, and information on the lubrication system The coal mill is used to pulverize coal as the main device in direct pulverizedcoal thermal power plantsVA1 NHI 00100 M M1C MAN 1001 Rev0 MGS4766 Double Inlet At present, the economic benefits of double inlet and double outlet ball mills, which are commonly used in coalfired power plants, need to be improved Based on this, this paper explores the factors influencing the output of double inlet and double outlet ball mill by establishing the output system of double inlet and double outlet ball millSystem dynamics model of output of ball mill – DOAJBall adding device is low speed coal mill, especially the vitals of doubleinlet and doubleoutlet steel ball coal mill positive pressure direct blowing powder systemLow speed coal mill is when grinding coal dust, and the steel ball in mill constantly weares and teares, thereby cause grinding, interior ball load declines, the reduction of exerting oneselfFor this reason, need to adopt ball Ball charging device for steel ball coal mill Google Patents

Direct Blowing Pulverizing System Modeling Based on IPLSSVM

In order to solve the problem that the output of ball mill pulverizing system is difficult to directly measured in thermal power plant with double inlet and double outlet ball mill pulverizing system which is a large delay, strong nonlinear system It introduces the pruning method to improve the incremental least square support vector machine's sparsity that based on the incremental least 1Analysis on the Principle of Coal Level Control System of a Ball Miller双进双出钢球磨煤机煤位控制系统原理分析 2Pulverized Coal Fineness Adjustment and Analysis of Doubleinlet and Doubleoutlet Ball Mill双进双出钢球磨煤机煤粉细度调整试验及分析 3Calculation and Selection of Drying Media for Steel Ball Coal Grinder with Dual Ins and Dual Outs双进双 双进双出钢球磨煤机,double inlet and outlet tube mill英语 The directfired system with duplex inlet and outlet ball mill has strong hysteresis and nonlinearity The original control system is difficult to meet the requirementsStructure of duplex inlet and outlet ball mill systemA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

Two sets of basic assumptions between the output of a doublein

At present, the economic benefits of double inlet and double outlet ball mills, which are commonly used in coalfired power plants, need to be improvedCoal ball mill is mainly used in coal power plant or mineral calcining system Skip to content Home; Product Center; Ball Mill Parts Menu Toggle Ball Mill Shell; The main bearing is made of cast steel, and the rotating large gear is processed by casting hobbing There are liner plates on the inner cylinder wall, with good wear resistance, Coal Ball Mill Grinding for Different Kinds of Pulverized CoalCoal Moisture: The degree of drying, and therefore the required mill outlet temperature (from 6580 0 C) will depend upon the type of coal ground Some residual moisture in fine coal is recommended (Graph below) to minimize the potential of spontaneous ignition of fine coal, which will again vary for different coal types as below:Coal Grinding Cement Plant Optimization2020年8月12日 As the significant ancillary equipment of coalfired power plants, coal mills are the key to ensuring the steady operation of boilers In this study, a fault diagnosis model was proposed on the An investigation of performance characteristics and energetic

MGS Doubleinlet Doubleoutlet Steel Ball Coal Mill

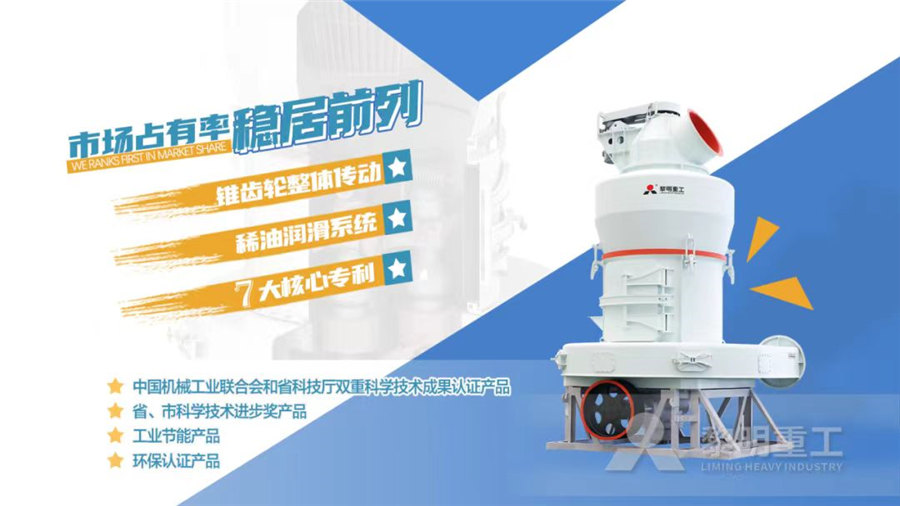

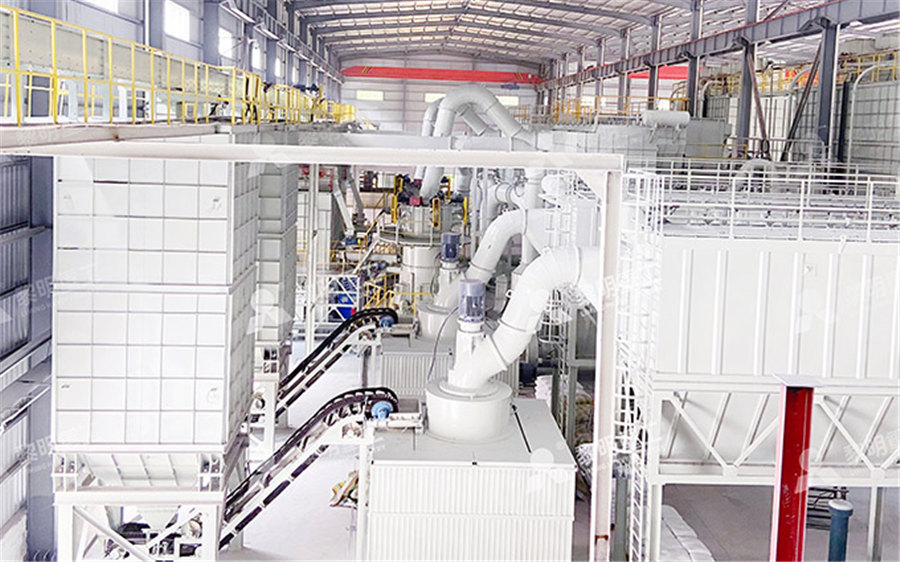

MGS double inlet and double outlet coal mill is a new type of coal mill independently developed by our company on the basis of introducing the design, process, inspection and test technology of French BBD coal mill and American Dtype coal mill It has advanced structure, stable performance, complete functions, and reliable operation2017年6月15日 Mechanism Modeling and Simulation on Pulverizing System of a Doubleinlet Doubleoutlet Coal Mill June 2017; Dongli Gongcheng Xuebao/Journal of Chinese Society of Power Engineering 37(6):467474;Mechanism Modeling and Simulation on Pulverizing System of a Double MGS double inlet and double outlet coal mill is a new type of coal mill independently developed by our company on the basis of introducing the design, process, inspection and test technology of French BBD coal mill and American Dtype coal mill It has advanced structure, stable performance, complete functions, and reliable operationMGS Doubleinlet Doubleoutlet Steel Ball Coal MillFrom the operation mechanism of the ball mill with double inlets and outlets, this paper gives a research work to the simulation of the ball mill with double inlets and outlets, and proposes a corresponding mathematical model of the six controlled with six control variables of the ball mill with double inlets and outlets, and simulates with Matlab using the operation data of a power Research of Mathematical Model of the Ball Mill with Double

.jpg)

BBD double inlet and double outlet tube coal millLiaoning

BBD double inlet and double outlet tube coal mill BBD double inlet and double outlet tube coal mill is the major equipment for direct blow pulverizing system which is used in the power plant, cement factory and papermaking factory This coal mill can continuously work, fast response and flexibly be operated, the easymaintain, stable output and fitness, big storage, low ratio of air to coal 2015年8月1日 Mill problems originate mainly due to poor controls or faults occurring within the milling system As discussed by GQ Fan and NW Rees [3], the control of mills remains very simple in most of the power plants due to the fact that the mill system is highly nonlinear with strong coupling among the variables and it is very difficult to measure some important Review of control and fault diagnosis methods applied to coal mills Bridge Type BucketWheel Blending Reclaimer MGS double inlet and double outlet coal mill MPG medium speed coal MFQ coal mill MTZ Steel ball coal mill Environmental Protection Equipment Crushing Equipment MGS Doubleinlet Doubleoutlet Steel Ball Coal Mill Coal Mill北方重工The air swept ball mill is an ideal grinding machine that merges pulverizing and drying into a single It has the characteristics of high efficiency, energy saving, and environmental protection It is often used as the main equipment in the coal preparation system, which is capable to grind coal of various hardness (the fineness of pulverized coal can reach 85% and the moisture content Air Swept Coal Mill AGICO Ball Grinding Mill ball mill machines

DL/T 4672019 English PDF (DL/T 4672004) Chinese Standard

2024年10月20日 313 Directfired pulverizing system A system in which the coal pulverizer conveys pulverized coal directly to the burner Usually includes medium speed coal mill, double inlet and double outlet steel ball coal mill, fan coal mill (Threemedium drying, twomedium drying) direct blowing powder milling system2016年8月1日 Fig 1 shows the structure of a duplex inlet and outlet ball mill The system is equivalent to two parallel cylinders joined together in one ball mill to achieve high milling efficiency Milling work is carried out by the collision, squeezing and grinding of the steel balls inside the mill The working principle described as follows [10]Modeling and control of ball mill system considering coal moisture 2018年12月15日 The coal pulverizing system of this boiler is a doubleinlet and doubleoutlet, positivepressure, directblow steel ball mill system The vent air nozzle is arranged under the swirl burners, at an angle of 28° to the horizontal, and is in onetoone correspondence with the burner on the archEffects of secondary air distribution in primary combustion zone 2019年1月6日 home; about us; product crushing system; screening system; grinding system; benefication systemMill Performance Shenyang Casting and forging industry Co, Ltd

.jpg)

Modeling and Control of Coal Mill

(2012) is used to develop the coal mill model The following assumptions are made to develop the coal mill model: (1) Coal in the mill is either pulverised or unpulverised, ie different particle sizes are not considered Variations of the mass of coal particles (eg depending on th e moistureThe invention discloses doubleinlet doubleoutlet steel ball coal mill straight blowing type milling systems to enter stove Coalfired capacity computational methods, it includes:1st, in doubleinlet and doubleoutlet steel ball coal mill(1)Entrance air quantity controllable register(5)Coal pulverizer inlet Wind volume detector is set on pipeline afterwards(6);2nd, in double CNB Doubleinlet doubleoutlet steel ball coal mill 2019年12月12日 SEPHS owns independent intellectual property rights of double inlet and double outlet ball mill, and also successfully applied for patent for inventions of double inlet and double outlet ball mill and dynamic separator used for coal mill MGS ball mill is an excellent straight blow lowspeed ball mill which is used for power plant and has many 上海电气上重碾磨特装设备有限公司software and to use in the further designs of ball mills 11 FLS UMS Type Cement Ball Mill In 1893 FLSmidth (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventor After being thoroughly redesigned and refined, the tube mill influenced the cement industry in the coming century FredrikDESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

MPG Medium Speed Coal Mill NHI

Although there were manufacturers producing other types of medium speed coal mills in China at that time, the relevant national departments, taking into account the unique technical advantages of the MPS type medium speed mill and the future development direction of the mill in the power industry, still approved the introduction of the design, production and manufacturing Pulverized coal combustion includes a series of complex physical and chemical processes such as pulverized coal pyrolysis, combustion, turbulentCombined operation mode of subcritical Wflame boiler and coal mill