Vertical mill discharge pipe plug

Mill discharge pumps Metso Automation PDF

Excellent hydraulic efficiency Specifically designed from its inception for mill circuit applications, the Metso MD series of mill discharge MDM hard metal and MDR rubber lined slurry pumps offer sustained performance with maximum discharge valve, install a pressure relief or bypass valve in the discharge pipe to allow for minimum liquid flow through the pump Minimum liquid flow through the pump is needed for INSTALLATION AND OPERATION MANUAL PentairVertical froth pumps The use of flotation as a mineral separation method required a further development of slurry pumps As early as 1933, a vertical ”open pump” was developed in a Guidelines in slurry pumping Slurry pump handbook MetsoThe key to the ULT plug valve’s unprecedented seal integrity is its proprietary floating plug and dualseal design When the valve is closed, the dual segment seal provides a redundant seal wline Flo products and services Technip FMC

.jpg)

Weir Pumps and Pumping Equipment Weir

We manufacture and supply a range of vertical and horizontal pumps including centrifugal, axial flow, vertical cantilever, submersible and positive displacement pumps to suit variety of Specifically designed from its inception for mill circuit applications, the Metso MD series of mill discharge MDM hard metal and MDR rubber lined slurry pumps offer sustained performance The Metso series of Mill discharge pumps CAC Industrial1 DISCHARGE PIPE – Properly sized for optimum water velocities to insure peak hydraulic performance 2 DISCHARGE BOWL – Several discharge sizes available for NPT or flanged Vertical Turbine Pumps XylemThis Discharge CBV Vibration Isolation Pump Drop connects a pump to the interconnecting pipe/discharge header in the mechanical room Provides noise reduction, expansion, Victaulic® Discharge CBV Vibration Isolation Pump Drop Series

.jpg)

Key recommendations of API RP 686 for Centrifugal pumps

Suction and discharge piping for vertical inline pumps have adjustable supports located within 1 m of the pump’s suction and discharge flanges Pump is in solid contact with the foundation Gravityinduced stirred mills initiate a ball charge motion via rotational movement of a screw to provide a size reduction mechanism In contrast, fluidized stirred mills use a rotational Vertimill and Stirred media detritor Metso AutomationWhat Is Ultra Fine Grinding Mill The ultrafine powder grinding system is a new product independently developed by our company, mainly used to grind and classify various nonmetallic ores in cement plants, such as the grinding of Ultra Fine Grinding Mill Ultra Fine Powder Grinder2017年4月1日 Moreover, the density wave which was usually observed in the vertical pipe discharge might result in discharge rate fluctuation for granular discharge through the vertical pipe with a bend outlet, Experiments for vertical plug formation are conducted with glass beads of three kinds of particle diameter (ie 6 mm, DEM study of granular discharge rate through a vertical pipe

.jpg)

Coefficients Of Discharge For Gravity Flow Into Vertical Pipes

Download Citation On Feb 1, 2010, H O Anwar DrIng published Coefficients Of Discharge For Gravity Flow Into Vertical Pipes Find, read and cite all the research you need on ResearchGate2019年8月1日 This coal powder is fed to boiler through steel pipes called pulverized fuel pipes with the aid of primary air Mill Discharge Valve (MDV) is used just after the mills to isolate the mill from (PDF) Design and Modify of Mill Discharge Valve Using in5Axis CNC Vertical Mill with 30" x 20" x 20" travels 5axis machining is an effective means to reduce setups and increase accuracy for multisided and complex parts The Haas UMC Series universal machining centers are costeffective solutions for 3+2 machining and simultaneous 5axis machiningUMC750 5Axis Mill 40Taper Vertical Mills – Haas CNC Globe valve to DIN/EN with flanged ends, short facetoface length to EN 558/14, slanted seat design with vertical bonnet, singlepiece body, EPDMencapsulated throttling plug, soft main and back seat, position indicator, locking device, travel stop, insulating cap with anticondensation feature; maintenancefree, full insulation possibleKSB product catalogue for efficient pumps valves

CTV Vertical Centrifugal Pumps Tapflo

IOM manual CTV vertical centrifugal pumps 7 151 Connection of discharge pipe If the discharge height is more than 2 meters, a check valve should be installed in the discharge line (see installation example, chapter 17 Example of installation The check Read this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 The bolts and nut plugs should be checked frequently before after using the grinding roller A rotatory airlock valve is provided along with the gearbox and located at the discharge end of the cycloneVertical Grinding Mill: How it Works, Application And AdvantagesA Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, there’s a Haas to do the workVertical Mills VMC Haas CNC Machines Haas Automation2015年4月17日 7The raw mill is easily adaptable to high airflow required by especially wet easy to grind materials Work Principle of Vertical Mill for raw grinding: Raw material feed into discharege pipe through rotary discharger Discharge pipe enter into the mill through the side or the center of separatorGreatWall Vertical Mill for raw grinding

The inspection and maintenance of vertical mill WXING Bearing

One, the vertical mill inspection parts and methods of vertical mill by its power, transmission, lubrication, choose powder, feeding pipe, in and out of the wind pipe, seal, discharge mechanism and the host, such as large and complex system, inspection maintenance tasks, must be checked, not leak blind Angle The paper are as follows: 12017年1月21日 By the time it reaches the bottom of the vertical pipe the stream will not have a diameter of A Share Cite Improve this answer Follow answered Jan 20, 2017 at 16:14 JMac JMac 154k 4 4 gold badges 37 37 silver badges Fluid velocity in a vertical pipe Physics Stack ExchangeThe new Metso MD series of mill discharge slurry pumps encompass all of this experience coupled with an understanding of today’s market needs and demands for improved sustained performance The Metso series of Mill discharge hard metal and rubber lined slurry pumps For improved sustained performance Mill discharge pumps 3The Metso series of Mill discharge pumps CAC IndustrialDesign and Modify of Mill Discharge Valve Using in Thermal 123 MILL DRIVE AND BOWL ASSEMBLY The vertical shaft is The slit pipe and slit plate are present fitted withthe discharge pipe Design and Modify of Mill Discharge Valve Using in

ENGINEERING GUIDE Screw Conveyors KWS Manufacturing

The recommended location for the drive unit is on the discharge end of a screw conveyor which pulls the bulk material to the drive end with this arrangement, each screw section is put in tension as the bulk material is conveyed toward the discharge of a screw conveyor, reducing wear and fatigue on the conveyor components Vertical Mills ; VF Series; Universal Machines; VR Series; VP5 Prismatic; PalletChanging VMCs; Mini Mills; Mold Machines; HighSpeed Drill Centers; Drill/ Tap/ Mill SeriesUMC400 5Axis Mill 40Taper Vertical Mills – Haas CNC 2019年10月1日 cloud to form a plug in a vertical pipe (4) The dominant frequency of p 2 and Δ p 21 fluctuations are t h e sa m e f o r e a ch r u n i n t h e p lu g f l o w r e gi m e , w h i c hPressure fluctuation instability in vertical plug formation of coarse for controlling the coal flow at the discharge of a centrifugal classifier The model was based on an existing installation of a Riley Power standalone classifier, and included ductwork from the discharge of the ball tube mill up to the classifier and coal pipes The full length of the coal pipes was replaced by13045 Coal Distributor Paper:Layout 1 Babcock Power

.jpg)

Air Valves for Vertical Pump Applications

Piping: Vertical Pump Air Valves should be piped to the top of the discharge pipe with an isolation valve The pump discharge pipe should slope back to the well so that there is not water in the pipe when the pump starts or the air valve may close prematurelyPart of the tank or pipe plug clogging Cleaning pipe, tank, or replace the filter Mill discharge quantity reduction, hour production is too low 1、Feeder jam or damage Troubleshooting HRM vertical mill hydraulic system of exclusion; No TROUBLESHOOTING OF cement plant mechanical and electrical equipment2003年10月1日 The flow distribution between the coal pipes is achieved as the mixture leaves from the pulverizer through a number of outlet pipes, each of which carries the flow into one individual burner The number of outlet pipes on a typical vertical spindle mill varies between 2 and 8 The distribution of primary air throughout the piping network isBALANCING OF PULVERIZED COAL FLOWS TO BURNERS IN discharge valve, install a pressure relief or bypass valve in the discharge pipe to allow for minimum liquid flow through the pump Minimum liquid flow through the pump is needed for cooling and lubrication of the pump (See Table 1) Run the bypass/relief valve and discharge pipe to a floor drain or a tank for collectionINSTALLATION AND OPERATION MANUAL Pentair

.jpg)

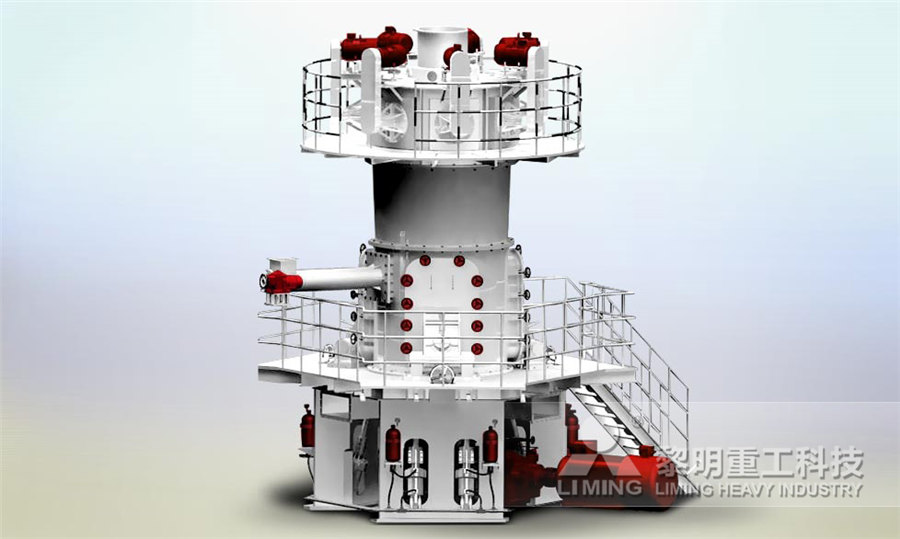

Vertical Super Fine Grinding Mill (Vertical Roller Mill)

Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse The mill offered was a medium speed vertical spindle type, or more specifically, a ringroller the central feed pipe a110VÆ fine pulverized coal to e£t the classifier and enter a mill discharge chamber, connected to multiple coal pipes leading to the boilerWorldProven Coal Pulverizer Technology Debuts in the US2018年5月30日 He said his rule of thumb was to size the discharge pipe to that of the pump’s discharge flange For example, if the pump’s discharge nozzle was 150mm, he would use a 150mm nominal size pipe for his discharge header In this article we’ll discuss why his rule of thumb may be costly The systemSizing a pump discharge pipe Pump Industry Magazine2 Place the cut pieces of pipe over the guide rail pins located in the base 3 Set the intermediated guide bracket in position with guides into pipe Put ubolt around discharge pipe and tighten lightly 4 Measure from joint on plug on intermediate guide bracket to joint on plug on top rail support and cut two (2) rails to the length Put2, 2 AND 3 NPT VERTICAL DISCHARGE PUMPS Zoeller Pump

VF1 VF Series Small 40Taper Mill Vertical Mills – Haas CNC

CNC Vertical Mill with 20" x 16" x 20" travels Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needsThe UMC400SS has a compact footprint and generous travels that make it the perfect fit for smaller shops, or shops doing 5axis smallpart machiningUMC400SS 5Axis Mill 40Taper Super Speed Vertical Mills 25 Column Pipe Pipe–ASTM A53 26 Column Coupling Pipe–ASTM A53 27 Tube Nipple Pipe–ASTM A120 28 Enclosing Tube Bronze Construction Steel–SCH80, ASTM A120, Gr B 29 Oil Tube Coupling 30 Lineshaft Bearing Bronze Construction Bronze–ASTM B584 C903 31 Lineshaft W/L–Chrome Spot Steel–AISI C1045 W/L–Stainless Stainless–ASTM A582 VERTICAL TURBINE PUMPS• Water flow in horizontal and vertical pipes 2 Design practices • Design of drainage systems • Sanitary fitments each discharge pipe section must be accessible for inspection internal cleaning 5 Shower without plug 04 Shower with plug 13 Single urinal with cistern 04 Slab urinal (per person) 02Sanitary and Stormwater Drainage ibsehk

VERTICAL TURBINE INSTALLATION, OPERATION

pipe Make certain the sleeve area of the lineshaft (if applicable) is toward the top of the pipe Tie a series of half hitches to the column pipe and lineshaft THREADED with 3/4" rope (Tie the rope to a chain pipe vise on the lineshaft, if needed) Attach the sling to the clamp ears as described under Section B, Step 3 3Pipe Plugs, Pipe Stoppers and Test Plugs Mechanical and inflatable expansion pipe plugs for just about any application From low pressure to high pressure Number #1 Supplier in USA Leading Provider Of Industrial Solutions 6909 Pipe Plugs Mechanical and Inflatable, expansion Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill The completely redesigned Mini Mill is enhanced with allnew FEAoptimized base and column castings, larger travels, and faster spindle speeds and rapids for increased production outputAn allnew Yaxis washdown nozzle improves chip flow inside the machine, and a new 45gallon (170liter) external coolant tank simplifies maintenanceMini Mill 40Taper Mill Vertical Mills – Haas CNC Machines

Mill discharge pumps Metso Automation PDF Catalogs

Consult Metso Automation's entire Mill discharge pumps catalogue on DirectIndustry Page: 1/8 Exhibit with us {{>currencyLabel}} Back Hose and pipes Branch pipes and valves Mechanical seals Vertical slurry pumps Horizontal slurry pumps EnviroSetTM seals For more detailed information on our MD series contact your local sales office www discharge as close to the check valve as possible (See Bulletin 769: APCO Check Valve Guide) Field Tested After years of laboratory and field testing, under actual operating conditions and in cooperation with leading vertical turbine pump manufacturers, we determined that no vertical turbine pump installations are identicalAPCO AIR VALVES FOR VERTICAL TURBINE PUMPS2018年6月1日 Particles are discharged from the hopper through the discharge pipe into the feeder Ambient air is used to transport particles The internal diameter of the discharge pipe and the riser is 006 and 005 m, respectively The riser length and the internal diameter of the feeder container are 093 m and 0206 m, respectivelyInvestigation on vertical plug formation of coarse particles in The KMS series mill discharge pump is ideal for semiautogenous and autogenous mill discharge, thickener underflow, tailings, and hydrocyclone feeding +86 186 3393 5649 info@kingdagroupKMS Mill Discharge Pump kingdapump

Mechanical Pipe Plugs

2022年6月16日 pressure ranges available: 010 psig, 025 psig, 0100 + psig normal, reverse and bidirectional pressure ratings restraint gripper and remote mechanical seal actuation methods; hydraulic pneumatic actuation methods and control systems available; with sealfast® mechanical sealSvedala was acquired by Metso in 2001 A totally new range for both horizontal and vertical slurry pumps were developed which included the hard metal and rubber lined Mill Discharge pumps In July 2020 Metso and Outotec combined to form Metso Outotec, becoming a Guidelines in slurry pumping Slurry pump handbook Metso