The purpose of quicklime ore grinding machine

Quicklime preparation Gebr Pfeiffer

Quicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to mortar It can also be used as a drying or Quicklime products neutralise exhaust gas emissions, waste water from production processes, sewage sludge, and untreated water destined for drinking water They also eliminate The Right Grinding Machines for Your Quicklime Industry Liming The purpose of this article if to introduce the development of the Cimprogetti hydration unit, including the modular CIMHYDRAXCOMPACT, and to analyse how the market for hydrated Developing a modular lime plant Cimprogetti2023年12月8日 Quicklime absorbs moisture or adds water to become hydrated lime The main component is calcium hydroxide Ca (OH)2, which is used in environmental protection, medicine, food and other industries Limestone or Limestone crushing technology and equipment SBM

.jpg)

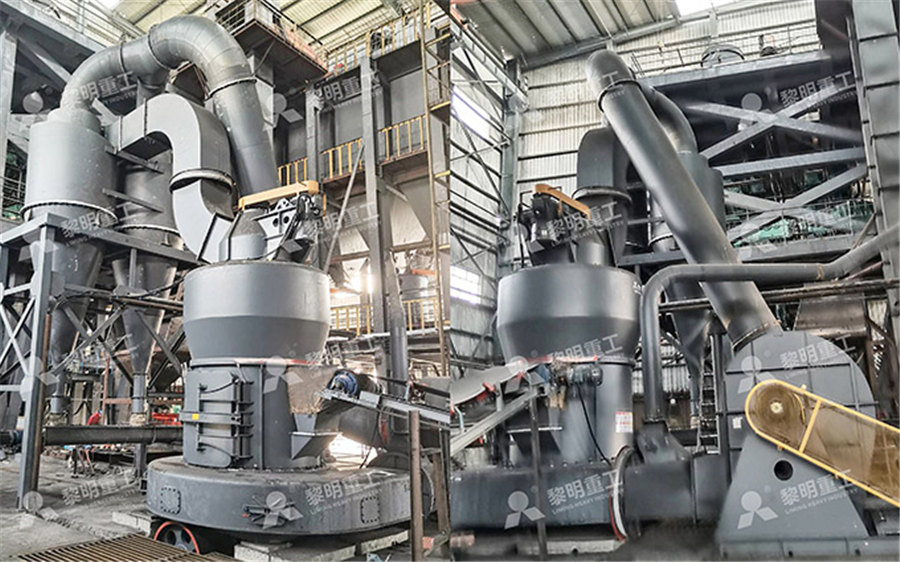

Vertical mill: The preferred equipment for quicklime production

The vertical mill is integral to the quicklime production process After limestone is calcined in the lime kiln, the resulting quicklime is fed into the vertical mill for grinding The mill ensures that Quicklime is a commonly used desiccant to remove water vapor by chemical absorption, especially suitable for products in steel, medicine, desiccant, puffed food, instrumentation, quicklime processing plant, quicklime grinding machine, quicklime 2022年4月20日 Quicklime absorbs moisture or adds water to become slaked lime, the main component is calcium hydroxide Ca (OH) 2, used in environmental protection, medicine, food and other industries Limestone or limestone are Limestone crushing and grinding production lineLimestone can be directly processed into stone using crushing equipment and fired into quicklime Quicklime absorbs moisture or adds water to become hydrated lime The main component of hydrated lime is calcium hydroxide Limestone Crushing Process JXSC Mineral

Exploring the Different Types of Grinding Machines

2019年11月1日 A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the 2024年1月23日 Basic Grinding Machines: Entrylevel grinding machines, suitable for smallscale operations or less complex tasks, typically range from $5,000 to $20,000 MidRange Grinding Machines: These machines, offering What is Grinding: Definition, Process, Types2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone crushing technology and equipment SBM 2021年1月16日 Your Single Disc Surface Grinding Machine will look like a horizontal spindle surface grinding machine albeit smaller in size since it does not need a reciprocating or circular table The grinding action in your machine takes place by the abrasive particles on the face of the grinding wheel You will be able to give the feed (depth of cut) by moving the wheel headSurface Grinder Types of Grinders How They Work Fine

[GYQ0R)ZQ]ESS4NJ.jpg)

How to do a good job of grinding in the lime industry?

2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine powder is classified by the classifier under the action of the air flow of the fan and then sent to the main machine2018年8月17日 The concept of ore blending is a very relevant notion in modern high tonnage production mines It is not only essential for the prolongation of the mine life of the concerned mine but as well as a The effects of ore blending on comminution behaviour and 2019年1月28日 What is biomass briquetting Biomass briquetting is to briquette and carbonize the scattered, light, difficult to store cellulose biomass, turn it to a kind of fuel Biomass briquetting can increase capacity and calorific value of biomass, improve combustion performance, make the bio waste become a kind of commodity energy source This conversion technology is The principle of biomass briquetting and bio briquette process2024年4月19日 Grinding Wheel: The grinding wheel is one of the most critical components of a grinder machine It is typically made of abrasive materials like aluminum oxide or silicon carbide The grinding wheel rotates at a high speed, creating the cutting action needed to remove material from the workpieceThe Grind: Understanding The Processes Of Grinding Machines

.jpg)

The Right Grinding Machines for Your Quicklime Industry

Offer tailored grinding mills for quicklime In the paper and glass manufacturing industries, our lime products regulate the pH value They are used for the same purpose in aluminium smelting plants and precious metal refineries The entire airflow system of this machine is a closed cycle and circulates under positive and negative pressureThe working tool is in fact any cutting tools including knives, scissors, joiner´s and other tools having similar properties and functions Grinding systems of this type have to be of good quality, reliable and easily operable Even operator who has not undergone any training must be able to reach very good results with such machineThe most important purpose of the grinding machine!2022年12月22日 Scope of application: It is suitable for quicklime grinding and processing, requiring large output, low energy consumption, and intelligent environmental protection Five core technologies: ① Grinding roller linkage pressurization technology, production capacity, under the same power, output increased by 20%;Type Selection of Quicklime Deep Processing Equipment2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray Lime/quicklime for metallurgy – how producing and

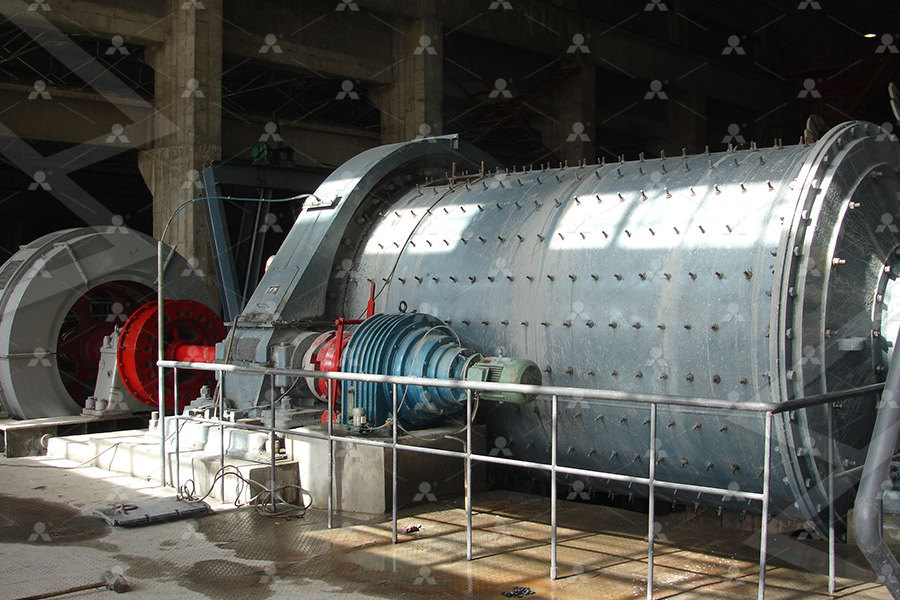

Grinding Machines Overview, Working, Types, and

2023年5月30日 A grinding machine’s electric motor provides rotational motion power to the grinding wheel via a belt and pulley system So, when we turn on the electric motor, it rotates at a specific angular velocity (10015000 RPM, 2023年10月13日 Principles of particle reduction The most common method for obtaining a homogeneous sample is grinding of comminution Grinding samples has many benefits for sample preparation since it increases homogeneity, increases surface area and decreases particle size which can improve extraction efficiencyPrinciples of Sample Preparation by Grinding or ComminutionOre grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;Ore Grinding Machines: Ball Mill, Rod Mil Grinding Media2024年2月19日 Grinding machines, harnessing the formidable force of steam engines, emerged as indispensable assets in factories worldwide These early contraptions, though crude by modern standards, Evolution of Grinding Machines: From Past to Present

.jpg)

An Overview of Lime Slaking and Factors That Affect the Process

pebble quicklime is used Once the slaking tank is emptied, the water for the next batch is added to the slaking tank and the system goes to a standby mode waiting for an operator to start the next batch cycle Figure 4 shows a batch slaker for use with pulverized quicklime Batch slakers are used where only a few small batches are needed2021年7月3日 Creep feed grinding is a slow, onepass operation that makes a deep cut of up to one inch in steel materials at low table speeds between 05 and 1 ipm It is not suitable for conventional grinding machines, but for those which are compatible with it, it offers high productivity and cost effectivenessMachining 101: What is Grinding? Modern Machine ShopThe quality of the quicklime is largely dependent on the efficiency of the grinding process, which is where the vertical mill comes into play The vertical mill, also known as the vertical roller mill, has emerged as a leading piece of equipment for the production of quicklime due to its advanced technology and operational excellenceVertical mill: The preferred equipment for quicklime productionComparison of Lime Kiln Types Each type of lime kiln has its unique characteristics that determine its suitability for different applications Batch or intermittent kilns are ideal for smallscale production and are simple to operate, while continuous or annular kilns are ideal for largerscale production and produce highquality quicklimeDifferent Types of Lime Kilns for Industrial Applications

Factors Affecting The Quality of Quicklime

The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the limestone, as well as operating conditions in the kiln 2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers are widely used in ore crushing, aggregate Types of Crushers: Choosing the Right One for Each 2020年6月29日 These grinding machines are designed to sharpen milling cutters, reamers, taps and other machine tool cutters The generalpurpose cutter grinder is the most popular and versatile toolgrinding machine Various Chapter 17: Grinding Methods and Machines2023年9月1日 How Surface Grinding Machines Work Surface grinding machines operate by rotating an abrasive wheel on a horizontal spindle that is mounted on a reciprocating table The workpiece is held on the table and moves back and forth under the grinding wheel, while the wheel itself remains stationary The grinding wheel is typically made of bonded The Advantages of Surface Grinding Machines: A Comprehensive

.jpg)

(PDF) A comprehensive review on the grinding process:

June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLink2015年1月1日 On the other hand, eccentric grinding machines are special purpose machines that can be separated from the circular grinding machine, because they are equipped with very dynamic Xaxis, which changes the machine structure significantly Nevertheless, circular grinders and noncircular grinders are closely related to each other (Fig 3)Grinding Machines SpringerLink2022年12月30日 Purpose The purpose of this paper is to evaluate the efficiency of grinding operations in terms of how mechanical properties (eg, strength properties and ore texture) affect the Bond Work Index(PDF) Evaluation of gold ore properties and their impact on grinding

.jpg)

Vertimill® Metso

Vertimill® is a unique product offered exclusively by Metso Grinding efficiency, reduced media consumption, lower installation cost, minimal maintenance, and minimal liner wear make Vertimill® the lowest total cost of ownership in many applications, substantially improving the profitability of concentratorsQuicklime grinding powder production process Quicklime must be pretreated before milling because the rough stone cannot directly enter the Raymond mill for milling, so it needs to be crushed before this The specific equipment and process flow of the quicklime milling production line are as follows: Quicklime grinding equipment:How to choose quicklime powder grinding mill?2021年11月23日 This is a small grinder operated with electric power It can be easily carried anywhere Grinding can be done by holding it in hand It is used for cleaning heavy welding jobs On one end of the motor shaft, a grinding wheel 14 Types of Grinding Machines [Working, Diagram☞ Metals such as steel and iron are extracted from ores These ores contain impurities such as silicates To remove them, quicklime is added to the ores, and the mixture is melted at high temperatures The silicates bond with the lime to form a liquid called slag, which is immiscible with the molten metalThe Amazing Uses of Quicklime You Probably Didn’t Know

.jpg)

Stone Dust Making Machine For 325 Mesh Quicklime Grinding

2024年11月7日 In above quicklime grinding plant case, the customer using our HGM grinding mill as a stone dust making machine to process quicklime (calcium oxide) and calcium carbonate into a fine, 325 mesh powder Quicklime, due to its chemical properties, is in high demand for various industrial applications, including water treatment, chemical manufacturing, and 2022年2月28日 Limestone flour is used in a variety of industrial sectors such as power and heat generation, glassmaking, papermaking, the construction industry and construction materials manufacturing, the The Effect of Calcination Temperature on The Quality of Quicklime 2022年8月31日 Dear Colleagues, The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants It not only provides the appropriate particle size for subsequent separation operations but also enables the liberation of valuable minerals from the gangueGrinding Modeling and Energy Efficiency in Ore/Raw Material 2022年4月20日 Lime is divided into quick lime and slaked lime After being calcined, limestone becomes calcium oxide CaO (commonly known as quicklime), which is generally in the form of lumps and is used in water quality treatment, asphalt improvement, desulfurization, building materials, medicine and other industriesLimestone crushing and grinding production line SBM Ultrafine

Factors influencing the reactivity of quicklime ResearchGate

2008年1月2日 This paper describes the factors influencing the reactivity of quicklime; namely the chemical composition of the raw material, the calcination and decrepitation processes to manufacture calcium 2021年2月20日 During the production process, adding too much lime will accelerate the speed of ore settling and concentration, which is not conducive to normal operation (such as thickener operation), and at the same time, it will generate CaCO 3 precipitates blocking the pipeline; on the other hand, adding insufficient amount will not only affect the effect of drug removal but also The Magic Effect of Lime in Mineral Processing JXSC MachineThe class Basics of the Surface Grinder provides an overview of the components, considerations, and varieties of the surface grinding machine Surface grinders are classified by their table types and spindle orientations, and vary in levels of automation Wheels, workholding devices, and coolant also vary based on the workpiece and grinding operationSurface grinding is a Basics of the Surface Grinder 231 Tooling USMEQuicklime is used in a wide variety of applications, including the manufacture of iron and steel, the manufacture of paper and pulp, the treatment of water and flue gases and the mining industry In the basic oxygen steelmaking (BOS) process, quicklime Quicklime Preparation, Properties, and Applications with FAQs