HOME→Petroleum coke grinding machinery process flow Petroleum coke grinding machinery process flow Petroleum coke grinding machinery process flow

Petroleum coke grinding machinery process flow Petroleum coke grinding machinery process flow Petroleum coke grinding machinery process flow

.jpg)

Crushing Equipment for Petroleum Coke Plant by

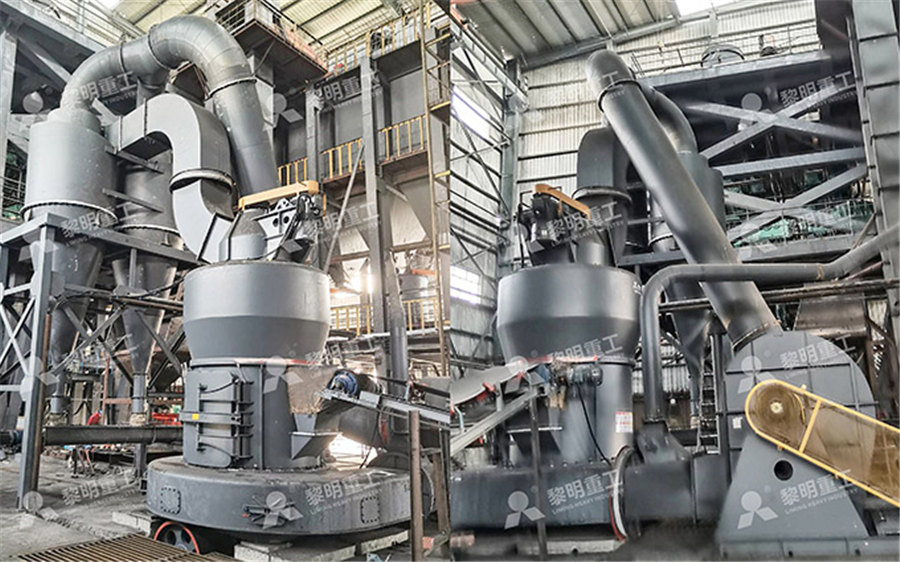

2016年12月12日 Grinding machine is based on petroleum coke characteristics, using numerical simulation software to design the most suitable crushing and classifying flow field, to optimize main2024年2月27日 To unlock its full potential, specialized grinding machines have been developed to process petroleum coke into finely ground powder In this comprehensive article, we delve Petroleum Coke Grinding MachinesPetroleum coke powder processing flow: The petroleum coke crushed by a crusher, and then by the dryer for drying (some do not need drying), and finally by the MTW European mill strong Petroleum coke flour and processing flowKefid MachineryThe main area of application of petroleum coke is the electrolytic aluminum industry, which accounts for more than 65% of the total consumption of petroleum coke, followed by coal, uses of petroleum coke petroleum coke grinding mill hcm

Petroleum coke grinding production line and application

Petroleum coke is a carbonrich solid fuel and byproduct produced during the refining of crude oil It is the result of cracking processes that break down heavy, long hydrocarbon molecules into Here, we show that realtime monitoring of the grinding vessel acceleration allows the automatic evaluation of blending efficiency Carbon anodes used for, eg, smelting aluminium consist of Realtime monitoring of efficient grinding and blending of HCMilling(Guilin Hongcheng) provides exclusive Petroleum Coke Vertical Roller Mill equipment with customers for grinding Petroleum Coke powder It is a kind of advanced pulverizing Petroleum Coke HLM Vertical Roller MillPetroleum coke is the end wasteof the oil refining process Its appearance is black or dark gray honeycomb structure After grinding into powder, it can be reuse In the field of glass fuel Kefid petroleum coke grinding equipmentKefid Machinery

.jpg)

Petroleum Coke Crusher: Choosing the Right Equipment

2024年6月2日 To efficiently process pet coke, specialized equipment known as crushers is required The crusher can effectively break large pieces of petroleum coke to the required 2014年3月1日 The production of petroleum coke (petcoke) in the refineries is progressively peaking up because of the trend of processing heavy crudes and in turn, a renewed interest in delayed coking process(PDF) Petroleum coke gasification: A reviewThe Petroleum coke ball mill, pet coke ball mill, or pet coke grinding mill is important mechanical equipment specially used for grinding petroleum coke, which is an accessory product in the petroleum refining process The ground Petroleum Coke Ball Mill Buy Ball Mill for Pet Coke 2023年2月9日 A polishing sequence involves grinding at around 200 rpm on a 320grit silicon carbide disk exposing the CPC particles This is followed by grinding on 500, 1000, and 2000 grit silicon carbide disk at same rpm, using water both as a lubricant and a coolant as shown in Fig 1d The polishing cloth was used for fine polishing by applying 3 µm highperformance Method for Calcined Petroleum Coke Evaluation to Improve the

.jpg)

A comprehensive review on the grinding process: Advancements

2022年6月24日 Grinding is a manufacturing process which significantly contributes in producing high precision and durable components required in numerous applications such as aerospace, defence and automobiles This review article is focused to uncover history, witness the present and predict the future of the grinding process2020年4月6日 Petroleum Coke Processing Equipment Petroleum coke grinding mill i The qualified powder will flow into the pulse dust collector and be collected Bauxite Powder Process Machine 4002500MeshPetroleum coke grinding mill Milling Equipment Capacity: 450 Petroleum coke is distillation to separate the light and heavy oils, heavy oil turn into end product by thermal cracking process Tell from the appearance, coke is irregular in shape and sizes of black lumps (or particles) a metallic luster; coke particles having porous structure, the main elements is carbon, possession of more than 80wt%, the rest is hydrogen, oxygen, nitrogen, Grinding Petroleum Coke Powder2011年2月26日 The process is automatic in that there is a continuous flow of coke and feedstock, and coking occurs both in the reactor and in the surge drum Health and safety considerations In coking, temperature control should be held within a close range, as high temperatures will produce coke which is too hard to cut out of the drumPetroleum Refining Process ILO Encyclopaedia of Occupational

.jpg)

Petroleum Coke Official Satisfactory Wiki

Petroleum Coke is a fuel item distilled from Heavy Oil Residue As the AWESOME Sink does not accept fluids, converting Heavy Oil Residue into Coke is one way to sink it, solving the fluid deadlock problem in the early petrochemical setup It was formerly used in the production of Aluminum Scrap without alternate recipes It can be burned in the Coal Generator, which 2024年6月2日 Petroleum coke, or pet coke, is a carbonaceous solid derived from oil refinery coker units or other cracking processes It serves as a valuable fuel source in various industries, including cement, power generation, and metallurgy To efficiently process pet coke, specialized equipment known as crushers is requiredPetroleum Coke Crusher: Choosing the Right EquipmentPetroleum coke grinding mill Petroleum coke is a product obtained by separating crude oil from heavy oil by distillation, and then transforming the heavy oil through a thermal cracking process As a fuel, petroleum coke can replace heavy oil, which is a good way to apply new energy It can also be used in graphite, Petroleum coke grinding mill, Petroleum coke mill, Petroleum coke HCMilling(Guilin Hongcheng) provides exclusive Petroleum Coke Vertical Roller Mill equipment with customers for grinding Petroleum Coke powder It is a kind of advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying Its fineness can achieve 200325 mesh (7544μm) The production capacity is 5200T/HPetroleum Coke HLM Vertical Roller Mill

What is Grinding Process How It Works Different

2022年11月28日 Grinding is a type of finishing process in mechanical processing, with less machining and high precision It is widely used in the machinery manufacturing industry The heattreated and quenched carbon 1997年1月1日 In a summary, the abovementioned experimental results suggest that carbon materials obtained in this selfsintering process can have high density and good flexural strength, though the process is rather simple and economic, and the raw petroleum needlecoke can have good selfsinterability as long as a suitable treatment, such as grinding in this investigation, is The effect of grinding on the sintering of raw petroleum coke2021年1月1日 calcination process of green petroleum coke in rotary kiln Peng LI a, b , Baokuan LI a, b * , Zhongqiu L IU a , Yang YU a a School of Metallurgy, Northeastern University, Shenyang , ChinaA synergy model of material and energy flow analysis for the During a machining process with a trackbound cutting edge engagement, the cutting edge of the grain penetrates the workpiece upon a flat path and, after a phase of elastic deformation, triggers plastic flow of the workpiece material (Fig 3)Due to the shape of the cutting edge, the angle between the cutting edge contour and the workpiece surface is very small at the beginning of Grinding Process SpringerLink

Technology for separating powdered materials from petroleum coke

2024年2月7日 After refining petroleum products, a lot of petroleum coke residue remains From year to year, the amount of coke on the planet is increasing, and scientists around the world are looking for ways 2021年12月1日 Petroleum coke is a solid, carbonaceous byproduct of oil refining and is normally used for heating or as an anode in aluminum and steel productionSustainable production of graphene from petroleum coke using A petroleum coke ultrafine pulverizer is a machine or device used to grind petroleum coke into ultrafine powder +17 [ This process involves grinding the coke using specialized grinding equipment that applies mechanical force to break down the The pulverized petroleum coke particles will be classified by air flowPetroleum Coke Ultrafine Pulverizer2021年2月1日 This study aimed to create activated carbon thin film (ACTF) as a hybrid nanocarbon via a simple and efficient method through a singlestep mixing process using thermal functionalization techniquesGranulated activated carbon production based on petroleum coke

Realtime monitoring of efficient grinding and blending of petroleum coke

grinding process (B) shows the condition after inefficient grinding with material loss on the bottom side Discussion By using the acceleration sensor signal of the grinding vessel, it is possible to evaluate the grinding and blending process of petroleum coke Based on the calculation of the acceleration SD, periods of efficient grinding can2023年1月29日 It is worth mentioning that, The chemical formula for calcined petroleum coke is CxHy, where x is the number of carbon atoms and y is the number of hydrogen atoms in the molecule Petroleum Coke Uses Petroleum Petroleum Coke Types, Uses and SpecificationsCalcined Petroleum Coke(CPC) is a kind a petrochemical product, whose raw material is green petroleum coke This coke is the product of the coker unit in a crude oil refinery The combination of energy recycling with calcining therefore Calcined Petroleum Coke/CPC Carburizing Machine1 Software Material: Petroleum Coke 2 Feed dimension: 00mm Moisture % three out measurement: 325mesh(D97), particle dimension may be adjusted Four Output: shot coke 3t/h4t/h ; sponge coke 4t/h5t/h 5 Provide completed grinding machine (together with crusher, conveyor tools and grinding machine)Petroleum Coke Ring Roller Mill Producer

(PDF) Calcinations of Petroleum coke ResearchGate

2014年1月1日 Abstract — Petroleum coke is a process that involves steps such as thermal decomposition, polymerizationion and condensation Flow scheme of general electrode p roduction shown in figure 32014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready availability, and relatively (PDF) The History and Future Challenges of Calcined Petroleum Coke Here's a general overview of the process, with a focus on the use of a European version vertical grinding machine: 1 Calcining: Petroleum coke or coal coke is heated to high temperatures in a kiln to drive off volatile components, leaving behind a more pure carbon materialCalcined coke powder production process European version 2013年5月15日 The objective of this study was to analyze dry grinding kinetics of three different solid fuels in terms of selection and breakage distribution functions values using a batch laboratory ball parisons of Dry Grinding Kinetics of Lignite, Bituminous

.jpg)

Changing the Fineness of Calcined Petroleum Coke with Ball

2019年2月16日 Calcined Petroleum Coke Density Separation Process: Solution to Maintain Anode Quality with Degrading Coke Density “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany2017年4月28日 FLM1000 grinding machine is suitable for petroleum coke, including crusher, conveyor equipment (including auger and powder pneumatic conveying),grinding machine Simple process flow diagram Petroleum coke Ring Roller Mill Manufacturer by feng li MediumThe Birth of Petroleum Coke: From Crude Oil to Carbon Petroleum coke is a byproduct that emerges during the oil refining process, specifically from the residue left behind after the distillation of crude oilThis residue, known as “resid” or “bottomofthebarrel,” is the source material from which petroleum coke is derivedWhat is Petroleum Coke or Petcoke? Its Types, Applications, and 2018年3月22日 Petroleum coke or pet coke is a product obtained from oil of all kinds during the oil refining process Petroleum coke is a carbonrich solid originating from petroleum refining and is obtained by Analysis of petroleum coke from low grade oily sludge of refinery

Preparation and properties of oilsubstituted fuel based on petroleum

2019年5月24日 To improve the stability of petroleum coke water slurry (PCWS), bubblePCWS based on biomass fermentation was researched in this paper The results showed that the stability of bubblePCWS Phrase one: Crushing of raw material Big petroleum coke blocks were being crushed into suitable size of grinding mill feeding which is 1520mm Phrase two: Grinding Manganese material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Grinding mill has to go through hot air if moisture is over 6% for drying to save Petroleum Coke Grinding Mill QuotationPetroleum coke is the key raw material of carbon industry and new energy industry Using petroleum coke as raw material to make artificial graphite has become a major application field of petroleum coke The petroleum coke grinding mill, also known as petroleum coke grinding mill, is a major supporting equipment for petroleum coke downstream applicationsPetroleum Coke Crusher Petroleum Coke Grinding Mill Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedGRINDING PROCESS GRINDING GRINDIN

.jpg)

Modeling and Simulation of Petroleum Coke Calcination in Pot

2015年10月13日 The aim of this work was to establish a mathematical model for the analysis of calcining process of petroleum coke in a 24pot calciner via computational fluid dynamics (CFD) numerical simulation method The model can be divided into two main parts (1) heterogeneous reacting flow of petroleum coke calcination in the pot was simulated using a twofluid model 2022年6月18日 All content in this area was uploaded by Barhm Abdullah Mohamad on Jun 18, 2022(PDF) Lecture Notes in Modern Petroleum Refining ProcessesGrinding is the common collective name for machining processes that utilize hard, abrasive particles as the cutting medium The grinding process of shaping materials is probably the oldest in existence, dating from the time prehistoric humans found that they could sharpen their tools by rubbing them against gritty rocksGrinding Processes SpringerLink2021年8月23日 Petroleum coke is a solid, Note that CK2 and CK3 were received as relatively large pieces and required grinding prior to the ECE process (flow rate 60 mL/min)Sustainable production of graphene from petroleum coke

Hydrocracking in Petroleum Processing SpringerLink

2015年1月1日 Modern hydrocracking technology has been in use since 1960 However, there is a long history of hydrocracking that began early in the twentieth century (Scherzer and Gruia 1996; Robinson and Dolbear 2006)Hydrocracking technology was developed in Germany in the 1910s when it was used for coal conversion to secure a supply of liquid fuels from domestic