Highfine vertical mill serpentine coupling

Modeling and vertical torsional coupling vibration control of the

2022年3月14日 This article establishes a mechanicalelectricalhydraulic vertical torsional coupling vibration mathematical model, and investigates its vibration suppression control 2024年9月1日 In this paper, the working process of the vertical stirred mill is taken as the research object, and the performance of the vertical stirred mill is analysed through the DEM Performance analysis of vertical stirred mill based on multi Here, to allow such electronics to better serve practical applications, ranging from wearable devices to soft robotics, we propose a novel vertical serpentine conductor (VSC) with superiorVertical serpentine interconnectenabled stretchable and Nature2015年2月14日 Through testing and analyzing the vibration signals of the mill in the rolling process, the rolling mill’s coupled model is established with comprehensive consideration of Tandem strip mill’s multiparameter coupling dynamic modeling

Electromechanical coupling characteristics analysis of vertical

2024年1月15日 The electromechanical coupled characteristics during the startup and steadystate operation stages of the mill are analysed using the ECSMBDDEM coupling model for 2014年4月6日 Then a verticalhorizontal coupling nonlinear vibration dynamic model of rolling mill rolls is proposed, based on the interactions between this dynamic rolling force and mill structure The(PDF) Analysis of VerticalHorizontal Coupling Vibration 2014年4月6日 This study establishes a vertical–horizontal coupling vibration model of hot rolling mill rolls under multipiecewise nonlinear constraints considering the piecewise nonlinear [PDF] Analysis of VerticalHorizontal Coupling Vibration 2016年12月29日 Through the theoretical and simulation research, it is found that rolling mill do exist verticaltwist coupling vibration, electromechanical coupling vibration and liquid Study on the VerticalTorsion Coupling Vibration of Sixhigh

Vertical vibration diagram of rolling mill ResearchGate

Download scientific diagram Vertical vibration diagram of rolling mill from publication: Adaptive Fuzzy Vertical Vibration Suppression Control of the MechanicalHydraulic Coupling Rolling Mill In a vertical fine grinding mill, material is fed from the top and ground by the action of grinding media, such as steel or ceramic balls The grinding media is agitated by either a slowspeed rotating agitator (as in the Tower Mill) or a highspeed impeller (as in the VXPmill )Vertical mills for fine grinding – FLS2021年1月15日 A unidirectional vertical coupling structure is designed based on optical throughsilicon vias (TSVs) and gratings to couple and steer the optical interconnects in 3D optoelectronic integrated circuits The optical TSVs provide highspeed vertical optical data transmission over short distancesSimulation research of highefficiency unidirectional vertical coupling 2023年5月11日 The twodimensional grating coupler is optimized and verified with finitedifference timedomain simulations, achieving a high coupling efficiency of −153 dB and a low polarizationdependent loss of 0015 dB when coupling to a standard singlemode fiber at approximately 1310 nm wavelengthDesign of a Completely Vertical, PolarizationIndependent Two

.jpg)

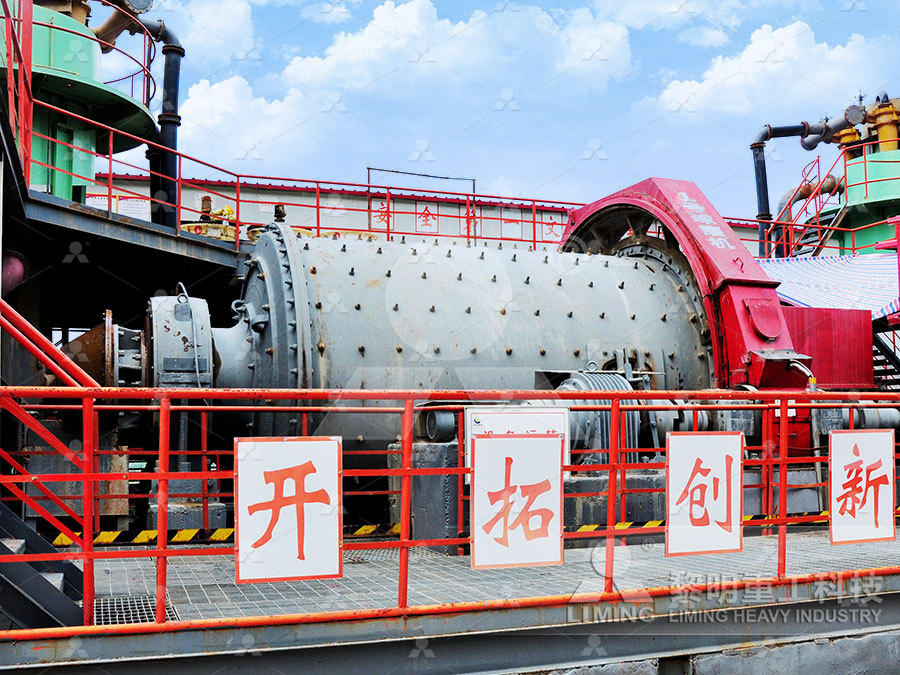

Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill

Newtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill; Compact Jet Mill and Separator Combined System Kurimoto Pocket Jet; Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Batch Type Highspeed Planetary Mill Kurimoto High GVertical mill merges fine crushing, drying, grinding and powder selecting into a single, which simplifies the production process It has the advantages of high grinding efficiency, low power consumption, large feed particle size, easy adjustment of grinding fineness, simple process, less land occupation, low noise, simple operation and maintenance, low cost and less wear Vertical Mill In Cement Plant Cement Vertical Mill AGICO Request PDF On Sep 1, 2024, Hui Yuan and others published Numerical investigation of a vertical roller mill using DEMMBD coupling method Find, read and cite all the research you need on Numerical investigation of a vertical roller mill using DEMMBD 2024年1月15日 DEM [[28], [29], [30]], as a specialized approach for studying particle dynamics, has been widely employed by researchers to simulate the operational processes of stirred mills and the dynamic behaviour of grinding media inside the millSinnott et al [31] conducted a study on tower mills and pin mills, utilizing threedimensional DEM simulations to analyse the flow Electromechanical coupling characteristics analysis of vertical

(PDF) Drives for large vertical roller mills ResearchGate

PDF On Jan 1, 2017, J Harder published Drives for large vertical roller mills Find, read and cite all the research you need on ResearchGateCLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill technologies The top technical team members were joined this project Besides, highquality wearresistant parts are used to develop milling equipment which Ultra fine vertical roller millUltra Fine Millultramillindustrial 2023年10月23日 Efficient grating couplers (GCs) for perfectly vertical coupling are difficult to realize due to the secondorder back reflection In this study, apodized GCs (AGCs) are presented for achieving Highperformance grating couplers on 220nm thick silicon by 2014年4月6日 Analysis of VerticalHorizontal Coupling Vibration Characteristics of Rolling Mill Rolls Based on Strip Dynamic Deformation Process April 2014 Shock and Vibration 2014(1):111(PDF) Analysis of VerticalHorizontal Coupling

FYEFEPS2HDZ49G5Z0[B.jpg)

Effect of operating parameters on fine particle

2017年1月10日 This paper evaluates the effects of operating parameters on fine particle grinding process with a vertically stirred media mill The effects are investigated through size reduction under different 2020年1月1日 This paper investigates the adaptive fuzzy vertical vibration suppression control problem for the sixhigh rolling mill system Firstly, a new vibration model is established with the consideration (PDF) Adaptive Fuzzy Vertical Vibration Suppression Control of CCA also has a range of products for Vertical Pumps View Vertical Pumps Other Applications Vertical rigid couplings can be found in many other applications, including mixers, turbines, or any other equipment that spins on a vertical axis If there is only a thrust bearing in the motor, but none in the pump, a rigid vertical coupling would Vertical Rigid Couplings Coupling Corporation of AmericaAdvantages of Using Vertical Shaft Couplings Vertical shaft couplings offer advantages such as high torque capacity, flexibility in accommodating misalignment, and reduced maintenance costs Challenges in Vertical Shaft Coupling Challenges include dealing with highstress environments, ensuring precise alignment, and selecting the appropriate vertical shaft coupling

.jpg)

Vertical Stirred Mill Mineral Processing Equipment CITIC HIC

Vertical stirred mills are a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle The significant advantages that the vertical stirred mills have over the ball mills are smaller size, less auxiliary equipment required, more simple system and more options of processing methodsGrid couplings are aimed at high output, high torque gear applications, while gear couplings are heavy duty products with large bore capacities Most products are made from cast iron, though some (such as chain couplings) use carbon steel Surface treatment techniques, including phosphate coating, help to protect against corrosionSKF Couplings and bolts SKFAmerigear Flexible Spindles For specific operating capacities and coupling data, refer to the Ameridrives Sales Drawing 2 GENERAL INFORMATION Ameridrives Amerigear SM series spindles are designed for use in rolling mill applications Amerigear spindles transmit torque while operating at specific misalignments between driving and driven equipmentAmerigear High Capacity Industrial Mill SM Spindle2024年9月1日 To improve vertical mill performance, a vertical stirred mill is used as the research object Firstly, an electromechanical multibody dynamic model (EMBD) of the vertical stirred mill is established, followed by the establishment of a discrete element method (DEM) analysis model of the grinding media, and then the DEMEMBD coupling model is formedPerformance analysis of vertical stirred mill based on multicoupling

Study on the VerticalTorsion Coupling Vibration of Sixhigh Rolling Mill

2016年12月29日 Proposes a method of constructing sixhigh rolling mill verticaltorsion coupling dynamics model base on the multifreedom vibration systems theory Finally by comparing the mean value of the vibration amplitude, quantitative analysis of the mutual influence degree of torsional vibration and vertical vibrationWhat Is Cement Vertical Mill The cement vertical mill is a type of grinding equipment that merges fine crushing, drying, grinding, and powder separating into a single, which simplifies the production process and has many irreplaceable Cement Vertical Mill Vertical Grinding Mill2023年12月1日 The stirred mill was fit to use for fine grinding the middling with a high content of complex intergrowth, especially appropriated for milling P80 1030 μm minerals to liberate more valuable Electromechanical coupling characteristics analysis of vertical ® Mill Spindles Heavy Duty, High Performance Design 2 ameridrives ® Coupling Products 1802 Pittsburgh Avenue P O Box 4000 Erie, PA USA 165124000 tel 8144805000 fax 8144535891 ISO 9001 R E G I S T ER D F M 1 0 0 2804 Q M 8 A C C R E DITE B Y R v A Ameridrives InternationalAmerigear Mill Spindles Heavy Duty, High Performance Design

.jpg)

Adaptive Fuzzy Vertical Vibration Suppression Control of the

This paper investigates the adaptive fuzzy vertical vibration suppression control problem for the sixhigh rolling mill system Firstly, a new vibration model is established with the consideration of the coupling of mechanical and hydraulic systems and the unknown uncertainty on nonlinear rolling force Then, the adaptive active control strategy is proposed to suppress chatter of the 2023年12月4日 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics The capacity of the VRM depends not only on the grinding material properties but also on the operational parameters of the VRM This study investigatedNumerical Investigation of Vertical Roller Mill Operation Using About Vertical Flexible Couplings When a vertical pump or mixer has a thrust bearing, the coupling between the motor and pump likely needs to provide for misalignment capability with a vertical flexible coupling In these situations, CouplingCorp can use its Flexible Shaft Couplings to meet the need In many cases, vertical flexible couplings may be []Vertical Flexible Couplings Coupling Corporation of AmericaElectronics 2022, 11, 3031 4 of 15 Figure 3 F3 frame model 22 Mathematical and Physical Model of Vertical–Torsional Coupling The rolling process was completed by the rolls, which extruded Dynamic AmplitudeFrequency Characteristics of Vertical

.jpg)

Vertical–Horizontal Coupling Vibration of Hot Rolling Mill Rolls

Metals 2021, 11, 170 4 of 24 Figure 2 Structure diagram of a fourhigh hot rolling mill 21 Piecewise Nonlinear Spring Force Model The hydraulic elastic stiffness refers to the nonlinear 2021年6月15日 As the mainstream equipment for grinding powder processing, vertical mills have a direct relationship with the interests of enterprises in their production and operation links Vibration produced by the vertical mill not only Characteristics and Cause Analysis of Vibration in 2021年9月17日 Some examples of this type of shaft coupling are sleeve, compression and flange coupling Once a rigid coupling is used to connect two equipment shafts, they act as a single shaft Rigid couplings find use in Types of Couplings Fractory2024年7月9日 Considering the dynamic variation of roll gap and the transverse distribution of dynamic rolling force along the work roll width direction, the movement and deformation of rolls system, influenced by the coupling of vertical chatter and transverse bending vibration, may cause instability and also bring product defect of thickness difference Therefore, a rigidflexible Dynamic modeling and analysis on rigidflexible coupling

.jpg)

CLUM Ultrafine Vertical Grinding Mill

Production of coarse powder and general fine powder above 45um, stable operation, high cost performance and high noise Ring roller mill: 2um content is about 20% or more, the highest fineness is 810um, middle and highend finished powder Produce 1015um powder, stable operation, short life of wearing parts, high noise and low output Ball mill2024年9月15日 Consequently, a numerical simulation method of Discrete Element Method (DEM) coupled with MultiBody Dynamics (MBD) is proposed in this work to study Kisen Vertical Mill (KVM), an external circulation vertical roller mill developed by Sinoma International Intelligent Technology Co, Ltd, for a deeper understanding of grinding process in the VRM, in which Numerical investigation of a vertical roller mill using DEMMBD Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powderBarite Ultrafine Vertical Roller Mill2023年3月21日 Application of ultrafine vertical mill in the processing and production of ultrafine heavy calcium Considering the diversified needs of heavy calcium powder products, the “CLUM ultrafine vertical mill + secondary (or tertiary)” classification process is often used in the design of vertical grinding powder engineering systems There are two reasons:The advantages of ultrafine vertical mill in the processing and

(PDF) Performance Comparison of the Vertical and ResearchGate

2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the (PDF) Performance Evaluation of Vertical Roller Mill in2021年1月18日 DOI: 103390/MET Corpus ID: ; Vertical–Horizontal Coupling Vibration of Hot Rolling Mill Rolls under MultiPiecewise Nonlinear Constraints @article{Peng2021VerticalHorizontalCV, title={Vertical–Horizontal Coupling Vibration of Hot Rolling Mill Rolls under MultiPiecewise Nonlinear Constraints}, author={Rongrong Peng and Vertical–Horizontal Coupling Vibration of Hot Rolling Mill Rolls