Environmentally friendly bauxite powder making equipment

.jpg)

Which machines are needed to process bauxite powder?

(1) Cyclone Collector: Collects fine bauxite powder and reduces dust in the processing environment (2) Bag Filter: Captures fine particles released during the grinding process, Looking for a reliable bauxite grinder? Look no further than Weifang Jinghua Powder Engineering Equipment Co, Ltd Our company specializes in providing highquality and efficient equipment China Bauxite Grinder Manufacturer, Supplier JINGHUA2020年2月1日 The aim is to reduce formation of CO 2 to produce primary aluminium in a more environmentally friendly manner The inert anodes have been developed to replace the carbon The aluminium industry: A review on stateoftheart technologies 2024年9月1日 The SDR approach encompasses three techniques: powder metallurgy, extrusion, and spark plasma sintering, all of which operate under solidstate conditions and Recycling aluminium for sustainable development: A review of

.jpg)

China Bauxite Pulverizer Manufacturer, Supplier JINGHUA

Looking for a reliable bauxite pulverizer? Weifang Jinghua Powder Engineering Equipment Co, Ltd offers highquality pulverizing equipment for efficient processing Contact us today!2022年3月1日 The main technologies include two types: one is to recover valuable components such as aluminum, iron, and scandium by acid leaching, which has technical problems such as Comprehensive Application Technology of Bauxite Residue Explore the damaging impact the extraction of bauxite mining for aluminium for construction has on our natural environment globallyEnvironmental Impacts of Aluminium Bauxite Mining 2024年1月24日 Here we present how this red mud can be turned into valuable and sustainable feedstock for ironmaking using fossilfree hydrogenplasmabased reduction, thus mitigating a Green steel from red mud through climateneutral hydrogen

The Green Revolution in Powder Metallurgy Eurobalt

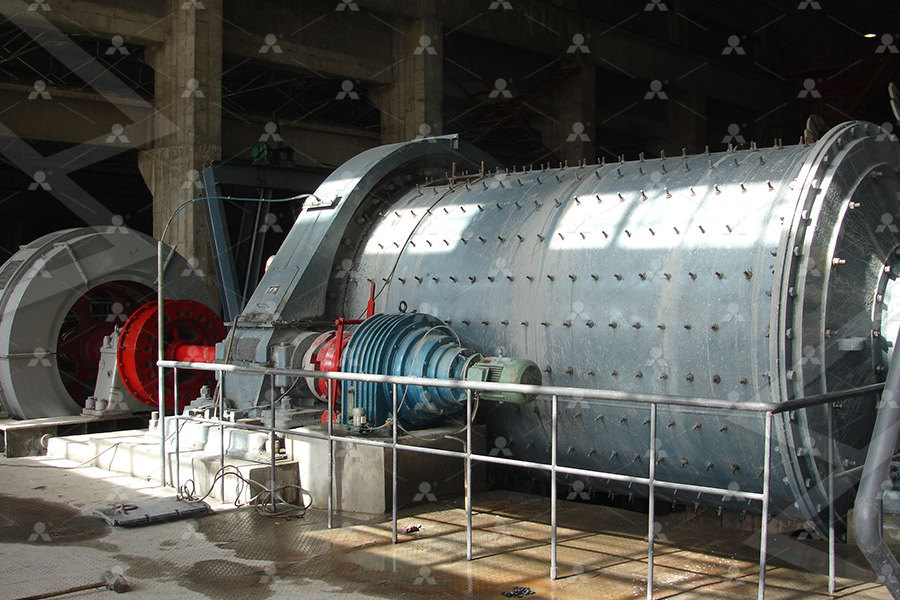

2024年1月29日 Powder metallurgy, often hailed as an ecofriendly revolution, brings forth a unique blend of efficiency and environmental consciousness This manufacturing method boasts a netshape capability, meaning that the 2024年6月5日 The aluminum production process is energyintensive and results in greenhouse gas emissions, making it important to explore sustainable practices in bauxite mining Bauxite has a global significance as a source of aluminum Bauxite Mining for Aluminum: Environmental and Raymond mill is a highly efficient and environmentally friendly powder making equipment, which produces fine and uniform particle size In mineral processing, classification equipment is often used in conjunction with ball mills, including Grinding Classification Equipment JXSC MachineryVacuum Investment Powder Mixer Menu Toggle Menu Item; 100kg Silver Refining Machine Menu Toggle You can also judge a quality goldcoinmaking equipment manufacturer by the number of good products they have there Coin Making Machine, Onestop Solution Supplier for

.jpg)

Which machines are needed to process bauxite powder?

Bauxite powder processing equipment Processing bauxite into powder involves several types of machinery, Jaw Crusher: Used for primary crushing of large bauxite rocks into smaller pieces, making them suitable for further processing (2) Impact Crusher or ensuring an environmentally friendly operation 6 Storage and Packaging Equipment Meet the new RECO 2 Recovery Systems Our RECO 2 Recovery Systems allow dry ice producers to nearly double their dry ice output by collecting revert gas during production and recycling it to make more dry ice pellets with less liquid CO 2 (LCO 2) Offering a modular design and multiple liquefaction capacities, we ensure that you will drastically improve the conversion Dry Ice Production Equipment Machines Cold JetHighperformance Equipment MTW, LM, LUM, and SCM series Ecofriendly Production To ensure environmentally friendly production, various measures are implemented, including the adoption of dust removers and sealing at each component 4Qualified bauxite powder will discharge via the discharge valve, then packing into bags; Material Cases Bauxite2021年6月11日 Petroleum coke powder is generally divided into four types: coarse powder processing (03 mm), fine powder processing (20400 mesh), ultrafine powder processing (4001250 mesh) and micro powder processing (12503000 mesh)Types of grinding mills for petcoke grindingTypes of grinding

10 Sustainable Building Materials for EcoFriendly Construction

Compared to traditional concrete, Ferrock is made from 95% recycled materials, which is much more environmentally friendly than traditional cementbased products Additionally, it has the potential to absorb more carbon dioxide than it emits during production, making it a more carbonneutral building material2024年10月15日 Our CHOICE lab tests reveal the environmentallyfriendly cleaning products that perform well and those that don't, the following products making eco claims score just 5% more with a CHOICE Expert Rating of 50% And as much as powder dishwasher detergents seem like a good option if you're on a budget, The ecofriendly household products that actually work CHOICE2024年4月12日 24 Test methods 241 Macroperformance testing The standard consistency water consumption, initial and final setting time and 2 h/adiabaticflexural and compressive strength of modified phosphogypsum were tested in accordance with “Building Gypsum” (GB/T97762008) According to “Gypsumbased selflevelling mortar” (JC/T10232021), the 30 Highly efficient modified phosphogypsum building gypsum powder 2017年3月17日 Environmentally Friendly Construction Equipment and Methods with you hamesha 18005470086 CE manufacturing companies are now focusing on making green equipment that emit far lesser amount of smoke and give energy as well fuel efficiency So, the time has come to go green! Contact Us Prev NextEnvironmentally Friendly Construction Equipment and Methods

.jpg)

Recycling aluminium for sustainable development: A review of

2024年9月1日 To reduce these obstacles and improve the environmental advantages of recycling aluminium, technological developments, more stringent laws, and environmentally friendly activities are crucial [12] Tatsuhiko Aizawa et al conducted a study highlighting the production of small and thinwalled aluminium alloy parts using the PinInjectionGate (PIG) Lets define cleaning and sanitizing, since they are two different processes, which should not be confused Cleaning your equipment means that you have removed all of the visible dirt and residue on your equipment, sanitizing means you have treated your equipment with a chemical solution that will eliminate, or prevent the growth of spoilage organisms (molds, wild yeasts, Simplifying Cleaning and Sanitizing for Home WinemakersThe formulation of powder coatings relies on materials that do not include harmful elements, making them more environmentally friendly and reducing potential health risks In addition to excluding heavy metals, powder coatings also contribute to lower levels of volatile organic compounds (VOCs) in comparison to certain liquid paint applicationsIs Powder Coating Environmentally Friendly?2023年7月24日 This contributes to air pollution Powder coatings, on the other hand, are solventfree They emit significantly fewer VOCs, making them a more sustainable and environmentally friendly choice Further, powder coating minimizes waste by allowing the reuse of excess powder Any overspray can be collected and reused, resulting in minimal material How Powder Coating and ECoating Promote EcoFriendly Metal

.jpg)

Regulating sulfur migration and transformation in low water

2024年8月15日 The production of prepared LWCPG is environmentally friendly When 80 % phosphogypsum aggregate is used to replace natural sand aggregate in the preparation of lightweight concrete (LWC), approximately 42 t of phosphogypsum aggregate can be utilized, reducing the consumption of natural sand aggregate by 614 t, saving 3070 MJ of energy, and 2023年6月7日 Environmentally Friendly New Catalyst Using Waste Alkaline Solution from Aluminum Production for the Synthesis of Biodiesel in Aqueous Medium(PDF) Environmentally Friendly New Catalyst Using Waste The bamboo powder making machine is an industrial ultrafine grinding mill independently developed and produced by SBM It can grind bamboo into bamboo powder of 1503000 mesh, and the fineness can be adjusted freely according to needs Bamboo powder has a wide range of uses and is a new type of energysaving and environmentallyfriendly raw Bamboo Powder Making Machine2024年1月16日 Unlike dieselpowered machinery, electric equipment does not rely on gasoline or diesel fuel, making it an environmentally friendly choice This is particularly crucial as the construction industry currently accounts for approximately 39% of the world’s CO2 emissions related to energyElectric Construction Equipment: Pioneering Sustainable Solutions

The Benefits Of Recycling Aluminum Over Plastic: Exploring The

2022年12月16日 Manufacturing equipment such as furnaces can be extended with less energy consumption Recycling aluminum reduces the need to mine fresh bauxite ore in has never been more cost effective, faster, or energy efficient than it is now A metal can is 100 percent recyclable, making it the most environmentally friendly (and 2022年2月1日 DOI: 101061/(asce)mt19435533 Corpus ID: ; Production of Environmentally Friendly Concrete Incorporating Bauxite Residue and Silica Fume @article{Ghalehnovi2022ProductionOE, title={Production of Environmentally Friendly Concrete Incorporating Bauxite Residue and Silica Fume}, author={Mansour Ghalehnovi and Naeim Production of Environmentally Friendly Concrete Incorporating Bauxite 2023年5月4日 Environmentally Friendly New Catalyst Using Waste Alkaline Solution from Aluminum Production for the Synthesis of Biodiesel in Aqueous Medium May 2023 DOI: 1020944/preprints0377v1Environmentally Friendly New Catalyst Using Waste 2019年1月31日 However, bauxiteliquid residue leaching can have a devastating effect on aquatic life and ecosystems Studies have shown that the seawater neutralisation technique carries the risk of covering Environmental Impact of Bauxite Mining: A Review

11 Best Natural And Nontoxic Cleaning Products (2024)

2024年10月7日 Best For Home delivery refill shipments Gives Back Charitable partnerships with environmental causes Price Varies; $499 flatrate shipping for orders under $49; $299 Supply Chain Fee is added to each order as well Grove Collaborative is rethinking what it means to maintain a clean home with natural products The company offers a multitude of household, Bauxite powder Enhanced roller grinding mill is a specialized piece of industrial equipment designed for the fine grinding and processing of bauxite, Environmentally Friendly The enhanced roller grinding mill is versatile and can be used for various types of bauxite and other materials, making it suitable for multiple industries, Bauxite powder enhanced roller grinding mill2024年3月25日 We conduct the same tests for ecofriendly cleaning products in the Good Housekeeping Institute Cleaning Lab as we do for any other traditional cleaner Whether that involves testing each product 20 Best EcoFriendly Cleaning Products of 2024 Good When it comes to powder coating, its reputation for durability and finish quality is welldeservedBut how does it stack up in terms of being environmentally friendly? This is the question we'll tackle today From its chemical composition to waste management, we’ll delve into the ecological aspects of powder coating to see how green it really isIs Powder Coating Environmentally Friendly?

Red mudbased inorganic polymer spheres: Innovative and environmentally

2020年11月1日 Red mud, also known as bauxite residue, is a toxic waste produced from the alumina refining of the bauxite ore by the Bayer process (Khairul et al, 2019) One of the main challenges associated with recycling is the pH value, usually ranging between 92 and 128, due to the addition of sodium hydroxide during the refining process ( Chen et al, 2019 )2021年4月19日 Environmentally friendly lowcost porous ceramics are prepared with 982 wt% mining waste as the raw materials at 1180 °C The glass powder forms liquid phase at high temperatures, promoting the Preparation of environmentally friendly low‐cost mullite porous Factors to consider in the washing powder production line When formulating the product in the washing powder making machine, it’s essential to pay attention to the pH of the washing powder to ensure it is compatible with the human skin and can clean effectively The optimum pH range for laundry detergent is 9105Laundry detergent making equipment Making2013年12月20日 Ishii states that a Powder Metallurgy method is used to produce the thermoelectric modules from environmentally friendly materials such as SiGe, Mg2Si, and Mn18Si in which reduced thermal conductivity is Powder Metallurgy products in fuel efficient and

An environmentally friendly design for lowgrade diasporicbauxite

2009年8月1日 A new environmentally friendly design for lowgrade diasporicbauxite processing which is different from the Bayer and sintering processes was proposed in this paperTAHA International Group TAHA is a multidiscipline solutions provider with corporate offices in Luxembourg (TAHA International SA) and the Netherlands (TAHA International BV), offering innovative, environmentallyfriendly and Dross management industrial waste TAHA amount of glass powder added increases, the content of silicon oxide increase, because the glass powder will transform into silicon oxide, as shown in Fig 3 The content of mullite increase rst and then decrease with increasing content of glass powder The maximum is 642% when the content of the glass powder is 4 wt%Preparation of environmentally friendly low‐cost mullite porous 2024年10月7日 Nike, an American multinational corporation, leads not just in sales of footwear, apparel, sports equipment, and accessories, but also in environmental stewardshipBesides highlighting green initiatives in their advertising, this industry giant sets a stellar example in ecofriendly practices In their quest for sustainability, Nike passionately champions a product line 17 Green Companies That Are Good For You and The Environment

.jpg)

The aluminium industry: A review on stateoftheart technologies

2020年2月1日 Equipment and technology for mining bauxite have been omitted as opportunities for heat recovery technologies is of a lesser significance Technology with the ability for WHR is the primary focus, although some of the equipment provided has little ability for WHR but has been added to give a fuller picture of the state of the art2017年4月11日 Starting from the mineral bauxite one obtains aluminum by first refining it to alumina (Al 2 O 3 ) via the Bayer process and then smelting the alumina by the HallHéroult process [8]Aluminium Production Process: Challenges and Opportunities2009年8月1日 Over the past several decades environmentally friendly design has been applied to an increasingly diverse range of technologies and innovative solutions for the management of resources (Todd et al, 2003, Graedel and Allenby, 2004, Kharel and Charmondusit, 2008)Green process design has been recognized as a new significant orientation in the evolution of An environmentally friendly design for lowgrade diasporicbauxite Moreover, the powder coating process allows for the recycling of excess sprayed powder through a process known as powder reclamation This process can lead to significant improvements to product utilization, as it allows the recapture and reuse of the powder overspray trapped in filters or fallen to the floor of the spray booth1Powder Coating and the Environment Colourific Custom Coaters

Recent advances in green energy and product productions

2015年6月20日 This paper presents a short overview of some of the more current advances related to the productions of green energy and products; to environmentally friendly, healthier and safer technologies and processes; advances in CO2 capturing, storage, and recycling; and novel methods for sustainability assessment in decisionmaking The presented innovative research