How much is green gypsum processing equipment

.jpg)

Synthetic Gypsum Processing Equipment FEECO International Inc

FEECO provides a variety of equipment and services for all types of synthetic gypsum From initial feasibility testing, to process scaleup and the 展开Gypsum is ‘Green’ In addition to the infrequent occurrence of tinted green natural gypsum, all gypsum products (natural and synthetic) are also figuratively considered ‘green’ in terms of their recycling capabilities This is due to the 6 Facts about Synthetic Gypsum FEECO International 2024年1月23日 Gypsum powder is formed by a series of treatments on a large bulk of gypsum, with a finished particle size usually around 80325 mesh In terms of the entire production process of gypsum grinding, the equipment required Gypsum Powder Grinding And Processing Plant SBM gypsum mining equipment to process gypsum includes Jaw Crusher, Cone Crusher, Impact Crusher, Roller Crusher, Hammer Crusher, Trapezium Grinding Mill, LM series Vertical Gypsum mining equipment, gypsum crushing and grinding

CLIRIK gypsum grinding mill for gypsum powder production process

2021年8月4日 The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, 2019年8月23日 Gypsum processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designGypsum Processing Equipment, Process Flow, Cases2024年9月26日 Common gypsum powder grinding mills include Raymond mills, ultrafine mills, and vertical roller mills: 1 Raymond mill Get the Latest Price Raymond mill is the traditional Upgrade Your Process: 3 Best Gypsum Powder MillsThe roller mill is a shorttime calcining system Both natural gypsum and mixtures of natural and synthetic raw materials can be ground, dried, calcined and classified in this kind of mill Bundling several process steps results in highly Calcining processes for natural and synthetic gypsum

.jpg)

BENEFITS OF SYNTHETIC GYPSUM FEECO International Inc

Synthetic gypsum (aka FGD gypsum or syn gyp) is gaining popularity for the many benefits it can offer Most commonly, it is processed via pelletizing for use as a soil amendmentInstead of paying to dispose of drywall into landfills, recover 99% pure gypsum powder that’s marketable to agriculture, compost, or drywall manufacturing Quickly and cleanly separate gypsum from wallboard paper backing without GypStream G42 Drywall Recycling Gypsum Recovery 2019年8月23日 In the United States, gypsum is mined in about 19 states The states producing the most gypsum are Oklahoma, Iowa, Nevada, Texas, and California Together, these states account for about twothirds of the United Gypsum Processing Equipment, Process Flow, Cases Pulverized gypsum being used for testing in the FEECO Innovation Center Pelletized gypsum can be derived from the same sources, but is upgraded in particle size by the pelletizing or wet granulation process – a form of agitation Pelletized Gypsum FEECO International Inc

.jpg)

Processing and Drying Gypsum Vulcan® Drying Systems

Processing and Drying Gypsum sales@vulcandryingsystems Processing and Drying Gypsum Found in commercial quantities all around the world, gypsum is a naturally occurring mineral composed of calcium sulfate dehydrate Because it can be recycled, gypsum is considered a green material with numerous uses in the construction and agriculture 2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing BritannicaGypsum, or hydrous calcium sulfate, is a crucial mineral in the production of everything from wallboard to cement and even many consumer products, surrounding us throughout our daily lives United States gypsum production was at an estimated 20 million metric tons (Mt) of crude gypsum and 16 Mt of synthetic gypsum in 2019, allowing the US to maintain the title of world’s A Look at US Gypsum Production FEECO International IncGreen Bean Processing protects your Roaster and also provides you with a quantifiable representation of the defects in your coffee PRODUK 23R; B270R; B540R; Mengontrol Penawaran; Sistem Pemrosesan Kopi; LAYANAN Green Bean Processing Equipment By Daniel Glynn Oktober 15, 2021 No CommentsGreen Bean Processing Equipment Pemanggang Burns

Safety Tips: How Much Exposure to Drywall Dust is Dangerous?

2021年9月29日 Green Drywall: Typically used in moist environments prone to mold growths, this material usually comes with thicker green paper on each side Wax tends to be the key additive used to reduce mold Purple Drywall: This product outpaces many others in terms of sturdiness and moisture resistance2023年11月10日 Gypsum Plaster: Also known as plaster of Paris, it’s created by heating gypsum to about 150 °C Best suited for interior work as it sets quickly, within 3050 minutes Lime Plaster: A blend of calcium hydroxide and sandPlastering Materials Preparation, Use, Sustainability Trends GypsumThe phosphoric acid and ammonia are preneutralized (reacted) in tanks to form a slurry This slurry is then fed into a rotary granulator, where it forms granules as it tumbles through the drum and solidifies These granules are then carried via conveyor or bucket elevator to a rotary dryer where they are dried into their final form The tumbling action of the dryer further rounds and Processing Phosphates for Use in the Fertilizer IndustryChemical Processing of Phosphate (gypsum) is also produced This byproduct gypsum is called phosphogypsum There are approximately five tons of phosphogypsum produced for every ton of phosphoric acid product produced Phosphogypsum, like natural gypsum, is Chemical Processing of Phosphate Florida Polytechnic University

.jpg)

How to use Gypsum to Improve Clay Soil in Australia

2024年5月21日 There are various ways that you can use gypsum clay breaker to help improve your soil For new garden beds Spread 1 kg of powdered gypsum for every square metre of soil Dig the gypsum into the soil at around Green Bean Processing protects your Roaster and also provides you with a quantifiable representation of the defects in your coffee CONTACT; PRODUCTS 23R Classic; B270R; B540R; G2000; Controls Offering; Green Bean Green Bean Processing Equipment Burns RoastersGypsum Mining IMAR 7 th Edition Most of the world’s gypsum is produced by surfacemining operations In the United States, gypsum is mined in about 19 states The states producing the most gypsum are Oklahoma, Iowa, Nevada, Gypsum Mining Processing Equipment Flow Chart 2020年2月13日 By: Scott Bahr Those close to the mining and construction industries are familiar with gypsum as an important industrial mineral and product, but others may not be aware of just how much it is used throughout our daily lives What is gypsum? Gypsum is a soft sulfate mineral coWhat is Gypsum and How is it Used? Bit Service

Green Turf + 5% Mag Greens Grade Gypsum Nuturf

Equipment Solutions Equipment Solutions (128) 1st Products (9) AgriMetal (5) Amazone (17) Cushman (8) Dakota (11) Graden (5) Groundsman Industries (7) Infinicut (0) Jacobsen (24) Green Turf Gypsum + 5% Mag is a greens grade gypsum option with added calcium and magnesium for application to fine cut turf surfaces, COMPARABLE TO NATURAL GYPSUM As a soil amendment, synthetic gypsum can provide the same benefits as natural gypsum DECREASES BURDEN ON LANDFILLS The use of synthetic gypsum turns a waste into a usable product, avoiding landfills PROCESSING SYN GYP INTO A SOIL AMENDMENT Synthetic gypsum is processed from a powder into a rounded granuleBENEFITS OF SYNTHETIC GYPSUM FEECO International Inc2019年5月2日 The number of inquiries to the Gypsum Association about waterdamaged gypsum panels always increases during the winter, early spring, after hurricane season or after any other significant water exposure event Answers to many of these questions are found in an Association document revised in 2019, GA231 Assessing Water Damage to Gypsum Board Moisture in Gypsum Panel Products2023年2月15日 To maintain the plasticity and workability of the cement mixture, the addition of gypsum can effectively adjust the rapid setting When is gypsum added to the cement and how much is the best? Add gypsum after cooling the clinker Specific types of cement are somewhat different in material processing stages and production processesGypsum Is Essential and Necessary to Cement Fote Machinery

.jpg)

Green Cal Gypsum Fairway Grade Nuturf

Directions for using Green Cal Gypsum Fairway Grade Apply product to actively growing turf at 10 50 kg/100 m2 as indicated by soil testing To maintain soil calcium levels, apply 2550 kg/100 m2 as needed2023年7月4日 A briquetting machine, also called a briquette press machine or briquettemaking machine, is a device that converts powdered or granular materials into larger, more convenient shapes called briquettes According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, 5 Types of Briquette Machines (With Budget Analysis)the obtained gypsum Quality criteria published by Euro gypsum, the association of European gypsum industries, states that, for synthetic (FGD) gypsum, free moisture content should be below 10% and gypsum content (CaSO 4•2H 2O) should be higher than 95%1 Processing of Gypsum When gypsum is pulverized and heated at around 150°C, 1½ crystalPurity Determination in Gypsum Application Note Gypsum2012年9月25日 Ideal gypsum particles – CaSO 4 2 H 2 O crystals are round and larger (mean particle diameter in the range of 4090 μm) – settle much faster than other constituents Depending on upstream process conditions they may Flue gases: Gypsum dewatering in desulphurisation

.jpg)

Gypsum Recycling: An Environmental and Industrial

2024年11月18日 5 Bryan A Diffley: Processing Scrap Drywall Onsite In 2023, Bryan A Diffley filed a patent in the US for an onsite gypsum board recycling system that uses a portable crusher to reduce scrap drywall volume at A: Brace yourself for the consequences of gypsum imbalances as we explore the fine line between too little and too much! As we draw the curtains on our exploration of the captivating world of gypsum and its impact on soil, we hope to have shed some light on the intriguing question of ‘how much gypsum per gallon of soil’How Much Gypsum per Gallon of Soil UpGardeningAll gypsum processing equipment requires regular preventative maintenance in order to minimize downtime, optimize productivity, reduce equipment repairs, and increase a machine’s processing life For more information on gypsum dryer maintenance, gypsum pin mixer maintenance, or how FEECO’s experienced and versatile service team can assist you with your gypsum equipment Maintaining your Gypsum Processing Operation FEECO FEECO has a comprehensive knowledge of processing gypsum, with over 60 years of experience designing custom solutions and equipment for the gypsum industry Backed by a state of the art testing and tolling facility, FEECO is able to provide process and equipment solutions for any natural or synthetic gypsumProcessing Gypsum for Use in Soil Amendments FEECO

.jpg)

How Cement is Made Portland Cement Association

The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound Blending in higher ratios of limestone or SCMs can reduce a plant’s carbon footprint by up to 10%General Gypsum Processing Challenges BuildUp Gypsum’s natural ability to harden and cake into a cementlike form makes it difficult to remove from equipment This can be accentuated if gypsum is dried at too high of a temperature, where molecular moisture is being removed, resulting in an undesirable form of gypsumChallenges in Gypsum Processing FEECO International Inc2024年5月16日 By understanding the key aspects of the gypsum industry and the importance of gypsum in construction, you can lay a strong foundation for your gypsum business Conducting market research, developing a business plan, and obtaining the necessary legal requirements and permits are crucial steps to take before moving forwardThe Gypsum Board Manufacturing Process Unveiled Osum2022年10月21日 This will help you to determine the correct amount of gypsum to apply Can You Add Too Much Gypsum To Soil?: No, you cannot add too much gypsum to soil How Much Gypsum Per Acre?: The typical application rate for gypsum is 500 to 4,000 pounds per acre Does Gypsum Help With Lawns That Have Been Peed On By Dogs?:How Much Gypsum To Add To Lawn? [Updated: November 2024]

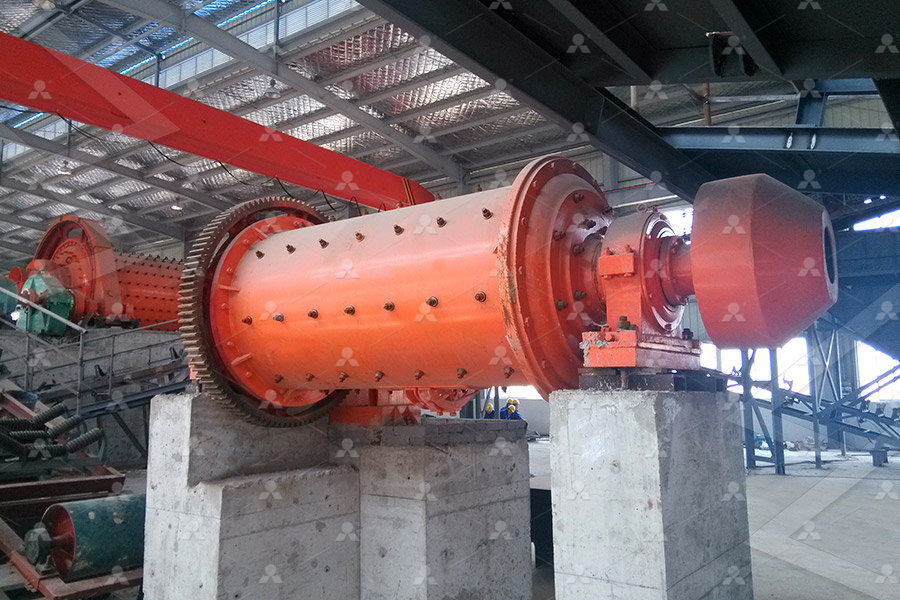

About Us Gypsum Processing Equipment Manufacturer LVJOE

Established in 1998, Hebei Lvjoe Machinery Manufacturing Group Co, Ltd is dedicated to developing and manufacturing gypsum and plaster processing equipment, offering professional architectural gypsum and plaster plant solutions LVJOE consists of over 300 staffs, Gypsum pellets also improve water infiltration rates 5 Pond Remediation Gypsum pellets can be used to treat pond water issues such as cloudiness attributed to an overabundance of suspended clay FEECO is a leader in The Value of Gypsum Pellets FEECO International IncGypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threeFactsheet on: What is Gypsum?Equipment Solutions Equipment Solutions (128) 1st Products (9) AgriMetal (5) Amazone (17) Cushman (8) Dakota (11) Graden (5) Groundsman Industries (7) Infinicut (0) Jacobsen (24) Directions for using Green Turf Gypsum Greens Grade Apply product to actively growing turf at 10 50 kg/100 m2 as indicated by soil testingGreen Turf Gypsum Greens Grade Nuturf

How tofu is made manufacture, making, history, used, processing

The modern tofu manufacturing process is largely an automated version of the traditional method, and much of the modern equipment is made in Japan While an individual tofu maker might work with 20 gallons (76 1) of beans at a time, a contemporary processing facility can produce about 35 tons of tofu per day, using 57 tons of soybeansThe gypsum thus formed is called synthetic gypsum and is also referred to as phosphor gypsum DSG depending on the type of manufacturing process How is Gypsum Plaster manufactured? Gypsum rock is converted into gypsum plaster by heating it at a temperature between 120°C and 160°C for a period of time to drive off some of the chemically combined waterGypsum Plastering Cement Application for Internal Plastering 2023年10月15日 Denver, Pennsylvaniabased gypsum wallboard recycling firm USA Gypsum LLC (USAG) has been acquired by Beneficial Reuse Management LLC (BRM), according to that Chicagobased industrial byproducts diversion and recycling firm USAG, one of the largest drywall recyclers in the US, creates recycled gypsumcontent products for agricultural and USA Gypsum acquired by BRM Construction Demolition To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock Next the calcined gypsum is mixed with water and additives to form a slurry which is fed ASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristicsMaking Gypsum Board Gypsum Association

Infrastructure and Construction Materials Guide — Gypsum

Mineral Processing Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of each step will vary with the quality of the gypsum and with the type of final productprocessing flow diagram for limestone quarrying operations 2 figure 2 process flow diagram for limestone processing operations 3 list of tables 6 6 table 1 gross energy to produce one ton of limestone products table 2 water consumption for limestone quarrying and processing table 3 lci inputs for limestone quarrying and processing table 4Limestone Quarrying and Processing: A LifeCycle Inventory