Process of approving quicklime production equipment

Production of Quicklime Lime and Limestone Wiley Online Library

1998年5月14日 Production of Hydraulic Limes References F Schwarzkopf , “ Lime Burning Technology – a Manual for Lime Plant Operators ”, 3rd ed , Svedala Industries, Kennedy Van Saun, 1994 Hydrated lime is a important industrial chemical, mainly composed of calcium dihydroxide CO(OH) 2 It is produced by hydrating quicklime, essentially calcium oxide, using a specific Developing a modular lime plant Cimprogetti2007年12月1日 The process model can be used both for determining optimum modes of operation in existing kilns and for optimum kiln design for the new Valec twinshaft kilnProduction of Quicklime ResearchGateQuicklime and hydrated lime production including deadburned dolomiteLime Production an overview ScienceDirect Topics

Level Measurement of Quicklime Inventory in Limestone Production

Accurate measurement of stored quicklime provides inventory insight for streamlined production and delivery schedules After calcination, the quicklime comes out of the kiln in lumps, grains, Quicklime and hydrated lime can significantly improve subgrade engineering properties by increasing the stability, impermeability, and load bearing capacity of the subgrade It is QUICK LIME AND BYPRODUCTS PEC Consulting GroupHow lime is produced There are two main forms of lime; quicklime and hydrated lime Quicklime is produced by heating any material containing calcium carbonate to a temperature of around Lime An Introduction1998年5月14日 Summary This chapter contains sections titled: Introduction Principles of Lime Burning Development of Lime Kilns Modern Kilns Selection of Lime Kilns Kiln Control Mass Production of Quicklime Lime and Limestone Wiley Online Library

.jpg)

Lime and its Production

Combining Quicklime (CaO) and water (H20) produces Calcium Hydroxide (Ca (OH)2 slaked lime and heat There are three main ways of slaking the Quicklime: in damp sand to produce a combustion of limestone for the production of quicklime in CaO Hellas Inc, a quicklime plant situated in the city of Thessaloniki in northern Greece An aqueous solution of 30 % weight MEA was Optimal Design of Solvent Based Post Combustion CO2022年10月12日 In order to prevent the backflow of dust generated in the digestion process, the equipment is equipped with a special discharge port for steam and dust, which can be discharged to a special dust removal system through connecting pipes, and is used in conjunction with the DMC pulse dust removal Q device with the hydrated lime equipment, which can handle Introduction to the process flow of hydrated lime equipmentThe production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madeWhat is Quicklime and How is it Made? Science Struck

.jpg)

QUICK LIME AND BYPRODUCTS PEC Consulting Group

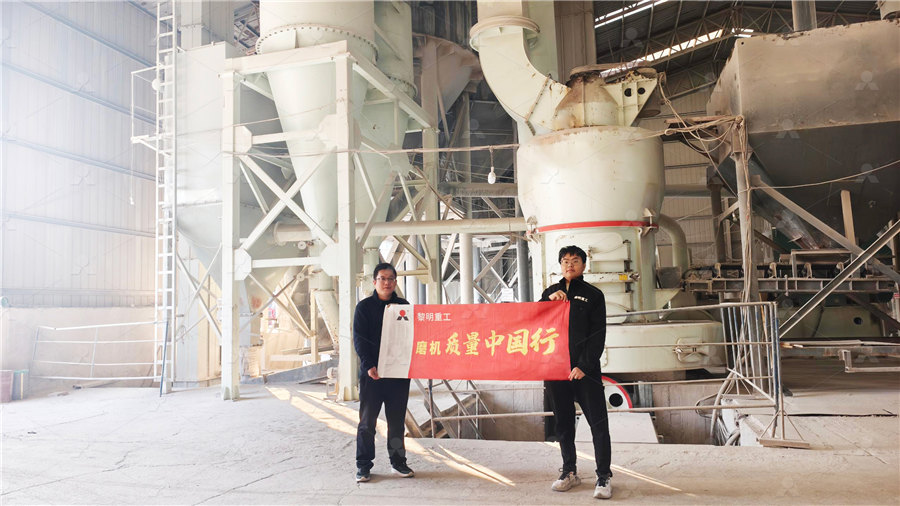

Commercial sales accounted for 91% of total lime consumption and 92% of domestic production Captive lime accounted for the remainder of consumption and was used in the production of steel in basic oxygen furnaces (BOF), magnesia production, precipitated calcium carbonate production, sugar refining, and refractories (deadburned dolomite)The vertical mill stands out as the preferred equipment for quicklime production due to its high efficiency, energy savings, environmental protection, and ease of maintenance Its advanced grinding technology and compact design make it an ideal choice for lime producers looking to enhance their operational capabilities and product qualityVertical mill: The preferred equipment for quicklime productiondioxide—a process known as calcination This leaves quicklime, or calcium oxide (CaO), a material that has been used by humans throughout history Adding water to the quicklime will result in an exothermic reaction and the production of hydrated lime, or calcium hydroxide (Ca(OH) 2), a fine dry white powder not dissimilar to baby powderQUICKLIME, HYDRATE OR LIME SLURRY? CarmeuseLime Slaker Detention Lime Slaker Specification Feeding Particle Size: 30 Processing Capacity : 120t/h Motor Power : 15105kw Application Areas : Lime plants, steel plants, desulfurization systems, sewage treatment, fine chemical preparation processeLime Processing Plant for Quicklime and Hydrated Lime Production

.jpg)

Production of Quicklime Lime and Limestone Wiley Online

1998年5月14日 Production of Hydraulic Limes References F Schwarzkopf , “ Lime Burning Technology – a Manual for Lime Plant Operators ”, 3rd ed , Svedala Industries, Kennedy Van Saun, 1994 This study analyzes Quicklime Production By Thermal Decomposition Method, covering manufacturing, process flow, operating expenses, and financial considerations +1 307 363 1045 sales@procurementresourceQuicklime Production By Thermal Decomposition MethodAs a relatively economical lime kiln, the Parallel Flow Regenerative (PFR) lime kiln is used as the main equipment for the production of quicklime by various steel industries PFR lime kilns Reactivity of quicklime depending on the burning temperature2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray Lime/quicklime for metallurgy – how producing and

Quicklime for Paper Pulp Production Techmicom

2024年5月4日 By adjusting the pH levels with quicklime, then manufacturers can prevent corrosion of equipment and ensure the quality and stability of the final product Overall, quicklime is an essential chemical in the paper production industry due to its versatile properties and its ability to improve the efficiency and quality of the manufacturing processHigh calcium quicklime (CaO) is produced when limestone, or calcium carbonate (CaCO 3), is heated in a kiln through the process of calcination CaCo 3 + heat > Cao = CO 2 After limestone with high calcium content is sourced from our High Calcium Quicklime Carmeuse2024年6月23日 Production Process of QuickLime The production process of Quick Lime, also known as Calcium Oxide, involves high temperatures and chemical reactions Here’s a breakdown of how this super substance is made: Calcination: The extracted limestone is then heated in a kiln at temperatures exceeding 900°C During this process, carbon dioxide is QuickLime 101: Everything About This Super Substance ZME2022年12月22日 Production of 20400 mesh (080037mm) quicklime and limestone preparation technology and process CLRM series Raymond mill Processing fineness: 200400 mesh (080037mm) Standalone production capacity: 3560T/H (depending on the model)Type Selection of Quicklime Deep Processing Equipment

.jpg)

Quicklime: A Primer

2023年10月27日 Quicklime is an alkaline substance produced from heating limestone in specialized kilns Humans have used quicklime since antiquity for construction, agriculture and metalwork applications It is still used in all of these industries and more; there is a lot to learn about this substance It is Produced from Limestone Quicklime is used as a building material, 2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years)Calcium Carbonate Manufacturing Process and EquipmentProcess equipment is used in several applications like water treatment, steam power generation, pipelines, Industries use filters for removing unwanted substances from the main product during a process or application Different kinds of filters are available in the market as per the requirement of the process such as air filter, Understanding Process Equipment Types of Process Equipment2024年4月16日 Store your quicklime After you’ve let your quicklime cool, you need to prepare to store it Storing it properly is extremely important as quicklime is a potentially dangerous substance There are a number of things you should consider when storing quicklime Store it in a dry heavyplastic or metal container Seal your container wellHow to Make Quicklime: 10 Steps (with Pictures) wikiHow

.jpg)

Briquetting Process an overview ScienceDirect Topics

During the First and Second World Wars briquettes were discovered to be an important source of energy for heat and electricity production by using simple technologies The briquetting process is the conversion of agricultural waste into uniformly shaped briquettes that are easy to use, transport, and store (ElHaggar, Adeleke and Gadallah, 2005)The production process of building materials has already got rid of manpower, and then uses automatic production equipment to complete production process Building materials machinery equipment plays a very important role in the production process of building materials, and determines the quality, efficiency and safety of production to a certain extent [3] Production Equipment an overview ScienceDirect Topics22 Production of Slaked Lime from Shuk Quicklime The quicklime (calcium oxide) was obtained from Shuk limestone by calcination at temperature of 1000 0 C, particle size of 90 µm and time of 3 hrs Then, the slaked lime (Ca(OH) 2) was produced by hydration/slaking of Effects of process variables on the reactivity of slaked lime Fig 1 World lime production by country 2012 Quicklime and hydrated lime production including deadburned dolomite China the top producer of lime (with approximately 220*metric tons) has been removed in order to not skew the graph (Miller, 2013)e estimated, p preliminary, 1 World totals, US data, and estimated are rounded to no more than three significant digits; may not Lime Production an overview ScienceDirect Topics

World lime production by product category in millions of tons

Net CO2 emissions from the production of quicklime can be reduced by introducing renewable solid fuels or sustainably produced electricity for heating of the process1998年5月14日 Summary This chapter contains sections titled: Introduction Principles of Lime Burning Development of Lime Kilns Modern Kilns Selection of Lime Kilns Kiln Control Mass and Heat Balances InstrumentaProduction of Quicklime Lime and Limestone Wiley Online different processes occurring during the production of lime is shown in Figure 21 During the kiln operations the limestone reaches temperatures as high as 900 °C, and carbon dioxide is driven off limestone to leave socalled quicklime The quicklime descends through the cooling zone and is discharged at the base of the kiln2A2 Lime production GB2009 European Environment Agency2024年3月27日 Quicklime takes a crucial role as a flux in the iron and steel production process It is essential in the production of steel, helping to remove impurities from molten iron, resulting in a stronger, higherquality product Pulp and paper production Paper manufacturing Quicklime is involved in the production of pulp and paper by assisting in A Glimpse Of Quicklime: The Power Mineral You Should Know

Impact of quicklime reactivity and origin on Autoclaved Aerated

2011年1月1日 Quicklime is a key component of Autoclaved Aerated Concrete (AAC), with typical quicklime contents of order 15 wt% in Europe It is the mostly used source of calcium oxide that eventually ends up The process emissions of lime production, ie the CO 2 released during limestone calcination excluding that released from the combustion of fossil fuels, are esti In the pig iron production process, quicklime is used far less, where it is mixed with limestone in a proportion of 1:6, mainly in the sintering process [7] 226 F P CAMPO ET ALNatural and enhanced carbonation of lime in its different The digital weighing feeder; is the quicklime digital dosing unit, provided to Enhance the product quality uniformity The automatic adjustment of the feeding screw conveyor speed allows a constant feed rate in tons per hour of quicklime through the weighing screw conveyorHydrated Lime Production Plant MEKITCOproduction costs to a minimum In the majority of cases, a very major production cost will be the fuel used Thus, the efficiency of the burning process (as opposed to the whole process of production which will involve labour costs etc) is judged by how much fuel it takes to produce a quantity of quicklime For instance, a limeHOW TO CALCULATE EFFICIENCY OF YOUR LIME BURNING PROCESS

Quicklime Production Cost Analysis Reports 2024 Procurement

Particulars Details; Product Name: Quicklime: Scope: Manufacturing Process: Process Flow, Material Flow, Material Balance Raw Material and Product Specifications: Raw Material Consumption, Product and Coproduct Generation Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment Costs, Contingency, Engineering and Consulting 2007年12月1日 Production of Quicklime December 2007; DOI:101002 the final client and the supplier of the technology and key equipment process and makes it possible to burn crushed limestone in small Production of Quicklime ResearchGatecompared (eg BET vs quicklime reactivity, BET vs bulk density and BET vs expansion) With this knowledge, as well as a demand for higherquality hydrated lime production, a need for lower CAPEX requirements, and easier transportation of equipment to more remote parts of the world, Cimprogetti took the decision to redesign its hydration Developing a modular lime plant Cimprogetti2022年2月1日 Decomposing limestone (CaCO 3) into quicklime (burnt limestone; CaO) releases significant CO 2 emissions, both from the combustion of fuel needed to heat the kiln to temperatures over 1,000°C, and by the release of CO 2 from the reaction itself (CaCO 3 → CaO + CO 2)Because quicklime is a key ingredient in the production of cement, as well as being Reducing the carbon footprint of quicklime production

.jpg)

Development of a SmallScale Lime Kiln and Experimental

2018年7月7日 They apply regenerative preheating of all combustion air Sample CCS2 was obtained from a production using classical mixfeed shaft kiln Traditional samples of quicklime (TVit and TCS) were obtained during the experimental calcinations Productionrelated characteristics of the collected samples are presented in Table 42019年11月1日 Lime (CaO) is a main ingredient of technologies employed in a wide variety of industries such as construction, agriculture, food processing, disinfection, water treatment, SO2 post combustion Characterization and Optimization of Lime Production Process2017年7月31日 Calcination of Nkalagu limestone for the production of agricultural quicklime is presented It entails improving the quality of limestone through calcination processA CASE STUDY OF DIFFERENT LIMESTONES DURING QUICK LIME 2024年2月27日 Quicklime is produced through the thermal processing of limestone in industrial kilns During quarry operations, fine particulate quarry dust adheres to limestone lump surfaces, increasing the Impact of Limestone Surface Impurities on Quicklime Product

.jpg)

Process Equipment Design The National Academies Press

Very rigid, stiff structural elements of unit process equipment are required, since these are primary factors determining positional accuracy and the level of precision inherent to the process 1 Required are innovative equipment designs that dampen vibrations (so that they are not transmitted to the tooling and workpiece), which originate from the process or external sources