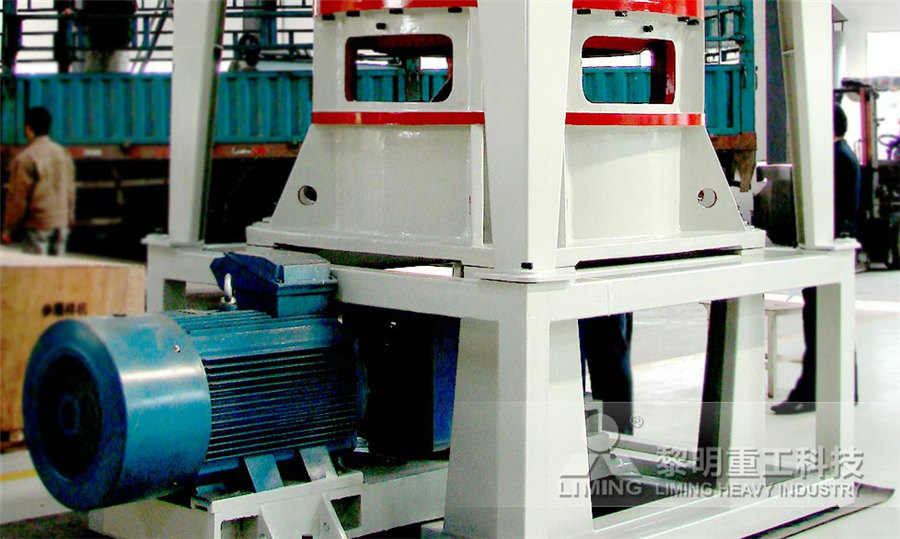

Highpressure ore roller mill 3D drawing

High Pressure Grinding Rolls for Minerals AusIMM

This paper discusses wear and the measures taken to overcome this problem; availability and the procedures implemented to reduce downtime for replacement of the rolls; criteria for selection 2022年3月15日 This paper unifies highpressure grinding rolls crusher (HPGR) models of the working gap, mass flow rate, power draw, and centre and edge product particle size Unifying highpressure grinding rolls models ScienceDirect2002年10月11日 The crushing roller is one of the main parts of a highpressure grinding roller, which is a type of highly efficient ore crushing equipment In the work reported in this paper, a 3D design and analysis of the crushing roller of a highpressure 2002年10月1日 The crushing roller is one of the main parts of a highpressure grinding roller, which is a type of highly efficient ore crushing equipment In the work reported in this paper, a 3D design and analysis of the crushing roller of a highpressure

.jpg)

Our Dynamic HPGR Technology for Mineral Grinding

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore When it comes to feed material characteristics, the specific 2019年11月1日 HighPressure Grinding Roll (HPGR) stands out as one of the most efficient types of grinding machinery, in terms of energy consumption and the size reduction rate [5] Highpressure grinding rolls: model validation and function High Pressure Grinding Rolls (HPGR) technology is accepted as an energyefficient and costeffective alternative for treating specific mineral ore types HPGR technology has been A Review of the Modeling of High Pressure Grinding Rolls JSTAGEHigh pressure grinding rolls is a modern technology that is proven to reduce the operating costs in full scale plants when compared with other milling technologies, especially with low grades HIGH PRESSURE GRINDING ROLLS MODELLING WITH

.jpg)

High pressure grinding rolls HRC 8 HRC Metso

low energy and wear parts consumption It delivers unbeatable performance in aggregates, manufactured sand, mining, industrial minerals and recycling applications material between High Pressure Grinding Rolls (HPGR) technology is accepted as an energyefficient and costeffective alternative for treating specific mineral ore types HPGR technology has been A Review of the Modeling of High Pressure Grinding Rolls1998年1月1日 The high pressure roll mill, HPRM, a newly invented size reduction equipment, has been recently added to the list of comminution machines and is classified as a highly efficient equipment(PDF) THE PERFORMANCE OF THE HIGH PRESSURE 2002年10月1日 The roller is one of the main parts of a highpressure grinding roller, which is a type of highly efficient ore crushing equipment Its working life is strongly affected by the materials used3D design and analysis of the crushing roller of a highpressure

.jpg)

High Pressure Roll Mill / RHP 16Lab Minerali Engineering

The RHP 16Lab is a roller mill built to simplify the grinding treatment in laboratories, specially dedicated to hard minerals The RHP 16Lab was designed after the multiyear of experience of Minerali Industriali in the field of highpressure roller mill, from which inherit all the main advantages: low energy consumption, easy2012年12月28日 The highpressure grinding roll (HPGR) technology is currently one of the most efficient methods of hard ore comminution from the scope of the energy consumptionOptimizing the performance of highpressure grinding roll based ore 2016年1月1日 The highpressure grinding roll (HPGR) is a type of roller mill that continuously produces particlebed comminution Since the capacity of the HPGR is determined by not only operating conditions Influence of type of lining in highpressure grinding rolls on With High Pressure Roller Mills products are produced with a precipitous granule distribution High Pressure Roller Mill ECP ECP 36 ECP 60 ECP 85 ECP 180 ECP 300 ECP 450 ECP 600 Max press force (kN) 360 600 850 HighPressure Roller Mill ECP Hosokawa Alpine

.jpg)

Highpressure mill, Highpressure grinding mill All industrial

Find your highpressure mill easily amongst the 16 products from the leading brands (LONGI, Hosokawa, Metso, ) on DirectIndustry, the industry specialist for your professional purchases roller horizontal for ore highpressure grinding mill WGM series Output: 30 t/h 7,400 t/h2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in High Pressure Roller Mill With High Pressure Roller Mills ECP products are produced with a precipitous granule distribution Product portfolio HighPressure Roller Mill ECP Roller Press To the machine Machine for medium fine crushing of hard materials and for producing sharpedged particles Your High Pressure Roller Mills Hosokawa AlpineThe HPGR (high pressure grinding rolls/rollers) is the core equipment of the high pressure grinding process The machine reduces particles by compressing and crushing the feed between two counter rotating, parallel rollers with a small gap between them This forces the rocks against each other and compresses the feed’s density to 80% of its solid [](HPGR) high pressure grinding rolls/rollers for cement, ores

.jpg)

高压辊磨机在金属矿选矿与球团预处理领域的工艺和

2019年4月12日 Based on the current research results and industrial data, this paper compares the process flow of highpressure roller mill in metal mine and pellet pretreatment industry, Cordes H Operating experience with a roller 6 天之前 Due to the relatively weak force at the joints between different minerals in the ore, cracks are more likely to occur in these parts during the crushing process of the highpressure roller mill The degree of monomer dissociation High pressure grinding rolls HPGR for iron ore, 2019年2月5日 High Pressure Grinding Roll (“HPGR”) techn ology is very rapidly gaining a wide acceptanceHIGH PRESSURE GRINDING; HOW HIGH CAN YOU Vertical roller mill Manufacturer High Pressure Grinding mill ; Vertical Mill; Ball Mill; Raymond Mill; Crusher Solutions loesche vertical roller mill 3d drawing Solution for ore mining vertical coal roller mill cad ga drawing Supplier of Vertical Roller grinding mills its auxilary ball mill, hammer mill, roller Ball Mill Vertical Roller Mill 3d Crusher Mills, Cone Crusher, Jaw

.jpg)

Enduron® High Pressure Grinding Rolls (HPGR) Weir

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes, from fine pellet feed all the way up to coarse grinding of 75mm copper, gold or iron ore When it comes to feed material characteristics, the specific ore type is not detected by an Enduron® HPGR, however ore hardness, size and bed compressibility are important FLS double roll and ERC crushers offer efficient, reliable crushing with low maintenance and optimised wear life Choose double roll crushers for your soft to mediumhard materials, or ERC crushers for highthroughput, highefficiency crushing of hard and abrasive oresRoll crushers – ERC and double roll crusher – FLS2002年1月22日 The compaction of the particle bed in a high pressure roller mill causes pressure and shear forces on the rollers, which have been measured simultaneously with a sensor As known, the pressure peak arises short above the gap neck, the shear is firstly orientated against and then in the rotation directionShear stresses and material slip in high pressure roller mills2023年12月6日 Table 4 reports the evaluation metrics for the highpressure roller mill particle size qualification rate prediction models established by the three algorithms Table 3 highlights that the proposed ɛGASVR model has the smallest MAE of 001834 and RMSE of 000004, the lowest among the three algorithmsAdditionally, R 2 is 089, closer to the ideal value of 1Prediction method of particle size qualification rate of highpressure

.jpg)

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, DESCRIPTION The Cylinder mill, commonly known as the Roller Press works by crushing the material between two cylinders kept under pressure by a hydraulic system horizontal for ore highpressure Contact roller mill HPGR2024年1月1日 The highpressure roller mill mainly consists of the feeding system, working rollers (a fixed roller and a movable roller), the driving system (main motor, reducer, belt pulley, and gear shaft), the hydraulic system, the stand, the transverse leakproof device, the discharge device, the control system, etcRoller Mill SpringerLinkOptimise your results with a high pressure grinding roll, the most energyefficient way to process mining ores Suitable for industries including iron ore, precious metals, base metals and other, the HPGR’s ability to weaken rock structure provides metallurgical benefits downstream (ie enhanced kinetics for heap leaching)FLS High Pressure Grinding Rolls – Efficient grindingHigh capacity High Pressure Grinding Rolls for all your use cases During its relatively short history in minerals processing, HPGR technology has undergone significant development in machine roll wear surfaces and control philosophy Roller mill HPGR FLSmidth DorrOliver Eimco

Enduron High Pressure Grinding Rolls Weir Group

4 Enduron® High Pressure Grinding Rolls 5 Traditional Crushing HPGR Grinding F F F F 4 5 4 Compacted cakes 5 Grinding pressure 2 Feed material 3 Fixed roller 1 Floating roller 1 2 3 HPGR in operation HPGR in operation Comminution principles: high pressure comminution and breakage process between rollers Azone Czone Ezone D d a0 y u Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Confined bed comminution in highpressure grinding rollers Research of iron ore grinding in a verticalrollermill2024年5月31日 This paper presents an industrial verification test, adding a high pressure grinding roll and magnetic separation operation after the thirdstage fine crushing operation to reduce the particle size of ball mill feed and improve the processing capacity of grinding operation The optimal process parameters of high pressure grinding roll and magnetic separation were High Pressure Grinding Roll and Magnetic Separation for Energy The grinding principle and the high efficiency classifier ensure the reduction of electric energy consumption by up to 40% as compared with conventional ball Closed mill housing pressureshock proof up to 35 bar: 3: Optimized free flow areas: 4: MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

HighPressure Grinding Roller Presses for Minerals Processing

rotating rollers, whereby the ore is chokefed between the rollers The feed material is compressed from the bulk density to 70–85 % of the real density and the individual particles are exposed to very high pressure Comminution takes place in the packed material bed rather than through direct contact with the rollersHigh pressure grinding mill, also known as high pressure roller mill, can grind nonflammable and explosive materials with Mohs hardness not greater than 93 and humidity below 6%Its main components include main engine, reducer, analyzer, pipeline device, blower, dust collector, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric control system, etcYGM High Pressure Grinding Mill2018年12月21日 can be reduced by up to 5 kWh/t compared to a roller mill, due to the efficiency of the highpressure grinding and a separating system optimized for the respective application Combining a polycom ® highpressure grinding roll and a staticdynamic sepol ® separator in a finish grinding plant for raw material increases energy efficiency Industrial Solutions polycom highpressure grinding rollThe Single Driving High Pressure Roller Mill Series PGM is specially designed to pregrind the cement clinkers, the mineral dross, the steel clinkers and so on into small granules, to ultracrush the metallic minerals (iron ores, manganese ores, copper ores, leadzinc ores, vanadium ores and others) and to grind the nonmetallic minerals (the coal gangues, feldspar, nepheline, dolomite Smelting of Laterite Nickel Ore Intelligent High Pressure Roller Mill

Review on vertical roller mill in cement industry its

2021年1月1日 Ball mill, vertical roller mill and highpressure rollers can be considered to be mechanically reliable The wear rate in g/t is higher in the ball mill than in the vertical mill or highpressure roller, but as the unit cost for wear parts is lower for the ball mill than for the vertical or highpressure mill, the total cost of wear parts is similar for the three mill systems [113,115–117]2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and Ball Mill Trunnion Bearing Lube Systemliming Ddkb Vertical Roller Mill 3d Crusher Mills, Cone liming MIAG ROLLER MILL MODEL 800 liming Crusher Solutions DDKb da 1000/800×250 ; N° 12 roller mill liming model DDKb roll 800/1000 x F 250 Roll Mill Vertical Roller Mill 3d Crusher Mills, Cone Crusher, Jaw 2023年8月5日 The highpressure roller mill's output particle size is related to the properties of raw ore, roller surface pressure, speed, and material moisture content When the roller surface pressure and roller surface speed are constant, the ore moisture content increases, the uniformity coefficient of the middle material increases, Factors affecting the particle size of the highpressure roller mill

Relationship between operating pressure and gap in roller

Download scientific diagram Relationship between operating pressure and gap in roller press (tests for porphyry) (Saramak, 2011 c) for two series of similar laboratory tests denoted as " test 1 2022年3月15日 This paper unifies highpressure grinding rolls crusher (HPGR) models of the working gap, mass flow rate, power draw, and centre and edge product particle size distribution models to produce a framework that allows the simulation of the equipment for process optimization and control studiesUnifying highpressure grinding rolls models ScienceDirectThese rollers are fed by two pressure feeder rollers which take prepared cane from a vertical chute and may be assisted by an under feed roller at the exit from the chute The arrangement of rollers in three roller mill is as follows Fig No 1– Three roller sugar mill [7] IJERTV4IS IIStatic Structural Analysis of Crushing Rollers of Three Roller Sugar Millhydraulic systcm The grinding pressure on the high pressure sidc of the hydraulic cylinder in U1e range betwcen 50 bar and 100 bar is inducing the grinding forces into the material in the gap between U1e rollers and lhe table The low pressure side of U1e hydraulic cylinder h as apressure of about 1 O % of the pressureU Schaefer LOESCHE VERTICAL ROLLER MILLS FOR MINERAL

.jpg)

Highpressure grinding rolls: model validation and function

2019年11月1日 Specific power draw: Simulation and optimization of twostage ball mill grinding circuit of molybdenum ore Adv Powder Technol, 27 (2016), pp 10731085 Shear stresses and material slip in high pressure roller mills Podwer Technol, 122 (2002), pp 136144Hydraulic Cone Pressure Germany; Pe250*400 Iron Ore Grinding Ball Mill; PE150×250 Ball Mill Iron Capacity Tph High; Hammermill Crusher Principle Of It can be used to deal with materials whose size below 500x Learn More; loesche vertical roller mill 3d drawing Solution for ore mining Sitemap Clients Cases Service Pf 1214 Loesche Mill Drawing Crusher Mills, Cone Crusher, Jaw