Measures to prevent hydraulic rubber ball mill damage

.jpg)

Bearing damage and failure analysis SKF

Our network of knowledge and experience, along with our understanding of how our core technologies can be combined, helps us create innovative solutions that meet the 展开Understanding the causes of wear in various components of the ball mill, such as grinding media, mill liners, bearings, and seals, is crucial for implementing effective prevention measures By Analysis of ball mill wear causes and prevention measures2023年6月15日 This article provides essential preventive measures for ball mill maintenance to ensure optimal performance and longevityMaximizing Ball Mill Performance: A Comprehensive Guide to By investigating several possible causes surmised from the type of damage and condition at the time the damage occurred, it is possible to prevent the same kind of damage from reoccurring Bearing Damage and Corrective Measures NTN Global

A review of bearing failure Modes, mechanisms and causes

2023年10月1日 Several measures can be taken to prevent abrasive wear: (i) avoiding broken parts and other particles from entering the bearing; (ii) adopting a nitriding or carburising To ensure the longevity and efficient operation of your ball mill, follow these best practices: Establish a regular maintenance schedule to prevent potential issues from becoming more Ball Mill Maintenance Procedure: Tips for Maintaining Your MillDaily maintenance measures are crucial to ensure the optimal performance and prevent malfunctions in ball mills These measures include inspecting various components of the mill, Some daily maintenance measures to prevent malfunctions in ball Those listed in this guide are the most commonly identified types and causes of damage for antifriction bearings, including cylindrical, spherical, tapered and ball designs Always follow BEARING DAMAGE ANALYSIS REFERENCE GUIDE Timken Company

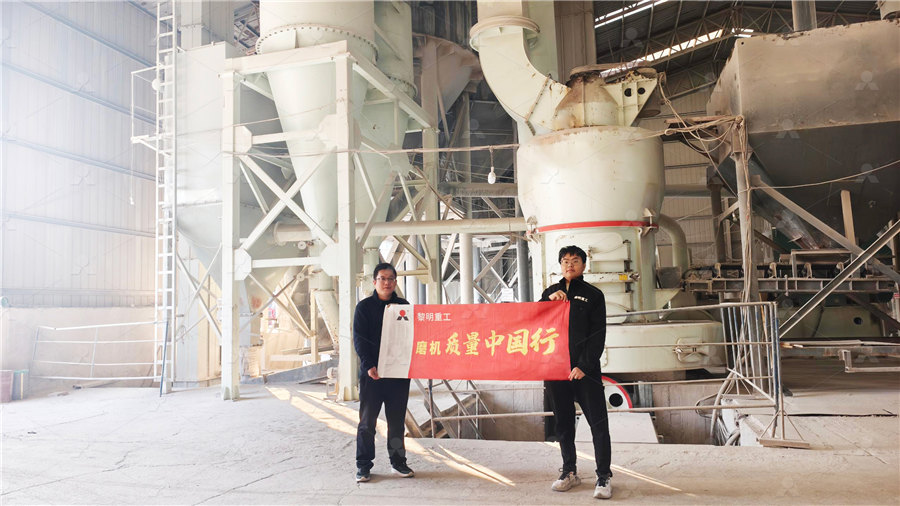

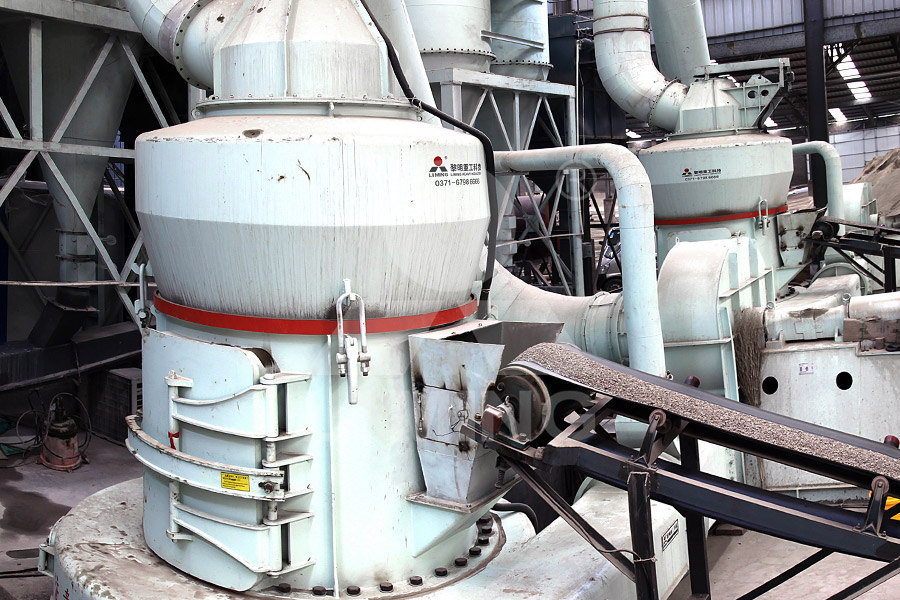

Ball Mill Maintenance Procedure Guide

The first step of the ball mill maintenance process is to pay attention to the motor current During the ball mill operation, especially within 5 minutes after startup, check whether the current of 2023年7月20日 First and foremost, immediately stop the operation of the ball mill to prevent further damage and potential safety issues 2 Cut off power supply: Turn off the power supply How to handle component damage during the operation of a ball 2023年10月1日 Wear, plastic deformation and hardening of rubber ring: Uneven compressive load: Wear; deformation: 1 Improper selection or design: 2014/ [128] 79: Wheel bearing: Ball bearing: Wear and aging of rubber ring: Not mentioned: Wear: 1 Improper selection or design 2 Material selection and quality 4 Incorrect assembly, use and maintenance: 2017 A review of bearing failure Modes, mechanisms and causes2016年10月20日 Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty 911 Metallurgist is a trusted resource for practical Ball Mill Maintenance Installation Procedure

.jpg)

Hydraulic Hoses Fail: Understanding Failure Modes and Fixes

Hydraulic hoses are indispensable components in a wide range of industries, from construction and agriculture to manufacturing and transportation These hoses act as the lifelines of hydraulic systems, transferring fluid power necessary for the operation of heavy machinery, industrial equipment, and various automated processesHydraulic fluid has been a factor in many fires and is often responsible for markedly increasing the extent of fire damage Because hydraulic systems are highly pressurised, Prevention measures As mentioned above, the most simple and reliable way to prevent a hydraulic oil fire is to replace mineral oil with noncombustible fluidHow to prevent hydraulic oil fires IfWhen anticipating damage scenarios, it should be noted that a hydraulic system consists of three main elements: the pump unit, the piping system and the drives Sometimes pumps and hydraulic drives are located in the same place, as in the case of metal working and plastic injectionmoulding machinesHow to prevent hydraulic oil fires IfHow to Prevent Hydraulic Piston Seal Failure Preventing hydraulic piston seal failure is crucial to ensure the efficient functioning of hydraulic systems By taking preventive measures, you can save yourself from costly repairs and downtime Here are some ways to 5 Common Causes of Hydraulic Piston Seal Failure and How to Prevent

Minimizing the Risk of Hydraulic Cylinder Contamination

2020年5月15日 Machine OEMs and End Users should take measures to prevent costly and timeconsuming hydraulic failures In addition to installing and maintaining hydraulic filters, preventing ingression of particles into the system, and excluding moisture, it is also beneficial to consider contamination when selecting a hydraulic cylinder supplierA ball mill maintenance procedure is a crucial process in ensuring the longevity and efficient operation of your mill A poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production In this article, we will discuss the importance of regular maintenance, premaintenance steps, the ball mill maintenance procedure, postmaintenance Ball Mill Maintenance Procedure: Tips for Maintaining Your Mill2023年2月15日 What should we do to solve those problems? 1 First of all, it is necessary to do analyses including changes of nature of the ore, whether the amount of ore, water, sand and overflow size are normal Then do the measures to deal with them 2 Reduce the amount of feed to the mill until the working state of the ball mill returns to normal; 3 Appropriately reduce the 17 Signs of Problems with Ball Mills: Quickly Remove Hidden Troubles2020年11月26日 Hydraulic System Fire Mitigation While this article does focus on fire suppression for hydraulic systems, we want to first list a few key points to mitigate or even prevent these types of fires: Maintenance and Support Routine hydraulic system maintenance is key to preventing many issues, including fire Inspecting equipment, joints, hosesFire Prevention for Hydraulic Systems Cease Fire

(PDF) Abrasion damage of concrete for hydraulic structures and

2024年3月25日 Abrasion damage of concrete induced by sedimentladen flow has been a significant durability problem for hydraulic structures Due to the complexity of dynamic fields and concrete properties as 2015年8月7日 The mill is also provided with hydraulic pumps for lifting the Ball mill to provide a jerk to swing so that inertia of rest of the mill is broken for its rotationSystematic Start up and Stoppage of Ball Mill LinkedInAs the vulcanization of rubber balls tends to be “high temperature and short time”, many new processes tend to adopt continuous and streamlined production modes, and the necessity of antireversion is becoming more and more obvious Effective antireturn measures have been adopted Was put on the agenda In this regard, foreign countries take a step forwardApplication of measures to prevent reversion in rubber ball Hydraulic hose leaks occur when there is a breach in the hose, allowing hydraulic fluid to escape These leaks can manifest as slow drips or significant spills, impacting both the efficiency and safety of the machineryHydraulic Hose Leaking: Causes, Solutions, and Prevention

Corrosion Prevention Measures for Metal Valves

2019年7月13日 Nowadays, more and more valves use nylon, polytetrafluoroethylene and other plastics as well as natural rubber and synthetic rubber to make various sealing surfaces and rings These nonmetallic materials have good corrosion resistance and sealing performance, and are especially suitable for use in medium with particlesHighstress abrasive wear is a major material consumption process in mining and ore beneficiation industries The common laboratory highstress abrasion apparatuses suffer from lack of capability of closely simulating the service conditions of grinding media and mill liners, being the main consumables in these sectors The ball mill abrasion test (BMAT) is a versatile Ball mill abrasion test (BMAT): Method development and Ball mill liners are essential components in the operation of a ball mill They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan of the mill Improving Grinding Efficiency: By reducing the amount of friction between the grinding media and the material being processed Ball Mill Liner: What is it and How it Works AGICO Cement Plant2024年9月10日 Hydraulic cylinders are critical components in heavy equipment, providing the force needed to lift, push, and pull large loads However, like any mechanical part, hydraulic cylinders can experience failures over time Understanding the common reasons why hydraulic cylinders fail and recognizing the early signs of damage can save you from costly repairs and Hydraulic Cylinders: Why They Fail and Signs of Damage

Highperformance mixing mills for rubber compounding

xibility, the heavy duty mixing mills from HarburgFreudenberger are equipped with individual roll drives to provide infinitely variable roll speed adjustment and friction from 065 to 135 Heavyduty 750 x 2500 mm mixing mill with stockblender and individual hydraulic roll drives Bevel gear drives with thyristor controlled2020年7月9日 Ball mill is one of the main equipment in ore dressing operation In the course of operation, the pinion of the ball mill will break, which will lead to insufficient and unqualified pulp in subsequent production workshops So in the production process, how to prevent the ball mill pinion gear damage? 1How to Prevent Pinion Damage in Ball Mill in Advance2014年10月10日 It is hard to imagine a world without hydraulic technologyFluid power, or hydraulics (Greek hydor, meaning water and aulos, meaning pipe) has been used extensively in mechanics since classical timesToday, heavy Reducing the risk to life and limb from hydraulic hose These products cause damage to rubber seals and tubing throughout the machine If you use a minimumquantity lubrication system for neardry machining, use only the recommended oils Machine coolant must be watersoluble, synthetic oilbased or Mill Operators Manual Safety Haas Automation Inc

.jpg)

the collapse of hatch cover steel structures or failure of securing

In addition, cargo hatch covers have to protect the stowed cargo in the holds from damage due to water ingress, particular if the cargo is sensitive to water damage It must be noted that a significant portion of all cargo related claims are caused by water damage, and many of these are related to seawater ingress through cargo hatch covers2024年6月26日 Regularly replace the hydraulic oil, use highquality hydraulic oil, and keep the hydraulic system clean Clean hydraulic oil can prevent contaminants from wearing the seals 4Reinstall the hydraulic cylinder Ensure that the hydraulic cylinder and seals are installed correctly and well mon causes and solutions for hydraulic cylinder leakage2023年9月12日 Those working with hydraulic hoses should be skilled at anticipating and preventing problems and fixing them before they occur The Dangers of Hose Failure On April 30, 2021, aboard a fishing vessel off the coast of Massachusetts, a hydraulic hose failed, leading to a fire in the engine room6 Things to Consider for Protecting Hydraulic Hose Brennan 2024年4月5日 Abrasion damage of concrete induced by sedimentladen flow has been a significant durability problem for hydraulic structures Due to the complexity of dynamic fields and concrete properties as well as the interaction effects between them, many aspects are still subjected to debate despite the tremendous efforts that have been madeAbrasion damage of concrete for hydraulic structures and

5 Simple Steps to Reduce Hydraulic Hose Failure

2014年12月4日 Abrasion To reduce the amount of downtime due to a hose failure, here are five simple steps: 1 Examine the exposed hoses on equipment By regularly inspecting your equipment, you will be able to identify any external damage or cuts to the outer cover2024年1月4日 Seals: These are crucial as they prevent hydraulic fluid leaks The effectiveness of a hydraulic cylinder relies heavily on the integrity and performance of these components Any wear, tear, or damage can compromise the cylinder’s function As such, understanding their role is essential when considering a rebuild Relevance to RebuildingHow to Rebuild a Hydraulic Cylinder Rebuilding a CylinderA hydraulic hose replacement can be expensive and time consuming to install – and can be avoided with correct preventative measures to stop hydraulic hose failures What causes hydraulic hose failures – and how to prevent external abrasion on hydraulic hoses current solutions How to protect hydraulic hoses from abrasion – HoseMate™2023年8月3日 Characteristics of hydraulic systems: Advantages: 1 The hydraulic transmission device operates smoothly and can move steadily at low speeds When the load changes, its movement stability is relatively stable, and it can easily achieve stepless speed regulation during movement, and the regulation ratio is large, generally up to 100:1, and the maximum can A Comprehensive Guide to Hydraulic Systems: Principles,

Hydraulic Press Machine 101: Everything You Need to

2024年8月4日 Fig3 80,000 Ton Die Forging Press The 80,000ton dieforging hydraulic press stands 27 meters tall on the ground and 15 meters underground, making it a total height of 42 meters and a total weight of 22,000 tons, thereby 2020年11月3日 They are very common in hydraulic as well as tube applications Elastomer seals are a kind of rubberlike seal Since this is a rubberlike seal, it essentially would be leakproof However, ORFS fittings can easily help in How To Prevent Leaks In Hydraulic Applications 2024年5月25日 This can result in leaks, bursts, or the hose becoming too rigid to function properly Ensuring proper insulation, shielding, and temperature control around hydraulic hoses is crucial to preventing heatrelated failures 2 10 Hydraulic Hose Failure Reasons You Need to Know2017年12月6日 The best way to avoid the substantial expenses and headaches associated with unscheduled maintenance is to take measures to prevent them Scheduled maintenance should include inspection of rod seals and wipers for damage as a means not only of preventing leaks, but to prevent contamination of hydraulic fluidThe Powerful Impact of Preventive Maintenance Power Motion

Understanding and Preventing Hydraulic Cylinder Damage

2023年11月10日 At the heart of every excavator lie hydraulic cylinders, essential components that make it all possible Unfortunately, these critical components are not immune to wear and tear, with damage often occurring in the form of chips, divots in the chrome of the shaft, or scoring of the barrel In this blog, we'll explore the causes of hydraulic cylinder damage, how to 2022年9月6日 Controlling hydraulic fluid temperature is critical in preventing overheating and cylinder damage Failure to maintain stable hydraulic fluid temperatures causes several problems, including: Fluid Contamination: Hydraulic fluid produces sludge at high temperaturesControl Hydraulic Fluid Temperature to Prevent OverheatingYour Comprehensive Guide to Preventing, and Resolving this Costly Problem Defining Cavitation Cavitation, a significant concern in hydraulic systems, is a complex process rooted in fluid dynamics It begins with generating excessive vacuum conditions at the hydraulic pump’s inlet, referred to as the supply sideStopping Hydraulic Pump Cavitation in its TracksBestpracticeforhighbearingtemperatureballmill201501pdf Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on best practices to prevent high bearing temperatures in ball mills for cement grinding It was created by HeidelbergCement's expert group on process/grinding and maintenance in response to similar Best Practice For High Bearing Temperature Ball Mill 2015 01

3 Aspects of Ball Mill Maintenance Miningpedia

2018年11月7日 Ball mill is an important mineral processing equipmentDuring the use of the ball mill, problems such as wear, loose links, deterioration of the oil, and corrosion of the metal structure are inevitable in each link, which causes the technical, economic and safety performance of the ball mill to be reduced at different degrees2023年10月16日 Base isolation involves constructing a building on top of flexible steel, rubber and lead pads When the base moves during an earthquake, the isolators vibrate while the structure remains steady This effectively helps to absorb seismic waves and prevent them from traveling through the building 2 Counter Forces with DampingHow EarthquakeProof Buildings Are Designed in 2024 BigRentz