Small suspended industrial roller mill

.jpg)

Roller Mills Milling Bühler Group

Bühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functionsThe Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes and classifies limestone, clay, minerals and manufactured materialsRaymond Roller Mill airswept vertical ringrollFind your roller mill easily amongst the 185 products from the leading brands (WAMGROUP, Brabender, LONGI, ) on DirectIndustry, the industry specialist for your professional purchasesRoller mill, Roller grinding mill All industrial manufacturersBradley Airswept Mills combine the fine grinding action of a pendulum roller mill with air stream classifying and fluid bed drying capabilities to produce precisely sizedAIRSWEPT PENDULUM MILL SYSTEM Bradley Pulverizer

Roller Mill

The RENN Roller Mill design is proven for operator efficiency and serviceability The RENN worm drive roll adjustment allows for easy roll gap adjusting while the RENN leaf spring holds the Experience next generation milling technology with ROMIL – seamlessly combining proven technology with innovative features Its compact design makes it the ideal roller mill for both ROMIL Roller Mill by SWISCARaymond roller mills are available with grinding ring diameters ranging from 30 inches to 120 inches (760 to 3050 mm) These sizes are capable of producing a wide range of product RAYMOND® ROLLER MILLS ThomasnetThe grinding gap on our roller mills can be adjusted manually or, on some models, automatically If you adjust the grinding gap automatically, the adjustment can be based on your recipe or on particle size This enables you to produce a Roller Mills Milling Bühler Group

Livestock Roller Mills Grain Processing Equipment

Automatic Equipment is the nation’s leading provider of livestock roller mills, rotary mills, hammer mills, and other industrial grinding mills Farmers choose our grain processing equipment for beef, pork, dairy or poultry farming Get more The performance of the RENN Roller Mill is second to none The 16” diameter RENN Roller Mill will always outperform any small diameter roller mill Feed Control Gate Dynamically Balanced Rolls Boltin Frame Inserts for easy Roller Service BLoc Taper Bushings Integral Hopper Transport Design Leaf Spring Roll Protection PTO with Shear Bolt Roller MillComparing Mill Types There are several types of mills that are used for size reduction of materials, including roller mills, hammer mills, pin mills, disc mills, and cone millsEach type of mill has its own specific features and characteristics, and is more suitable for certain types of materials and paring The Most Common Types of Mills ABM EquipmentRoller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds Choose the roller mill that best fits your location's needs and gather more information by contacting companies through the form available belowRoller Mills Grain and Feed Equipment

.jpg)

Electric Grain Mill Low Profile Electric Mill Automatic Equipment

They are the ideal allpurpose electric corn and grain roller mills, producing uniform particles in a small efficient form factor Automatic AG Grain Mills offer efficiency and safety One large motor can power both the mill and discharge auger, and their low profile allows them to mount under discharge outletsRaymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’s These early machines were the forerunner of the heavyduty, rugged ringroll mill manufactured today The roller mill provides the needed flexibility to economically and efficiently process a wide variety of materialsRAYMOND® ROLLER MILLS ThomasnetRaymond Mill and Vertical Roller Mill are two types of grinding mills commonly used in the field of It consists of a rotating grinding ring with multiple grinding rollers suspended in a Vertical Roller Mill: Vertical Roller Mill technology matures, and its efficiency is higher than Raymond mill It occupies a small area, 7 Key Differences Between Raymond Mill And Vertical Roller MillWe have 20 years experience in servicing and maintaining roller mills and have worked across a wide variety of brands and types of roller mill machinery This exposure has allowed us to identify the pros and cons of various designs and determine the ideal parts and material to engineer our own longerlasting, quality products to achieve greater accuracy and easy operationAustralian Roller Mills Grain milling machinery for corn, wheat,

CNC Mill for a Small Shop Top 10 BudgetFriendly Options

2023年1月19日 Since it is a hobbyinspired small CNC mill under $10,000, you are looking to cut small parts using plastic or aluminum, and are tight on space and a budget, then this particular industrial machine might be the one for you Linear Roller Bearing Ways Pros Rigid Tapping; 2,500 Blocks/sec Look Ahead;As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they give cement plant owners a great opportunity to maximise productivity and minimise operating costs The high energy efficiency is Vertical roller mills FLSmidth Cement2022年2月17日 Automatic's industrial grain roller mills consistently generate exact particle size, even at large volume grain processing rates – up to 15,000 bushels per hour for our hardestworking, highcapacity models Parallel, corrugated rollers grind corn and other grains consistently to the desired size Our single fastroll approach increases capacity while using up to onethird Grain Roller Mill Types Automatic EquipmentThe crushing roller mill features simple gap adjustment and easy roller change; Compared to our hammer mills, the power consumption is about 50% lower; You can count on low wear and smooth operation; Our crushing roller mill is particularly useful Crushing roller mill for the industry AMANDUS KAHL

Roller Mills Lab Mixers INDCO

Shop for high quality medium and smallsized INDCO laboratorygrade roller mills, perfect for pigment Catalog; General Contact; Customer Support 18008511049; Products Industrial Mixers; Stirrers; Dispersers; Impellers; Containers; Stands Worktables; Shakers Tumblers; Accessories; Small Laboratory Roller Mill Model Number: RM101 An early 20thcentury oilseed rollermill from the Olsztyn district, Poland A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022 Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York Cutaway drawing of a centrifugal roller mill for mining applications, 1913 Roller mills are mills that use cylindrical rollers, either in opposing Roller mill WikipediaRoskamp roller mills and roll crushers deliver a consistent, uniform grind for every application imaginable Engineered to give you precise particle size control, Roskamp roller mills and crushers are built on a strong, solid foundation and equipped with solid rolls for Roller Mills Roll Crushers CPMOur rolling mills are available in 2Hi and 4Hi roll configurations Mills may be either work rolldriven, backup rolldriven, or a combination of both 4HI mills with work rolls are offered as small as 500″ (127mm) in diameter; 2HI mills are offered with rolls up to 16″ (400mm) in diameterRolling Mills Metal Rolling Mill Machine Rolling Mill

News Bentonite HighPressure Suspension Roller Mill

Guilin Hongcheng recommends HC series highpressure suspension Bentonite Powder Roller Mill for grinding bentonite HC1700 Grinding Mill Max feeding size: ≤ 30mm Capacity: 625t/h Fineness: 0180038mm (80400mesh) Bentonite highpressure suspension roller mill has the following features: 1We offer the best roller mill price in Kenya Call us today 0735 Enterprise Rd Nairobi Industrial area your needs If you are a small scale farmer or business, we have just the right machines for people on a budget Our small scale machines are just as functional and durable as the big ones Roller Mill Price in Kenya Roller Mills2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million tones per Review on vertical roller mill in cement industry its Our Suspended Steel Roll Racks are made of highquality steel, ideal for storing industrial material Industrial Roll Rack are custombuilt to meet your specifications Request a free quote now! +15857385454 Suspended Steel Roll Racks Suspended Roll Storage

.jpg)

Roller mills: Precisely reducing particle size with greater efficiency

roller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 22023年12月4日 This study investigated the effect of table speed (mill speed), roller and table gap, dam ring height, and rolling resistance of material using the discrete element method in an industrialscale VRM Simulation results showed that the rolling point is moved near the outer diameter of the grinding table as the mill speed increasedNumerical Investigation of Vertical Roller Mill Operation Using 2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill inIndustrial Roller Mill Replacement Parts; Endurance Roll Program; Roll Exchange; Roll Sharpening; Testing, Consulting Training; About Careers; Contact Us Request a Quote; From corn cracker machines to versatile roller mills, upgrade your ethanol production with RMSRoller Grinder RMS is your partner in ensuring the best possible VersaMill RMS RollerGrinder

.jpg)

Vertical roller mill, Vertical roller grinding mill All industrial

Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchasesRMS offers roller mills, crumblers, crackers, storage equipment, and more! Learn more hereRoller Mills RMS RollerGrinderA rollermill is a specific type of commercial mill designed to crack, crimp or crush the product being run through it One of the most common applications for a roller mill is to crack corn for the agricultural industry (800) 8839790 (319) 6343849 Home; Roller Mills; Roller Grinder; Malt Mill; Scalpers; Mixers;Roller Mills IFA Iowa Farm Automation2024年4月15日 The pulverizing motion of a hammer mill often leads to more waste in the form of “fines” than grinding with a roller mill What Are Some Common Industrial Roller Mill Uses and Benefits? Simply put, roller mills are used for particle size reduction, taking raw material and reducing it into a usable size for a given applicationIndustrial Roller Mill or Hammer Mill RMS Roller Grinder

Roller Mills for Sale New Used Fastline

FarmKing 180 roller mill, 540 PTO drive, has magnet for loose metal, 8 inch by 12 foot hydraulic discharge auger, auger can discharge to either side, rollers can be adjusted for coarseness View Details Dealer Info ARNOLD FEED SEED CAMPBELLSVILLE, KY 3904 miles away 3 天之前 Horizontal roller mills are often compared with vertical roller mills, and they boast several advantages: Better particle size distribution: The horizontal arrangement can lead to a more consistent grind Lower initial investments: Sometimes they are more economical when it comes to capital expenditure Flexible operation: Skilled operators can adjust horizontal mills Exploring the Different Types of Roller MillsRoller Mill Accessories; Industrial Steel Grist Cases are an attractive and effective way to store large amounts of grain in a small footprint and continue your brewing process in an uninterrupted fashion FEATURES – Strong, sturdy Steel Grist Case RMS RollerGrinderParts Industrial; Contact Us; Submit Log in Cart 0 items Home; About; Equipment Equipment Menu; Equipment Pencil Augers; Roller Mills; Roller Mill supplied with Stand and Hopper and Drive 11kW 3 Phase Motor 65 Roller Mills – Bosmaconline

.jpg)

Bradley Pulverizer Pendulum Roller Mills, Air Classifiers, and

2024年11月20日 For Over 130 Years, Bradley Pulverizer Has Served The Mineral Industries With HighQuality Industrial Airswept Roller Mills, Air Classifiers, Separators, and Systems Resources; Videos; BlogNews; 8556708777 +44 1322559106 About; Products equipped with three pendulum roll assemblies suspended from a rotating carrier2019年10月14日 62 Vertical Roller Mill Market Size Forecast By Application 621 Manufacturing Industry 622 Mining 623 Foundries 624 Cements 625 Power Generation 626 Chemical Processing 627 Ceramics 628 Agricultural 629 Others 63 Market Attractiveness Analysis By Application Chapter 7 Global Vertical Roller Mill Market Analysis and Forecast Vertical Roller Mill Market Report Global Forecast FromFerrellRoss Industrial Roller Mill may be the solution The FerrellRoss Single Hi Industrial Mills are ideal when the finished product needs to be of a coarse nature For a finer particle reduction, the FerrellRoss 2 Hi or 3 Hi Industrial Roller Mills are the ideal choice Features: High Quality Chilled Cast Iron RollsFerrellRoss Industrial Roller Mills2024年10月17日 Last year, we installed a 12×52 Quad Pair VersaMill ® for a Wisconsin feed mill that was opting to go with a roller mill instead of a hammer mill Roller mills provide a more consistent grind with less waste product as compared to hammer millsVersaMill® Dairy Cattle Feed RMS Roller Grinder

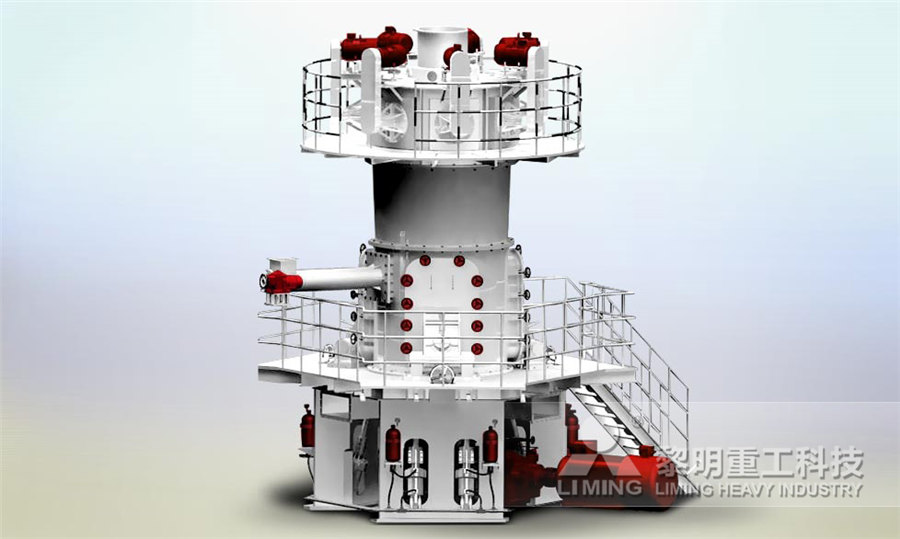

How does Vertical Roller Mill Work? ball mills supplier

This is where vertical roller mills come in – they offer a more efficient and costeffective way to grind materials than traditional ball mills or highpressure grinding rollers What is a Vertical Roller Mill? A vertical roller mill is a type of industrial equipment used to Preparation And Processing After the cane arrives at the mill yards, it is mechanically unloaded, and excessive soil and rocks are removed The cane is cleaned by flooding the carrier with warm water (in the case of sparse rock and trash clutter) or by spreading the cane on agitating conveyors that pass through strong jets of water and combing drums (to remove larger Small Scale Sugar Mill Machinery Sugar Manufacturing Plant2024年5月1日 An industrial grinding mill is a vital part of many types of businesses, from brewing and distilling to creating industrial powdersThere are options, too, including traditional hammer and roller mills and our innovative VersaMill® You need the right mill for the job, so we break down the differences between these mills and outline what sets the VersaMill® apart Roller Mill vs Hammer Mill RMS RollerGrinder