Diatomite mining process Diatomite mining process Diatomite mining process

Diatomite Mining Processing Equipment Flow Chart

Diatomite Mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read moreProcessing methods range from simple drying, crushing, sizing and packaging to carefully controlled and highly sophisticated calcining and air classification procedures, employing the OneMine Diatomaceous Earth Mining And Processing2019年8月23日 Throughout most of the world, the lower cost of and higher recovery from openpit quarrying relative to underground mining encourages operators to use surface mining methods Where the diatomite sequence is Diatomite Processing Equipment, Flow, Cases JXSC Figure 1 shows a typical process flow diagram for diatomite processing The processing of uncalcined or naturalgrade diatomite consists of crushing and drying Crude diatomite Figure 1 Typical process flow diagram for diatomite processing

.jpg)

Diatomite IMA Europe

Today, diatomite is typically mined by openpit quarrying techniques using conventional, heavy duty earth moving equipment then transferred to a processing plant At the plant, three Diatomites are formed in both marine and freshwater systems where the processes of diatom formation, diatom preservation, and sedimentation conspire to produce diatomaceous Diatomite an overview ScienceDirect TopicsIn 2020, production of diatomite was estimated to be 770,000 tons with an estimated processed value of $260 million, free on board (fob) plant Six companies produced diatomite at 12 Diatomite USGS Publications Warehouse2019年6月28日 The Nature of Diatomite; The History of Discovery and Ancient Applications; Diatomite Occurrence and Distribution; Diatomite Mining and Processing; Diatomite Diatomite in Use: Nature, Modifications, Commercial Applications

Diatomite IMA Europe

Diatoms can uniquely absorb watersoluble silica to form a highly porous, yet rigid skeletal framework of amorphous silica Diatomite is light, rigid, exceptionally porous, absorbent and pure Diatomite is uniquely processed in several ways, 2010年1月14日 Diatomites (or kieselguhrs) are mineral deposits of diatomaceous algae, those commercially exploited being restricted to a relatively modem age, starting from the Miocene Diatomite: Its Characterization, Modifications and Applications2022年6月1日 Presently, we fabricated a welldispersed, irondoped gC 3 N 4 composite (FGDx, where x represents Fe loading content) using urea and FeCl 3 on a diatomite surface to be suited for efficient reactivity under visible light irradiation (Fig S1)As a heterogeneous catalyst, the new composite operates via two modes, viz photocatalysis and the Fenton processBinding Fedoped gC3N4 on the porous diatomite for efficient AP42 Section: Reference: Title: 1122 2 F L Kadey, "Diatomite", Industrial Rocks And Minerals, Volume I, Society Of Mining Engineers, New York, 1983 Note: This is a reference cited in AP 42, Compilation of Air Pollutant Emission Factors, Volume I Stationary Point and Area SourcesF L Kadey, Diatomite, Industrial Rocks And Minerals, Volume I

.jpg)

Chinese firm begins diatomite mining process in

It is all systems go for exploration of diatomite in Baringo County by a Chinese firm, Chuanshan that was awarded a mining and exploration license in May 201III PROCESS DESCRIPTION1,3 Most diatomite deposits are found at or near the surface and can be mined by open pit methods or quarrying Diatomite mining in the United States is all open pit, normally using some combination of bulldozers, scrapercarriers, power shovels, and trucks to remove overburden and the crude materialFigure 1 Typical process flow diagram for diatomite processingAP42 Section: Reference: Title: 1122 2 F L Kadey, "Diatomite", Industrial Rocks And Minerals, Volume I, Society Of Mining Engineers, New York, 1983 Note: This is a reference cited in AP 42, Compilation of Air Pollutant Emission Factors, Volume I Stationary Point and Area SourcesF L Kadey, Diatomite, Industrial Rocks And Minerals, Volume I 2020年1月17日 Furthermore, as already mentioned, the presence of diatomite leads to a consolidation process due to the formation of a polysilicate on the surface of diatomite and in particular, the Process strategy to fabricate a hierarchical porosity gradient in

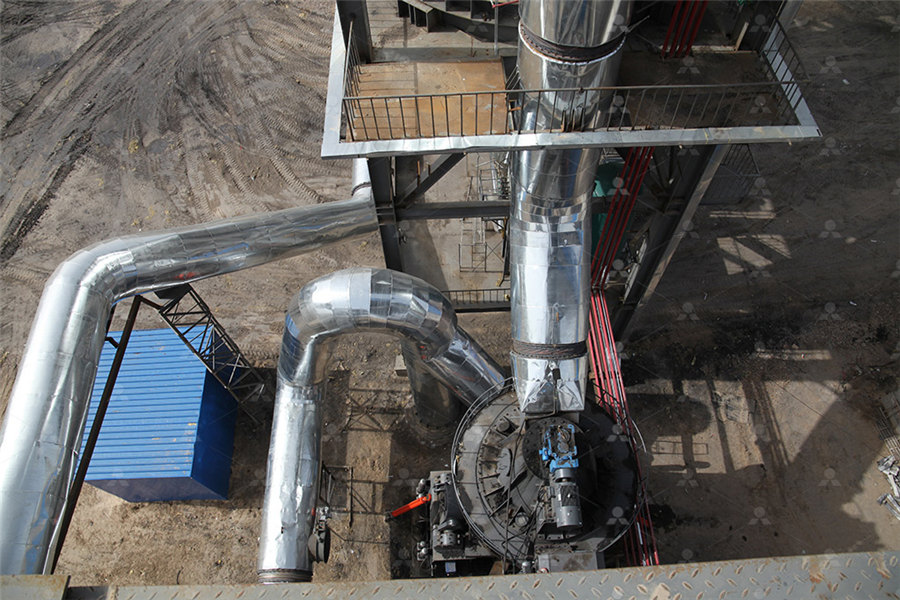

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Diatomite Mining In Nigeria, The PreFeasibility Report

Diatomite mining and processing requires heavy earthmoving equipments and huge processing facilities To get the desired grade of diatomite is highly energy intensive process Diatomite can absorb liquid three times the weight of its own World diatomite (also called diatomaceous earth) output decreased during recession years, but now the 2012年1月1日 Procedia Environmental Sciences 12 ( 2012 ) 79 – 86 18780296 © 2011 Published by Elsevier BV Selection and/or peerreview under responsibility of National University of Singapore doi: 101016/jproenv201201250 2011 International Conference on Environmental Science and Engineering (ICESE 2011) A Hybrid Treatment System Combining Enforced A Hybrid Treatment System Combining Enforced Diatomite Process Followed Diatomite deposits, the skeletal remains of tiny aquatic plants called diatoms, are found in many parts of the world Only a few of these de posits are of commercial value Open pit mining is used in nearly all deposits now being worked Processing methods range from simple drying, crushing, sizing and packaging to carefully controlled and highly sophisticated calcining and air OneMine Diatomaceous Earth Mining And ProcessingIn addition to diatomite deposits in Gilgil, the mineral has also been discovered in Baringo Currently, according to [9], diatomite mining in the area is carried out by artisans in an opencast method The amount is yet to be quantified but it is estimated to be of substantial quantity [9]Exploring the Use of Kenyan Diatomite As A Source Of Refractory

.jpg)

Raise Your Glass to Diatomite Thermo Fisher Scientific

2016年10月25日 The International Diatomite Producers Association web site explains the process as follows: The mining and processing of diatomite requires large processing facilities and heavy earth moving equipment Diatomite is diatomite from Jilin, Zhejiang and Inner Mongolia of China The diatom of Jilin diatomite is the shape of a disk The Inner Mongolia diatomite is boatshape diatom, while that of Zhejiang diatomite is cylindrical shape diatom (Hu et al 2017b) Diatomite is an ideal humidity controlling material owing to its excellent porous feature Hu et alPore structure and surface properties of diatomite with 2019年8月23日 Throughout most of the world, the lower cost of and higher recovery from openpit quarrying relative to underground mining encourages operators to use surface mining methods Where the diatomite sequence is Diatomite Processing Equipment, Flow, Cases JXSC 2021年6月1日 Diatomite mining and processing requires heavy earthmoving equipments and huge processing facilities To get the desired grade of diatomite is highly energy intensive process Diatomite can absorb liquid three times the weight of its own World diatomite (also called diatomaceous earth) output decreased during recession years, but now the Diatomite Mining In Nigeria, The PreFeasibility Report

PRODUCING A MICROPOROUS DIATOMITE BY A SIMPLE

Diatomite may be used in a filtering process as a believed that application of selective mining in the production can reduce the contamination Microscopy study of the original sample showed2016年9月1日 Whitening experiment of Linjiang diatomite was studied by acid leaching and calcination methodThe effects of acid leaching temperature, acid leaching time, acid concentration, solidliquid ratio Experimental research on acid leaching and calcination process 2015年8月3日 Herein, nature diatomite was chosen to adsorb fluoride prior to NF process The characterization of diatomite was investigated by SEM and XRD, and the feasibility was studied by XPS and FT–IR The influences of diatomite dosage, pH, ionic strength and anions concentration were researched by batches of adsorption experimentsRemoval of fluoride by nature diatomite from highfluorine water: 2013年12月1日 Concentrates of diatomite produced using a scrubbing, sedimentation classification, and acid leaching process from a low grade diatomite ore (Jilin, China) had a chemical composition of 8247% SiO A novel method for purification of low grade diatomite

.jpg)

Investigating the role of diatomite admixing on the water

1Department of Mining Engineering, Faculty of Engineering, University of Birjand, The process of calcining the raw diatomite was carried out during 4 hours without a fluxing agent at 900° C The raw diatomite was pretty white but turned to brown color after calcining A total of 24 treatments were prepared2018年6月1日 Request PDF Impurities removal process for highpurity silica production from diatomite This study presents a novel chemical process for the extraction of high purity silica from diatomiteImpurities removal process for highpurity silica production from diatomiteIII PROCESS DESCRIPTION1,3 Most diatomite deposits are found at or near the surface and can be mined by open pit methods or quarrying Diatomite mining in the United States is all open pit, normally using some combination of bulldozers, scrapercarriers, power shovels, and trucks to remove overburden and the crude materialFigure 1 Typical process flow diagram for diatomite processing11221 Process Description12 Diatomite is a chalky, sedimentary rock consisting mainly of an accumulation of skeletons remaining from prehistoric diatoms, Volume I, Society Of Mining Engineers, New York, 1983 Title: AP42, CH 1122: Diatomite Processing Author: EFIG Subject: AP42, CH 11: Mineral Products Industry Keywords: factors AP42, CH 1122: Diatomite Processing

About ADIL African Diatomite

About us Home About us About ADILWho we are?African Diatomite Industries Limited (ADIL) was established in 1942 as the leading mining and processing diatomaceous earth filter aid products in the East and Central African region 2013年1月1日 The adsorption of investigated pollutants is an endothermic and spontaneous process changes in sediment transport within the lake due to changes in lake bathymetry caused by diatomite miningDiatomites: Their Formation, Distribution, and UsesDiatomaceous earth consists of the fossilized remains of diatoms that accumulated over millions of years It usually comprises 80% to 90% silica, 2% to 4% alumina minerals, and 05% to 2% iron oxide, although the precise composition of every deposit is different [3] Deposits may contain different amounts of silica depending on the sedimentation conditions, the presence of other Diatomaceous earth Wikipedia2012年9月24日 PDF Contamination of water by heavy metals is a global problem, to which an inexpensive and simple solution is required Within this context the Find, read and cite all the research you (PDF) Turning the volume down on heavy metals using tuned diatomite

.jpg)

Process integration of KOH/diatomite preparation and

2023年1月15日 Among these catalysts, KOH/diatomite obtained the best catalytic activity The total yield reached 986% Meanwhile, the activities of NaOH/diatomite and LiOH/diatomite catalysts decreased successively The activity difference between these three catalysts is attributed to the activity difference of their corresponding alkali metal hydroxides [21]2019年11月28日 Wu Zhiqiang, chief economist of the Shandong Land and Mining Co Ltd that owns Chuanshan mining company, said his company plans to process the diatomite in Baringo county in order to spur industrial development in the regionChinese firm to begin diatomite mining in Kenya in January 年8月1日 This study presents a novel chemical process for the extraction of high purity silica from diatomite The process involves leaching of raw diatomite with acid prior to alkali extraction, solubilization of treated diatomite with alkali solution to form sodium silicate solution, and precipitation of silica gel by adding sulfuric acidImpurities removal process for highpurity silica production from diatomite2021年6月4日 Diatomite/kaolinitebased geopolymer (GP) was synthesized and incorporated in zeolitization process (Z/GP) to investigate the role of the zeolite phases in inducing its retention capacity of the Insight into the role of the zeolitization process in enhancing the

African Diatomite

African Diatomite Industries Limited (ADIL) was established in 1942 as the leading mining and processing diatomaceous earth filter aid products in the East and Central African region The company is located 120kilometersNorthwest 2020年9月9日 The pseudofirstorder kinetics and the Sips isotherm model were preferable to describe the adsorption process of basic fuchsin on alkaliactivated diatomite115 and the thermodynamic parameters Improvement of the mining technology in the diatomite mine, 2016年1月1日 The structural incorporation of aluminium (Al) into diatomite is investigated by preparing several Al–diatomite composites by loading an Al precursor, hydroxyl aluminum polymer (Al 13), onto the surface of diatomite and heating at various temperaturesThe results indicate that Al was incorporated and implanted into the structure of diatomite by the Possible mechanism of structural incorporation of Al into diatomite 2016年12月1日 Impacts of aluminum speciation and water pH on coagulation/diatomite microfiltration (DMM) process were investigated in this study Three commonly used Albased coagulants, aluminum sulfate (AS), polyaluminum chloride (PACl), and Al 13 ([Al 13 O 4 (OH) 24 (H 2 O) 12] 7 +), were employed to explore the role of Al speciationFloc characteristics, Effect of aluminum speciation and pH on inline coagulation/diatomite

.jpg)

Study on the adsorption process of Cd(II) by Mndiatomite

2021年10月1日 Table 1 shows that, compared with diatomites, the specific surface area of the modified diatomite increased by nearly 8 times SEM images indicated that, through the manganese oxide modified, the specific surface area of diatomite increased significantly In addition, during the grafting process of manganese oxide, the pore structure grafted on the 2017年12月21日 3Dstructured silica exoskeletonsdiatomite was used as reactive inorganic ingredient, with and without metakaolin to produce sustainable multifunctional diatomitebased geopolymeric foamsSetting up the production process of diatomite based ceramic 2016年1月1日 For the latter, previous studies have shown the Al incorporation into the framework of diatomite by mimicking the deposition process of the diatom shell at the sediment–water interface [26], [22], [34] A new aluminosilicate phase might form during the process and coat the surface of the diatom frustules [22]Possible mechanism of structural incorporation of Al into diatomite 4 Process Flow Diagram for Kaolin Mining and Dry Processing 9 5 12 Typical Process Flow Diagram for Diatomite Processing 22 13 Process Flow Diagram for Talc Processing 24 Table 1 Emission Estimation Equations and Default Emission Emission Estimation Technique Manual UNITAR

.jpg)

CuFe2O4/diatomite actuates peroxymonosulfate activation process

2023年5月15日 Less diatomite could not make CuFe 2 O 4 distribute evenly, while excess diatomite reduced the catalytic performance because of the low catalytic capacity of diatomite itself In addition, the removal efficiency increased with the addition of PMS from 010 g L − 1 to 040 g L − 1 (Fig S7b)2018年8月1日 This study presents a novel chemical process for the extraction of high purity silica from diatomiteThe process involves leaching of raw diatomite with acid prior to alkali extraction, solubilization of treated diatomite with alkali solution to form sodium silicate solution, and precipitation of silica gel by adding sulfuric acidBesides, the process includes washing of Impurities removal process for highpurity silica production from diatomite