HOME→Fly ash processing machinery principle Fly ash processing machinery principle Fly ash processing machinery principle

Fly ash processing machinery principle Fly ash processing machinery principle Fly ash processing machinery principle

Utilization of fly ash by pelletization process; theory, application

2000年7月1日 A study is undertaken to evaluate the potential use of SomaB thermal power plant (located in Manisa/Turkey) Fly ash as lightweight aggregate for numerous applications 2023年2月20日 This paper is aimed at providing a comprehensive overview of advances in the mechanical processing of fly ash and fly ashderived materials, in addition to highlighting the A critical review on mechanochemical processing of fly ash and fly 2021年7月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides Fly Ash properties, characterization, and applications: a reviewIn this article, we will discuss the fly ash processing flow, equipment used, and application values in detail Fly Ash Collection and Conditioning: The fly ash is first collected from the flue gas Fly ash processing process flow, fly ash equipment and application

How to Process Fly Ash and What Is It Used for

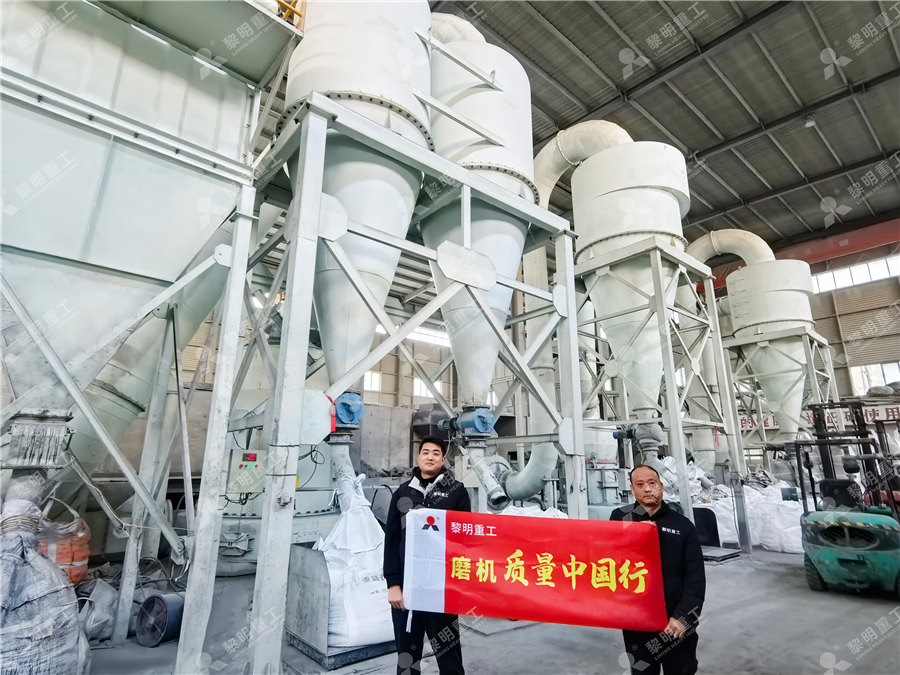

Summary: The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc Fly ash is the fine ash collected from the flue gas after coal combustion Fly ash is the 2021年1月1日 This paper reviewed the milling equipment effect on particle size, surface properties, and chemical compositions of activated ash Increasing in the surface area, pozzolana activity and the(PDF) Fly ash morphology and surface modification via 2020年12月17日 Treatment techniques of incineration fly ash were investigated to determine effectiveness in obtaining environmentally stable material, and, finally, possible applications of incineration fly ash for utilization were Incineration Fly Ash and Its Treatment to Possible The fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste Fly Ash Processing Plant Cement Equipment

.jpg)

fly ash mixer /conditionersEver LuckyEnvironmentalMachinery

fly ash mixer /conditioners Humidifying mixer is mainly used for spraying, Dust suppression fog cannon machine Dust humidifier mixer SJ double shaft dust humidifier mixer Singleaxis humidifier has the characteristics of large processing volume, compact structure, advanced technology, stable and reliable, Fly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA Fly Ash Processing Plant Superfine Final Product2021年7月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides (Si, Fe, Ca, and Al Fly Ash properties, characterization, and applications: a reviewfly ash processing equipment from china fly ash processing equipment from china China Fly Ash, Fly Ash Manufacturers, Suppliers MadeinChina 22031 products China Fly Ash manufacturers Select 2018 high quality Fly Ash products in best price from certified Chinese Fly Line manufacturers, Fly Fishing suppliers, wholesalers and factory on MadeinChinafly ash machinery for processing Capabuild

.jpg)

Fly Ash Brick Making Machine Manufacturer, Supplier, Exporter

Buy superior quality Fly Ash Brick Making Machine at most affordable price range offered by HARDIC MACHINERY Change Language English Hindi Home Also, they need less mortar and less labor during construction Fly Ash Brick Making Machines manufactured and supplied by Hardic Machinery are assembled with quality tested components as well 2023年5月24日 Environmental Impact of Fly Ash and Bottom Ash Like many industrial processing byproducts, fly ash and bottom ash can negatively impact the environment if not managed properly Both fly ash and bottom ash can contain heavy metals and other toxic substances that can contaminate the surrounding environment Special caution must be taken The Difference Between Fly Ash and Bottom Ash Powder Bulk 2020年12月17日 Treatment techniques of incineration fly ash were discussed to determine the effectiveness of obtaining environmentally stable material, and, finally, possible applications of incineration fly ash for utilization were discussed based on identifying the processing suitability, performance and environmental impact of incineration fly ash for its applicationsIncineration Fly Ash and Its Treatment to Possible Utilization2022年5月22日 It is timeconsuming and uneconomical to estimate the strength properties of fly ash concrete using conventional compression experiments For this reason, four machine learning models—extreme learning machine, random forest, original support vector regression (SVR), and the SVR model optimized by a grid search algorithm—were proposed to predict the Compressive Strength Prediction of Fly Ash Concrete Using Machine

Compressive strength prediction of fly ash concrete by using machine

2021年5月28日 In this research, the machine learning techniques such as, minimax probability machine regression (MPMR), relevance vector machine (RVM), genetic programming (GP), emotional neural network (ENN) and extreme learning machine (ELM) were utilized in the event of forecasting the 28 days compressive strength of fly ash concrete In the present examination, Wxtytech offers reliable and fast fly ash packing machines that can be combined with palletizing, load securing, and data processing systems Skip to content +86 150 0612 2126; manager@wxtytech; Close this search box HOME; PRODUCTS Packaging machinery is used to package materials for easy sale, storage and use, Fly Ash Bagging Machine,Packaging Machine,Palletizing Machine Fully automatic Fly ash bricks making machine made in India, perfect for manufacturing Fly Ash Block Ash Brick Ash Block 1d, 2nd Phase, Peenya 1st Stage, Peenya II Phase, Peenya, Bengaluru57 +91 ; Fly ash bricks Machine manufacturer in IndiaManufacturer of a wide range of products which include Nexus Automatic Rotary Fly Ash Bricks Machine (Model No : NRA2), Nexus Automatic Rotary Fly Ash Bricks Machine (Model No : NR3) and Nexus Automatic Rotary Fly Ash Nexus Rotary Fly Ash Bricks Machine – Nexus

How do You Process Fly Ash?

Processing Fly Ash The processing of fly ash involves several steps to ensure that it is suitable for its intended use The following are the common steps involved in processing fly ash Collection The first step in processing fly ash is its collection from power plants Fly ash can be collected using two methods: electrostatic precipitators Minimum order quantity: 1 Set (A) Production Types Paving Block , Concrete Brick ,Fly Ash Brick , Interlock Block , Canal Tiles ,Etc(B) Production Quantity 4000 4500 PC Shift (Standard Size )(C) Machine Capacity 90 ton (D) Motor hp 10 hp (Hydraulic Tank ) 05 hp Bin Vibrator (E) Manpower 3 person , 1 Skilled , 2 Un Skilled (D) Mold Area 300 mm *300 mm (E) Electrical Fly Ash Brick Making Machine Semi Automatic Fly Ash Brick Making It involves the conversion of fly ash into an amorphous material By doing so, it rids the fly ash of 999% of its hazardous organic constituents and fixes the heavy metals in the final glasslike product [7, 8] Its composition largely comprises SiO 2, Al 2 O 3, and CaO In fact, MSW fly ash typically falls within the margins of the CaOAl 2 O HIGH TEMPERATURE PROCESSING OF FLY ASH FOR THE Fly ash Multifunction Brick making Machine Concrete fly ash hollow brick block making machine can produce different hollow blocks, solid blocks and paving blocks by changing mould 2 Advanced Technology in Fly Ash Brick Machine: Vibration molding technology is adopted by this machine, so the block machine has more stable and higherefficiency working statusFly Ash Brick Making Machine Brickvision Equipment

Processing of Coal Fly Ash for the Extraction of Alumina Values

2020年5月8日 Abstract Coal fly ash is a lightweight incombustible particulate generated during coal combustion Alumina content in the fly ash is present in the mullite phase, and its high stability calls for alternative processing for conversion to reactive phase before leaching Mechanical activation with sodium hydroxide was found unsatisfactory for the breakdown of Figure 1 shows fly ash produced in a typical pulverizedcoalfired utility boiler and collected by an electrostatic precipitator There are two commonly used methods for removing the fine powdery fly ash from the fly ash hopper of the precipitator – a wet method or a dry method [12–15]In the wet method, water is used to flush the fly ash out of the hoppers and the ash slurry is pumped Fly Ash SpringerLinkEverlucky Machinery Dust Humidification Mixer Design to Needs, Find Details and Price about Fly Ash Humidifier Dust Humidification Mixer from Everlucky Machinery Dust Humidification Mixer Design to Needs Botou Ever Lucky Machinery Co, LtdEverlucky Machinery Dust Humidification Mixer Design to NeedsBuildings 2022, 12, 690 4 of 16 Buildings12022,112,16901 41of1161 1 1 Figure121Schematic1diagram1of1the1random1forest1model1(Reprinted1with1permission1from1[18])1 2 Compressive Strength Prediction of Fly Ash Concrete Using Machine

Separation Technologies’ 17 Years of Commercial Experience in Fly Ash

RWE npower Aberthaw ash processing facilities 3 ST ASH PROCESSING FACILITIES Controlled low LOI fly ash is produced with ST’s technology at twelve power stations throughout the US, Canada, the UK and Poland The processed fly ash is marketed under the ProAsh® brand throughout these market areas ProAsh® fly ash has been approved forIn addition, fly ash dryer made by Fote Machinery is commonly used in ore processing, building materials, metallurgy, railway, highway, and other fields for drying materials with certain humidity like ore powder, zin powder, kaolin, Rotary Fly Ash Dryer in Cement PlantFote the power plant fly ash every year which make turning waste into treasureThe author studied the vertical milling machine grinding ash process, which improves the grinding efficiency, to meet the requirements of the project fly ash handling equipment Ash grinding in the country started relatively late [3], which is still relativelyGrinding Fly Ash Process and Equipment with Vertical Milling MachineLeading fly ash brick machine manufacturers in India, specializing in quality manufacturing and global exports Explore innovation with Brick Machinery today! WELCOME TO HARDIC ENGINEERING; mixwellindia@gmail +91 99042 01922 / +91 98984 74351; HARDIC ENGINEERING brickmachinery Toggle menuFly ash brick machine manufacturers in India

How to Process Fly Ash and What Is It Used for sbmchina

Summary:The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc How to Process Fly Ash and What Is It Used for Fly ash is the fine ash collected from the flue gas after coal combustion Fly ash is the main solid waste discharged from coalfired power plants2022年8月4日 Blast furnace slag (BFS) and fly ash (FA), as miningassociated solid wastes with good pozzolanic effects, can be combined with superplasticizer to prepare concrete with less cement utilization Considering the important influence of strength on concrete design, random forest (RF) and particle swarm optimization (PSO) methods were combined to construct a Concrete Strength Prediction Using Different Machine LearningFly Ash Processing Equipment: Baghouse filters or electrostatic precipitators for fly ash collection Drying and grinding machines for conditioning fly ash (rotary dryer, fluidized bed dryer, ball mill, vertical mill) Silos and storage containers for fly ash storage Pneumatic conveyors and other material handling equipment for fly ash handlingFly ash processing process flow, fly ash equipment and The Acceptable Fly Ash Bricks Machine Cost In Aimix At the mention of the price, many clients think highly of it when purchasing the machine It is no exaggeration to say that the price is one of the most important reference factor for the customers The high efficiency decreases the cost of machine processingFly Ash Bricks Making Machine Cost Aimix Concrete Block Machine

Hardic Machinery (BRAND of MIXWELL), Ahmedabad

2017年7月13日 Manufacturer of Fully Automatic Fly Ash Brick Making Machine, Fly Ash Brick Making Machine Brick Making Machine offered by Hardic Machinery (BRAND of MIXWELL) from Ahmedabad, Gujarat, India Hardic Machinery (BRAND of MIXWELL) Odhav, Ahmedabad, Gujarat GST No 24AAIHN8473J1ZP Call 81% Response Rate2023年2月20日 Substantial amounts of solid residue, known as coal fly ash (CFA), are produced during coal combustion Fly ash (FA), the main component of coal ash, is generated in enormous quantities all over the world due to its increasing production Fly ash (FA) comprises powdery, fine particles mainly of spherical shape, which may be hollow or solidA critical review on mechanochemical processing of fly ash and fly ash Leading Manufacturer Exporter of Fully Automatic Fly Ash Brick Block Making Plants Across the India Brand: Karmyog, Fully Automatic Fly Ash Brick making machinery with world class technology News Events; Careers; Blog; Fully Automatic Fly Ash Brick Making MachineSemi Automatic Fly Ash Brick Making Machine Manual Fly Ash Brick Making Machine : Although this kind of machine is the least expensive, it needs a lot of manual labor It is appropriate for smallscale production and has an hourly Blog Fly Ash Brick Making Machine: Types, Benefits

.jpg)

Fly Ash Brick Making Machinery MadeinChina

Sourcing Guide for Fly Ash Brick Making Machinery: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: block making machine, brick machine, concrete block making machine2022年9月22日 Interpreting the Strength Activity Index of Fly Ash with Machine Learning September 2022; Advances in Civil Engineering Materials 11(2) processing, and storage conditions, 3,15, 32 (PDF) Interpreting the Strength Activity Index of Fly Ash with Machine Fully Automatic Fly Ash Brick Making Machines, Fly Ash Brick Making Machine, Machinery, Manufacturer, Exporter, Supplier, Pune, Maharashtra, India Call Now +91 99224 43405 Find Us Pune Home; About Us; Products Fully Automatic Fly Ash Brick Making Machines; AAC Block Making Plants ( Autoclave Aerated Concrete )Fully Automatic Fly Ash Brick Making Machines2022年9月8日 Fly Ash Dryer can dry fly ash from moisture content 45% to about 8% or even "bone dry " in large quantity directly Asfter being dried, fly ash (coal ash) can be used as raw material in cement and concrete production Fly ash dryer also is called fly ash drying machine,pond ash dryer, fly ash drying machine, rotary fly ash dryer machine, etcFly Ash Dryer Rotary Drying Machine Rotary Dryer, Drying Machine

Fly Ash SpringerLink

2011年1月1日 127 Chemical Composition Chemical composition of fly ashes include silica (SiO 2), alumina (Al 2 O 3), and oxides of calcium (CaO), iron (Fe 2 O 3), magnesium (MgO), titanium (TiO 2), sulfur (SO 3), sodium (Na 2 O), and potassium (K 2 O), and unburned carbon (LOI) Amongst these SiO 2 and Al 2 O 3 together make up about 45–80% of the total ash 2024年8月29日 Over the last decade, there has been a substantial increase in the amount of construction waste, leading to growing societal and environmental concerns around the recycling of this refuse Concrete waste is one of the most significant forms of construction waste As a result, in order to examine the influence of recycled coarse aggregate (RCA) on concrete, this Enhancing Sustainable Concrete Production by Utilizing Fly Ash Collected fly ash first should be carefully mixed with the binder in the mixer(s), then put the mixed material to a fly ash briquette machine, finished flying ash briquette will be get Set up a dryer to dry the briquette for immediate use or put it somewhere for a much longer time but much lower in cost drying – the natural drying wayWhat is fly ash in steel plant, why and how to make it to briquette2024年3月4日 Chloride ion corrosion has been considered to be one of the main reasons for durability deterioration of reinforced concrete structures in marine or chlorinecontaining deicing salt environments This paper studies the relationship between the amount of fly ash and the durability of concrete, especially the resistance to chloride ion erosion The heat trend map of Machine Learning Method to Explore the Correlation between Fly Ash