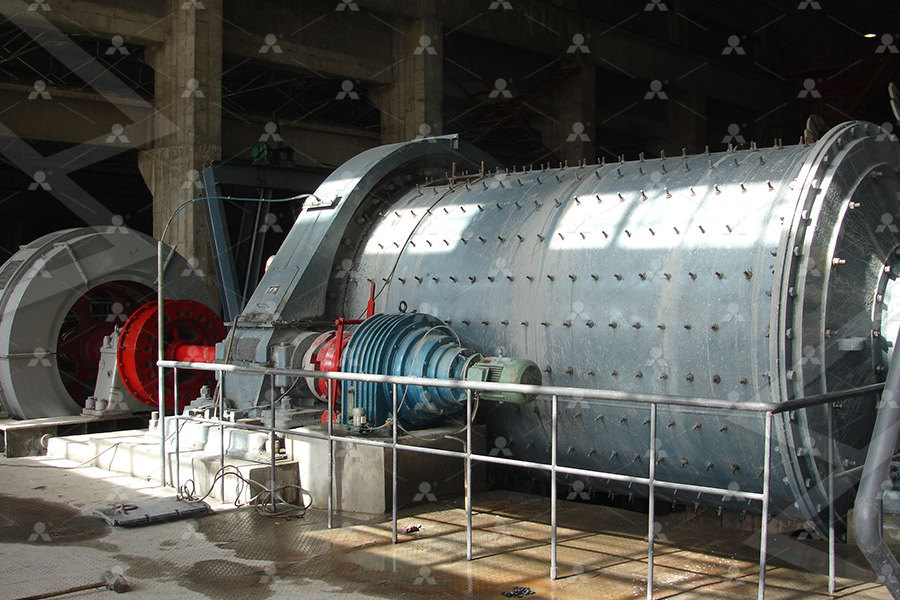

Anhai NdFeB rare earth ore grinding mill

NdFeB Powder Making Process Grinding Plant

2023年12月14日 NdFeB scrap mainly contains high concentrations of rare earth elements, such as neodymium, iron, boron, etc The specific ingredients and causes are as follows: Chips: Powder, debris, etc, from the workpiece during Grinding of rare earths With the AFGR jet mill One of the major challenges in processing NdFeB is that neodymium is pyrophoric: very fine particles oxidise when they come into contact with Rare Earths Hosokawa Alpine2015年6月14日 In this investigation, the possibility of a pyrometallurgical treatment of such grinding slurries should be determined Since REEs have a high oxygen affinity, the main Recovery of rare earth elements from NdFeB based grinding slurriesIn this paper, the rareearth elements were selectively dissolved from a crushed and roasted NdFeB magnet with a minimum amount of acid, further purified with solvent extraction and From NdFeB magnets towards the rareearth oxides: a recycling

REE Recovery from EndofLife NdFeB Permanent Magnet Scrap

2016年9月20日 NdFeB permanent magnets contain about 31–32 wt% of rareearth elements (REEs) Recycling of REEs contained in this type of magnets from the EndofLife (EOL) NdFeB permanent magnet scrap is regarded as an important secondary resource which contains rare earth elements (REEs) such as Nd, Pr and Dy Recovering these valuable REEs from the Hydrometallurgical Recovery of Rare Earth Elements from NdFeB 2020年3月26日 The production of rare earth oxides from beach sand involves several steps such as mining, preconcentration of the heavy minerals, separation of monazite, and finally, Mineral Processing of Rare Earth Ores SpringerLink2016年10月14日 ModelBased Comparison of Recycling Processes for Grinding Slurries from NdFeBMagnet Production Thematic Section: Green Rare Earth ElementsInnovations in Ore ModelBased Comparison of Recycling Processes for Grinding

.jpg)

Fine Grinding and Classifying of Rare Earth Alloys

Neodymiumironboronmagnets (NdFeB) are socalled rare earth magnets, which are characterized by their high energy density This makes them particularly interesting for 2023年11月13日 Rare earth is a crucial mineral resource that has significant applications in the electronic device industry In recent years, with the continuous improvement and updating of various electronic devices, electric vehicles have been promoted globally The excellent properties of rare earth fluorescent materials have made rare earthcontaining electronic devices widely Recycling NdFeB Magnets and Rare Earth Fluorescent Materials PDF On Sep 13, 2017, Ksenija Milicevic and others published Recovery of rare earth oxides from NdFeB magnet grinding slurries and their reuse in molten salt electrolysis Find, read and cite Recovery of rare earth oxides from NdFeB magnet 2024年1月1日 Recent advances in electrochemical methods show promise for more sustainable recycling of rare earth elements (REEs) from endoflife NdFeB permanent magnets(PDF) Recent advances in electrochemical recovery of rare earth

Fine Grinding and Classifying of Rare Earth Alloys

Neodymiumironboronmagnets (NdFeB) are socalled rare earth magnets, which are characterized by their high energy density Product after grinding on a Jet Mill Product after grinding on the MJET and classifying on the MCLASS Conventionally produced product 0 02 04 06 08 10 12 14 16NdFeB permanent magnet scrap is regarded as an important secondary resource which contains rare earth elements (REEs) such as Nd, Pr and Dy Recovering these valuable REEs from the NdFeB permanent magnet scrap not only increases economic potential, but it also helps to reduce problems relating to disposal and the environment Hydrometallurgical routes are considered Hydrometallurgical Recovery of Rare Earth Elements from NdFeB The chemistry of rare earth metals, compounds, and corrosion inhibitors T Behrsing, PC Junk, in Rare EarthBased Corrosion Inhibitors, 2014 132 Location and ores The main rare earth ores are monazite, bastnaesite and xenotime Monazite is largely a light rare earth (La, Ce, Pr, Nd) phosphate (93–94%) and is often found as a component of mineral sands, which are Rare Earth Ores an overview ScienceDirect TopicsSubsequent Classifying of Rare Earth Powders and its Influence on the Properties of NdFeBMagnets In a subsequent step, undesirable finest particles are separated by classifying the ground material with a NETZSCH Highefficiency Fine Classifier mClass (optimized version of CFS/HDS) to obtain a powder with a defined, narrow particle size distributionRare Earth Alloys NETZSCH Grinding Dispersing

.jpg)

Recovery of Rare Earth Elements through Spent NdFeB Magnet

2022年8月31日 Due to their remarkable magnetic properties, such as a high maximum energy product, high remanence, and high coercivity, NdFeB magnets are used in a variety of technological applications Because of their very limited recycling, high numbers of spent NdFeB magnets are widely available in the market In addition to China’s monopoly on the supply of 2021年9月28日 1 THE RARE EARTH ELEMENTS Figure 1 Periodic Table of the Elements In the periodic table of the elements, rare earth elements (REEs) are the group of elements in the row labelled “lanthanides” and are highlighted in blue, but also include yttrium (Y) and scandium (Sc) because these elements possess similar chemical characteristics 11 Natural What are Rare Earth Elements (REEs), where are they found and 2021年12月6日 A simplified approach for rare earth elements leaching from NdFeB (neodymiumironboron) magnets was investigated The possibility of simplifying the magnet recycling process by excluding grinding (PDF) Leaching of Rare Earth Elements from NdFeB Magnets 2021年6月1日 By expanding gravimetric separation to finegrained ore and to sediment systems (loess deposits, shallow to deep marine muds), the grain size of the tailings can be still in the medium silt to Life Cycle Assessment studies of rare earths

.jpg)

Mineral Processing of Rare Earth Ores SpringerLink

2020年3月26日 221 Occurrence Rare earth minerals occur as fluorites, oxides, tantalates, carbonates, phosphates, sulfates, borates, silicates, etc (Qi 2018)List of different rare earth minerals are presented in Table 23The average concentration of REEs in the earth’s crust is found to be 150–220 ppm, which is much higher than the concentration of other base metals From NdFeB magnets towards the rareearth oxides: a recycling process consuming only oxalic acid Tom Vander Hoogerstraete a, Bart Blanpain b, Tom Van Gerven c and Koen Binnemans * a a KU Leuven, Department of From NdFeB magnets towards the rareearth oxides: a 2018年8月9日 p>Sintered NdFeB as a thirdgeneration rare earth permanent magnet material, has been in rapid development since 1980’s due to its broad industrial applications and high electromagnetic performanceNew Technology of Making NdFeB by Sintering ResearchGate2018年11月7日 PDF A new recycling process for the extraction of rare earths from neodymium–iron–boron (NdFeB) magnet scrap is being developed, based on the direct Find, read and cite all the research (PDF) An Exante LCA Study of Rare Earth Extraction from NdFeB

.jpg)

(PDF) Recovery of Rare Earth Elements from Spent NdFeB

2022年9月27日 China's dominance in rare earth production and supply along with an increase in the available NdFeB magnets in the market [1], strongly motivates the recovery of rare earth elements from secondary 2020年11月16日 Preleaching processing comprised threestage crushing of the ore to c 1/2 in (c 127 mm) size before grinding by utilizing a rod mill and two ball mills with cyclone classifiers to reduce the feed to 65% passing 200 mesh, or approximately 74 µm; throughput was increased by addition of a third ball mill21 The U was then leached from the ground ore using sulfuric acid Toward Closing a Loophole: Recovering Rare Earth Elements from 2018年3月22日 Neodymium, praseodymium and dysprosium are rare earth elements often used in high performance magnets Environmental impacts during the production of 1 kg neodymium iron boron (NdFeB) magnet from Comparative Life Cycle Assessment of NdFeB Permanent2018年2月1日 Request PDF Recovery of rare earths from spent NdFeB magnets of wind turbine: Leaching and kinetic aspects Increasing demands of rare earth (RE) metals for advanced technological applications Recovery of rare earths from spent NdFeB magnets of wind

Separation factors for extraction of rare earths by DEHPA and

NdFeB permanent magnet scrap is regarded as an important secondary resource which contains rare earth elements (REEs) such as Nd, Pr and Dy Recovering these valuable REEs from the NdFeB permanent Download scientific diagram SEMEDS analysis of NdFeB permanent magnets [54]; published by Elsevier, 2014 from publication: Hydrometallurgical Recovery of Rare Earth Elements from NdFeB SEMEDS analysis of NdFeB permanent magnets 2023年11月9日 The screened rare earth ore enters a ball mill for dry grinding, improving mineral powder fineness and uniformity Overgrinding can waste resources and reduce recovery of brittle minerals FTM Machinery offers ball Unlocking Potential: Rare Earth Elements Processing 2022年12月19日 China’s dominance over the supply of rare earths — which are critical Figure 3 — Geographical Concentration of Supply Chain Stages for Sintered NdFeB Magnets From center: Rare earth rebateuponexport Of Chinese Behemoths: What China’s Rare Earths

.jpg)

From NdFeB magnets towards the rareearth oxides: a recycling

First, the old rareearth mines can be reopened but this will take some time2 Secondly, rare earths can be substituted by other less expensive rare earths or dblock metals, but this o en results in products which are less effective and usually requires a new product design2 Thirdly, recycling of rare earths from scrap produced throughout the2021年11月17日 The rare earth content (about 30 wt%) of these magnet scraps is generally higher than that of raw ore, and the recovery of rare earth elements from them helps to stabilize the global rare earth Sustainable Recycling of RareEarth Elements from NdFeB 2023年4月1日 1 Introduction Due to their high economic importance and supply risks, the European Commission consider the rare earth elements as critical elements 1 Their recovery by recycling of industrial waste from technological equipment, and in particular from endoflife products and waste electrical and electronic equipment “WEEE” could allow access to a Journal of Rare Earths ScienceDirect2018年6月26日 Reference Wübbeke 25 Overall, China uses 60% of world’s rare earth production 26 Among the other major consumers is Japan, which consumed 20,175 mt of rare earths in 2016 27 11,141 mt or 55% of the total use was sourced from China, 4237 mt from France, and 2623 mt from VietnamRare earths: A review of the landscape MRS Energy amp

(PDF) Process development to recover rare earth metals from

2015年8月31日 The escalating demand of rare earth metals (REMs) in various applications and their continuous depleting ores have laid emphasis to produce metals from their complex resources by developing energy 2020年3月1日 Makarova et al (2020), studied the electrochemical leaching of Fe and rare earths from NdFeB magnets, using sulfuric acid as a leaching agent and oxalic acid to precipitate the REEElectrochemical leaching of rareearth elements from spent NdFeB Therefore, rare earths recovered from waste residue would reduce the demand of rare earth elements from primary sources In this study, the feasibility of recycling rare earths through a hydrometallurgical process was investigated The selective leaching of Nd from grinding sludge can successfully raise the rare earths concentration to 70% TheSelective Extraction and Recovery of Rare Earth Metals (REMs)2021年4月27日 NdFeB magnets are widely used in various applications including electric and hybrid vehicles, wind turbines, and computer hard drives They contain approximately 31–32 wt% Rare Earth Elements (PDF) NdFeB Magnets Recycling Process: An

.jpg)

Rareearth recycling needs market intervention

2021年3月26日 Rare earth elements (REEs) are at the forefront of discussions, given their crucial role in cuttingedge and ecofriendly innovations that propel the industrial revolution towards a green economyERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sinaCHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION2024年1月26日 Rare earth elements (REEs) are a group of 17 chemically similar elements that are essential for a wide range of modern technologies One of the main sources of REEs is monazite, which contains (PDF) EXPLORING THE POTENTIAL OF RARE EARTH ELEMENT2023年4月1日 This study proposes an advanced leaching method using organic acids to recover rare earth elements (REEs) from NdFeB permanent magnets from endoflife computers hard disk drives (HDDs) The endoflife HDDs were first dismantled in order to recover NdFeB magnets, which were then thermally demagnetized at 350 °C during 30 min before crushing in a ball mill Evaluating organic acids as alternative leaching reagents for rare

.jpg)

Mechanism and kinetics of enhancement of cerium dissolution

Analysis of the sulfuric acid leachate were 074 (without grinding of the ore), 087 (for ore that had been ground for 10 min), 083 (20 min grinding), The chemical composition of the weathered residual rare earth ore, 080 (60 min grinding), 079 (360 min grinding), and 068 (720 min obtained from the Republic of South Africa, was measured by xray grinding)Effect of frictional grinding on ore characteristics and selectivity of This study explored the impact of microwave pretreatment on the grinding efficiency of bastnaesite ore using a stirred mill Bastnaesite ore was prepared using a staged crushing and A simplified approach for rare earth elements leaching from NdFeB Chapter 7 – Grinding Mills Semantic Scholarearths without concerns about radioactive trace elements (Th and U) present in ores and for which the regulations are very strict, (4) helping the rareearth market to stay in balanceFrom NdFeB magnets towards the rareearth oxides: a recycling boron magnets and rare earth fluorescent powders This article summarizes the main application pathways of rare earth elements in electronic equipment as well as the research status and technological development trend of recovering rare earth elements from electronic waste INTRODUCTION Rare earth is one of the key mineral resources,Recycling NdFeB Magnets and Rare Earth Fluorescent Materials

.jpg)

Lab Vacuum Ball Mill with sieve – ZJH minerals

Lab vacuum ball mill with sieve Description; XMQS series vacuum ball mill with sieve adopting the integrated design of ball mill and screen, grinding and sieving works at same time in the drum of the ball mill, the material grinded into the expecting size will be discharged after sieving, the coarse material not passing the sieve will go back into the ball mill drum and grinding again