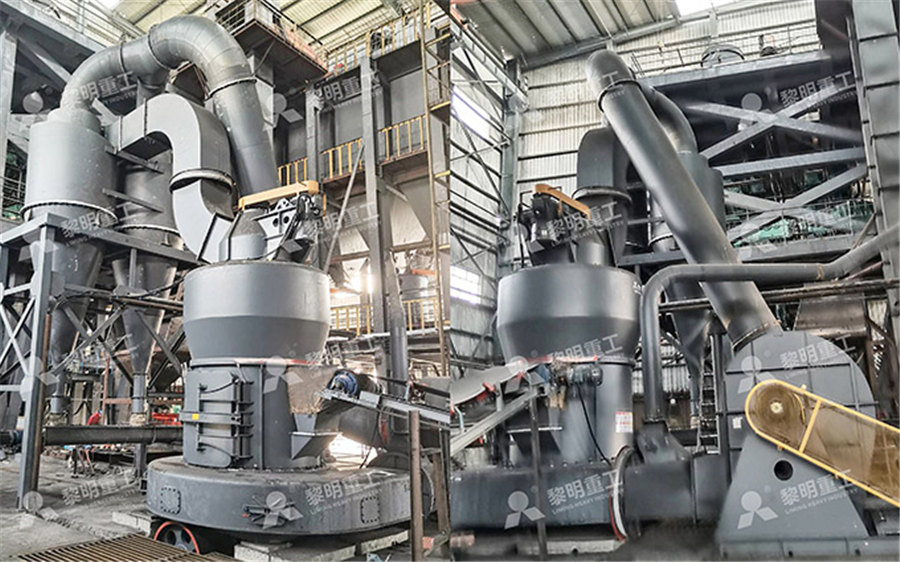

Limestone mill model

.jpg)

EnergyModel and Life CycleModel for Grinding Processes of

2022年5月22日 Therefore, the first aim of this research work was the examination of main grinding parameters of the limestone particles to determine an empiric energymodel Dry and 2007年1月1日 This chapter provides an overview of the existing mathematical models for the simulation of grinding and classification in mill–classifier circuits not only for ball mills but also Chapter 20 Modelling of Mills and Milling CircuitsThe matrix model was used for simulation of a VRM with highefficiency slat classifier in OMYA’s limestone processing plant in Eger, Hungary, on a technology with Pfeiffer’s 2800 C vertical Modeling and simulation of vertical roller mill using population Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium Limestone Quarrying and Processing: A LifeCycle Inventory

.jpg)

Energymodel and Lifecyclemodel for Grinding

2021年11月12日 This paper summarises wet grinding processes for limestone in a laboratory stirred ball mill with a comparison the different grinding parameter, stressing factors affecting their applicability2020年9月1日 The present work takes advantage of a mechanistic mill model originally developed for ball mills and the discrete element method (DEM) to simulate breakage in a Mechanistic modeling and simulation of a batch vertical stirred millThis research work sets up a new complex model with the help of mathematical equations between life cycle assessment and specific energy results, and so improves the energy and EnergyModel and Life CycleModel for Grinding Processes of Find your limestone mill easily amongst the 34 products from the leading brands (SIEBTECHNIK, Liming, NEUE HERBOLD, ) on DirectIndustry, the industry specialist for your professional purchasesLimestone mill, Limestone grinding mill All

.jpg)

Breakage Characteristics of HeatTreated Limestone

The results from this study indicate that ball mill grinding of limestone can be described based on the populationbalance model This kinetic model approach can provide a basis for the design of milling processes for the utilization of low 2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder Limestone Grinding Mill That You Need To Know2014年5月1日 Onsite operational tests were performed in OMYA's limestone processing plant in Eger, Hungary, on a technology with Pfeiffer's 2800 C vertical roller grinding mill The matrix model of the (PDF) Matrix Model Simulation of a Vertical Roller Mill Guilin HCM Machinery offer limestone mill, limestone processing solutions for Limestone Processing Plant Welcome to Guilin HCM Machinery Official WebSite! facebook model selection scheme: Vertical mill or large scale Limestone Mill High Efficiency, Large Capacity, 200

Optimization of Ball Mill Grinding of a LimestoneType Brecciated

2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with the combination of different balls (127–375 mm) and interstitial filling of 50% (20% ball filling ratio at fixed material filling ratio = 4%) The net power consumption in a ball mill is Brief Introduction Limestone powder grinding mill is a kind of new hightech milling machine This mill is mainly used for grinding coarse limestone, the finished product size can be adjusted discretionarily from 80325 meshes and finished product Limestone Powder Grinding MillFote MachinerySome of the most common types of aggregates in rock crushing are sandstone, gypsum, gravel, and limestone The type of rock you plan to process and your desired product size will determine the size and model of rock crushers best suited for your application How Do Rock Crushers Work? Typically, a hopper is used to hold and feed the rock to the Rock Crushers Pulverizers Williams Crushergrinding kinetics models allowed to determine the dependence of function between the growth of the selected particle size fraction in the product and the residence time of material Keywords: mineral processing, electromagnetic mill, limestone grinding, sorbent for flue gas desulphurization, process modelling, grinding kinetics 1 IntroductionAdjustment of limestone grinding in an electromagnetic mill for

.jpg)

EnergyModel and Life CycleModel for Grinding Processes of Limestone

2022年5月22日 The idea of a life cyclemodel based on the limestone powder particle size limestone sample in the Bond mill was 11245 kg and the proportion by weight of particlesThe Raymond Roller Mill is an airswept vertical ringroll mill with an integral classification system that simultaneously dries, pulverizes Kaolin, Barytes, Gypsum, Limestone, Phosphate Rock, Talc, Coal, Hydrated Lime, Petroleum Coke, Pigments, Phenolic Resins or similar materials Product Inquiry Newsletter registration DownloadsRaymond Roller Mill airswept vertical ringroll2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium oreOptimization of Ball Mill Grinding of a LimestoneType Brecciated What is a Hammer Mill Used For? A hammer mill is a particle size reduction machine After the material is fed into the machine, the hammer mill uses its continual highspeed hammer to grind and crush the material into smaller Hammer Mills for Material Reduction Williams Patent

.jpg)

Limestone Grinding Mill

Limestone Grinding Mill Limestone Grinding Mill Feeding Size: ≤20 Fineness: 302500 Mesh Capacity: 0430 T/H Raw Materials: calcite, chalk, limestone, dolomite, kaolin, gypsum, and talc etc, totally more than 100 kinds of materialsThe more suitable limestone Raymond mill model of HCMilling(Guilin Hongcheng) is HCQ2000 HCQ2000 belongs to the limestone Raymond mill of the improved series of HCMilling(Guilin Hongcheng) The overall power is 537KW, the News What Is The Installed Capacity Of Raymond Limestone ultrafine vertical mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6 (the Moh’s hardness), such as gypsum, calcium carbonate, limestone, quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcLimestone Ultrafine Vertical MillLimestone Raymond mill 80600 mesh Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: various nonflammable and explosive materials with Mohs hardness less than 93 and humidity less than 6%Limestone Raymond mill 80600 mesh SBM Ultrafine Powder

.jpg)

Grinding Technology of Limestone With Ball Mills PDF Mill

The document discusses grinding technology for limestone using ball mills It covers: 1 The properties and applications of limestone powder 2 Wet and dry grinding processes 3 Different types of grinding circuits including classical ball mill, airswept mill, birotator, and compound mill circuits 4 Details of mill internals such as ball charges and linings for compound and double HRM Limestone vertical HRM vertical mill can be used to grind materials with a diameter less than 44mm on the rotary disc by rollers with certain pressure It has advantages of high grinding efficiency, strong dry capacity, easily adjustable grinding size, low noise, low power consumption, simple process flow, low wear rate, low operation costs, etcHRM Limestone verticalHefei ZhongYa Building Material Olde Mill Blend is a blend of squared, ledgerock, and random shapes (50% squared, 25% random, 25% ledgerock) In our modified 'Estate Blend', we add a small amount of our Weatheredface Limestone, to add the vibrant white / lighter tone contrasting pieces you Weatheredge Limestone Olde Mill Estate Blend with White Selecting the right model of grinding mill for limestone desulfurization powder technical upgrade project Limestone desulfurization is a widely adopted method for reducing sulfur dioxide emissions from industrial processes, particularly in power plants and steel millsSelecting the right model of grinding mill for limestone

(PDF) Suspended Solid Removal of Palm Oil Mill Effluent Using

2020年7月22日 PDF Severe environmental pollution could occur in water bodies which serve as the discharge sites for improperly treated palm oil mill effluent Find, read and cite all the research you need 2023年8月14日 Though Limestone Hill Farm is Grade II listed, the mill itself is not listed, as it is not considered to be part of the model farm It represents one of only four waterpowered corn mills in the county however and is considered to be of great historic significance for the local areaWatermill at Limestone Mill Hill Farm South Yorkshire Local Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Limestone Powder Ultrafine Vertical Roller Mill2023年8月14日 Though Limestone Hill Farm is Grade II listed, the mill itself is not listed, as it is not considered to be part of the model farm It represents one of only four waterpowered corn mills in the county however and is considered to be of great historic significance for the local areaWatermill at Limestone Mill Hill Farm Local Heritage List Platform

.jpg)

EnergyModel and Life CycleModel for Grinding Processes of Limestone

Energies 2022, 15, 3816 2 of 20 and in other areas of the economy, limestone powder, are widely utilized In addition, limestone is a widely used construction material as an additive for cement in 2019年12月5日 When selecting the limestone wet ball mill model, we must consider the changes in the hardness and fineness of the ore The selected limestone wet ball mill model can be used more widely to ensure the smooth commissioning of the equipment at the initial stage; 3 Due consideration is given to large equipmentLime Ball Mill JXSC MachineLimestone Grinding Projects Which Use MTW Grinding Mills CASE1 Model: 1 Set of LM130K Vertical Roller Grinding Mill Raw Material: Limestone Output Size: 325 Mesh D90 CASE2 Model: 1 Set of LM190K Vertical Roller Grinding Mill Raw Material: Limestone Output Size: 200 Mesh D80 Location: RussiaLimestoneGypsum FGD Wet Desulphurization2021年11月12日 In second step, a lifecyclemodel of the limestone product has been developed from the raw material extraction through its wet grinding to the use stage as construction material with the help of Energymodel and Lifecyclemodel for Grinding Processes of limestone

]@S0{UDKK%G24F3JGHC.jpg)

Limestone Mills Williams Crusher

Hammer Mills Williams manufactures a large variety of hammer mills and hammer crushers wellsuited to handle limestone crushing applications As the manufacturer holding the very first hammer mill patent to utilize midair impact crushing, Williams takes great pride in providing quality, rugged machines for many applicationsPrice shown above is per square foot (PSF) 35 inches thick; average ~50 lbs PSF *** CONSIDERATIONS REGARDING FULL BED STONE *** In our pricing model we are assuming an average of 40 square feet of coverage per ton of full bed stone In reality, square foot coverage achieved will vary dramatically from project to proWeatheredge Limestone Split Face Olde Mill Blend TumbledThe structural design of the limestone ball mill is similar to the ordinary ball mill The main shaft uses a largediameter doublerow selfaligning rolling bearing, which reduces friction and energy consumption by 20% to 30%, making it Limestone Grinder AGICO Limestone Grinding MillFote Machinery is specialized in producing limestone mill which has more than 30 years production experience, and we also have marble grinding mill, clinker grinding mill, barite grinding mill, Model: 4525: 4119: Feeding Size(mm) FTM Grinding Mill for Calcium Carbonate, Limestone

.jpg)

Grinding Limestone powder

Limestone is grinded by limestone grinding mill to prepare limestone powder Limestone powder making machine model selection program Product fineness (mesh) 200 mesh D95 250 mesh D90 325 mesh D90 Model selection scheme Vertical mill or largescale Raymond mill 12024年8月1日 The coupledphase model describes the ultrasonic propagation phenomenon in suspensions based on hydrodynamic approaches and Consequently, an ultrasonic transmission signal was acquired and recorded During the operation of the wet mill pulping system, the limestone slurry was pumped from the reservoir to the test section for Online measurement of particle size in highconcentration limestone 2024年1月18日 Limestone has been widely used in human civilization history due to its wide distribution and easy availability in nature How to choose a limestone grinding mill Limestone is the commodity name for limestone used as a mineral resourceHow to choose a limestone grinding mill SANDMINEThis is a reservoir found just South of the Woolery Stone mill It was captured using a Phantom 2 v2 with GoPro Hero 4 Black and reconstructed in Autodesk Recap 360 Limestone lined pool 3D model by Alex Elvis Badillo (@abadillo)Limestone lined pool 3D model by Alex Elvis Badillo (@abadillo)

.jpg)

Limestone Grinding Mill That You Need To Know

2023年9月19日 Đá vôi grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Vật liệu áp dụng: calcium carbonate crushing processing, gypsum powder processing, khử lưu huỳnh nhà máy điện, nonmetallic ore pulverizing, coal powder preparation, vân vân Main limestone grinding machines Vertical limestone mills price Select 2024 high quality limestone mills price products in best price from certified Chinese Limestone Grinding Mill manufacturers, Cement Mill suppliers, wholesalers and factory on MadeinChinalimestone mills price MadeinChinaPrice shown above is per square foot (PSF) 35 inches thick; average ~50 lbs PSF *** CONSIDERATIONS REGARDING FULL BED STONE *** In our pricing model we are assuming an average of 40 square feet of coverage per ton of full bed stone In reality, square foot coverage achieved will vary dramatically from project to proHarvest Gold Limestone Olde Mill Blend Natural Brick Stone MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China MPS 5000 B mill for raw material grinding, Turkey Tracim, TurkeyCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills