What is the control box of 200 mesh coal powder mill

Coal mill pulverizer in thermal power plants PPT

2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants It describes how pulverized coal is dried, ground, circulated, and classified within the mill to produce a fine powder that is then transported to A 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh or smaller 200 mesh coal powder mill/coal powder preparation production lineThe Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and Raymond Bowl Mill designed and built for flexibility QlarA modern 200 mesh coal powder preparation system should be integrated with automation and control systems to ensure consistent product quality and optimize energy consumption The Choosing the right vertical mill for 200 mesh coal powder

.jpg)

A Comparison of Three Types of Coal Pulverizers Babcock Power

The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in raw coal top size, 7% moisture and produces pulverized coal that is 70% passing 200 mesh fineness (red line) This is pretty standard Now, take that same pulverizer and provide fuel The Storm Approach to Coal Pulverizer OptimizationInstrumentation and control is an integral part of a coalfired power station A modern, advanced IC system plays a major role in the profitable operation of a plant by achieving maximum Instrumentation and control in coalfired power plant ICSCThis article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

.jpg)

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill Review of control and fault diagnosis methods applied to coal mills V Agrawal, PMV Subbarao, in Journal of Process Control, 2015 1 Introduction Coal mills or pulverizers play a very essential part in the coalfired power production system Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for Coal Mill an overview ScienceDirect Topicscoal passing through 200 mesh (75 µm) is weighed and the HGI is derived from the empirical equation: HGI = 693W +13 where W is the weight of crushed coal passing through 200 mesh (75 µm) Indian bituminous types of coal have an HGI ranging between 45 to 70 Moisture content and volatile matter in the coal also affect the HGI valuesA Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee

The Storm Approach to Coal Pulverizer Optimization

raw coal top size, 7% moisture and produces pulverized coal that is 70% passing 200 mesh fineness (red line) This is pretty standard Now, take that same pulverizer and provide fuel that is 40 HGI, still ¾” top size and still 7% moisture, but increase the fineness requirement to 80% passing a 200 mesh sieveA 200 mesh coal powder mill, also known as a coal powder preparation production line, is an industrial system that grinds coal into fine powder with a particle size of 200 mesh or smaller This powder is then used for various applications, such as combustion in power plants, steelmaking in blast furnaces, or as a component in cement and other industrial processes200 mesh coal powder mill/coal powder preparation production Fuel preparation for a pc boiler occurs in a mill, where coal is typically reduced to 70% through a 200mesh (74μm) screen Figure 2 shows a particlesize distribution from a bowlmill grinder typically used in power plants A typical utility specification for particle size distribution of the coal is that 70% of the mass should pass through a 200mesh screen, which is equivalent to 70% Pulverized Coal Boiler an overview ScienceDirect TopicsModern instruments, like the AS 200 control and AS 300 control from Retsch, additionally enable the required amplitude to be entered digitally exceed a volume of 200 ml (eg 300 g sand) For a mesh of 05 mm, the limit is 80 ml, for a 0125 mm The Basic Principles of Sieve Analysis RETSCH

.jpg)

Pulverised Coal an overview ScienceDirect Topics

With a PCfired unit, the coal is first pulverized in a mill to the consistency of talcum powder, which means that at least 70% of the particles will pass through a 200mesh sieve The pulverized coal is generally entrained in the primary combustion air before being blown through the burners into the combustion chamber, where it is fired in The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in the mill and flat grinding surfaces, develops shearing action as well For both mills a constant centrifugal force is maintained The speedA Comparison of Three Types of Coal Pulverizers Babcock PowerGoogle's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesGoogle TranslateO serviço do Google, oferecido sem custo financeiro, traduz instantaneamente palavras, frases e páginas da Web do português para mais de cem outros idiomasGoogle Tradutor

What Is Coal Hammer Mill? SBM Mill Crusher

2023年5月17日 Can a coal hammer mill be used for other materials besides coal? Yes, we can grind and pulverize every kind of material except coal with coal hammer mill A hammer mill is adaptable for processing different materials, despite the name suggesting that its principal use is for crushing coalThis depends on the thickness of the wire or strand used to make the mesh Most ISM flow control components do not contain filter screens any finer than cinnamon (ground) 70 to 200 clay 01 to 2 coal dust 1 to 100 coffee (ground) 5 to 400 concrete dust 3 to 100 copier toner 200 No 200 200 Mesh 00500 00020 00750 0 0030 250 MESH and MICRON SIZES Industrial SpecWhile all these are regarding the mill performance, the coal fineness and mill out let temperature also affect the boiler performance The coal fineness has an effect on the combustion performance like the bottom ash percentage combustibles when the plus 50 mesh percentage goes up It has been very well established that in the case of tangential firing system, the Boiler Performance and Mill Outlet Temperature Bright Hub in the mining or coal processing operations Fig3 Mill fuel piping connections to furnace II COAL MILL SPECIFICATIONS PERFORMANCE ANALYSIS Typical Coal Pulveriser Mill Details in 660 MW SuperCritical [3] Unit is as given in table Table No 1 Table1 Coal mill Type Bowl Type Mediumspeed Coal mill Number of Mills 6set/ boilerPulveriser Mill Performance Analysis Optimisation in Super

Coal Mill Manufacturers Powder Making Machine Price

Phrase one: raw material crushing Coal blocks will be crushed to 15mm50mm fineness by crusher Phrase two: drying and grinding 1Coal material with low moisture will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding The hot air in the mill will dry the coal This will reduce drying cost 2For high Favorable control behavior High drying capacity, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsCement Factory Quality Control White Cement Manufacturing Technology Technical Cement Forum / Coal Mill Pulverized Coal 200 Mesh The forum in now closed, please join us on the International Cement Review Linkedin Group eric 13/07/2010 17:39:26Coal Mill Pulverized Coal 200 Mesh International Cement ReviewNOTE: 60% thru 200 mesh vs 80% thru 200 mesh, difference in particle surface area (mm 2) is 857% 800 Passing 200 Mesh (%) 640 600 770 750 680 650 630 and reduce and/or minimize slagging Because of Figure 1 recommendations for achieving the following Simply, optimum coal fineness and desirable portions of air fuel to the burners is A case study of how vertical spindle pulverizer performance is

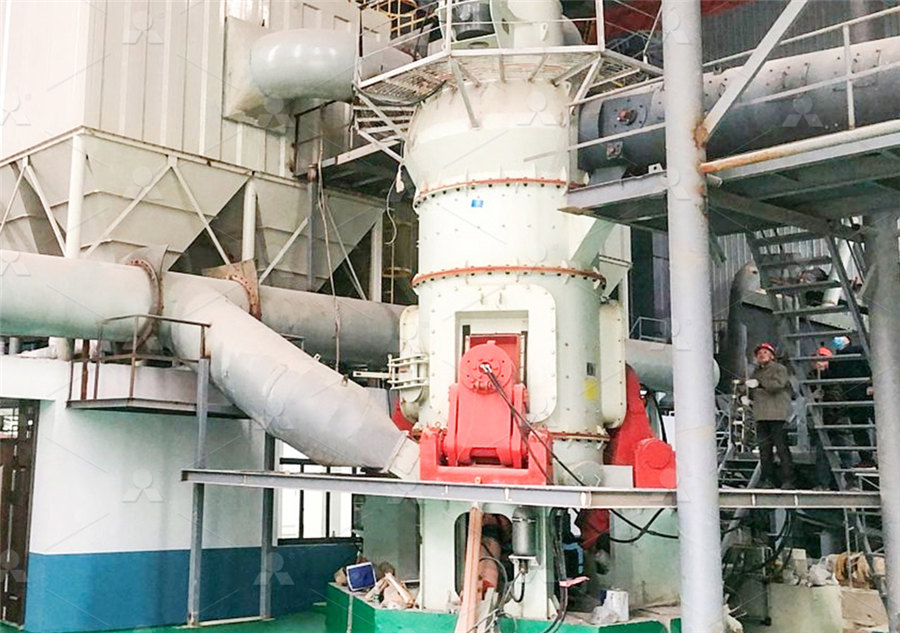

200 mesh coal pulverizer grinding mill delivery site

2023年11月20日 HGM series ultrafine grinding mill is used by customers to grind pulverized coal, with an output of 5tph, and a finished powder fineness of 200 mesh It is +17Coal strength will also increase with increased confining pressure (Hobbs, 1964), as shown in Figure 32At atmospheric pressure or unconfined conditions, dull coals can be two to three times stronger than brighterbanded lithotypes from the same seam with the same rank (Medhurst and Brown, 1998, and Lawrence, 1978), and low rank coals can be up to 14 times stronger than Coal Strength an overview ScienceDirect TopicsThe capacity in pounds per hour of the mill is calculated on the assumption that the coal hardness is 55 on the Hardgrove Grindability Index and has a moisture content of 8% This would produce an output based on 70% of the coal passing through a 200 mesh screen Capacities available range from 3,500 #/hr (#312) to 59,100 #/hr (753)Industrial Bowl Mills Bowl Mill Pulverizer for Sale Wabash Power½ 2in / 1050mm, the roller mill can produce particles ranging from coarse, granular products of approximately 10% R2000 micron 90% minus 10 mesh (10%R2000 microns) to as fine as 999% minus 325 mesh (0001%R44 micron) Applications A roller mill is most effective processing materials that are 5 or less on the Mohs scale of hardnessRaymond Roller Mill airswept vertical ringroll

.jpg)

Online measurement of pulverized coal fineness on a 300

2021年6月1日 This was mainly due to the sparseness of coarse coal powder, leading to a low probability of coal powder larger than 200 μm to be captured by the measurement system Although the obvious difference of PCF for mill D and B can be revealed with SAD directly, R 90 results and distribution curves were still with deviations comparing to the sieving method2010年10月7日 Coal pipe F9 on pulverizer B was the only pipe that met the original plant fuel specification guarantee of 70% passing 200 mesh, which is far short of the 75% minimum we usePulverized Coal Pipe Testing and Balancing POWER Magazine2 Raw coal properties – Hardgrove index and moisture level 3 Pulverized coal fineness The raw coal is fed into a rotating bowl via a center feed pipe The rate of coal feed is normally determined automatically by a combustion control system, taking into account the MW demand on the unit, coal quality, and the number of coal pulverizers in Bowl Mill Coal Pulverizer COAL HANDLING PLANTS2021年11月27日 The powder grinding mill is the equipment and a motor Auxiliary equipment includes jaw crusher, bucket elevator, electromagnetic vibrating feeder, electric control cabinet, etc Users (30mesh) –0033mm What is Powder Grinding Mill? JXSC Machine

.jpg)

200 Mesh Coal Based Powder Activated Carbon for

200 Mesh Coal Based Powder Activated Carbon for Waste Water Purification, How does your factory do regarding quality control? A:Quality is priority My company always attaches great importance to quality controlling from the very Get the perfect consistency for your nutraceutical products with our powder mesh sizes guide Learn about the importance of particle size We use cookies This website uses cookies in order to enhance the overall user experience Take a look at our Cookies Policy for more information Only essentialsPowder Mesh Sizes Nutraceuticals Group2020年6月29日 ROLE OF MILLS • Produces Pulverized coal 80% of which passes through 200 mesh • Air mixed with Pulverized coal (PF) is carried to the coal nozzle in the wind box assembly • PF from coal nozzle is directed towards the center of boiler burning zone • Preheated secondary air enters boiler and surrounds the PF and help in combustionclassifications and working of mills in a power plant PPT70% control In the majority of hammer mill applications the key factor determining finished particle size is the screen Any material that enters the grinding chamber must be reduced to a size small enough to pass through the screen that covers the mill's Intro to Size Reduction Schutte Hammermill

.jpg)

HighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

Our vertical coal mill is designed to enhance the process, maximizing energy efficiency Home; Products compact equipment, low dust emission, and efficient combustion of coal powder Working Principle Fineness of pulverized coal (200 mesh pass %) 80: Coal moisture content (%) ≤1: Main motor Power (kW) 55: 110: 132: 180: 250250: 315 than 72% passing a 200 mesh screen, and with 1% maximum remaining on a 50 mesh screen Most of Che auÉhoisi experience has been on boilers firing Eastern Bi€uminous coal However , some testing and experience has been Obtained on Western Lignite fuels with moisture above 35% and as received,Storm Technologies, IncGoogle's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesGoogle TranslateIn the pulverized coal combustion system, coal ground to a very fine size (70–80% passing through a 200mesh screen or 75 μm) is blown into a furnace Approximately about 10% of the total air required for combustion is used to transport the coalPulverised Coal Combustion an overview ScienceDirect Topics